How is hot water supply organized in an apartment building?

The supply from the central distributor, where heating is carried out, is carried out through pipelines laid above or underground - routes. They are necessarily insulated so that the working environment does not cool down or freeze as it passes to consumers. Next, the highways are divided and brought to high-rise buildings, in which distribution is carried out across levels and apartments. One of the most important factors that determines the design and method of supplying hot water to an apartment building is the source of the heated liquid. Depending on this, there are two types of systems

- Open with a fence from the heating network. The hot water supply line runs from the central boiler room parallel to the heating pipes. Replenishment can be carried out from the supply or return line, depending on the time of year. During the demi-season period, when the coolant does not heat up to a high temperature, hot water is taken from the line coming from the main unit. In winter, hot water for domestic needs is most often supplied from the return line. This scheme is used in most old apartment buildings.

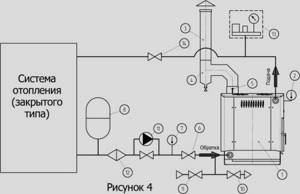

- Closed (boiler rooms) with a fence from a centralized cold water supply system (CWS). In this case, the quality of the working environment is much higher, since it must meet the requirements of the drinking water complex. Heating to the required degree is carried out in separate equipment: a heat exchanger connected to the thermal power plant, a storage tank, a gas water heater. Most often, a boiler hot water supply system for an apartment building is more efficient and comfortable, since the temperature in the pipeline does not depend on the operation of the heating network.

Steam production

The huge steam boiler in the turbine hall - the height of a 9-story building is not the limit - can be called the heart of the thermal power plant. It is powered by prepared fuel, releasing a huge amount of energy. Under its force, the water in the boiler turns into steam with an outlet temperature of almost 600 degrees. Under the pressure of this steam, the generator blades rotate, resulting in the creation of electricity.

The thermal power plant also produces thermal energy intended for heating and hot water supply to the region and city. For this purpose, there are selections on the turbine that remove part of the heated steam before it reaches the condenser. The exhausted steam is transferred to a network heater, which acts as a heat exchanger.

DHW schemes in MKD

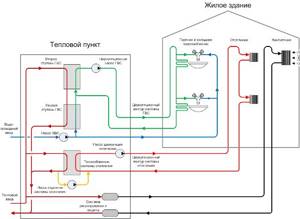

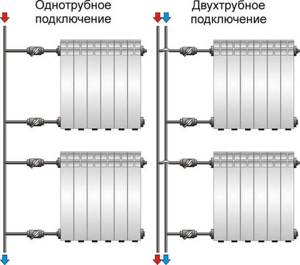

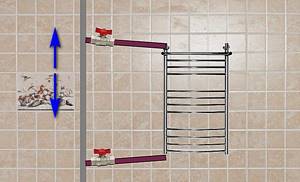

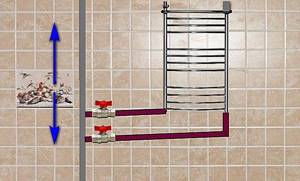

Depending on the method of moving the working environment, two types of network wiring are distinguished, which are shown in Figure 1.

Fig.1

Dead end

Such a system assumes the presence of one supply line through which hot water moves to the distribution points. Its main advantage is ease of organization and the ability to save on materials. There are many more disadvantages

- significant overuse of resources

- cooling as it passes through the pipes and during a static stay in the pipeline

- increased proliferation of bacteria in a stagnant environment

Due to these disadvantages, a dead-end hot water supply system is not in demand in a modern apartment building.

Circulating

A more efficient scheme, the installation of which requires the laying of two highways. The supply, through which the heated working medium enters, and the return, through which its unused volume is discharged. Liquid movement in a closed cycle is carried out using a pump. Despite the need to install additional equipment and lay longer communications, the circulation circuit is more economical and more comfortable to use due to many advantages

- constant movement of water allows the user to get it hot at any time of the day

- absence of stagnation

- rational consumption of resources

- Convenience and efficiency of temperature control

Heating network

Once in the tubes of network heaters, the water is heated and transferred through underground pipelines further into the heating network due to pumps driving the water through the pipes. Heating networks, as a rule, carry water at 70-150 degrees - it all depends on the temperature outside: the lower the degree outside, the hotter the coolant.

