The widespread increase in tariffs is causing a complete revision of the entire heating system. Many owners of houses and buildings are beginning to think about which radiators are better and more economical to use for heating.

The modern technology market offers consumers a fairly wide range of heating radiators. Models differ in design, power, and manufacturer. Heating appliances today are used in a wide variety of conditions.

The working conditions in the city central heating system are rightfully recognized as the most stringent. Therefore, in order to provide your home with warmth and comfort for a long time, you need to take the choice of a heating radiator seriously.

Design and principle of operation of aluminum radiators

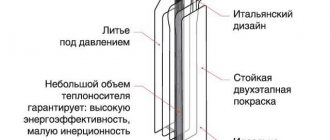

Due to the design features and the material from which they are made, aluminum radiators show the highest heat transfer coefficient. Models are often distinguished by their laconic appearance and reasonable cost. The current range of radiator models of all key brands can be found on the website https://millimetr.ru, where related heating equipment is also presented.

Aluminum radiators have clear geometric shapes and a modern design. However, after a wave of accidents associated with these heating devices, they lost much demand. Today, when choosing a heating device, consumers study the features more carefully.

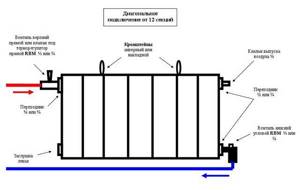

Aluminum models can have different sizes and power. The radiator consists of several separate sections or collectors. For their production, various alloys of aluminum and other metals are used.

The most common height of devices is 35, 50 cm. The length of such systems can be adjusted depending on the required number of sections. Factory radiators are supplied in sections of 10 pieces. And this can be called an advantage, since the factory twist is much stronger.

The role of the coolant in such a radiator is played by water, which can have a negative effect on the device. In order to protect it from oxidation, many manufacturers treat the inner surface with a polymer composition. Radiators that have not undergone this treatment are unsuitable for use in multi-storey buildings.

Today there are two types of aluminum radiators:

- regular model, designed for 6 atm.;

- reinforced model, designed for 16 atm.

It is worth noting that inexpensive, low-budget models are more suitable for use in private homes, houses with an individual heating system.

Steel radiator

Steel radiators appeared more than ten years ago. The main idea is to combine a convector and a radiator. Unlike cast iron, steel radiators use much less coolant, but due to their design, they are in no way inferior in efficiency. This is the main advantage of steel radiators.

Working on the principle of a convector, steel radiators allow achieving efficiency of up to 90%. Also, it is worth noting the classic style, which for the most part does not stand out much against the background of modern interior design.

Unfortunately, this type of radiator is not without its drawbacks. Steel radiators cannot be left without coolant, as corrosion can quickly form inside. It is also not advisable to use steel radiators in the case of using centralized heating systems, as I will introduce the incompatibility of this type of radiator with high pressure.

Design and principle of operation of cast iron radiators

For decades, people have been using cast iron radiators to heat their homes. Many people strongly associate them with quality and durability. Cast iron batteries are excellent for installation in houses with individual heating, and for use in apartments where heating is centralized and the pressure is about 25 atmospheres.

For the production of modern cast iron batteries, ductile cast iron is used, which is an analogue of the material for the production of cookware.

By design, cast iron models are batteries consisting of separate sections connected by nipples. The nominal dimensions of the heat flow, battery dimensions and number of sections may directly depend on the manufacturer.

The most vulnerable places in heating devices that operate under high pressure are the joints. Cast iron batteries have a minimum number of connection points due to the cast structure.

They also have a larger flow section diameter, which makes it possible to better cope with various types of contaminants that enter the coolant along with water.

Comparison of cast iron and steel

Sometimes the question “which is better” when it concerns different types of heating batteries is not entirely correct. Often, heaters are simply used in different types of heating systems, so it makes no sense to compare their technical characteristics.

The question is which batteries are better, cast iron or steel, from the same category. A comparison of these devices will prove this:

| Parameters/1 section | Steel radiators | Cast iron batteries |

| Thermal power | from 317 W | from 120 to 160 W |

| Weight | from 7.8 kg | 0t 3.5 kg to 7 kg |

| Volume | from 3.3 l | 0.8 l |

| Design | panel | sections |

| Operating pressure | 8.7 bar | 9 Bar |

| Best before date | 10 years | 35 years |

| Coolant heating | +110 | up to +150 |

| Resistance to water hammer | No | Yes |

| Corrosion resistance | No | Yes |

As can be seen from the table, the question is not whether steel or cast iron batteries are better, but that the former perform well in autonomous systems, where there are no water hammers and the coolant is clean, and the latter - in conditions of central heating.

Steel panels have several disadvantages that their cast iron counterparts do not have:

- In case of a leak, you will have to repair or completely replace the entire panel, whereas with cast iron radiators you can replace the faulty section with another.

- The panels are connected to each other by a welding seam, and no matter how high-quality it is, under constant water hammer it can leak.

