Home / Boiler room /

I was bombarded with questions about the requirements for a boiler room in a private house, especially from architects and clients. A number of conditions must be met in order for you to receive gas without any problems. Nobody canceled the old norms, but the new ones began to contradict the old ones, and hence a lot of questions. In this article I will popularly answer these questions, and we will put an end to this muddy topic.

Colleagues, this article is for architects and clients, so I will roughly convert the thermal power (kW) into the area of the house (m2). This will make it clearer for more than half of the readers.

In the “More” tabs I will provide links to standards.

My name is Alexey Goltsov . I have been designing engineering systems for about 9 years.

Some people build a house without a design, rely on the experience of the builder, and then spend hundreds of thousands of rubles fixing the problems. My Customers value their time, they want to live in a house, and not deal with solving problems.

Design allows you to take into account all the nuances on paper, select the optimal equipment and accurately calculate materials. Buy everything you need at once, and not live on the construction market. But projects are also different.

Installation companies produce free designs. They design expensive technical solutions in order to later make money on the equipment.

The services of design companies are expensive. They work strictly according to standards, do not discuss anything with the Customer and do not know the nuances of installation. Therefore, the projects turn out to be correct, but not optimized.

In my work I represent the interests of the Customer. I discuss different system options, explaining the pros and cons. I select the systems that are optimal in price and efficiency. I save where I can save. After designing, I hand over the projects for installation, check the estimates so that you are not deceived, and provide designer supervision.

Standards for a boiler room in a private house

Where did the confusion come from?

A boiler room in a private house is not legally a “boiler room”. Legally, we are not designing a boiler room, but a “heat generator room”. And a boiler in a private house is not a boiler at all, but an “individual heat supply source”, because its power is less than 100 kW and even less than 360 kW, which is regulated by SP 89.

According to SP 89 clause 3.1 – A boiler room is always a building or a complex of buildings. According to SP 60.13330.2012 clause 6.6.2 - heat generators - automated boilers designed for individual heat supply to buildings up to 360 kW.

Therefore, SP 89 “Boiler installations,” which everyone considers to be the main document, in no way applies to boiler rooms in a private house. Its scope of application is in buildings from 3000 m2 (from 360 kW). Any reference to this standard is illegal.

Basic requirements for boiler houses in 2021:

SP 281.1325800.2016 – requirements for boiler rooms (section 5);

SP 41-104-2000 – an earlier version of SP 281 with more stringent requirements (section 4);

SP 31-106-2002 – requirements for the placement of boiler equipment (clause 6.2-6.3) and pumping groups (clause 4.4.8);

SP 7.13130.2013 – requirements for the chimney outlet on the roof (clause 5.10-5.24);

SP 402.1325800.2018 – requirements for the placement of gas equipment in the kitchen and boiler room;

SP 124.13330.2012 – requirements for the heating network if the boiler room is located in a separate building (for example, a bathhouse or garage).

Regulations

You should immediately decide on the regulatory framework. Until mid-2003, SNiP standards No. 2.04.08-87 were in force. On July 1, 2003, SNiP 42-01-2002 came into force. All requirements and standards for installing boiler rooms in a private home must be taken from this document.

It is advisable to know the standards, although the design of a boiler room in a private house should be drawn up by a specialized organization. This way you can decide on the possibility and impossibility of installing this or that heating equipment, as well as what work you have to do in order to adjust the existing or under construction premises to the standards. For every difficulty or controversial issue, it is worth going to the design department of the gas supply organization and talking with them. There are a lot of nuances associated with the features of each house, which can only be solved by being tied to the house plan or its design.

Rules for placing a boiler room in a house

The volume of the room should be more than 15 m3, but this is not enough.

When converting 15 m3 into area, it is only 5 m2, which is unacceptably small for placing equipment. Minimum required 8 m2 (24 m3).

The boiler room can be located in the basement, basement or on the first floor.

It is possible to place a furnace room on the 2nd floor only in theory. In practice, the solution is complex, because such a boiler room must be located entirely above a technical room, for example above a garage. But the nail in the lid of this wonderful idea comes from the point below.

It is prohibited to place near bedrooms.

You can take a risk and place the boiler room across the wall from the bedroom, but this is prohibited by regulations.

The escape route from the boiler room to the street should be no more than 12 m.

The escape route may be through a staircase or corridor.

The height of the room is at least 2.2 m.

In this case, the height from the top of the equipment to the ceiling must be at least 1 meter.

A window and a door are required.

More details in the section “ Window in the boiler room.” Size and location "

Ventilation is required.

More details below in the section “ What should be the ventilation in the boiler room .”

Requirements for placing a boiler room in a house

Norms and optimal values of coolant temperature

Communications and alarm 17. Heating and ventilation 18. Water supply and sewerage 19. Additional requirements for construction in special natural conditions 20.

List of professions of boiler house workers by category of work and composition of special household premises and devices Appendix B (recommended). Devices for draining water and removing air Appendix D (mandatory).

Safety factor when choosing smoke exhausters and blower fans Appendix E (recommended).

Requirements for a boiler room attached to a house

In addition to the points above, boiler rooms attached to the house should not be located on the side of the main facade. The distance between the window in the boiler room and the nearest window in the house should be more than 12 meters. See picture below:

Rules for the location of a boiler room in a private house

The distance from the furnace floor to the window of the upper floor of the house should be more than 9 meters. Therefore, most often there cannot be windows above the attached boiler room on the facade of the main house, which means there cannot be living quarters.

The boiler room should not be attached to the house from the main facade.

SP 281.1325800.2016 clause 5.14.