The central heating point (CHS) becomes the transfer point for the coolant. It serves an entire system of buildings, an enterprise or a microdistrict at once. This is a kind of intermediary between the object that creates heat and the direct consumer. If water in a boiler room is heated due to fuel combustion, then the central heating station works with an already heated coolant.

Main elements of hot water supply in MKD

To understand how hot water is supplied in a multi-storey city building, you need to know what the system consists of. Typically, its installation uses a standard set of equipment and components.

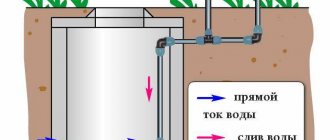

Water metering unit

The first stage that the working environment goes through after entering the building. It consists of several devices

- shut-off valves necessary to shut off the flow. Ball valves, gate valves, etc. are used as it.

- filtering equipment that retains relatively large contaminants: rust, sand, scale, silt. For this purpose, a mesh sump or tank with a drain valve is installed, passing through which the particles settle to the bottom

- meters recording hot water consumption

- pressure gauge

- bypass line (bypass). It is not installed in all networks, but it is convenient in case of repair, as it allows you to turn off the equipment without stopping the operation of the entire complex

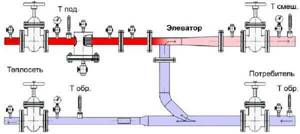

Elevator unit

Next, the hot water system, fed from heating in an apartment building, goes through the mixing stage, in which the working medium reaches the desired temperature. This occurs by adding portions from the cooled main line to the excessively hot coolant coming from the boiler room under high pressure. The process is carried out in special equipment - a water-jet elevator. Between it and the inlet valves there are inserts of the DHW network. There can be 2 of them (one for supply and return) or 4 (two for each line). In the first case, a dead-end scheme is implemented, in the second - a circulation scheme.

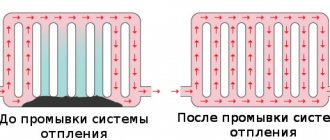

Bottlings

They are horizontally located pipes running in the basement from the elevator and water metering units and serving as a connecting link between them and the risers. They must have a maximum diameter (32-100 mm). It is selected taking into account the consumption and needs of the network with a reserve for the future, since communications tend to “overgrow” over time. A dead-end hot water distribution system in an apartment building involves the installation of one bottling system, and a circulation system - two.

Risers

Provide vertical distribution of the working environment. As a standard, two pipes (DHW and cold water) are installed on one row of apartments, located one above the other. However, depending on the features of their layout, other options are possible.

- 2 risers per dwelling, provided that the water collection points are located at a considerable distance

- 1 vertical pipe for 2 apartments, when the neighbors’ bathrooms are located through the wall

- use of horizontal jumpers that allow you to connect up to 7 consumers to one line

The diameter of the riser is usually 25-40 mm.

Eyeliners

This element completes the hot water supply scheme for a multi-storey building. It is necessary for wiring inside the apartment. For its installation, pipes with a diameter of 15 mm are usually selected from polymers, but more often from steel. The use of metal structures is more justified due to the high probability of water hammer in the system. Most often, apartments use tee wiring, which is easier to install, maintain, and repair. A more complex collector circuit is more common in private construction.

Heating system of a two-story house with natural circulation

Owners of their own country houses know that heating their home is a paramount and expensive task, but it is made easier by the fact that almost all existing heating schemes can be repeated independently, without resorting to the paid services of professionals

A house with one or two floors does not matter, since in terms of purchases and labor costs the indicators will not double, but less. The implementation of a heating scheme with natural circulation (in everyday life it is simply called “gravity” or “physics”), which does not involve the inclusion of a circulation pump and related accessories, will help to save a little more. Moreover, the circuit has been tested for decades, and during this time it has not shown any failures, since it consists of a minimum number of components and parts

Moreover, the circuit has been tested for decades, and during this time it has not shown any failures, since it consists of a minimum number of components and parts.