- Narrow channels for coolant, on the one hand, ensure a small amount of coolant in the device, which has a positive effect on its thermal power, and on the other hand, they quickly become clogged due to low-quality coolant in the central heating network.

- The cost of stainless steel devices is higher than cast iron. It is not advisable to install them in an apartment with central heating, but in a private house they will not only heat it effectively, but also decorate the interior.

If you have to replace old cast iron radiators, then an alternative to them should be heaters with either the same parameters or better ones.

Advantages and disadvantages of aluminum models

Advantages of aluminum batteries:

- elegant appearance, lightness of construction;

- high heat transfer;

- affordable price;

- the ability to add or remove sections, depending on changes in conditions or wishes of the owners.

Disadvantages of aluminum radiators:

- poor resistance of the aluminum wall to the possibility of sudden pressure drops that can occur in central heating networks;

- high sensitivity to the quality of the coolant itself or to the quality of hot water.

Heating efficiency with aluminum and cast iron batteries

All Ogint aluminum radiators come with a 5-year warranty →

If we compare cast iron and aluminum radiators in terms of heating quality and efficiency, then the undoubted advantage of aluminum batteries will be. They are superior to cast iron counterparts in all the most important parameters.

In particular, the heat transfer of cast iron and aluminum radiators is significantly different. The thermal power of one cast iron section, depending on the dimensions, is 100-160 W. For an aluminum radiator section, the power can exceed 200 W. This is achieved due to the high thermal conductivity of aluminum and the special design of the section, which has a curly shape with ribs, which increases the level of heat transfer by convection and radiation. At the same time, due to the smaller size and dimensions of the sections, their number in the battery can increase, which allows you to effectively heat a large room. Aluminum radiators also have minimal thermal inertia. Thanks to this, they reach the maximum temperature and effectively heat the room almost immediately after the system is put into operation.

The internal volume of an aluminum section ranges from 0.7 to 1 liter, while one cast iron section can hold 4.5 to 6 liters of water. Due to this, the difference in efficiency between aluminum and cast iron radiators is very high.

When using aluminum radiators in the system, the boiler has to heat 4-5 times less volume of liquid. Fuel consumption is reduced accordingly. In addition, due to the smaller volume of water, the load on the boiler and pump is reduced, which increases the service life of the equipment.

The big advantage of aluminum radiators is their low weight. The weight of one section is about 1 kilogram, which is about 8 times less than cast iron. As a result, the installation of radiators is greatly simplified, and they can be mounted on almost any wall.

Aluminum batteries have a modern aesthetic design, which allows them to fit perfectly into almost any interior. Such radiators are painted during the production process, which means you will not need to paint them before installation. In this case, powder coating technology is used, which allows us to obtain a very strong and durable coating that provides reliable protection against corrosion and excellent appearance for many years.

Taking into account all the characteristics, we can say that aluminum radiators are the best option for use in autonomous heating systems. They will provide the highest quality and efficient heating of rooms while saving energy. At the same time, operating conditions in individual systems make it possible to ensure their long-term service.

Advantages and disadvantages of cast iron models

Advantages of cast iron batteries:

- low maintenance and long service life;

- excellent inertia or ability to retain heat;

- chemical neutrality, thanks to which cast iron batteries can be washed;

- excellent resistance to pressure and hydraulic influence;

- resistance to high temperatures;

- resistance to mechanical impacts.

Disadvantages of cast iron radiators:

- outdated technology. Cast iron models cannot be connected to a system with automatic thermostats;

- slow warm-up;

- the need to use a significant amount of water;

- large weight and size.

Installation of aluminum radiators

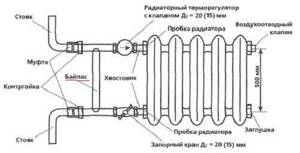

It is best to install aluminum radiators in the warm season. Immediately before purchasing batteries, you need to determine exactly how many you will need. If you are thinking about whether to carry out the installation yourself or involve specialists in this matter, remember that incorrect insertion of the battery can cause breakdown of the entire system.

At the first stage of installation, the device is assembled according to the instructions included with the radiator. Having chosen the location of the battery under the window, brackets are attached to the wall. Before installation, the entire system is washed with water.

From a design point of view, it is best to connect an aluminum radiator from the bottom. Next, the battery is hung on brackets and connected to the pipeline using clamps. All connections are sealed using plumbing flax. The entire system is being tested.

Installation of cast iron radiators

Water is removed from the pipes, and the heating circuit must be shut off. The remaining coolant is pumped out by a pump if necessary. The battery is hung on pre-prepared supports; for single-pipe systems, a bypass is used.

The radiator is connected to the main system using threaded connectors. All joints are carefully sealed. You can use any insulating materials, tow. If you have a welding machine, all joints of the bends can be welded.

After installing the device, pressure testing is carried out, which should only be carried out by professionals with special equipment.