The size of a gas boiler room in a private house

I recommend taking the minimum size of a gas boiler room as 8 m2. The standard value of 5 m2 (or 15 m3) is not enough to accommodate equipment.

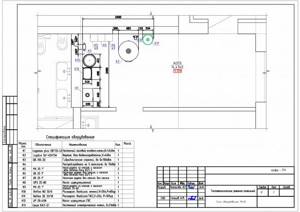

Location of equipment in the boiler room of a private house

If you place all the equipment on one wall, you will need 3.2 m in length and 1.7 m in width only for the equipment without taking into account the opening of doors and windows. It is often difficult to provide a length of 3.2 m, so we move some of the equipment to another wall of the room. In this case, the equipment placement area will be 2.5x2.5 meters.

Layout of boiler room equipment for 2 walls

The furnace room in a private house is often used as a laundry room. A washing machine and dryer are installed in it. In this case, the boiler is void of warranty, because According to the boiler passport, chemicals cannot be placed in the boiler room. But at the same time, I advise you not to pay attention to this. Warranty boiler maintenance is more expensive than replacing parts at your own expense.

Examples of gas boiler house projects

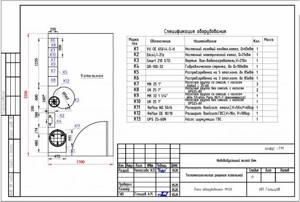

Viessmann project for a house 420m2

Project for a house 350m2

Project for home and spa 1200m2

If you need preliminary arrangement of equipment in the boiler room to coordinate the architecture or a full-fledged project, call me at 8-963-729-71-20.

Placing the boiler in the kitchen, pantry or hallway

If the area of the house is less than 350 m2 , you may not equip a boiler room at all. You can place a boiler with a capacity of up to 50 kW (up to 350 m2) in the kitchen or kitchen-dining room. Gas services will approve such a decision without question if the volume of the kitchen is more than 21 m3 (or 7 m2), and the kitchen-dining room is more than 36 m3 (12 m2). The kitchen also needs a window and a natural exhaust duct to the roof.

According to SP 402.1325800.2018 clause 5.1; 5.5; 5.13.

I will emphasize that placing a boiler in the kitchen is a standard solution for private homes in Europe, but in Russia, due to ignorance of the laws, people try to “play it safe,” although gas workers are more likely to find errors in the boiler room than in a small nook of the kitchen. In this case, we will place the wall-mounted boiler in the kitchen cabinet.

The main equipment - boiler, pumps, mixing groups, distribution manifold and expansion tanks can be installed in the space under the stairs or in a cabinet measuring 1.0 x 1.5 m. There are no strict requirements for this equipment, except for ease of maintenance and repair.

The chimney from the boiler will go to the facade without rising to the roof or through the shaft to the roof.

Each boiler room has its own correct solution, so I recommend sending me your layout and consultation. You can also install the boiler in the pantry or in the hallway if there is no bedroom above the floor.

It is prohibited to install the boiler in bathrooms and bathrooms!

What can be placed in the furnace room

Before arranging a boiler room, you need to draw up a list of equipment that you plan to install in a country cottage. First of all, this includes units that ensure the operation of the heating system, cold and hot water supply (CW, DHW), and various electrical installations. Here is a complete list:

- heat sources – boilers using different types of fuel, internal units of a geothermal heat pump;

- units for preparing hot water - electric or indirect heating boiler, geyser, instantaneous water heater;

- buffer capacity of the required volume;

- hydraulic separator (hydraulic arrow) with manifold;

- comb with mixing unit for water heated floors;

- cold water treatment and water treatment equipment - filters, hydraulic accumulator, pump, automation (pressure switch);

- piping elements - pipes, circulation pumps, expansion tanks, shut-off and control valves;

- house electrical panel.

Note. The storage water heater does not have to be placed in the furnace room. An electric boiler can be placed in the bathroom, a gas water heater in the kitchen. But if the dimensions of the boiler room allow, it is better to assemble all the devices in one technical room.

The electrical panel can also be installed inside the heat generator room, on a separate wall. In the remaining free space, you can place bulky household appliances, for example, a washing machine, a freezer.

From the given list we select the necessary equipment, guided by the project or the current heating and water supply scheme. We draw the layout of the room to scale and move on to design - the placement of all water and heat supply units. But first you have to study...

Size of pellet boiler room in the house

A common situation: there is no gas, but gas services feed you breakfast. Considering that out of 12-15 projects per year, approximately 5 of them are pellet ones, the problem with gas remains relevant.

Pellets are 0.8x3 cm blocks of compressed sawdust from coniferous and deciduous trees.

Pellet boiler room - bunker and boiler

A pellet boiler room usually consists of 2 rooms: a bunker and a boiler room.

If there is no gas, a pellet boiler room is the most adequate option, but you can’t do without a full-fledged room for equipment. The main difference between pellets and ordinary firewood: pellets can be fed into the boiler automatically from a large box - a hopper. This is very convenient because... allows you to heat the house in your absence.

Pellets are poured into the bunker from the back of a Kamaz truck or in large big bags. The edges of the bunker are beveled and filling it to the top is problematic, so the volume of the bunker is 2 times less than the volume of the room itself where it is located.

We choose the size of the pellet hopper based on how long the pellets will last in the coldest winter. The standard bin size for unloading 1 vehicle is 6 m3.

Such a bunker will be enough to heat a house of 400 m2 (50 kW) for 6 months. The size of the room for the bunker is 4.5x6 m, height 2.5 m).