Possible malfunctions in the DHW complex

Due to the similarity of typical systems of multi-story buildings, the problems that arise in them are also standard, with rare exceptions. Some of them can be fixed by residents themselves without a long wait for a technician from a service company. Key points on this list

Valves leaking

Occurs on shut-off valves along the line of the rod. Appears due to damage and wear of seals. It can be eliminated by turning the thumb knob all the way. In this case, the thread will press the oil seal as much as possible, eliminating the leak.

Crane noise

The cause of the malfunction lies in the mixer itself, or more precisely in the internal element - the faucet. The deformed gasket vibrates and blocks the flow, creating rhythmic water hammer. Since hot water enters the house under high pressure, this problem is usually more pronounced on the red tap. The malfunction can be eliminated by removing the valve axle and replacing the seal on it. As an option, you can install a new ceramic element that does not have this drawback.

Cold heated towel rail

The problem may arise due to the accumulation of air in the horizontal jumper on the DHW riser. You can blow out the plug by contacting your neighbors on the top floor. If it is not possible to come to an agreement with them, the fault is eliminated from the basement. To do this, you need to shut off your riser in the basement, and then open all the hot water taps in the apartment. The air will escape through them, after which the supply can be started.

Automatic collector-beam system

The supply of coolant to radiators connected via radial wiring can be made automatically adjustable. In this case, instead of a plastic manual control cover (position 4 in the figure “Complete manifold block”), a small-sized electromechanical servo drive is installed on the thermal valves of the return manifold (position 2 in the figure “Complete manifold block”), connected by a cable to an analog thermostat or controller. Radiators are connected to heating pipes without any fittings at all (ball valves can be installed).

Dimensions of the thermal valve servo drive.

Such a scheme has increased capital costs, while simultaneously providing an increased level of comfort. The user-desired air temperature can be set from the control panel of the room thermostat, the signals of which are processed by servo drives on the thermal valves of the return manifold. The system can be controlled by a so-called chronothermostat, which provides the user with the ability to set a temperature control program for a week, differentiated by day of the week and time of day.

Conclusion

A heating system with collector-beam piping provides the user with the possibility of hydraulic balancing and individual adjustment of operating modes of heating devices. A certain increase in the length of pipes during radial distribution is obviously compensated by a decrease in their diameter and ease of installation.

How to implement alternative heating for a private home

Two-pipe heating system for a private house - classification, types and practical design skills

Single-pipe and two-pipe heating distribution in a private house

Prevention of hot water systems

This process is aimed at preventing malfunctions in the network so that the DHW circuit for an apartment building functions without interruptions. To this end, employees of the management company must

- inspect all communications every two months to identify deviations

- ensure proper thermal insulation of the pipeline to prevent freezing

- fulfill tenant requests in a timely manner

- bleed air pockets as necessary

- install additional vibration and noise insulation if the equipment makes loud noises during operation

- annual planned shutdown of the DHW supply for routine or major repairs

If all of the above measures are carried out in accordance with the schedule, the hot water supply system of an apartment building, regardless of the layout or type of wiring, will function properly and uninterruptedly.

Estimated standards for hot water consumption

It should be noted that there are many standards for calculating resource consumption; in the housing sector, there are no standards for water use per person without the use of a water meter. This is due to the fact that population density varies greatly in different regions of our country. In other words, each region has its own regulations. In accordance with the rules, a certain amount of water is supplied to the populated area. At the same time, they take into account the volume of water used by residents of those apartments in which water meters are installed.

From the total volume of water supplied, the volume that passed through the metering devices is subtracted. The resulting difference is divided by the number of people registered in a given residential area. It is these people who bear the cost of used water. This situation has arisen largely because there are many places of unauthorized water consumption and water meters are not installed everywhere, by the way, unlike countries with developed economies. Consumption rates are calculated using a multiplying factor.

