Design features of cast iron radiators

Cast iron radiators are the most durable

The batteries have the most traditional appearance. The design includes several sections connected to each other by nipples. To seal the joints, heat-resistant rubber or paronite is used. The coolant channels inside have a round or elliptical cross-section. They produce one-, two- and three-channel sections.

The batteries are cast from gray cast iron. The material is wear-resistant and durable - radiators last more than 50 years. Salts are not deposited on the walls, small debris or sand does not cause damage. Even after 30–40 years, the diameter of the working channels remains almost unchanged.

The size of a cast iron battery depends on the number of sections. The size is selected based on the size of the heated room. But if the width of the product is determined by the number of elements, then the height and depth depend on the structure of the sections themselves.

The appearance of the product is unattractive. More modern models are produced with a flat front panel. Decorated with forged elements.

How to calculate heat transfer and power of radiators

In order to always maintain a comfortable temperature in the room, it is necessary to correctly calculate the heat transfer of heating devices and select them in accordance with the required characteristics.

This is the only way we can correctly calculate heating radiators so that the room is warm and comfortable in cold weather.

The thermal power of the heating device is indicated in its passport. However, this parameter may vary depending on actual operating conditions. The calculation of heat transfer from a radiator is determined based on the temperature difference - the difference between the average temperature of the coolant and the air in the room:

where Твх – coolant temperature at the inlet;

Тout – temperature of the coolant at the outlet;

Troom – air temperature in a heated room (a value of 20 degrees is considered comfortable).

In the technical specifications, the temperature regime is designated as Tin/Tout/Troom. and the temperature pressure is Tnap. If the heating system has indicators that differ from the values specified in the passport, then the thermal power of the radiator should be calculated using the formula:

where k is the heat transfer coefficient of the heating device (indicated in the passport);

A – area of the heat transfer surface of the radiator (indicated in the passport);

Tnap – temperature pressure.

By calculating the power of the heating battery, you can determine the required number of batteries or select a specific type of heating device that has sufficient heat output to heat a particular room.

Advantages and disadvantages

Modern design solutions

The advantages of the product are determined more by the material than by the design. Main advantages:

- Cast iron conducts heat well and accumulates it. The radiator takes longer to heat up than a steel or bimetallic one, but gives off heat for a long time after the boiler is turned off. An hour after heating stops, the residual heat transfer for cast iron models is 30%, while for steel models it is only 15%.

- The water used in central heating is not clean. Salts, mechanical impurities, sand destroy the pipeline material. Debris is deposited on the walls: the working diameter decreases over time, and the efficiency of heat transfer decreases. Cast iron is not afraid of salts and abrasive particles. After 30 years, the batteries work as efficiently as on the first day after release.

- Cast iron batteries cannot withstand constant high water pressure, but they are not afraid of water hammer. This option is used when arranging heating with natural circulation.

- Radiators last at least 50 years. If you change the gaskets on time, it will take even longer. Usually they are replaced not because of leaks or low efficiency, but to make the interior more modern.

- The price is the lowest among heaters.

Disadvantages of radiators:

- The main disadvantage is its considerable dimensions and heavy weight. The 8-section model weighs more than 60 kg. They are difficult to transport, lift to the top floor, and install.

- If when the heating is turned off, high thermal inertia acts as an advantage, then when turned on it turns into a disadvantage. The room warms up for at least 12 hours.

- To service the batteries, you need a large volume of coolant and a more powerful boiler. This is not a hindrance for central heating, since the system was originally designed to transfer a large amount of coolant. For an autonomous one, this is a significant drawback.

- There is no need to talk about design. Rough, heavy radiators hardly fit into the interior.

The advantages of a cast iron battery are well demonstrated in central heating systems. The disadvantages are visible when autonomous heating is installed.

Ways to increase heat transfer

There are several ways to increase the heat transfer of heating devices:

- Regular wet cleaning to clean the surface of the batteries. The cleaner they are, the higher their level of heat transfer.

- Equally important is the correct painting of the radiator, especially for cast iron appliances. The fact is that multi-layer applied paint prevents effective heat transfer. Before you start painting the heating radiator, you should remove the old layer. No less effective is the use of special enamels intended for pipelines and heating devices, since they have low resistance to heat transfer.

- To ensure maximum power, these devices must be installed correctly.

- Among the main mistakes made during installation, experts note:

- tilting the battery; - installing the device too close to the floor covering or to the wall; - blocking access to radiators with furnishings and installing inappropriate reflective screens. - To increase the efficiency of heating batteries, it would not hurt to inspect their internal cavity. Often, in the process of connecting heating radiators to the system, burrs are formed, due to which, during operation, blockages are formed that prevent the free movement of the coolant.

- You can place a heat-reflecting screen made of foil material on the wall behind the heating device.

Educational video about heat transfer from heating radiators:

Heat dissipation of a cast iron radiator

What is heat transfer and power of radiators

The power of cast iron heating radiators and their heat output are among the main characteristics of any device that provides room heating. Typically, manufacturers of equipment for heating structures indicate this parameter for one section of the battery, and the required number is calculated based on the size of the room and the required heat transfer of cast iron radiators.

In addition, other factors are taken into account, such as the volume of the room, the presence of windows and doors, the degree of insulation, climatic conditions, etc. The heat output of heating radiators depends on the material they are made of. It should be noted that cast iron is inferior to aluminum and steel in this matter. The thermal conductivity of this material is 2 times lower than that of aluminum. But this drawback is compensated by the low inertia of cast iron, which gains heat and releases it for a long time.

In closed heating systems with forced circulation, the efficiency of aluminum batteries will be much greater, but subject to the presence of an intense coolant flow. As for open structures, cast iron has more advantages with natural circulation. The approximate power of one section of a cast iron radiator is 160 watts, while for aluminum and bimetallic devices the same parameter is within 200 watts. Therefore, under equal operating conditions, a cast iron battery should have a large number of sections.

Dimensions of a cast iron radiator.

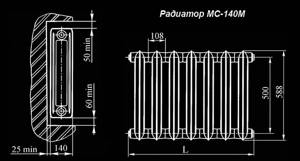

In the Soviet Union, the overall dimensions of cast iron radiators had a certain standard. In one section, the distance between the centers of the coolant supply and discharge pipes ranged from 30 to 50 cm. The width of the section was not standardized and varied among different manufacturers. Almost all modern batteries also have these standards. The most popular model among cast iron products is MS-140. (installed in many “Khrushchev” and 9-story buildings of the 60-80s). The distance between the centers of the pipes is 50 cm; battery height 58.8 cm; width 9.3 cm; depth - 14 cm. The variety of overall dimensions of batteries is explained by the needs of customers.