Separate rooms for bunker and boiler room

The standard size of a bunker for a home is 200-300 m2 - 1 m3 is enough for an average of 1 month. The size of the space for such a bunker is 2x2 m. The required size of the furnace room excluding the bunker is 2.5x3 m.

I am often asked:

Is it possible to place the bunker in the same room as the boiler?

Legally it is impossible. A bunker with a volume of more than 0.8 m3 must be located in a separate room. For personal safety, I would recommend placing a bunker with a volume of more than 1 m3 in a separate room. A bunker of 1 m3 or less next to the boiler.

According to SP 41-104-2000 clause 7.6.

Is it possible to first install a pellet boiler and then replace it with a gas one? What will change?

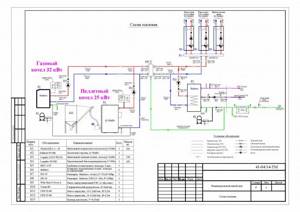

Can. There are 2 options here.

Option 1. In the pellet boiler room project, we can provide bends for connecting a gas boiler. When gas is supplied, you can install a gas boiler, connect it to the circuit and use the pellet boiler only as a backup.

The thermal diagram for the first option looks like this:

Thermal diagram of the boiler room, taking into account the connection of a gas boiler

Option 2. Buy a pellet boiler with the ability to replace the burner. In this case, you will not have to buy a full-fledged gas boiler, but will only be able to replace the burner. But in practice, the volume of the firebox in pellet and gas boilers is significantly different, so a gas burner with a pellet boiler does not work efficiently. You lose 10-20% efficiency.

Examples of pellet boiler house projects

House project 310 m2 and bathhouse 80 m2

House project 90 m2

House project 230 m2

Window in the boiler room. Size and specifications

Any boiler room must have a window. And not a simple window, but an easily removable window (LSK), made in accordance with GOST R 56288-2014 . The location of the window is unimportant. It can be on the wall, on the ceiling or in a pit if the furnace is in the basement.

Its main purpose is to protect the house from a blast wave. So that in the event of an explosion it is the window that blows out, and not the supporting structures of the building. At the same time, many people forget that the size of the window directly depends not only on the area of the room, but also on the glass material.

The calculations do not take into account the total area of the window (m2), but rather the area of the glass minus the frame.

Glass area in a boiler room up to 9 m2: at least 0.8 m2 (window 1500x600 is suitable).

Glass area in the boiler room is more than 9 m2 : 0.03 m3 per 1 m3 of room volume.

For example, for a boiler room 4x3x3 (LxWxH, m), i.e. with an area of 12 m2 and a volume of 36 m3, the glass area should be 36 * 0.03 = 1.08 m2. But it’s easier not to count on a calculator, but to use my table:

Boiler room window size

| Boiler room area, m2 | Window area m2 / example DxH, mm |

| to 10 | not less than 0.9 m2 / 1500x600 |

| 12 | 1.2 m2 / 1500x900 |

| 14 | 1.35 m2 / 1200x1200 |

| 16 | 1.6 m2 / 1500x1200 |

*The table shows the final window size taking into account the frame.

There was a lot of controversy about the characteristics of such a window.

If it is difficult to find LSK glass in accordance with GOST on sale, you can use a regular single-chamber double-glazed window with a glass thickness of no more than 4 mm2. In this case, the glass area for a room up to 10 m2 must be at least 1 m2 (window size 1500x900). For a room larger than 10 m2 - according to the table.

The window can be made of aluminum or PVC glass package, single, two- or three-chamber according to SP 402 clause 5.10.

Reinforced windows, triplex, polycarbonate are not suitable for a boiler room!

Coolant temperature depending on outside temperature

At the supply it is from 95 to 105 °C, and at the return - 70 °C. Optimal values in an individual heating system H2_2 Autonomous heating helps to avoid many problems that arise with a centralized network, and the optimal temperature of the coolant can be adjusted according to the season. In the case of individual heating, the concept of standards includes the heat transfer of a heating device per unit area of the room where this device is located.

The thermal regime in this situation is ensured by the design features of the heating devices. It is important to ensure that the coolant in the network does not cool below 70 °C.

Door requirements. Size and location

The door can open onto a corridor or staircase. In this case, the path from the boiler room door to the exit from the house should be no more than 12 m, as in the figures below:

Requirements for the boiler room door

Any door from the boiler room should open outward, and the width of the door should be 20 cm larger than the dimensions of the boiler or boiler. The size of the door is regulated only by the ease of servicing the equipment. Gas services pay the least attention to door size. Its material is much more important.

SP 31-106-2002 clause 6.3.8

The door must be fireproof type 3 with EI15. Simply put, a high-quality steel door with a non-flammable basalt fiber filling. Such a door costs about 15 thousand rubles. For example, T3-20 .

You can make the boiler room a passage room between the room and the veranda, but it is worth remembering that all doors must open outward and must be fireproof.

The door threshold should be at a height of 10 cm from the floor level. Those. When entering the boiler room, you must step over the threshold. This is necessary in case of an accident or water spill.

At the same time, a sewer drain must be installed in any boiler room for emergency water collection. The ladder does not have to be cast iron, you can use simple PVC. The water temperature in the boiler circuit rarely exceeds 55-65°C, so in the event of an accident, nothing will happen to the ladder.

SP 41-104-2000 clause 4.8 – About the evacuation route 12 meters; SP 281.1325800.2016 clause 5.29 – About the size of the door in the boiler room. SP 281.1325800.2016 item

Table with temperature graph

The operating mode of boilers depends on the environmental weather.