When making calculations, it is necessary to take into account the condition of plumbing fixtures and the presence of installed water heaters.

The water consumption coefficient in different regions differs because in each region water is consumed in different volumes. In this case, it is necessary to take into account the climate and the price of fuel intended for heating water.

The average rate of water consumption per person has been derived. During the daytime, this figure is 200 liters of cold water and 100 liters of hot water. An ordinary bathroom holds 250 liters of water, and if the resident does not take a bath every day, then it makes sense for him to think about installing water meters.

An installed meter will allow you to significantly save on water bills. The fact is that unauthorized water withdrawals, leaks, water consumption for the needs of the Ministry of Emergency Situations and much more are included in water bills in one form or another.

Design features of the heating circuit

In the heating circuit behind the elevator unit there are various valves. Their role cannot be underestimated, since they make it possible to regulate heating in individual entrances or in the whole house. Most often, the valves are adjusted manually by employees of the heat supply company, if the need arises.

Modern buildings often use additional elements, such as collectors, heat meters for batteries and other equipment. In recent years, almost every heating system in high-rise buildings has been equipped with automation to minimize human intervention in the operation of the structure (read: “Weather-dependent automation of heating systems - about automation and controllers for boilers using examples”). All the described details allow you to achieve better performance, increase efficiency and make it possible to more evenly distribute thermal energy throughout all apartments.

Cold water supply

The cold water supply system is significantly different. Its features are as follows:

- Water is not heated.

- A separate highway is created for the system.

- Maintenance of the system is possible by installing several valves.

Due to the normal temperature of the water, it can be supplied under high pressure. This is due to the fact that heat affects important elements of the system.

How does a boiler work?

Modern boilers are the most economical heating devices.

This is one of their main advantages. Actually, two main elements are responsible for the operation of the device - a tank and a heating element (heating element). The tank is a water storage facility and operates on the principle of an ordinary thermos. The internal coating of the tank slows down the cooling process of the water, so various manufacturers are actively experimenting with its improvement. Mainly for water heaters, tanks made of stabilized, alloy steel are used, which can resist the corrosion process. The interior is covered with glass porcelain. This substance has a specific structure, the main feature of which is neutrality. In addition, there are a number of other equally important properties. Glass porcelain has become popular among manufacturers also for the reason that it does not peel off. Consequently, even after years of operation, the water in the tank does not become cloudy, but remains clean.

According to the type of heating, boilers are divided into two main types, in particular:

- Direct heating.

- Indirect heating.

A direct heating boiler is a standard water heater that can be found in most modern apartments. The water in it is heated using a heating element, as we have already discussed above. When liquid enters the tank, the heating element is activated, which increases the water temperature to the maximum set value, after which it is maintained at the same level. The main advantage of devices of this type is the stability of their operation. They are absolutely independent of external factors, with the exception of

availability of electricity and water supply. The disadvantage is the rather long waiting time for heating if the tank is empty. In addition, such devices consume more energy than indirectly heated devices.

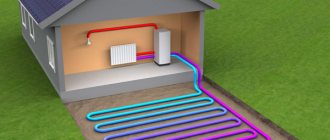

An indirect heating boiler is a device that uses process water from a boiler or other heater for heating. They install a special system through which the heating liquid circulates. This solution is most common in private homes using autonomous heating.

The advantages are efficiency and the absence of problems with heating elements - the main disease of direct heating boilers. Disadvantages include the need to constantly turn on the heating device to heat water, which makes them less versatile. They cannot be used in apartments with central heating.

Boiler: what it consists of, how it works.

Electric water heaters, also called boilers, have become a part of modern life. Lack of hot water in a private home, short-term and long-term shutdowns in the summer season - a storage heater can solve all these problems. It is a container in which the liquid is heated using a heating element.

Electric storage water heater diagram.

The storage heater is connected to the water supply system, a source of electricity and, with high performance, is very safe, reliable and economical.

How does an electric storage water heater work, what is the principle of its operation and what is its fundamental difference from an instantaneous water heater?

First things first.

