Before choosing materials and the method by which you plan to paint a cast-iron heating radiator, you need to decide for yourself what is more important - to ensure the durability and reliability of the metal radiator or to achieve an aesthetic appearance, which, in general, is important, given the fact that radiators and batteries made of cast iron, even new ones from the store counter, are far from the most beautiful.

Painting the internal surfaces of the radiator is difficult and time-consuming

Is it possible to paint cast iron radiators?

It is believed that each additional layer of paint on the surface of a heating radiator reduces its efficiency by an average of 10-15%. After four layers of paint, cast iron battery registers heat up twice as bad as new ones. Therefore, the desire to paint the cast-iron radiators in the apartment for the fifth or tenth time before the start of the heating season should be restrained by reason. Why do useless work, maybe replace the radiator yourself or entrust the repair to a specialist?

Trying to paint the cast iron body of a heating battery with your own hands only makes sense in two cases:

- After installing a new radiator. This must be painted, since most likely the store will sell the battery with a primed surface;

- After a major overhaul of the battery, including eliminating leaks, replacing registers, removing fistulas or depressurizing a connection.

In any case, there is a chance not only to protect the body from rust, but also to beautifully paint the heating radiator, especially cast iron, which requires care and attention. You will need to select the appropriate paint, choose the method of applying paint that is most suitable for home conditions.

It is the last point that always remains a stumbling block. If the registers are in the basement or garage, disassembled, then it is better to paint the cast-iron radiators with powder paint. It looks better and the quality of the coating is much higher. True, in order to paint, you will have to disassemble the radiator, load it and take it to the nearest paint shop at a car service center.

Powder paint gives the highest surface quality; it lasts for 20 years

Professional painters will definitely tell you the best paint for painting cast iron batteries. Perhaps it will be a polyester resin primer or a regular material for painting discs and brake blocks. It is clear that having it painted by a professional will cost a pretty penny, but if done correctly, you can forget for 20-30 years that the cast iron body ever needs to be painted.

The fastest way to paint a radiator

But most often it is not possible to solve the problem using the described method, usually for technical reasons, so you have to look for a way to paint the cast iron batteries in the apartment. At the same time, try not to be poisoned by a toxic solvent and at the same time provide the radiators with a more or less presentable appearance.

Which one is better to choose?

For a high-tech or perhaps loft-style interior, you can choose silver. For other cases, they are chosen based on the requirements for the radiator: wear resistance, the need to preserve the color longer, and the location of painting.

More often, alkyd paints are chosen for batteries - they are more familiar and reliable, while modern hammer paints are generally very expensive and look interesting.

But if you want to decorate the radiator in the nursery or other rooms with your own hands and you don’t plan to dry a mountain of diapers on the radiator, you should try acrylic: it gives a lot of scope for creativity. Acrylic is not chosen because it is not yet very familiar - the very idea that you can paint a battery with water-based emulsion yourself is still new. Water-based acrylic also has almost no odor and dries quickly (especially if the heating is on).

The most durable are polyurethane paints and acrylic compositions based on organic solvents.

What paint to paint cast iron radiators

First of all, you need to decide what specific paint can be used to paint the cast iron body. This is quite simple to do; the range is small; three or four main types of paints and varnishes are usually used for heating radiators:

- Transparent alkyd varnish with silver or titanium white;

- Car tint in aerosol packaging;

- Acrylic and water-dispersion paints.

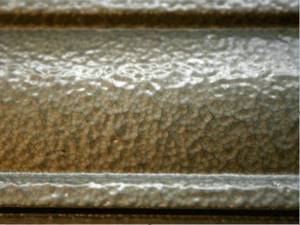

If possible, you can purchase so-called hammer paint. If you paint according to the rules, then after drying the layer will have a shine and a hammered surface. The strength of the hammer mixture coating is much higher than that of standard alkyd or acrylic materials, but the layer thickness is also noticeably higher. Accordingly, paint consumption on cast iron batteries, even if spray painted, will increase by 50-60%.

Silicone-aluminum paint - expensive but effective

Important! This treatment reliably protects the cast iron base of the battery from any mechanical damage, scratches, and exposure to detergents. But you can only properly paint a new, clean battery, without traces of old paintwork.