Heat transfer calculation

First of all, it is recommended to pay attention to the existing data sheet, which is attached to each product of this type. In it you can find the necessary information regarding the thermal power of one section of the product

These figures need significant correction. The heat transfer of bimetallic heating radiators, like aluminum ones, have excellent power ratings, and the judgment is based on the well-known fact that copper products have an excellent level of heat transfer, as well as aluminum ones. They have a high thermal conductivity, while heat transfer depends on many other factors.

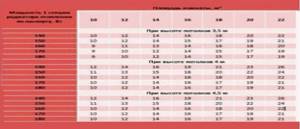

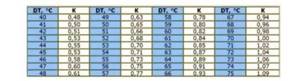

Heat transfer from the heating radiator is multiplied by a correction factor taken depending on the DT value

The figure indicated in the passport is correct only if the difference between the supply and processing temperatures is 70°C.

Using the formula, calculations are made as follows:

The instructions may have different symbols. Often only a difference of 70°C is mentioned and nothing more.

Characteristics of cast iron radiators of various manufacturers and models

In Soviet times, there were countless factories producing cast iron radiators - after all, there was no alternative. Here, for example, are just a few of their types: NM-140, NM-150, Minsk-110, R-90, RKSh. Almost all of them are no longer produced. Perhaps only one proven model lasts a long time - the MS-140, classic and good-quality.

New models look prettier; for example, the Ms-110 from the Santekhlit plant has a shallow depth (only 11 centimeters) and fits well under narrow plastic window sills.

Radiator MS - 110.

In Cheboksary they make FM radiators with one, two and three channels. Their outer side is flat, which looks quite aesthetically pleasing, and it’s easier to wipe off dust.

FM radiator models.

Beautiful two-channel radiators are produced in Minsk, about 10 models in total.

An example would be radiators 2K60P, 2K60PP, 2KP100-90-500, 2K60P-300.

Sectional batteries made of cast iron are also brought to us from abroad. Foreign products are smoother both outside and inside, so their heat transfer is higher. Let us note the Chinese company Konner (the “Hit”, “Modern” and “Fort” models are especially good).

Radiators from Konner, model Moder.

The Czech plant Viadrus, the Turkish company DemirDöküm and the Spanish concern Roca also make good radiators. European manufacturers make very elegant batteries with a cast-iron cast pattern. True, such radiators are an order of magnitude more expensive than domestic ones.

Table. Comparative characteristics of cast iron heating radiators of the most common manufacturers and models

Brand and model Section dimensions, H/W/G Operating pressure, atm Thermal power, kW Heating area by 1 section, m2 Water volume in a section, l Section weight, kg

| MS-140 | from 388 to 588/93/140 | 9 | from 0.12 to 0.16 | 0,244 | from 1.11 to 1.45 | from 5.7 to 7.1 |

| World Cup1 | from 370 to 570/80/70 | 9 | from 0.075 to 0.11 | from 0.103 to 0.165 | from 0.66 to 0.9 | from 3.3 to 4.8 |

| World Cup2 | from 372 to 572/80/100 | 9 | from 0.1009 to 0.1423 | from 0.148 to 0.207 | from 0.7 to 0.95 | from 4.5 to 6.3 |

| World Cup3 | from 370 to 570/90/120 | 9 | from 0.1083 to 0.1568 | from 0.155 to 0.246 | from 0.95 to 1.38 | from 4.8 to 7 |

| Konner Modern | 565/60/80 | 12 | from 012 to 0.15 | — | from 0.66 to 0.96 | from 3.5 to 4.75 |

We have given the main technical characteristics of cast iron heating radiators that are most often in demand. I think they helped you get the big picture.

How to choose cast iron heaters

When choosing radiators, we follow the standard algorithm. We determine the required thermal power, calculate the number of sections, and assemble heating devices for each room from them. Then - the purchase of heaters, installation kits and control valves.

What type of radiators is better to choose:

- For heating technical, utility and utility rooms of a private house, the MS-140M series or its variants are quite suitable.

- In residential premises, “accordions” are clearly inappropriate. Buy nicer “aluminum-look” batteries.

- If your budget allows, install designer appliances - domestic or imported, there is practically no difference. Find out the weight of the sectional heater in advance and consider the installation method - wall or floor.

Vintage taps for retro batteries from Carlo Poletti

- Conventional ball valves and balancing valves are not suitable for retro radiators purely visually. We need similar Carlo Poletti fittings.

- Place any batteries you like in a private cottage; they will easily withstand the pressure of an autonomous system.

- What devices are best for an apartment? The answer depends on the method of heat supply. With a centralized supply, it is not recommended to install cast iron due to periodic testing of the network. If the pressure “jumps” to 12 bar, the sections may crack.

Note. Before purchasing radiators, you can contact the heat supply organization and formally request the operating parameters of the pipeline network. But if the pressure is exceeded and the cast iron is destroyed, you will suffer losses that are difficult to compensate.

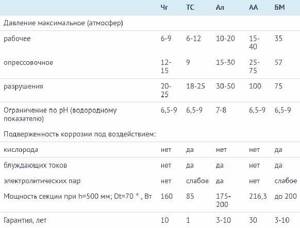

Heat transfer table for bimetallic heating radiators

The fact that bimetal heating radiators are the most expensive of all proposed designs of water heating systems, also metal, steel and cast iron, is known firsthand by everyone who has had to make repairs and replace home batteries. As proof of the great efficiency of bimetal, in most cases a relative table of heat transfer from bimetallic heating radiators is given with references to the heat conductivity of metals, and even to functional measurements of the ambient temperature in the room. Is a bimetal radiator so effective?

What is a bimetal radiator?

Essentially, a bimetallic heating device is a mixed design that embodies the advantages of steel and aluminum heating systems. The design of the heating device is based on the following elements:

- The heating device consists of two housings - an internal steel and an external metal one;

- Due to the inner shell made of steel, the bimetallic body is not afraid of aggressive hot water, can withstand high pressure and provides greater strength in connecting certain sections of the heating device into one battery;

- The metal case best transmits and dissipates heat flow in the air, and is not afraid of surface corrosion from the outside.

A comparison table can be used as evidence of the high heat transfer of a bimetallic housing. Among its closest competitors - cast iron radiators ChG, steel TS, aluminum AA and AL, the BM bimetal radiator has one of the best heat transfer rates, high operating pressure and corrosion resistance.