Wiring in the apartment

There are two main schemes for distributing water supply in an apartment:

- tee (sequential),

- collector

Both schemes have their advantages and disadvantages. Sometimes it makes sense to use a combination of these schemes.

The sequential scheme is the traditional way of designing and installing water supply in an apartment. This circuit consists of one common pipe to which all devices are connected in series. Tees are used to connect plumbing fixtures, which is why this scheme is called a tee. The main pipe must be larger in diameter than the others, as it takes on the functions of a collector.

One of its significant advantages is the smaller number of pipes compared to the collector circuit. Therefore, the costs of its installation will be minimal.

The collector wiring diagram is the optimal choice for large apartments, as well as in places where the installation of a large number of plumbing fixtures is required. Water from the common riser enters the collector and is then sent to consumers, that is, to appliances.

Each consumer is connected separately. One of the main advantages of the collector circuit is the uniform distribution of water. This means that the number of connected devices and the length of water pipes do not reduce the pressure for any of the consumers.

The video demonstrates the cold and hot water input unit in an apartment in a multi-storey building.

Dependence of the system on the heat source

The system can be classified according to a variety of criteria. If we consider them on a large scale, we can distinguish several options:

- Centralized are associated with the installation of a boiler room. It heats the medium, which is supplied to several multi-storey buildings at the same time.

- Locals are required to service only one structure. They are characterized by low power, since they are designed to heat a small volume of medium.

In industrial buildings, a system can often be installed that involves the use of secondary steam to heat the premises. This option reduces costs because thermal energy is reused.

Differences between open and closed water supply systems

Hot and cold water can be supplied through a closed or open water supply system. The differences determine the main operational characteristics. The standards for their installation are specified in various regulatory documentation.

Open heating supply

An open hot water system is characterized by the fact that water is taken from the heating network. This moment determines the possibility of using the environment exclusively for solving everyday needs: washing dishes, laundry, cleaning the room. The medium can be heated up to a temperature of +75°C. Its advantages include the following points:

- The open version is equipped with an expansion tank, which allows the removal of the air pocket.

- Just recharge. In this case, high pressure is not required, so you can use the system without fear.

- Such water supply does not lose its functionality even if there is a leak.

- The scheme is more suitable for structures in which there is a long and high consumption of hot water.

- The option under consideration is not suitable for tall structures. This is due to the fact that the water cools quickly, so it will immediately flow cold.

Open heat supply also differs from closed heat supply in the type of equipment used. It consists of the following elements:

- Heating boiler. It is responsible for increasing the temperature of the environment. Depending on the performance of the system being created, the boiler can operate on electricity or fuel. Modern equipment operates on the basis of automation, which reads the pressure in the system.

- Circulation pump. Often, when creating a heat supply, they are faced with the problem of a long pipeline length, as well as the need to raise water to a height. The circulation pump creates the required pressure and significantly increases the heating process.

- Top or bottom wiring. The most common is the lower one, since it involves placing the main equipment in the basement. This arrangement greatly simplifies the maintenance procedure.

- The entry of various impurities into the pipeline reduces the quality of water. Therefore, the installation of various filter elements is provided. During long-term operation of the system, it is necessary to periodically clean the filter elements, otherwise the pressure in the pipeline may increase significantly.

The disadvantages are that you need to constantly monitor the water level in the installed tank. From time to time it is necessary to replenish the capacity.

Closed heating supply

A closed hot water system is designed in such a way that the medium is heated from the coolant supplied from the heating network. The advantages of such heat supply include the following points:

- The temperature is maintained at a constant level. The working system in this case constantly has a temperature of about +70°C.

- It is possible to save on the amount of energy used. This is due to the fact that heating is carried out simultaneously to supply water and heat the room.

- Towel dryers are being installed. The constant high temperature makes it possible to install dryers in the bathroom. They will constantly heat the air in the room, which eliminates the possibility of mold.

- The task of sanitary and other control is significantly simplified. This is due to the fact that the medium does not enter the boiler, this reduces the likelihood of impurities appearing.