If we take various objects, for example, a factory building, a multi-storey building and a private house, they will all have an individual thermal diagram.

In the table we show the temperature diagram of the dependence of residential buildings on outside air:

| Outdoor temperature | Temperature of network water in the supply pipeline | Return water temperature |

| +10 | 70 | 55 |

| +9 | 70 | 54 |

| +8 | 70 | 53 |

| +7 | 70 | 52 |

| +6 | 70 | 51 |

| +5 | 70 | 50 |

| +4 | 70 | 49 |

| +3 | 70 | 48 |

| +2 | 70 | 47 |

| +1 | 70 | 46 |

| 0 | 70 | 45 |

| -1 | 72 | 46 |

| -2 | 74 | 47 |

| -3 | 76 | 48 |

| -4 | 79 | 49 |

| -5 | 81 | 50 |

| -6 | 84 | 51 |

| -7 | 86 | 52 |

| -8 | 89 | 53 |

| -9 | 91 | 54 |

| -10 | 93 | 55 |

| -11 | 96 | 56 |

| -12 | 98 | 57 |

| -13 | 100 | 58 |

| -14 | 103 | 59 |

| -15 | 105 | 60 |

| -16 | 107 | 61 |

| -17 | 110 | 62 |

| -18 | 112 | 63 |

| -19 | 114 | 64 |

| -20 | 116 | 65 |

| -21 | 119 | 66 |

| -22 | 121 | 66 |

| -23 | 123 | 67 |

| -24 | 126 | 68 |

| -25 | 128 | 69 |

| -26 | 130 | 70 |

There are certain standards that must be observed in the creation of projects for heating networks and the transportation of hot water to the consumer, where the supply of water steam must be carried out at 400°C, at a pressure of 6.3 Bar. It is recommended that the heat supply from the source be released to the consumer with values of 90/70 °C or 115/70 °C.

Regulatory requirements must be met in compliance with the approved documentation with mandatory approval from the Ministry of Construction of the country.

Link to download the chart

After installing the heating system, it is necessary to adjust the temperature regime. This procedure must be carried out in accordance with existing standards.

Wall requirements

The walls in the boiler room must be load-bearing or self-supporting and made of non-combustible materials.

In this case, walls made of sandwich panels or a wooden frame will not be suitable, both in terms of fire standards and the strength of the material. The wall must be type 2 fireproof, i.e. withstand fire and not collapse for 45 minutes.

Most often, walls are laid out of 120 mm brick, foam concrete or 200 mm aerated concrete blocks. These materials can withstand fire not for 45, but for 120 and 180 minutes.

A boiler of up to 200 liters, expansion tanks and almost always pump groups, a distribution comb and a hydraulic arrow are often hung on such a wall.

Is it possible to install a boiler room in a basement or basement?

Yes, you can, according to SP 31-106-2002 clause 6.3.2.

You can install a natural gas boiler room in the basement or basement only in a private house or townhouse. In apartment buildings, it is prohibited to introduce gas into basements and ground floors. You must also take into account that the path from the entrance to the boiler room to the exit from the house is less than 12 meters.

No one will allow you to lay a transit gas pipeline along the ground floor. The gas supply must be directly into the boiler room, so to optimize costs, I recommend locating the boiler room closer to the gas connection point on the site.

In basements and plinths it is prohibited to equip a furnace burning diesel fuel, diesel fuel or any other liquid fuel with a vapor flash point below 45 °C.

SP 402.1325800.2018 – clause 6.5, SP 41-104-2000 clause 3.5.

What kind of ventilation should be in the boiler room?

Ventilation is one of the main points that gas workers always look at to give you permission to use gas. The maximum number of disputes was about ventilation in the boiler room.

In addition to the chimney, any boiler room must have an exhaust shaft on the roof and an inlet in the door or wall.

I emphasize that the exhaust duct should go to the roof, and not just a hole to the street. What is needed is an exhaust duct to the roof. You can place it next to the chimney. It is prohibited to install fans on it. The exhaust duct should operate on natural draft. I will discuss the size of the channel and supply grille below.

Adjustment

Automatic control is provided by the heating regulator.

It includes the following parts:

- Computing and matching panel.

- Actuating device on the water supply section.

- An actuator that performs the function of mixing liquid from the returned liquid (return).

- Boost pump and sensor on the water supply line.

- Three sensors (on the return line, on the street, inside the building). There may be several of them in the room.

The regulator closes the liquid supply, thereby increasing the value between return and supply to the value specified by the sensors.

To increase the flow, there is a boost pump and a corresponding command from the regulator. The incoming flow is controlled by a "cold bypass". That is, the temperature decreases. Some of the liquid that has circulated along the circuit is sent to the supply.

Sensors collect information and transmit it to control units, resulting in a redistribution of flows that provide a rigid temperature scheme for the heating system.

Sometimes, a computing device is used that combines hot water and heating regulators.

The hot water regulator has a simpler control scheme. The hot water sensor regulates the flow of water with a stable value of 50°C.

Advantages of the regulator:

- The temperature scheme is strictly maintained.

- Elimination of overheating of the liquid.

- and energy efficiency

- The consumer, regardless of the distance, receives heat equally.

Requirements for boiler houses using solid and liquid fuels

The requirements for such premises are not very different from the requirements for gas boiler rooms.

The main differences are as follows:

1) Equip a separate door to the street. If in rooms with gas boilers a door to the street is not necessary, then in the case of solid fuel boilers a separate exit to the street is required. It doesn’t matter whether your boiler room is in the basement or on the 1st floor, there must be a separate exit.