The only significant drawback of this solution is the unattractive gray color of the battery.

Serebryanka and bronze

One way to properly paint cast iron radiators is to use paints and varnishes filled with metal powder, usually aluminum or bronze. The metal filler in the varnish increases thermal conductivity, while titanium, zinc, and lead oxides often impair heat transfer.

Silver turns out to be the most durable coating

Before applying paint, the surface is not primed, but cleaned to a metallic shine and, preferably, treated with a passivating compound. Before painting cast iron heating radiators with your own hands, rub the metal with a rag moistened with acetone or solvent No. 646.

Alkyd and pentaphthalic paints

One of the most difficult paint and varnish materials, it is possible to paint a cast iron body, but only for 4-5 years of service. The paint is viscous, you have to add a large amount of solvent, otherwise it will be very difficult to paint the cast iron battery inside the registers.

Gives a very thick coating, even with a single painting of the surface. Therefore, if you decide to paint the radiator with alkyd enamel, then it is better to choose specialized compounds and paint in one layer.

Acrylic and water-dispersed paints

On sale you can find special acrylic water-dispersion paints and varnishes. They provide a fairly beautiful coating; if you want to beautifully paint a cast iron radiator, it is better to choose acrylic heat-resistant enamel.

Water-dispersed ones are considered good for processing registers, but it is better not to use them for a cast-iron battery. Water-based emulsion does not protect metal well, and in addition, when intensely heated, it often turns yellow and becomes covered with gray dust.

Why you should not try to paint a cast iron battery

In addition to the options listed, there are at least a couple more types of paint that do not make sense to paint cast iron with. You should not paint with polyurethane and latex paints; they create a very thick layer, which increases thermal resistance and impairs heat transfer. And besides, the material ages very quickly and becomes cracked.

Oil paint has approximately the same properties. During the first two to three years after painting, the paint layer on a cast iron radiator will look absolutely perfect, but the radiator will heat very poorly.

Varieties of compositions for coloring batteries

When painting a battery, first of all you need to pay attention to the technical component of the dye. But aesthetic characteristics also play an important role.

Advantages of acrylic dyes

Acrylic paints, which belong to the group of water-based dyes, allow you to kill two birds with one stone. Their undoubted advantage is that they do not emit harmful substances, are odorless, and are safe for humans.

They dry quickly (about 30 minutes at a temperature of 18-23 degrees), have water-repellent properties, and form a very durable coating that is resistant to mechanical stress.

The technical and aesthetic characteristics of acrylic dyes are excellent for heating appliances

And, perhaps, the most important thing is that they can withstand high temperatures perfectly, maintaining their qualities and without changing their original appearance for seven to eight years.

During this time they will not turn yellow, crack or peel. The whiteness coefficient of acrylic dye is 96%, the color is very rich and bright, and the surface looks like a plastic coating with a slight shine.

Features of alkyd compositions

Alkyd paints have high heat resistance and are also suitable for painting batteries. They are superior in strength to acrylic compounds, have anti-corrosion properties, adhere well to the surface, forming an even and beautiful coating.

However, they are not as safe as water-based paints. The solvent included in their composition causes an unpleasant odor that remains in the room for at least a day.

Paints dry quite slowly, and a specific smell can persist even after drying. Alkyd dyes can only be used in a well-ventilated area, and it is advisable to leave it completely until the smell has completely evaporated.

When working with alkyd compounds, you must take precautions and thoroughly ventilate the room.

Another significant drawback is that paints retain their color for a relatively short time and begin to turn yellow over time. If you do decide to paint the battery with alkyd paint, it is better to choose a composition that forms a glossy finish.

In this case, the period during which the radiator will remain white increases by about 20%, compared to matte and semi-matte paints.

Other types of paint for heating devices

For painting heating radiators, paints based on aluminum and silicate resins are suitable, forming a dense and elastic layer on the surface on which cracks do not appear even with temperature changes.

Silicate paints are characterized by high adhesion and do not require preliminary priming of the surface; they are designed to work at very high temperatures. Their disadvantage is a strong unpleasant odor.

Another type of paint that is worth focusing on is hammer paint, which is a type of alkyd composition. They form a rather interesting, but very specific coating. After their application, the surface is not smooth, but as if beaten with a hammer (hence the name) or with a hammered effect.