- During installation, only steel pipes can be used due to the heating of the medium to a high temperature. Polymers are much cheaper and lightweight, but when heated they become more plastic.

- It is necessary to carry out periodic pumping due to losses occurring for various reasons. Losses amount to 0.5% of the total water volume in the network.

The only significant drawback is that a powerful water heater must be installed. The system is characterized by greater complexity, since heat exchange must be ensured. Therefore, difficulties may arise during maintenance.

Elements

A water metering unit is a piping unit of a water supply network consisting of shut-off valves, measuring instruments and fittings. The elevator unit is an element of the heating system that allows you to reduce the temperature of the coolant supplied from the thermal power plant to the set level.

The heating elevator mixes high-temperature coolant from the thermal power plant and cooled coolant from the return heating line of an apartment building.

Connecting ladder-type heated towel rails

What kind of “ladders” are there?

This is the most popular category of heated towel rail models these days. Such devices look very advantageous on the bathroom wall, they are easy to use - crossbars, and often additional shelves on top make it easier to hang things for drying or heating. Their high heat transfer is noted.

The form can be different, sometimes quite unexpected. But, as a rule, the design principle is preserved - two vertical pipes (let's call them collectors), connected by jumper pipes of smaller diameter. The connections for connecting the heated towel rail to the riser are located only on the collectors.

But the “ladders” can also differ significantly in the location of these pipes.

Thus, a separate group of models in this category is equipped with two pipes on one manifold, directed to the side. Such heated towel rails, quite understandably, are intended exclusively for side connection.

This ladder model allows only lateral connection. By the way, the model shown is not the most successful, since there is a “hump” above the upper pipe. Air will definitely accumulate in it, requiring removal - either periodically manually or through an automatic valve.

In other models, heated towel rail manifolds have the ability to connect both from above and from below. That is, two points will be used for tapping into the system, and the remaining two are either silenced or closed with air vent valves. Of course, such models provide much more “space” for choosing the optimal method of connecting to the riser.

Any two of the four ends of the vertical collectors can be used for insertion into the system. The remaining two are muffled or closed with an air vent.

However, there are also models in which exclusively the lower ends of vertical collectors are used for insertion - this is provided for by the design, and it does not allow other options. But there are also good connection diagrams for such devices.

Let's look at the available schemes in order

Schemes for lateral or diagonal connection of a heated towel rail

To begin with, there are two simplest and, at the same time, attractive circuits with their versatility and exceptional performance. If you look closely, you can see many similarities with those simplest options that are used with U or M-shaped devices.

Scheme of a simple side connection - both pipes are connected to one vertical manifold.

This scheme works great with universal-type “ladder” models. The bypass is ordinary, that is, it does not require either a reduction in diameter or displacement. The operation of the heated towel rail is practically not affected by the speed of water flow in the riser, nor its pressure, nor direction. If necessary, the liner sections can be quite long - up to 4 ÷ 5 meters. True, some important and perhaps not immediately noticeable and understandable nuances must be observed.

- The top connection point to the riser must be higher than the top connection point on the heated towel rail. Similarly, from below - the lower point of insertion into the riser - below the connection of the lower line to the device. This is achieved by giving the supply pipes a slight slope - a 20, maximum 30 mm height difference per linear meter will be enough

The slope, however, becomes optional if the distance of the device from the riser does not exceed 2 meters, and if pipes with a DN of 1″ or more are used for the liner, then you can be content with a strictly horizontal laying.

- The eyeliner sections must be straight. No bends are allowed where air can accumulate. (By the way, there is traditionally always more dissolved and suspended air in hot water pipes than in cold ones!)

- The diameter of the liner (internal, of course, that is, DN or DN) is at least 20 mm (this is external 25 for polypropylene and standard ¾" for metal pipes). Taps or valves - also with a passage of at least 20 mm.

- Pipes in the supply section are usually thermally insulated. Usually they are hidden in cut-out grooves, so insulation will be necessary in any case - so as not to dissipate heat in the wall

As already mentioned, no displacement or narrowing of the bypass is required. Let's say even more than that - such an “improvement” deprives the circuit of its versatility, since when feeding from bottom to top, it is possible that the heated towel rail circuit will completely block, and it will become inoperable.