In reality, things are even worse; many manufacturers indicate the amount of heat transfer in the form of heat output per hour for one part. In other words, the packaging may indicate that the heat output of the bimetallic part of the heating device is 200 W.

This is done forcedly, the data does not result in a unit of area or a temperature difference of one degree, in order to facilitate the buyer’s perception of certain technical specifics of the heat output of the heating device, while at the same time making a little advertising.

How beneficial is a bimetal radiator?

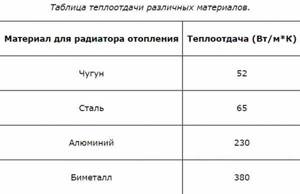

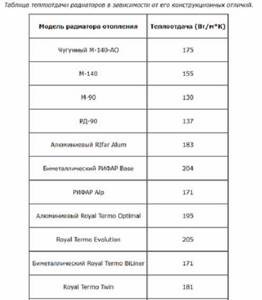

Often, to prove the high heat transfer of bimetal radiators, the tabular information below is given.

This kind of information is often used by stores and advertising as reliable data on the heat transfer of a wide variety of traditional heating systems. It is known even without reference data that the heat transfer of the bimetallic part is higher than that of a steel or cast iron structure; all that remains is to check how much better a bimetallic radiator is than aluminum. Is the difference really reaching almost 40%?

The table below shows data on heat transfer based on functional measurements of devices of certain models of heating devices, also bimetallic, metal and cast iron systems.

As can be seen from the table, the heat transfer between the outermost positions of heating devices of the same manufacturer, for example, metal Rifar Alum -183 W/m•K and bimetallic Rifar Base - 204 W/m•K, is no more than 10%, in other options the difference is even smaller.

What determines the heat transfer from a heating device?

Before trying to evaluate and compare the real performance of bimetal radiators, it is necessary to recall what determines the thermal performance of a particular heating system:

- Thermal pressure of the heating device. The greater the difference between the average surface temperature of the heating device and the air temperature, the more intense the heat flow transferred to the room air;

- Thermal conductivity of the heating device material. The higher the heat conductivity, the smaller the difference between the temperature of the coolant and the outer wall of the heating device;

- Case dimensions;

- Temperature and pressure of the coolant.

Main! In water heating systems, 98% of the heat transfer from the wall to the air is due to convection, due to which, in addition to the size, the shape of the heating device is also important. But since it is difficult to actually take into account the shape of the surface, in most cases they manage only by taking into account the size of the lines.

The first sign - thermal pressure, is calculated as the difference between the half-sum (Tin + Tout) / 2 and the air temperature in the room, Tin and Tout - the water temperature at the inlet and outlet of the heating device. There is even a correction indicator that specifies the heat output of the heating device when calculating the power of the heating system for a living space.

The table of the correction factor says that the heat transfer values of a bimetallic heating device, as well as a metal one, stated in the passport, will correspond to reality only during the first hour of operation of the heating supply, K = 1 with a temperature difference of 70 ° C, which is only possible in an unheated room. The coolant is rarely heated above 85°C, which means that the greatest heat transfer can be obtained only when the air temperature in the room is T = 15°C, or when using specialized types of coolant.

The next criterion is the heat conductivity of the radiator wall material. Here the bimetallic radiator loses to the metal version. The design of the bimetallic part of the heat supply shown in the diagram shows that the wall of the heating device consists of two layers - steel and aluminum.

Even if the thickness of the wall is the same, a bimetallic case under similar conditions does not usually have a greater heat transfer than one made of aluminum.

The dimensions of the two types of pipe coils are approximately the same and are designed to be installed in the space under the window sill. It is noteworthy that the bimetal and aluminum housing design has a much larger surface area than the cast iron or steel model. Thanks to this, the amount of heat transfer differs more strongly than a simple calculation based on the thermal parameters of metals - thermal conductivity and heat capacity.

It remains to figure out the temperature and pressure of the coolant.

Optimal operating conditions for bimetal heating systems

The structure and circuits of bimetallic and aluminum systems are in most cases similar. In the middle of the body of the part there is a main channel through which the heated coolant moves. The dimensions and shape of the channel correspond to the cross-section of the supply pipe, which means that the liquid does not experience additional turbulence and local overheating points.

If you look at the data in the table, it becomes clear that these two types of radiator designs are designed to withstand high pressure and, most importantly, high temperature of the coolant. In this case, the advantages of a bimetal heat exchanger are clear. First of all, the temperature difference increases; instead of the typical 70°C, the thermal pressure value can easily reach 100°C. For example, the pressure and temperature of the coolant at the entrance to the heating system of a multi-storey building is 15-18 Bar and 105-110°C, and for steam systems it is 120°C. Based on this, the correction rate for heat transfer efficiency increases to 1.1-1.2, which is almost 20%.

Secondly, the higher the pressure of the coolant, the higher the coefficient of heat transfer and heat transfer from the liquid to the metal. The value of heat transfer due to increased pressure can increase by 5-7%. In the end, summing up all the conditions, it may be that a bimetal heating device is perfect for heating tall buildings.

Despite the fact that manufacturers give approximately the same working life for two types of pipe coils, in fact, at very high pressure and heat supply temperatures, only bimetal can work for a long time. Hot water, even if there are additives and protective coatings, has a destructive effect on aluminum. A different matter is steel with alloying additives of manganese and nickel; its service life can be up to 15 years.

Conclusion

High heat transfer from a bimetallic heater can be obtained not only at high pressure. For two types of heating devices, even for cast iron and steel structures, it is possible to increase heat transfer by at least 20% if you use specialized types of antifreeze or antifreeze in home boiler systems as a coolant rather than water. The pressure will not change, it remains 3-4 atm., and the temperature at the outlet of the boiler increases to almost 95-97oC, which will increase heat transfer by 15-20%. Moreover, antifreeze will ensure good preservation of metal, cast iron, steel pipes and pipe coils.

Review of popular brands of manufacturers and their prices

High-quality cast iron casting, the original shape of the sections, and the stylishness of the patterned ornament create the unique attractiveness of the new type of cast iron batteries. Their price is higher than standard models. At the same time, the antique design of heating devices organically complements the classic, Gothic or English style of room decor.

The cost of products is significantly influenced by the scale of production. Some radiators are made only to order, which significantly increases their price compared to standard “Soviet”-style products. For example, one MS-140 section produced by the Nizhny Tagil Boiler and Radiator Plant can be purchased for 380 rubles.