2) Protect surfaces from overheating In solid fuel boilers, it is quite difficult to limit the temperature of the coolant, so the temperature of surfaces and pipes at some points can reach 120 ° C. Such overheated areas must be protected from contact with walls made of flammable materials.

For this, roofing steel sheets with a thickness of at least 3 mm are most often used. Such sheets cover the potential overheating zone 10 cm on each side and 50 cm above it.

3) Position the boiler correctly The boiler must be installed at a distance of at least 10 cm from the walls. It is necessary to leave 70 cm on each side of the boiler for ease of maintenance and repair.

4) Window size of at least 0.8 m2 If the area of the room with the boiler is more than 10 m2, the required window area is taken to be 0.085 m2 of window per 1 meter of area. So for a room of 12 m2, the window area will be: 12 × 0.085 = 1.02 m2.

5) The width of the doorway is at least 80 cm. The size of the landing The size of the doorway must be at least 80 cm, but be sufficient to replace equipment in the event of a breakdown. If the equipment is located in the basement, you need to remember not only the size of the door, but also the turning radius on the stairs that lead to the boiler room.

For example, the size of a doorway for a house of 350 m2 is better to be made at least 100 cm, because solid fuel boiler solid fuel boiler for a house of 350 m2 occupies 70 cm.

It is better to make the depth of the landing in front of the door at least 2.0 m, because solid fuel boiler length 1.5 m.

6) Equip a fuel warehouse I wrote about the requirements for fuel storage here. The fuel warehouse must be unheated, but covered. In the room with the boiler, you can only place a small loading tank with a volume of no more than 0.8 m3. The main supply of fuel must be stored in a separate room. For a pellet boiler room, it is better to add a window to such a warehouse for loading pellets from the street.

7) Ensure the height of the chimney The size of the chimney must be selected by the designer, but the height of the chimney must ensure that smoke is not blown in and dissipates.

The chimney is always installed above the roof of the highest part of the building. If the chimney passes closer than 1.5 meters from the ridge of the building, it is raised 500 mm above the ridge. If the chimney passes closer than 3 meters from the ridge, it is brought to the same level as the ridge of the building.

Operation and Safety

Since the system operating with gas is not safe, in case of any deviations from the norm, you must turn off the equipment and contact the company involved in its repair and maintenance. The fuel supply must be stopped immediately in several cases. These include:

- the appearance of a gas smell;

- coolant overheating;

- power outage;

- alarm activation;

- violation of the integrity of the pipeline section;

- a flame that goes out without shutdown or any other reason;

- poor quality ventilation, insufficient draft in the chimney;

- changes in sensor readings, which clearly indicate problems in the system;

- detection of incorrect operation of the system or control devices, one or more.

To prevent emergency situations, it is recommended to check the electrical cable and its insulation daily. Any defect requires its prompt replacement. The presence of a water supply or water containers in a gas boiler room is a prerequisite. Additional precautions include:

- purchase of fire extinguishers;

- fire alarm installation;

- supply of sand and other safe bulk material.

For large boiler houses it is necessary to prepare evacuation plans, however, this requirement, as a rule, does not apply to “gas rooms” serving private houses.

The room for this type of heating equipment is, first of all, designed to ensure the safety of people, so it is not entirely correct to talk about the operating principle of a gas boiler room. It is the equipment that operates in it, and the room only creates optimal conditions for the devices. And for a person protected by its walls from a far from safe type of fuel.

To conclude the topic, there is a popular video, short, succinct and, judging by the reviews, honest:

Boiler room design and calculation

Dear Customers! The boiler room is a key element of the heating system. Without exaggeration, it is the heart of your home. That's why,

We design boiler rooms only in conjunction with a heating and underfloor heating project . Placing the design of a boiler room in one hand, and heating and underfloor heating in others, means risking the quality of the system. Don't make this mistake. Projects must be carried out by one company. If your specialist does not know how to design boiler rooms, you can contact me for a comprehensive project.

1) Answers to questions First, we ask you to fill out Questionnaires. This will help you collect initial data, take into account your wishes and not forget anything. Based on your answers, We will draw up a Technical Specification and attach it to the Agreement.

2) Advance payment of 50% for the development of a preliminary design. Based on your responses, we approve the volume and cost of design work. We receive from you an advance of 50% for the development of preliminary designs.

3) Draft design We do not release a finished project without agreeing with the customer on the main solutions. Therefore, we first develop preliminary designs “in one line” in order to discuss and approve with you the placement of key equipment. We adjust the draft design as many times as necessary and incorporate your wishes until complete approval. We attach the agreed upon sketches to the Contract as a graphic part of the design assignment.

4) Advance of 50% for the development of the Working Design This payment confirms that you are satisfied with the key decisions and the Sketches have been agreed upon. Previously, we worked on postpaid basis. In this case, the customers were negligent in their preliminary designs and introduced wishes into the finished project, which greatly complicated the work.

5) Working draft Design companies do not develop sketches. They immediately complete a working draft, and then correct it 150 times. This always leads to mistakes, delayed deadlines and customer dissatisfaction. We do not adjust the working draft. We take into account all corrections and wishes at the sketch stage. Strictly according to the preliminary design, we develop a working design once and hand it over to you. Correction of the finished project is permissible, but in an amount not exceeding 15%.