With a top feed, a system with a narrowed bypass will definitely work, but not without some “preferences” for the owner. That is, there is no sense in sight.

So to speak, “in development” of this scheme, a diagonal connection of a heated towel rail is sometimes used.

The diagonal connection of a heated towel rail is not much different from the simplest diagram. Unless it's a particularly necessary complication.

In principle, all the requirements listed above remain in force. But does such a connection provide any advantages?

Apparently, a stereotype is at work here by analogy with heating radiators. There, indeed, a diagonal connection gives some gain in heat transfer, a few percent. And on the scale of, say, a whole house, the effect is noticeable. Here, in the conditions of one small heat exchange device, it can be guaranteed that no one will feel much of a difference. That is, you don’t have to complicate the installation. Although the scheme itself is, of course, fully working and very effective. By the way, the direction of the diagonal also does not play any role - you can choose any one.

These were, so to speak, basic schemes, and now there are several variations.

For example, there are old tees in the riser, spaced further apart than the height of the heated towel rail, and you don’t want to redo them. Or, for other reasons, the insert into the riser should be significantly higher and lower than the location of the device, say, in order to mask horizontal sections. No problems - everything is solved simply:

An option with tie-in points into the riser that are more spaced apart in height.

The only difference is the presence of vertical sections from the connection points up and down to the horizontal liner. By the way, the length of these vertical sections is not limited by anything - at least within reason.

The other extreme is that the old supply pipes from the riser are located too close to one another, but you don’t want to redo them. So, you can apply this scheme:

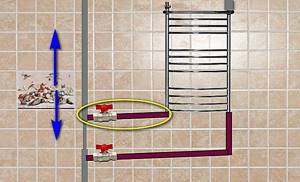

The lowest point of insertion while standing is still below the device. But with such a scheme, there is no way to do without installing an air vent.

The rule for placing the top insertion point above the device cannot be observed. And this creates a “hump” - a kind of step in which the air contained in the water can accumulate. And where, by the way, an air lock is guaranteed to form when the water supply in the riser is temporarily interrupted. This means that there is no escape from installing a device that allows this air to be vented. The installation location is shown with a yellow arrow.

In the simplest version, this is a Mayevsky valve, and air release will have to be done manually as necessary. A more modern option is an automatic air vent, which will independently release accumulated gases.

The Mayevsky tap is on the upper edge of the vertical manifold of the heated towel rail (in the picture on the left). An automatic valve that does not require constant user intervention will be much more convenient to use (right).

But what to do if there is still a narrowed or displaced bypass left from the old connection? Remake? Let's figure it out.

Even the simplest scheme has lost its universality: the direction of water movement is allowed only from top to bottom. The same fully applies to a circuit with a biased bypass.

Let's look at the simplest basic diagram, but with a bypass from a pipe, one step smaller than the diameter of the riser. (With a diagonal connection, nothing changes, so we won’t repeat it).

Practice shows that such a scheme will be guaranteed to work only when the water flows downwards. When directed upwards, there is a high probability that part of the upward flow will be redirected to the heated towel rail, where it will meet the flow going in the opposite direction - under the action of the heat pump, which was already mentioned above. That is, with a stream of cooled water flowing down under the influence of gravity. It turns out that two oppositely directed vectors meet. And there is a high probability that the heated towel rail circuit will simply shut down. The system turns out to be unstable, very much dependent on the temperature and pressure of the water in the riser. For example, when there is a large supply of hot water across floors, the circulation in the heated towel rail may stop completely or be barely noticeable. That is, the device will be either cold or barely warm.

In one word – “depending on your luck.”

In this case, the diagonal connection not only does not increase efficiency, but can, on the contrary, become an even greater brake on normal circulation.

Exactly the same picture will be with a biased bypass, so it makes no sense to present it separately. The only thing that can be said about this is that the offset bypass must be the same diameter as the riser. It happens that he is narrowed down, which is completely unacceptable.