Retro Style

A Russian brand that produces several collections of cast iron radiators in various styles: Empire, Rococo, Classicism, Baroque. Provides battery painting services according to customer preferences. You can choose imitation antique silver, Gzhel, red gold, bronze and other options.

The cost of one section of a vintage two-channel Retro Style Anerli is 16,367 rubles.

A battery of 5 low-profile multi-channel Retro Style Bolton sections can be purchased for RUB 19,219.

The Retro Style Chester cast iron radiator costs 41,696 rubles for 5 sections.

Prices for Retro Style cast iron battery models

cast iron batteries Retro Style

Guratec

The high-quality heating devices made in Germany are designed in a retro style. The surface of the sections is protected by a powder paint coating that is resistant to mechanical damage. Before being sent to consumers, products are tested on hydraulic stands.

The Guratec radiator of the Fortuna series, priced from 140 euros per section, is decorated with a beautiful vine ornament, and the range also includes products with images of dragons, lions and angels. The patterned surface of the batteries, painted to match the decor, will decorate a classic interior.

Prices for Guratec cast iron battery models

Guratec cast iron batteries

Roca

The representative of the Spanish industry has a hundred-year history of development. The first products were released in 1917. The company produces a variety of heating devices from aluminum, steel, cast iron with a retro-style design. The popular Epoca model is a battery of 6 cast iron sections, which sells for 29,420 rubles.

Demir Dokum

The factories of the Turkish manufacturer are equipped with automated production lines in accordance with modern European standards. Now you can buy in Moscow any of six models, which are presented in different standard sizes.

The products are distinguished by excellent performance characteristics, have a magnificent appearance, so they can decorate any interior. One section of the Demir Dokum Historic model costs 3,981 rubles.

Prices for Demir Dokum cast iron battery models

cast iron batteries Demir Dokum

Conner Modern

The products of the Russian manufacturer in the Art Nouveau style have good heat transfer rates. Products are manufactured using modern technologies. At a very affordable price, domestic cast iron radiators are not inferior to European ones in terms of workmanship. The cost of the Modern-500 series model of six sections is 4080 rubles.

Types of heating devices

There is no official classification of cast iron batteries. We can roughly divide heaters into 3 types:

- Soviet-style “accordion” type MS-140;

- devices with an increased heat exchange area, simulating new bimetallic and aluminum heaters, only cast from cast iron;

- designer batteries made in retro, modern style.

Comment. Let us remind you: all cast iron heating devices are sectional, that is, stacked.

It is unrealistic to classify products according to other criteria. Technical characteristics - weight, dimensions, heat transfer - vary widely. Let's look at the properties of batteries by group.

Pros and cons of traditional accordions

To begin with, we present the technical parameters of one fin of the MS-140M radiator, taken from the technical data sheet:

- total height – 588 mm, between holes – 500 mm, depth – 14 cm (the number is included in the marking);

- heat flow (power) – 160 W, surface area – 0.21 m²;

- working pressure – no higher than 10 Bar;

- the volume of water inside the section is 1.45 liters, the maximum temperature is 130 °C;

- weight – 7.12 kg;

- material – gray cast iron SCh-10, plugs – malleable cast iron KCh-30 or steel;

- gaskets - rubber.

Dimensions of the MS-140 heater and recommended installation distances

Note. The amount of heat flow is indicated under certain operating conditions: the difference Δt between the temperature of the room air and the coolant is 70 degrees. The calculation of heat transfer of section 1 is described in a separate instruction. The letter "M" in the marking means "modernized".

“Accordions” are produced by several Russian enterprises and the Minsk Heating Equipment Plant. The average price for a MS-140M battery section is 10 USD. e., minimum – 6 cu. e.

The mentioned Belarusian plant also produces modified versions of “accordions”, shown in the photo below:

- lightweight model 2K60 with a power of 120 W, the fin weighs 5.1 kg;

- 2KP100-90-500 depth 9 cm, heat output - 140 W;

- modification BZ-140-300 with an interaxial distance of 30 cm, power - 120 W.

The undoubted advantages of radiators remain their affordable price, durability and corrosion resistance to chemically active substances. However, the latter advantage is inherent in all batteries made of cast iron.

Flaws:

- Soviet “accordions” of the MC type do not meet current interior design requirements. The new modifications look better.

- Fragility. A slight impact can cause a microcrack to form in the metal, and then a leak. Freezing of the coolant definitely leads to destruction; the expansion of water causes cast iron to split.

- Significant mass of the heating device, aggravated by spaciousness. Due to the coolant, each section is made heavier by 1-1.5 kg. The multi-section heater cannot be hung on a wall made of aerated concrete or a plasterboard partition, only placed on the floor.

- Limited scope. Due to the maximum operating pressure of 10 Bar, the radiator cannot be used in an apartment with central heating, where the water pressure reaches 12 Bar (at the time of testing the network).

- There is no bottom connection to the heating system, pipes are connected only from the side.

Inertia (long heating and cooling) cannot be attributed to the pros or cons of radiators. This is a feature of thick cast iron walls that does not affect the quality of heating.

Important note. The efficiency of the boiler and the efficiency of the system do not depend on the amount of water in the batteries. The load on the circulation pump is like fairy tales. If the volume of coolant is large, then only the time of initial heating and final cooling will change. Listen to the expert's opinion in the video:

It is worth mentioning one more advantage of the M-140 series batteries. Since “accordions” were previously used everywhere, working sections can be found for free or purchased from scrap metal. According to reviews from owners of private houses, used cast iron radiators are often used for heating outbuildings and utility rooms.

Radiators with increased heat transfer area

The uniformity of the shapes of cast iron appliances is due to the manufacturing technology - casting. The extrusion method used to produce aluminum sections is not applicable here. But in recent years the picture has improved - products with a flat front panel and side ribs, reminiscent of light alloy heaters, have appeared on the market.

Reference. The aluminum-look batteries shown in the photo are produced by Russian, Belarusian and Chinese companies: Konner, STI NOVA, Minsk Plant.

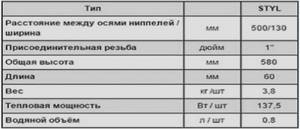

As an example, we list the characteristics of the KONNER Modern section with a standard center distance of 500 mm:

- total height – 60 cm, depth – 96 mm;

- heat transfer at Δt = 70 °C is 150 W;

- maximum water pressure in operating mode – 12 Bar;

- capacity – 0.9 liters;

- weight – 4.1 kg.