Composition of the heating and boiler room project

| HEATING: (According to GOST 21.602-2016) | BOILER ROOM: (According to GOST 21.606-1995) |

| • General data on the drawings • Plans of the heating system • Plan of the heated floor system • Axonometric diagrams of the heating system • Axonometric diagrams of the heated floor system • Diagrams of serial equipment connection units and pipe fastenings • Specification of equipment and materials. | • General data on the drawings • Thermal diagram of the boiler room • Layout plan for the boiler room equipment. • Foundation plan (for floor-standing boilers) • Chimney laying plan • Axonometric diagram of chimneys • Layout diagrams of the main boiler equipment. • Specification of equipment and materials. |

Thanks for reading the article! If you have any questions, write in the comments or on WhatsApp. I will help and advise. To order a heating project from me, please contact me by phone.

Preliminary project cost calculator

You might be interested in:

How to choose a design company? Guide for the Customer What is included in the design cost? 10 reasons to work with us

Comments

- Eugene:

01/12/2021 at 19:29Good evening! We often do ventilation for private owners, a question that has set the teeth on edge is whether it is possible to hang ventilation equipment (supplies or exhaust) in a boiler room or lay transit air ducts for other rooms (swimming pool, bathrooms, technical rooms)? Firefighters sometimes prohibit it through their fingers! Thank you!

Answer

- Goltsov Alexey:

01/13/2021 at 16:32

Evgeniy, good afternoon. Explosive mixtures of gases can form in a gas boiler room, so air recirculation in such rooms is unacceptable. If recirculation in the boiler room is unacceptable (i.e., the movement of air from the boiler room to an adjacent room), the installation of any air handling unit, regardless of its composition, is also unacceptable. I wrote the rules below. You have the right to route air ducts through the boiler room in transit. When crossing walls, install the OZK valve for 90 minutes. Requirements for transit air ducts are in SP 7.13130.2013 p6.10

If we install air supply and gas equipment in the same room, the fire hazard category becomes “G” (SNiP 41-01-2003 clause 7.10.3 subparagraph E) it is also in SP 7.13130.2013 (clause 6.7) SNiP 2.04.05-91 4.83. Equipment for supply ventilation and air conditioning systems should not be placed in rooms where air recirculation is not allowed. 4.47*. Air recirculation is not allowed: e) from 5-meter zones around equipment located in rooms of categories B, D and D, if explosive mixtures of flammable gases, vapors and aerosols with air can form in these zones;

Answer

- Eugene:

01/14/2021 at 17:38

Understood thanks!

Answer

- Natalia:

02/23/2021 at 19:53

The supply unit does not recirculate air, but drives it from the street and back. Why can't it be installed in the boiler room?

Answer

- Goltsov Alexey:

03/05/2021 at 22:02

Natalya, good afternoon. You're right. In the classical sense, air recirculation is different. But the presence of air requirements in the boiler room is an additional opportunity for the gas service to interpret these standards in approximately the same way as I did) You risk that your boiler room with ventilation will not be accepted for operation and the gas will not be turned on. To take risks or not is your choice.

Answer

- Igor:

02/26/2021 at 16:14

Greetings, but I don’t understand about smoke removal for the TTK. height of the pipe and location above the house? - boiler in the basement. Thank you

Answer

- Goltsov Alexey:

04/11/2021 at 21:03

Thank you Igor. I will supplement the article with an answer to your question.

Answer

- Chris:

03/05/2021 at 21:30

What can you, as a specialist, say about such a boiler room assembly?

Answer

- Goltsov Alexey:

03/05/2021 at 23:55

Good afternoon, Chris. I can technically study their solutions if you send me their designs. It is difficult to judge the performance of the system from 2 photographs. It struck me that the step of laying the heated floor changes periodically.

Answer

- Dmitriy:

04/05/2021 at 08:01

Alexey, good afternoon! Thanks for the detailed analysis of the options. Periodically, a boiler room is built in the garage building and a heating main goes to the house. Could you tell us in detail about the requirements for this option?

Answer

- Goltsov Alexey:

04/11/2021 at 21:00

Good afternoon, Dmitry. What exactly are the requirements? You bury the heating main in the ground along with the signal cables of the pumping groups. The heating main goes into the boiler room of the house. The boiler and pumping groups are located there. What exactly is the question?

Answer

- Alexei:

04/06/2021 at 09:05

Is it possible to enter the boiler room through another room, in particular through the bathroom?

Answer

- Goltsov Alexey:

04/11/2021 at 20:57

Good afternoon, Alexey. There are no prohibitions in this regard in the regulations. So it's possible.

Answer

- Ilgiz:

04/19/2021 at 09:36

The most normal article on a boiler room in a private house. Simple, clear and intelligible. With all the nuances that you encounter in the course of organizing the boiler room itself. Thank you very much for your work.

Answer

- Goltsov Alexey:

04/21/2021 at 15:35

Ilgiz, thank you for your feedback. I'm glad that the information was useful to you.

Answer

- Vladimir:

04/25/2021 at 09:04

Good afternoon Is it possible to install a washing machine, toilet and sink in the furnace room? Or some things are possible and some things are not?

Answer

- Goltsov Alexey:

04/26/2021 at 13:19

Vladimir, hello! It is prohibited to install toilets in a gas boiler room; you can install a sink. When installing a washing machine, your gas boiler will be void of the manufacturer's warranty. But there is no need to worry about this, since the warranty conditions for servicing boilers are always not in favor of the buyer.

Answer

- Paul:

04/26/2021 at 14:37

Alexey, good afternoon! “It is possible to place a boiler room on the 2nd floor only in theory. In practice, the solution is complex, because such a boiler room must be located entirely above a technical room, for example above a garage.” We have: Two kitchens located above each other on the 1st and 2nd floor. The wall of each kitchen borders the bedroom. Is it possible to place 1 boiler with a capacity of 29 kW in each kitchen?