So, the conclusion. If you “inherited” a riser with a narrowed or offset bypass, then you can leave it without alteration only when the flow direction is from top to bottom (as, by the way, according to all the rules it should be). If the direction is the opposite, or the owner has no information about this, it is better to switch to a universal scheme that is guaranteed not to fail.

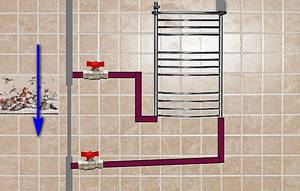

Bottom connection diagrams for heated towel rails

Many apartment owners like this kind of connection. Indeed, it is easier to hide it in scrubs or even under a decorative casing. Manufacturers, studying demand, offer many models designed specifically for this option.

It would seem - what secrets could there be? But no - with the bottom connection everything is even somewhat more complicated than with the side connection.

Let’s say right away that in terms of heat transfer efficiency, any bottom connection scheme is somewhat inferior to the universal “side” options. It may not be so noticeable at the everyday level, but still. The second general nuance is that any of the options with a bottom connection necessarily requires the installation of an air vent. There are no exceptions. Therefore, we will not repeat every time about the need for such a device.

So which schemes are acceptable?

A good universal bottom connection diagram

The simplest diagram is in the illustration. It is universal, that is, it will work in any direction of hot water flow. But if some conditions are met:

- It is advisable to place sections of the horizontal supply with a slight upward slope from the riser to the device, with a rise within 10÷20 mm per linear meter. This requirement does not apply to pipes with a diameter of 1 inch or more, and at a small distance, up to a meter, from the riser.

- In any case, the lower insert into the riser should be below the heated towel rail. For the top tie-in point, if a conventional direct bypass (riser section) is used, there is no hard and fast rule, although you should still strive to create a slight rise in the horizontal section.

- Supply pipes, which in such conditions are almost always walled up in walls, must be enclosed in thermal insulation.

This scheme is just a variation of the previous one. The only difference is that, for one reason or another, vertical sections are necessary before connecting the device. There are no additional requirements other than those previously listed. On the contrary, the guaranteed location of both tie-in points on the riser below the heated towel rail is the best option!

What to do if the riser has a narrowed or offset bypass, and a lower connection is required?

If you are lucky and the location of the bypass allows you to comply with the rule that the tie-in points into the riser are below the heated towel rail, then there is no need to worry. True, in this case it is strongly recommended not to skimp on the slope of the horizontal section of the liner. In this version, the circuit will fully retain its versatility and suitability for any direction of hot water flow.

Provided that the insertion points are located in this way and the slope of the horizontal supply is observed (the rise from the riser to the device), the circuit retains its versatility even with a narrowed or offset bypass.

But it also happens that the existing bypass is embedded high, and you don’t want to change its position. But this does not make it possible to comply with the recommendation regarding the position of the upper point of insertion into the riser - otherwise the heated towel rail will be lifted up to the ceiling. What should I do?

This scheme can come to the rescue, which, alas, is not without its drawbacks:

Not the best, but still, with reservations, a working diagram for the bottom connection of a heated towel rail.

What are the reservations?

— The permissible direction of water for guaranteed operation is exclusively from top to bottom. If the flow is directed upward, the heated towel rail circuit will most likely soon be blocked and circulation through it will stop.

— The top point of insertion into the riser definitely cannot be higher than the top edge of the heated towel rail.

If you cannot meet even one of these requirements, you will have to redo the riser, organize new tie-in points into it, and remove the old narrowed or displaced bypass. And apply a universal scheme acceptable to the case.

DHW. What it is?

DHW – hot water supply to meet the needs of the population, the temperature of the supplied medium reaches +75°C. This system is an important indicator of living standards. It is represented by a combination of several different elements:

- Water heater.

- Pump.

- Pipe

- Fittings.

The abbreviation in question is often used in regulatory documents. Different DHW systems are characterized by their own characteristics that must be taken into account.