The outside of the heater is covered with polymer enamel (usually white). Gaskets are EPDM rubber, the kit includes 4 end plugs. The cost of one KONNER Modern rib is 500 – 12 USD. That is, at least 4 pieces are sold. For rooms with low window sills there is a series of low KONNER G1 batteries with a center distance of 300 mm and a power of 120 W.

Externally, Konner heaters are very similar to products made of aluminum alloy - the front section is flat, heat exchange fins are cast on the sides

How are these batteries better than accordions:

- The heat transfer surface has increased thanks to the side fins and flat front panel.

- Accordingly, the share of infrared heating has increased. That is, the radiator began to transfer more heat through radiation.

- The depth of the fins has decreased without reducing heat transfer.

- The operating pressure is increased to 12 atmospheres.

The disadvantages of batteries are typical - the products are fragile and limited in coolant pressure. But we managed to solve the problem of appearance - now the heaters look no worse than bimetal. Prices have increased slightly - a section costs between 10...17 USD. e.

Note. The cost of a Belarusian radiator 2K60PP, equipped with a flat panel, is 21 USD. e. by the rib. The reason is the complication of the manufacturing process; mechanical processing of the frontal plane and painting were added.

Designer retro batteries

The selection of antique radiators is impressive in variety. In this case, technical parameters fade into the background, giving way to other characteristics:

- beauty;

- compliance with the design of the rooms;

- overall dimensions.

In addition to traditional two-channel devices, you can choose heaters with 3-4-5 channels. There are radiators with smooth surfaces and a relief pattern, designed for floor installation. Batteries in the Art Nouveau style have angular outlines, while retro ones are more rounded.

Explanation. Two-channel radiators have 2 vertical coolant flows, three-channel radiators have 3, and so on.

High-quality retro batteries are produced in the Czech Republic, Germany, Turkey, the Russian Federation, and more recently in China. Famous brands:

- Viadrus;

- Guratec;

- Demir Dokum;

- EXEMET;

- Retro Style;

- Iron Lion;

- taps and other retro-style fittings are produced by the Italian brand Carlo Poletti.

It is pointless to provide technical data for heaters, since the variation in power, dimensions and weight is too great. Prices also vary widely - from 20 to 250 USD. e. per section. Chinese and some Czech devices cost 20...30 USD. That is, Turkish and German are significantly more expensive. The cost greatly depends on the massiveness and design of the product.

The only parameter that remains unchanged is the operating pressure. In this regard, designer heating radiators are no better than “accordions”, since cast iron walls can withstand 15 Bar (maximum). The average value is 8…10 Bar. The table below shows the characteristics of several models:

| Radiator brand and model | A country | Weight, kg | Coolant volume, l | Thermal power, W | Price, y. e. |

| Viadrus KALOR 500/70 | Czech | 4 | 0.8 | 70.3 | 20.05 |

| Viadrus Bohemia 450/220 | Czech | 9.9 | 2.4 | 110 | 78.25 |

| Demir Dokum Nostalgia 500/200 | Türkiye | 9.6 | 2.3 | 163 | 52.20 |

| Retro Style Anerli 560/230 | Russia | 17 | 3.29 | 189 | 229.60 |

| EXEMET Modern 600/100 | Türkiye | 4.3 | 0.7 | 102 | 32 |

| EXEMET Classica 500/176 | Türkiye | 9.3 | 1.95 | 145 | 76.85 |

The negative and positive properties of retro heating devices in general repeat the advantages of previous varieties. The main difference is the high cost and massiveness of some batteries; the weight of 1 rib reaches 17...20 kg.

Manufacturers of cast iron radiators

It is not only Russian factories and enterprises in CIS countries that produce such products. There are many foreign manufacturers offering cast iron radiators in retro or techno style. Models from domestic companies are cheaper.

Minsk Heating Equipment Plant

One of the most famous manufacturers. It produces two- and three-channel cast iron batteries in a variety of designs. There are classic radiators and models with a flat surface - they are more efficient because they transfer heat better, as well as options with a pattern on the surface. The number of sections is determined by the customer.

Santekhlit (Russia)

The plant offers classic models. The depth of sections and height varies within very wide limits. There are models with a depth of only 11 cm. They can be easily placed under a narrow modern window sill. The length of the battery is determined by the number of sections.

Viadrus (Czech Republic)

The company offers products more suitable for autonomous heating. Radiators can easily withstand constant pressure of 12 bar and are very durable. Meet European quality criteria.

The design of the radiators is attractive. The plant produces 8 lines in different designs and 27 standard sizes. There are models with a flat surface, with exquisite patterns on sections, and with sections of unusual irregular shapes.

Main dimensions of cast iron batteries

Although the main criterion, which is accepted by all manufacturers, is the center distance, there are products that, with the same parameter, have differences in height, depth and width.

Basic indicators:

- The center distance is quite varied. It can vary from 220 mm to 900 mm.

- The height of the cast iron battery ranges from 330 mm to 950 mm.

- The depth is 85-200 mm.

- There are products with a width from 45 mm to 100 mm.

Given such a wide range, all products are divided into low, high and standard cast iron radiators. In each of these model ranges you can find the usual “accordion”, and antique products, and chic palace or Art Nouveau style, or modern samples with a flat outer panel.

As a rule, for low models, a place is found in rooms with panoramic windows, or where the walls are weak, for example, made of plasterboard. Their center distance does not exceed 30 cm, and their height is 38.8 cm. On the domestic market they are represented by models such as MS-110 and 90. Modern low analogues have a basic center distance of almost 40 cm. The most popular are products from such manufacturers as like Bolton220 (Turkey) and Viadrus (Czech Republic) - 34 cm.

The height of a cast iron radiator of a standard size is based on an interaxal distance of 50 cm. If you choose a Soviet “accordion” for an apartment of the usual type, then domestic manufacturers produce them under the following markings: MS-85 and 90, MS-110 and MS-140.

In this segment you can most often find designer models in an antique style. They are expensive, but they look impressive and heat wonderfully.

You should not look for a section size of a cast iron battery that is too high. Although new devices weigh half as much as old ones, radiators made of this metal cannot be found above 1 m. This model range is dominated by cast iron batteries from Demir Döküm (Türkiye). Their designer products are distinguished by their originality, the highest quality of cast iron and high cost.