Answer

- Goltsov Alexey:

05/20/2021 at 15:46

Pavel, good afternoon. Yes, you have the right to place boilers in kitchens. My text, which you quoted, refers to the boiler room.

Answer

- Natalia:

05/23/2021 at 14:58

Please tell me, we want to put a boiler in the summer kitchen, and the height of the kitchen is 2m, is it possible to put a boiler there?

Answer

- Goltsov Alexey:

06/05/2021 at 20:11

Good afternoon. No you can not. According to fire regulations, the height of the room must be at least 2.5 meters.

Answer

- Sergey:

05.25.2021 at 16:40

Alexey, good afternoon. Due to a mistake by the builders, a 110-diameter ventilation pipe was installed in the wall. Now we need to do another one. As far as I understand, there are two options - the first is stainless steel on the facade of the house (extremely undesirable for various reasons). The second, but this is our idea, is through the ceilings inside the house. However, it turns out that it will take place in living rooms (important - we are not talking about a chimney, but an air duct). The question is: is it possible to do this? It is planned to cover it with 10cm thick gas blocks, thus forming a shaft containing a 160 galvanized pipe. Exit through the roof.

Answer

- Goltsov Alexey:

06/05/2021 at 20:10

Good day, Sergey. Yes, option 2 is quite working in such a situation.

Answer

Determining the optimal location for the boiler room

Let's say you started a large-scale renovation of an old private house. It must definitely have a boiler room, but the outdated layout limits the possibility of placing it in the house. You cannot squeeze boiler equipment into a tiny room without ventilation, you cannot stretch a chimney from bottom to top through the bedroom or living room.

You can, of course, build an extension to a country house for the boiler room, but it is unlikely that this architectural excess will fit well into the overall look. What remains is the construction of a separate boiler house - a good, but expensive idea.

A separate boiler room should not be located too close to the house. But if you place it far away, there will be heat loss due to an unreasonably long heating main

And during new construction, the procedure for designing a boiler room inside a house does not cause any problems if you study the requirements for installing boiler equipment in advance:

- the volume of the room for heating boilers with a power of up to 30 kW must be at least 7.5 m3, from 30 to 60 kW - 13.5 m3, over 60 kW - 15 m3;

- ceiling height – at least 2.2-2.5 m, entrance door width – 80 cm;

- the norm of natural light is 300 sq. cm of glazing per 1 m3 of room, the window must have a transom for ventilation;

- Use only metal pipes for supplying gas to gas boilers; flexible hoses are prohibited;

- in the boiler power supply circuit, it is necessary to provide a thermal protection relay, and in rooms with a gas-fired boiler, it is necessary to install a gas analyzer - a device that detects gas leaks and sends a signal for emergency shutdown of the gas pipe;

- The boiler room should be separated from neighboring rooms by walls made of material with a zero flame propagation index - concrete, brick, wood with fire retardant impregnation;

- on issues of explosion and fire safety, the project is coordinated with the fire inspectorate.

All the rules and regulations are written in detail in SNiP for boiler installations with code II -35-76 , Code of Rules SP-41-104-2000 for the design of autonomous heat supply systems, document MDS 41-2.2000 , which sets out the requirements for the placement of heating units and water heating in low-rise residential buildings.

The location for the boiler room is selected individually in each case, taking into account the technical features and financial capabilities of the owner - the first floor of the house, basement, basement, extension, attic or separate building

Compliance with numerous requirements is dictated not by bureaucracy, but by safety precautions. A free-standing boiler room involves the hassle of constructing a foundation, main walls, laying pipes and their thermal insulation.

But in the house you get 100% absence of harmful chemical impurities that inevitably accompany any combustion process, and complete confidence not to suffer during an accident, the probability of which is negligible, but theoretically not excluded.

Basic requirements for a boiler room

The principle of operation of a gas boiler room is not the most important thing that those owners who plan to start supplying gas and arranging an installation that operates on it have to learn. As a rule, they have to face various obstacles that are “fixed” by representatives of gas services. The biggest drawback is that there is no specific document that would contain all the rules and requirements for equipment installed in boiler rooms of private houses.

For this reason, gas workers in different regions interpret the rules slightly differently, but one thing remains unchanged. This is increased attention to compliance with safety precautions when working with gas appliances. Following them will minimize losses in the event of a gas leak or explosion. Basic requirements differ depending on the location of the gas boiler room. Therefore, each option must be considered separately.

Boiler room located in the house

A boiler room can be considered any place where a boiler is located. This unit can be installed in the kitchen, as well as in other rooms: in basements, on ground floors. The height of the room where any gas equipment (stove, boiler) will operate must be at least 2.5 meters.

The room volume standards for a gas boiler depend on the power of the unit.

- For devices generating up to 30 kW of heat, a small room volume of 7.6 m3 is sufficient.

- Power in the range of 30-60 kW will require a larger room: its minimum volume must be 13.5 m3.

- For each kilowatt of power of a more productive device (> 60 kW), the volume is calculated separately. Its indicators are within 15 m3 (plus 0.2 m3). This volume allows you to install boilers of any power, but, naturally, there must be frames. They are required by fire safety equipment.

The room must have high-quality ventilation; a combination of natural and forced varieties is optimal. The kitchen should have a fairly large window, as well as a window that opens outward. An alternative is double-glazed windows with sliding or rotating elements. There is a separate requirement for the glazing area. The norm is 0.03 m2 per 1 cubic meter of volume. For example, for a room with a volume of 16 m3, the required window area is 0.48 m2. The dimensions of the window in this case will be as follows: width - 0.5 m, height - meter. The area of all frames in this case is not taken into account.