Hammer paints perfectly hide all the unevenness of a cast iron radiator - a property that is very useful for home owners with an old heating system

A significant advantage of hammer dyes is that the non-uniform texture will make various roughnesses, irregularities and other minor defects of radiators invisible.

This property is especially valuable when it comes to painting old Soviet-era cast iron batteries, the rough surface of which will be completely hidden behind the original coating.

Very often, silver paint is used to paint radiators, which is a mixture of varnish and aluminum powder. It withstands high temperatures perfectly and can be applied both to the primer and to the old coating. However, the paint has a persistent odor, so the room must be well ventilated during and after its application.

Silver can be purchased ready for application. You can prepare the composition yourself by mixing two parts aluminum powder with five parts varnish

Aluminum powder is an explosive substance. The process of cooking yourself is quite risky. You should not resort to it if there are easily flammable structures in the house, and especially small children.

What color to paint a cast iron battery

The most popular colors are white, cream, and blue; sometimes owners deliberately paint radiators white in order to improve the design of the window opening under which the battery is located. Dust is clearly visible on a white background, so you have to clean it quite often.

The optimal solution is blue, gray and beige colors. It is possible to paint the battery in darker, black and brown colors, especially since the corresponding paints are commercially available, but one can hardly expect any positive effect from such a color scheme.

Dispersion acrylic paint

Advantages:

- high drying speed, thanks to this you can use the room during repairs;

- no odor;

- The material is applied easily, resulting in a uniform layer.

It can withstand high temperatures, which is why it is often used for painting radiators, and during operation the coating does not crack, which allows it to be renewed less often.

There are 2 types of dispersion acrylic paint on sale:

- matte;

- glossy.

Materials of this group are applied in several layers, their quantity depends on the quality of the rough base. The pre-priming method is popular, for which dispersion acrylic paint diluted with water is used. This measure improves adhesion.

Preparing cast iron batteries for painting

Most mistakes made when trying to paint a cast iron radiator relate to improper surface preparation. Painting cast iron and steel surfaces are two big differences, since the paint applies evenly to the steel and provides good adhesion.

For cast iron everything is much more complicated. It will be necessary not only to remove the old paint and primer, but also to thoroughly clean the metal, as they say, until it shines, and degrease the surface with the available hot water with soda and solvent.

The metal will need to be cleaned until it shines.

You can remove old paint using a brush attachment on a drill with bronze bristles, or try using an industrial hair dryer and the same metal brush. It is impossible to use chemical paint removers or firing with a gas torch, since with severe overheating or the use of acidic solutions, the seal between the sections will burn out first.

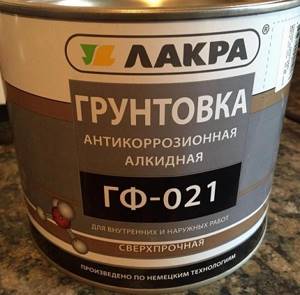

Do cast iron batteries need to be primed before painting?

If the battery is new and covered with factory primer, then there is no point in removing the layer. Most often, the quality of priming in a factory environment is higher than what can be achieved at home.

One of the best types of soil

The only exception is preparation for nitro paint. Usually the metal is cleaned and rubbed until shiny, after which a primer is applied based on zinc powder and nitro varnish, diluted two to three times stronger than required according to the instructions. This preparation ensures good adhesion of the nitro paint to the cast iron surface of the battery.

In other cases, it is recommended to cover a clean new or well-cleaned old battery with a thin layer of primer.

In order to obtain good adhesion, the primer is diluted one to one with P647 and rubbed into the surface with a dampened cloth. The layer of soil will turn out to be very thin, almost colorless, but this does not affect its characteristics. The paint will stick as well as on a thick layer, and the thermal resistance will decrease by 30-40%

Silicone paints

Silicone paints for heating radiators.

Contains polymer components (silicone). To obtain the desired consistency, add an aqueous or organic solvent.

Advantages:

- resistance to high temperatures;

- moderate elasticity of the finished coating, which eliminates the risk of cracking under the influence of temperature changes;

- it is not necessary to prepare the surface of heating devices;

- resistance to loads, the risk of abrasion during operation is reduced, which increases service life;

- good tolerance to ultraviolet radiation, due to which the original shade is preserved.