Before making a choice, you should carefully study the product data sheet and become familiar with its main parameters. Since any installation of radiators is preceded by a calculation of the power based on the area of the room, and their size directly affects this parameter, you should immediately check all the indicators so as not to subsequently purchase or remove sections.

Corrosion resistance level

The average values are presented in the table.

| Corrosion resistance (mm/year) of cast iron | |||||||||

| Cast iron | terms of Use | ||||||||

| Industrial environment | Chamber with 0.3% SO2 additive | Sheath liquid at 25 °C | Sea water* | 10% at 50 °C | 3% at 10-19 °C | 5% acid | |||

| sulfuric | salt | nitrogen | |||||||

| White | — | — | — | 0,05 | — | — | — | — | — |

| Grey | 0,14 | 0,24 | 0,27 | 0,06 | 0,02 | 0,08 | 31 | 27 | 26 |

| Lasting | — | — | — | — | — | — | — | — | — |

| ferrite | 0,18 | 0,29 | 0,22 | 0,06 | 0,01 | 0,08 | — | — | — |

| ferrite and pearlite | 0,18 | 0,24 | 0,26 | — | — | 0,08 | — | — | — |

| perlite | 0,14 | 0,22 | 0,29 | 0,06 | 0,01 | 0,08 | — | — | — |

| Malleable | — | — | — | 0,06 | — | — | — | — | — |

| Corrosion-resistant type 4N 15D7 | — | — | 0,05 | 0,02 | — | — | 0,15 | 0,3 | 21 |

| Silicon ChS 15 | — | — | — | — | — | — | 0,13 | 0,13 | — |

| *when tested in running water, corrosion is higher. The rate is 1 g/(m2∗h) = 1.2 mm/year. | |||||||||

Design as a factor of choice

Cast iron radiators are rarely made to look beautiful. Their task is to transfer heat, and not to please the eye. But some radiators are stylized and then used to create a beautiful interior . This is facilitated by an unusual shape or color on top of a standard primer.

Photo 2. Decorative heating radiator made of cast iron. Covered with black paint, decorated with decorative forging.

Some batteries are made in retro style . They are painted with an ornament and given a dark color. The radiators themselves have wheels, so they just need to be placed on the floor without attaching them to the wall.

And they also create abstract models of radiators. The main component is cast iron, but it is combined with another metal. They are available in various forms, so these batteries are suitable for any room.

Rules for choosing a cast iron unit

Cast iron is a massive material. It holds a huge volume of coolant; for example, a small section with a mass fraction of 150 and a weight of 7.6 kg contains 4.3 liters of water. A cast iron battery guarantees greater heat capacity than other structures made from metal factories.

When using cast iron units indoors, the temperature rises and falls little by little. The heat transfer of a cast iron battery is lower than that of an advanced bimetallic or aluminum radiator. In addition, such material retains heat incomparably longer. Before choosing a cast iron unit for your apartment, you need to pay attention to some things. Important parameters:

- Heat dissipation.

- Heat area of the radiating surface.

- Operating pressure.

- Heating system temperature.

The operating pressure is determined by the thermal conductivity of water. It is important that the radiator maintains the required performance. The more floors a building has, the stronger the operating pressure.

The operating temperature in the heating system means the degree of heating of the water and what temperature is required for subsequent heating. For example, an indicator of 90-70 means that the water entering the first part of the unit has a temperature of 90°C, and the leaving liquid in the final section is already 70°C.

Heat dissipation is an indicator that indicates how much heat is returned by one section of the battery over a certain period of time. When choosing a unit, its model is important. Many people have a biased attitude towards cast iron equipment, because memories from childhood come to mind in the form of a cast iron “accordion” under a window opening. But such units are a thing of the past. They had a small and inefficient heating area or heat transfer.

Some of the heat that enters the coolant from the heating boiler to the water heating radiators is slightly lost, because dense supply pipes are used for the units. High power steam boilers are used to heat water to 90°C. That is why in private buildings the heating system operates at a lower temperature.

The variety of such radiators is huge

Modern batteries are different from outdated “accordions”. They retain all the advantages of conventional cast iron appliances, but now many of the shortcomings have been eliminated by specialists. For example, the Minsk-made 160P500 unit is formed from thin plates, each of which has the smallest heating area and low power (only 70 W).

But the unit, mounted from plates, has a heating panel, which, unlike ribbed devices, has an extensive directed heat flow. Many other manufacturers offer a large selection and variety of such batteries. Advantages of modern models:

- Some modifications can be formed from separate sections. Thanks to this, the required power is selected.

- Now there are units that are sold assembled. For example, these include Connor, STI, Breeze. They are formed from a number of sections designed for a specific building.

To determine the required number of plates, an engineering calculation of the required thermal power per square meter of the apartment is carried out. For example, you purchase one heating battery of 14 sections or 3 units of 6 sections each.

Read also: calculation of heat transfer from sections of cast iron radiators.

In this video you will learn how to calculate the amount of heat:

Heat transfer from heating devices

The power or heat output of one section of a cast iron radiator is prescribed in the technical document of the battery. If the unit is used for low-temperature or medium-temperature heating structures, then the heat transfer of a cast iron radiator will be less than stated in the documents. To correctly determine the required number of sections, the actual power of the device is calculated using the formula Q = K × F × T, where:

- K is the heat transfer multiplier;

- F—distance of heating surface;

- T—temperature pressure.

If the incoming coolant temperature is 90°C and the outlet temperature is 70, then the room temperature will be 20°C. What is the heat transfer of a cast iron radiator with an area of 0.3 m² at a temperature of incoming water of 90°C and outgoing water of 70°C: it will differ from that stated in the passport. This difference occurs due to heat loss in the pipes. The reason for low temperature in the home may be insufficient pressure. Not all conditions can be provided in the laboratory.

To calculate the heat output of cast iron batteries, it is necessary to make the following calculations: 7 × 0.3 × 60 = 125 W. In the passport, this parameter is indicated with a small margin, so the resulting number is multiplied by 1.3. This multiplier is often used for popular models of heating units. Next, you need to make the following calculation: 125 × 13 = 163 Watts. The difference in calculations will be more noticeable if the water does not warm up above 70°C. Before purchasing the necessary unit for heating a room, you need to find out the real thermal values of the heating system in a particular room.

Saving on heating

The basic rule of saving is to correctly remember what you should not save money on. For radiators, the heat transfer of a cast iron battery is taken with a small margin. If necessary, the temperature can be lowered by reducing the liquid pressure or by controlling the shut-off valves. If the heat transfer, which is specified in the manufacturer’s passport, is lower, then the room will be cold.