Installing a mechanized hood, a device above a gas stove, and providing additional ventilation to the room (a gap under the door or holes in the bottom of the door) is highly recommended. The same requirements (with the exception of the stove hood) apply to other rooms in the house where they plan to organize a separate boiler room.

Requirements for free-standing combustion chambers

Such boiler houses are made with high boiler power - above 200 kW. In addition to those already stated earlier, there are several specific requirements. Here they are all:

- The material of walls, finishing and roofing must be fireproof.

- The volume of a separate boiler room is at least 15 cubic meters, plus 0.2 square meters for each kW of power used for heating.

- Ceiling height is at least 2.5 m.

- The glazing area is calculated based on 0.03 sq.m for each cubic volume.

- The window must have a window or transom.

- A separate foundation is required for the boiler; its height should not be higher than 15 cm above the floor level.

- With a relatively small weight (up to 200 kg), installation on a concrete floor is allowed.

- There must be an emergency gas shut-off system (mounted on the pipe).

- The doors are not reinforced, weakly secured.

- Ventilation in the room should provide three air changes in 1 hour.

When accepting and installing gas equipment in a separate boiler room, acceptance will be strict: all standards must be observed. Only in this case will you be given permission.

A separate boiler room can be like this

Gas boiler room in the utility room

As a rule, a separate room for a boiler room becomes an unaffordable luxury for most families, so this office space is often combined with other “special purpose” rooms: for example, gas equipment is installed in the bathroom, a storage room is converted for this purpose, etc. However, in any case it is necessary ensure that all conditions are met, otherwise it will not be possible to get the go-ahead from gas services.

Rules for a separate room in a private house

The very principle of operation of a gas boiler room places increased demands on the room and the equipment located in it. The main task of this room is to ensure the safety of residents. To guarantee this condition, it is advised to adhere to several rules.

- A private home is unlikely to require more than two heating devices, but this is the maximum number allowed for owners to install.

- Non-combustible materials for boiler room walls and doors - asbestos or steel sheets, plaster followed by painting or whitewashing.

- It is recommended to make a concrete screed for the floor. Non-slip tiles and porcelain tiles are considered the best finishing coating.

- Heating equipment should not be mounted directly against the wall of the room: it must be freely accessible.

A gas boiler room is the “place of residence” of potentially dangerous equipment, therefore storing any flammable materials in this room is strictly prohibited.

Construction of modular boiler houses

But what if there is no space for installing boiler equipment in the house, it is also not possible to build a separate building, but a boiler room for a country house is very necessary? In this case, a modular boiler room will help out. It is factory equipped and can be installed quickly.

The maximum volume of premises for heating in this way is 1300 m3. The module itself is a small mobile house (container), the length of which does not exceed 2.5 m. It is made of a double durable metal frame with insulation made of special fiber.

The modular boiler room is supplied with a 3-layer pipe with thermal insulation for supply to the house, 6 m long, which can be extended if necessary. The equipment is delivered ready-made and only requires connection.

A modular boiler house with a capacity of 10 kW is quite capable of heating a private house and supplying it with hot water. It can be dismantled and transported to another location

To operate a modular-block boiler room you need:

- install a container near the house;

- supply electricity (220V);

- prepare fuel (solid or diesel depending on the type of boiler);

- fill the heating system with water.

The modular boiler room has a backup power supply, which is enough to support normal operation in the event of a power outage during the day. The coolant temperature is adjusted automatically.

A modular boiler room can be purchased in a standard version or custom-designed based on your own needs. It is recommended to entrust installation to specialists.

Finishing the boiler room from the inside

Brick and concrete walls of the boiler room are plastered and painted with water-based paint. Additional decorative finishing - ceramic tiles, metal cladding panels. You should not leave the wall surface in its original form. It generates dust, and this harms the operation of boiler equipment.

In a wooden house, the walls are impregnated with a fire retardant compound. It is recommended to cover them on top with sheets of non-combustible plasterboard and also plaster them, and behind the boiler, for reinsurance, attach aluminum sheets to the wall surface.

Plastering is another protection against damp fumes, fire, and other influences. You can increase the level of fire resistance using special heat-resistant plaster. It can withstand high temperature heating and even open flame for 30 minutes. up to 2.5 hours.

The floor is leveled with cement-sand screed. The strength of ordinary ceramic tiles is not enough to cover the floor with, since boiler equipment is quite heavy, and there is a risk of dropping some heavy object. Porcelain stoneware will be more reliable. Tiles made from this material are super durable and are not afraid of heating to high temperatures and fire.

The drain gutter will protect you from accidental leakage. If this cannot be done, then waterproofing must be laid around the perimeter to a height of 5-10 cm from the floor, and the boiler must be raised on a pedestal, thereby eliminating possible contact with water. It can be easily built from bricks and lined with porcelain stoneware intended for the floor.

Tiles on the walls and floor of the boiler room will help keep the room properly clean. Its installation is no different from a similar operation in other rooms, but it is important to accurately mark all communications entry points before starting work.

It is better to choose a light-colored granite with a matte texture for the floor. Shoe marks and dust are not so noticeable on it.

There are pipes and wires under the ceiling in the boiler room. To disguise them, make a box from the same drywall that was used on the walls. The outside of the box is plastered and painted. It makes sense to leave inspection windows in it and cover them with removable metal bars.

It makes no difference which windows to install in the boiler room - plastic or wooden. In a fire, both will burn. The plastic will also begin to melt and release toxic substances.