Silicone paint is more expensive than analogues, but lasts longer.

How to properly paint old cast iron radiators

You can paint a cast iron battery quickly or efficiently. If you need to get the job done as quickly as possible, it is better to use a spray bottle or aerosol can to paint the rims. One cast iron battery will require at least two standard cylinders, which is approximately 250 g of paint.

The advantage of this method is a very thin paint layer and a high-quality glossy sheen. In addition, it is possible to paint even the most difficult to reach places, and do the job in a maximum of 10 minutes.

It is much easier to paint a cast iron battery using a spray gun, but at home or in an apartment, using a spray gun or air spray creates a lot of problems, so it is better to immediately abandon such technologies.

If you have a choice, it is best to paint the battery with a brush with very stiff bristles, no rollers or any other similar tools. The inconvenience of using such a brush is that the bristles splatter the paint a lot, so you have to take it in small portions and carefully rub it on the cast-iron surface. Working with such a tool is not very comfortable, but in any case, a hard brush allows you to qualitatively paint the oldest cast-iron battery that exists in the house.

In addition, a small brush with short, stiff bristles is very convenient for painting the inside surface of the registers. If you try to do this with a regular paint brush, most of the paint will simply flow onto the floor.

Important! The rigid base of the brush ensures good squeezing of air from under the paint layer, so after drying the paint layer will be thin, without cavities or peeling.

Heating radiator painting

During the work process, mistakes are often made: a thick layer is applied, preparation is neglected. This leads to deterioration in the appearance of the device and shortens its service life.

A good example for painting a cast iron radiator.

General dyeing technology

You need to start work by applying a small amount of paint to the battery. If the coating is uneven, the process is repeated. All subsequent layers are applied after the previous one has dried. It is recommended to work with 2 brushes: one wide, the second small, but with a long handle, flexible enough to reach difficult areas inside the radiator.

It is necessary to remove loose fibers; to do this, the brush must be fluffed. Work starts from the internal surfaces and moves from top to bottom. When moving to the outer walls, paint is also applied first to the upper areas. Defects (smudges) formed during painting are removed with medium-grit sandpaper. These areas are painted over when the composition is reapplied.

The nuances of painting aluminum radiators

Defects on aluminum heating devices can be removed using automotive putty. The surface is first cleaned, degreased, and coated with a primer. When the putty is dry, begin painting.

Aluminum radiators are treated with an aerosol; auto enamel is often used for this purpose. It should be applied to hot radiators - this ensures quick drying. There is no need to remove the old paint before applying a new coat.

How to paint an antique cast iron battery

In order to give the radiator the look of an antique heater, you need to choose the right paint color and texture. For example, you can try to design the battery in the form of a product made of non-ferrous metal, brass or copper. This will require special fillers that imitate a copper surface. You will have to paint in at least four to five layers, with intermediate polishing of each. The result is a cast iron battery very similar to the copper heat exchanger used for heating 150-200 years ago.

Antique water heating radiators often had decorative patterns; the manufacturer’s inscriptions were necessarily made on the surface, stamps and other attributes of individual production were placed. You can try to reproduce all this using stickers cut out of foil.

The decor will have to be glued to a protected cast-iron surface using heat-resistant adhesive compositions, for example, epoxy resin. After painting, the cast iron radiators will look very similar to an antique radiator.

Interesting ideas for painting cast iron batteries with your own hands

You can give a boring metal radiator a more personalized look with several colors or painting methods. For example, in a children's room, a cast iron radiator can be painted in several colors that best suit the color scheme of the room's interior.

For a good mood

For a hall or living room, it is best to paint the radiator in the style of wall decoration. This will make the heating system, radiator and pipes almost invisible against the background of the window trim.

A design can be applied to the front surface of the radiators, for example, imitating the technique of painting ceramic wall tiles.

In the simplest case, small inscriptions and photo tracings can be made on a white background. Using a stencil and blanks printed on a printer, you can easily turn a cast-iron battery into a cabinet covered with newspaper clippings.

The cast iron body, primed with white water-dispersion paint, can be painted with almost any basic paintwork materials, felt-tip pens, markers, and PVC painting materials. All that is required is talent, an artist's taste and a sense of proportion.