An example is Konner cast iron batteries. They have good performance in many respects, but in real operating conditions their heat transfer coefficient is 25% lower than indicated in the official documentation.

To prevent the room from getting cold in winter, you need to calculate in advance how many sections you will need

Often the heat transfer of the cast iron section is lower due to the fact that the temperature of the water in the heating system is lower than usual. Sometimes laboratories conduct tests at standard water temperatures, but in homes it may be lower.

To prevent the room from getting cold, it is necessary to foresee the temperature of the coolant and other indicators in advance. The lower the temperature of the liquid, the larger the plane of the battery should be. For example, at a water temperature of 60°C, a unit with a height of 0.6 m will be sufficient for radiation of 1 kW. The same equipment dimensions will be required at 30°C. Due to the low temperature of the coolant and an increase in the surface of the battery or the number of sections, heating consumption decreases.

Technical characteristics of cast iron radiators ms 140

At the moment, in our country, cast iron heating radiators MS 140 can be called the most common model of heating devices. These devices are manufactured in accordance with GOST 8690–94. Depending on the distance between the axles, there are five standard sizes of MS 140 batteries: 300, 400, 500, 600 and 800 mm.

Previously, all standard sizes were used quite widely, and they could be seen not only in residential apartments, but also in administrative and industrial buildings. At the moment, the most commonly used cast iron radiators are MS 140 500 and 300. Other modifications are extremely rare and, as a rule, they are made to order.

In view of the popularity of ms 140 500 batteries, you should consider the technical parameters of this model. For heating cast iron radiators brand MS 140, the characteristics are given for one section, since this is a purely sectional model. By selecting the required number of sections, you can create the optimal temperature regime in the room.

The main characteristics of heating radiators MS 140 500 are as follows:

- pressure. Working pressure is up to 9 atmospheres, and pressure testing is up to 15 atmospheres;

- heat transfer is low and equals 175 W;

- each section has two channels;

- section dimensions: height – 50 cm, width – 9.8 cm;

- the capacity of one section is 1.35 liters of water;

- The radiator is able to withstand coolant temperatures up to +130 degrees.

It is worth considering the design of a cast iron heating battery model ms 140 500. Gray cast iron is used for production. Nipples are made of malleable cast iron. Gaskets are installed between the sections. Heat-resistant rubber is used to produce gaskets.

What influences the dimensions of aluminum heating radiators

dimensions of heating radiators To connect individual elements of an aluminum radiator with the pipelines of the heating structure, use an installation kit, which includes:

- special brackets for hanging the battery on the wall in the amount of 2-4 pieces;

- Mayevsky valve - a device for bleeding air trapped in the system;

- a key designed for a faucet;

- pass-through radiator plugs with a diameter of 3/4 or ½ of the right or left type;

- plugs for the heating device, they are also called blind plugs;

- sometimes there are also dowels included to secure the brackets.

Depending on the type of manufacture of the aluminum alloy radiator, the heating device can be cast or extruded:

- Thanks to casting, the battery becomes durable and reliable. In this case, the sections are made up of individual parts, cast entirely and then assembled into a single heating device. Its lower part is welded last;

- in the process of using extrusion equipment, a heated aluminum alloy is forced through a special metal plate with holes. This method allows you to make a long aluminum profile of the required shape. When it cools, it is divided into segments that correspond to the size of the device. Only then are the top and bottom of the battery welded. In this case, it is impossible to adjust the radiator in length, and sections cannot be added or subtracted from it. Extrusion devices are quite rare on sale.

Technical characteristics of cast iron batteries STI nova 500

STI Nova devices are cast iron heating radiators made in Russia, which are distinguished by good quality and attractive appearance.

It is worth noting that this company STI produces products in the mid-price range. For example, a heating radiator for 10 sections will cost about 5 thousand rubles apiece. Technical parameters for Russian cast iron heating radiators STI nova 500 are as follows:

- The operating pressure of the device is 12, and the pressure test pressure is 16 atmospheres. So water hammer will not damage this model;

- The thermal power of the battery is 1.5 kW. And this is quite enough to warm up a room whose area does not exceed 15 square meters;

- The design of the device is somewhat reminiscent of aluminum or steel radiators.

Reviews on cast iron radiators STI nova 500 agree that the product is of high quality and fits perfectly into any interior. Efficiency and quick heating of the room are also noted.

Advantages compared to other batteries

- The undeniable advantage of a cast iron radiator over modern aluminum, steel, and bimetallic batteries is its durability. The half-century anniversary of the cast iron battery is a ubiquitous phenomenon. In some cities, the batteries that were cast in the century before last have survived to this day and continue to work properly.

- The cost of a cast iron product can only please the future owner - European prices for trendy aluminum or bimetallic batteries are not affordable for everyone. In addition, purchasing a large number of sections promises significant benefits.

- Another advantage of cast iron is the absence of any coolant requirements. Water of any quality is poured into the heating system.

- The thickness of the cast iron sections allows them to withstand the highest operating pressures. starting from 9 Atm and above. In addition, cast iron withstands water hammer very well, which is why it is preferred in centralized heating systems.

Technical characteristics of Conner cast iron batteries

Conner heaters also occupy a leading place among sales of heating devices on the market.

They have good technical parameters. Therefore, there are only positive reviews of Konner cast iron heating radiators. Batteries from this manufacturer are affordable. They are produced in different configurations, with different diameters of inlet pipes and different numbers of sections. The main technical characteristics of Conner cast iron radiators are given below:

- power – 120-180 W;

- the maximum coolant temperature is +110 degrees;

- battery operating pressure is 12 atmospheres. But the device can cope with pressure of 20 atmospheres. Conner units are not afraid of water hammer;

- radiators have wide channels. Therefore they do not create much local resistance.

The dimensions, weight and displacement of the sections of this model are slightly reduced. Feedback from owners on cast iron heating radiators Conner can be summarized as follows: they heat the room efficiently and quickly, are durable, and have an excellent design.

The choice of cast iron heating radiators today is quite large.

Selecting a suitable model for a specific heating system can be quite simple, you just need to rely on the properties and technical parameters of the device.

Therefore, it is so important to know the characteristics of cast iron heating radiators and be able to calculate the optimal values. The choice of type, model, size, power and other characteristics of a cast iron battery depends on the area and characteristics of the room, the number of windows and external walls, and the conditions of use of the heating device. Any cast iron heating radiator whose characteristics correspond to the heated room will work efficiently and create warmth and comfort in the apartment.

You can install a cast iron battery by calling a plumber or carry out this procedure yourself.

If you decide to install a cast iron radiator yourself, then it is very important to connect it correctly.

Otherwise, some problems may occur during operation of the device. For example, the battery will not warm up evenly. Leaking may also occur. Most often, if the heating radiator does not warm up completely, the reason may be due to improper installation. Therefore, if you are not a specialist and are not confident in your knowledge and abilities, it is better to seek help from professionals.

You also need to ensure that the device is in good condition. Especially when the battery life established by the manufacturer is coming to an end. A cast iron radiator can last much longer than the specified period if the device is of high quality, installed correctly and maintained in good working condition.

Indicators influencing the calculation of the number of sections

When choosing a radiator for a particular room, you need to take into account technical features. For example, the calculation will be different for a corner and non-corner room, for a room with different ceiling heights and different window sizes, etc. The most important parameters that are taken into account when determining the required radiator power are:

- the area of your premises;

- floor;

- ceiling height (above or below three meters);

- location (corner or non-corner room, room in a private house);.

- will the radiator be the main heating device;

- There is a fireplace and air conditioning in the room.

There are other important features that need to be taken into account. How many windows are there in the room? What size are they, and what kind of windows are they (wooden; double-glazed windows for 1, 2 or 3 glasses)? Was additional insulation of the walls done and what kind of insulation (internal, external)? In a private house, what matters is the presence of an attic and how insulated it is - and so on.

Cast iron radiators Conner (China)

According to SNIP, 41 W of thermal energy is required per 1 cubic meter of space. You can take into account not the volume, but the area of the room. For a 10 sq.m standard room with one door and one window, one door and an outer wall, the following heat output of the radiator will be required:

- 1 kW for a room with one window and an outer wall;

- 1.2 kW if it has one window and two external walls (corner room);

- 1.3 kW for corner rooms with two windows.

In reality, one kilowatt of thermal energy heats:

- In houses made of brick with a wall thickness of one and a half to two bricks, or made of timber and log houses (window and door area up to 15%; insulation of walls, roof and attic) - 20-25 sq. m

- In corner rooms with walls made of timber or brick of at least one brick (area of windows and doors up to 25%; insulation) - 14-18 sq. m

- In the premises of panel houses with internal cladding and a thermally insulated roof (as well as in the rooms of an insulated dacha) - 8-12 sq. m

- In a “living trailer” (wooden or panel house with minimal insulation) – 5-7 sq. m.

Operation of modern radiators with water

There are 7 characteristics that distinguish cast iron from other metals:

- Durability

The resource of the device is exhausted for a very long time, since it is capable of performing its function efficiently for 50 years or more.

In some cases, no repairs are carried out during this period. Considering the low cost, the result is a cheap system that requires almost no maintenance costs.

- High heat dissipation

Among other materials, cast iron transfers the temperature of water into the environment better than others. This is due to the ribs of the sections located vertically. The design and parameters of the metal allow the radiators to work for a long time even if the boiler is turned off or the latter loses its quality operation.

- Ability to withstand high heat

Cast iron batteries can easily withstand temperature increases up to 130-140 degrees , which makes it possible to use water vapor as a working substance. Although this is unreasonable, and such values are redundant.

- Modern radiators have a high safety margin

The container of the devices is protected from external physical damage. The internal part of the system can withstand operating pressure up to 18 atm . This helps with hydraulic tests during which large pressure values are applied.

- Corrosion protection

The latter is possible due to the iron contained in the alloy. To neutralize this problem, the inner walls are coated with a special substance. Thanks to the drug, oxygen released from the steam during strong heating does not interact with the metal. Then, as it cools, it combines with hydrogen again, becoming a liquid.

- High hydraulic resistance

The indicator depends on the diameter of the pipes that supply water to the radiator. For cast iron, the value is high, so there is no need to use a circulation pump. The liquid forces itself to travel through the system quite easily.

Attention! The device supports operation with any type of coolant. Both water and mixtures containing glycol can be poured into the cast iron piping.

- Low cost of the device and ease of installation

Cast iron have built-in connections: you just need to hang the battery on hooks that are embedded in the wall and connect it to the pipes.

This method of fastening is reliable, guarantees the absence of leaks, and reduces the risk of water hammer. The latter can sharply increase pressure and cause irreparable damage to the device.

The system is connected to the piping with threaded connections , which is safer than welding. This also allows you to combine different metals, such as cast iron sections with steel pipes. Despite the ease of installation, it is recommended to invite a specialist.

Recommendations for choosing heating batteries

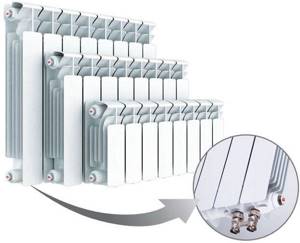

Externally, bimetallic radiators resemble aluminum ones; it is difficult to distinguish them. Without specific knowledge, visual differences are not easy to see. However, when it comes to performance characteristics, bimetallic batteries are much better than aluminum ones.

The best radiator currently is bimetallic. It is durable and can withstand high pressure, so it can also be installed in multi-storey buildings with a centralized heating system. As for aluminum products, they cannot always be used.

It is not recommended to use them in cases where:

- There is high pressure in the heating system

. Since aluminum is a brittle metal, if the maximum permissible pressure is exceeded, the product may not withstand and leak. For this reason, aluminum radiators are not used in multi-storey buildings connected to a central highway. - Non-freezing liquids, which are incompatible with aluminum, are used as coolants

. If such a coolant comes into contact with this metal, a chemical reaction occurs, leading to the destruction of the heating device. - The boiler has a copper heat exchanger

. Copper and aluminum are incompatible materials, since they form a galvanic couple, between which an electric current arises, destroying both elements. Aluminum suffers the most because its ions are attracted to copper. As a result, over time, the walls of the heating device will become thinner and may leak. However, such a problem will not arise if metal-plastic or polypropylene pipes were used to create the heating system - in this case, galvanic couples are not formed.

Panel steel radiators are used exclusively in autonomous heating systems. These batteries can be used with any coolant and even with copper heat exchangers. Steel radiators are quite durable, but they are susceptible to rust.

All types of heating radiators have certain advantages and disadvantages, so the choice depends on the specific situation. As for the characteristics and operating conditions, bimetallic radiators are the best, but not every family can afford to buy them.

Details about the types of heating batteries in the video: