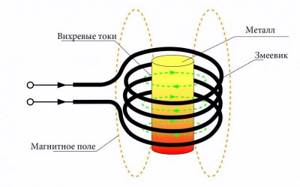

Induction heaters work on the principle of “derived current from magnetism”. A high-power alternating magnetic field is generated in a special coil, which generates eddy electric currents in a closed conductor.

The closed conductor in induction cookers is a metal cookware, which is heated by eddy electric currents. In general, the operating principle of such devices is not complicated, and if you have a little knowledge of physics and electrical engineering, assembling an induction heater with your own hands will not be difficult.

The following devices can be made independently:

- Devices for heating the coolant in a heating boiler.

- Mini furnaces for melting metals.

- Cooking plates

A do-it-yourself induction cooker must be manufactured in compliance with all standards and regulations for the operation of these devices. If electromagnetic radiation dangerous to humans is emitted outside the housing in lateral directions, then the use of such a device is strictly prohibited.

In addition, the great difficulty in designing a stove lies in the selection of material for the base of the hob, which must meet the following requirements:

- Ideally conduct electromagnetic radiation.

- Not a conductive material.

- Withstand high temperature load.

Household induction cooking surfaces use expensive ceramics; when making an induction cooker at home, it is quite difficult to find a worthy alternative to such material. Therefore, first you should design something simpler, for example, an induction furnace for hardening metals.

Principle of operation

The very principle of operation of an induction heater is not as complicated as it might seem. As an example, we can consider vortex-type heaters. They are widely used in heating boilers, most of the population is familiar with them. From the name it is clear that energy is generated from a magnetic field, which is transferred to the coolant.

The water that enters the device is heated by the supplied energy, after which it enters the heating system. To create pressure, an ordinary pump is used.

Thus, water circulates inside the system, protecting it from overheating. At the same time, the coolant constantly vibrates, which protects against the appearance of scale. In fact, this is the entire working diagram of this unit.

Advantages and disadvantages

According to manufacturers, the use of induction heating boilers for heating a home is a complete advantage with no disadvantages at all. Let's try to figure out what is the truth and what is a marketing ploy.

1. High efficiency. Efficiency up to 99% is typical for all types of electric boilers.

2. Maximum protection against scale. Since there is no direct contact of the induction winding with the coolant (unlike the heating element), scale can only form inside the pipes. But closed systems are characterized by a consistently low amount of salts. That is, there are no prerequisites for the formation of deposits.

3. Resource savings up to 35%. Before you buy an induction boiler and install it, remember that its main task is to convert energy into heat. To generate 1 kW, according to the law of conservation of energy, you also need to spend 1 kW of electricity. The only difference is the heating speed - the induction unit operates faster by about 20-30%.

4. Complete absence of detachable connections in the design, which eliminates the possibility of leakage. Not entirely true: the boiler includes 4-6 components connected into a unit. The price of the VIN induction heating system includes the boiler itself in a collapsible casing, a control cabinet, a safety group (sensors and relays) and capacitors, pressure relief valves, a set of contacts for connecting external devices.

5. High degree of electrical and fire safety. This is true, but you need to make sure that there is no leakage and that the amount of coolant remains constant. Otherwise, the device will heat up very quickly and there is a risk of explosion.

6. Does not have elements subject to mechanical wear, so the service life is more than 30 years. Firstly, the core is durable, but the varnish insulation on the primary winding (toroidal) is subject to aging. Its service life is 7-10 years. The result of destruction will be an interturn short circuit with corresponding consequences. Secondly, induction boilers are a relatively new product that has not been tested by time; the statement about 30 years of operation is unlikely to be true.

7. Compatible with other systems. You can connect heated floors, gas or wood boilers.

A clever meter that saves electricity. Pays for itself in 2 months! Everyone needs to know this in order to save!

8. They do not require a separate room or ventilation.

9. Does not require preventive maintenance. A boiler is, in any case, equipment with many sensors, relays, and terminals that periodically need to be changed and tightened. Of course, compared to gas boilers, this is insignificant.

Thus, most of the positive qualities are consistent with other types of electrical units. Now let’s analyze the shortcomings identified over several years of operation.

1. Cost. The price of the induction boiler SAV 5 kW is 40,000 rubles. Whereas the heating element Protherm Skat 6 kW is 23,000.

2. Significant weight with small dimensions. Since even the smallest unit weighs from 20 kg, it is recommended to mount them on the floor or hang them on a load-bearing wall using durable brackets.

3. The electromagnetic field generates strong interference in the long, medium wave and VHF ranges. Although manufacturers claim that they do not affect the human body, sanitary and medical officials claim the opposite. It is not for nothing that SNiPs contain standards and rules for the location of devices with high levels of radiation.

4. To operate the heating system in a house with 2-3 floors, a powerful circulation pump is required.

Homemade

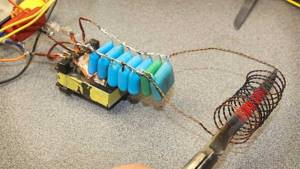

Obviously, a homemade simple induction heater will weigh little, but will have relatively good efficiency, with a compact size.

A pipe with a winding will be used as the core. You will also need a second, similar pipe. Its function will be heating.

Components

For the device you will need:

1. Plastic pipe; 2. Stainless steel mesh; 3. Steel wire; 4. Copper wire; 5. Welding inverter.

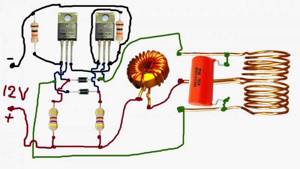

The circuit of an induction heater created by yourself will be very simple, hence the light weight and compactness of the device.

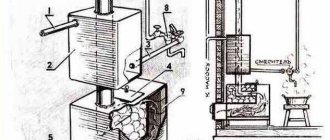

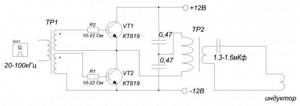

The basis is a coil that will play the role of an inductor. It is located in a plastic case. Inside the coil itself you need to place a piece of steel pipe, on which you need to make 2 pipes (inlet and outlet). They will be needed to circulate water in the heating system. The coil, in turn, must be connected to electricity for the device to function.

Note!

Do-it-yourself Gauss cannon: TOP-130 photos of the best ways to create it yourself. Design features + master class for beginners

DIY clamps - a step-by-step master class for beginners. Schemes for manufacturing different designs + 170 photos

Do-it-yourself electric scooter - a master class with step-by-step instructions for doing it yourself. Tips and simple patterns for beginners + the best photo reviews

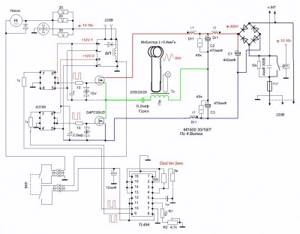

If there is an inverter, you can use a slightly different connection method. In addition, this will increase the frequency of the current, and as a result, the efficiency of the device.

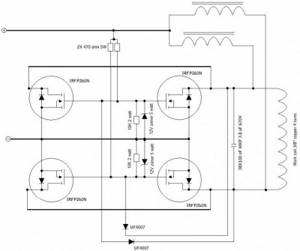

The converter itself, due to which another type of connection is possible, consists of 3 components:

1. Transistor control circuit; 2. Rectifier; 3. Two-transistor inverter.

A distinctive feature of this method is the secondary winding of the wire. It is short-circuited and is located in the first winding. In fact, the operating principle can be compared to a transformer, but the desired outcome is completely different.

In a transformer, they try to avoid heating, while in an induction heater, it’s the opposite. You can download the diagram for free.

You can get such an inverter from a welding machine, but the connection diagram will be somewhat more complicated. Thus, you can assemble induction heating with your own hands from a welding machine.

Note!

DIY rocking chair: TOP-120 photos of the best manufacturing options. Master class on creating a rocking chair at home

- Smokehouse from a gas cylinder - the best master class on making a homemade smokehouse with step-by-step photo diagrams for beginners

Do-it-yourself compressor: TOP-130 photo reviews of finished compressors. Step-by-step instructions + diagrams and drawings

Nuances

- When conducting experiments on heating and hardening of metals , the temperature inside the induction coil can be significant and amount to 100 degrees Celsius. This thermal heating effect can be used to heat water for domestic use or for heating a home.

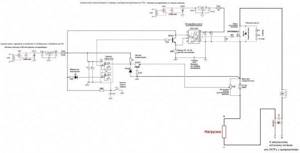

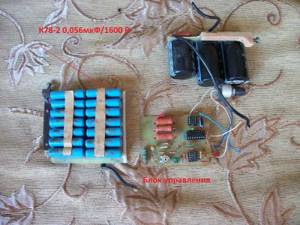

- The heater circuit discussed above (Figure 3) , at maximum load, is capable of providing radiation of magnetic energy inside the coil equal to 500 W. This power is not enough to heat a large volume of water, and the construction of a high-power induction coil will require the manufacture of a circuit in which it will be necessary to use very expensive radio elements.

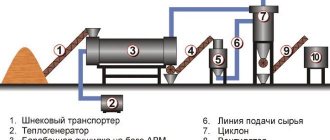

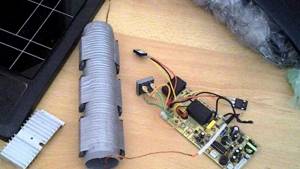

- A budget solution for organizing induction heating of liquid is to use several devices described above, located in series. In this case, the spirals must be on the same line and not have a common metal conductor.

- A stainless steel pipe with a diameter of 20 mm is used as a heat exchanger Several induction spirals are “strung” onto the pipe, so that the heat exchanger is in the middle of the spiral and does not come into contact with its turns. When 4 such devices are turned on simultaneously, the heating power will be about 2 kW, which is already sufficient for flow-through heating of liquid with a small circulation of water, to values that allow this design to be used in supplying warm water to a small house.

- If you connect such a heating element with a well-insulated tank , which will be located above the heater, the result will be a boiler system in which the liquid will be heated inside a stainless pipe, the heated water will rise upward, and its place will be taken by a colder liquid.

- If the area of the house is significant , then the number of induction coils can be increased to 10 pieces.

- The power of such a boiler can be easily adjusted by turning off or turning on the spirals. The more sections that are turned on at the same time, the greater the power of the heating device operating in this way.

- To power such a module you will need a powerful power supply. If you have a DC inverter welding machine, you can use it to make a voltage converter of the required power.

- Due to the fact that the system operates on direct electric current , which does not exceed 40 V, the operation of such a device is relatively safe; the main thing is to provide a fuse box in the generator power circuit, which in the event of a short circuit will de-energize the system, thereby eliminating the possibility of a fire.

- In this way, it is possible to organize “free” heating of the house , provided that batteries are installed to power the induction devices, the charging of which will be carried out using the energy of the sun and wind.

- The batteries should be combined into sections of 2, connected in series. As a result, the supply voltage with such a connection will be at least 24 V, which will ensure the boiler operates at high power. In addition, a series connection will reduce the current in the circuit and increase the service life of the batteries.

Application

Today, the scope of application of heaters of this type is very large. It is also necessary to take into account the fact that there are a large number of modifications and possibilities for upgrading heaters.

Industrial sector

It is used for melting metals, producing certain types of alloys, which are then used in a wide range of works. By creating alloys, metal wire is produced.

Various modifications of the induction heater are used for car service, for the purpose of heat treatment of spare automotive parts. In fact, the technology is used for the same purpose in medicine; medical devices, furniture and equipment are subjected to heat treatment.

Features of operation

Homemade heater assembly is only half the battle

Equally important is the correct operation of the resulting structure. Initially, each such device poses a certain danger, since it is not able to independently control the heating level of the coolant. In this regard, each heater requires certain modifications, that is, installation and connection of additional control and automatic devices

In this regard, each heater requires certain modifications, that is, installation and connection of additional control and automatic devices.

First of all, the pipe outlet is equipped with a standard set of safety devices - a safety valve, a pressure gauge and an air vent device. It should be remembered that induction water heaters will work normally only if there is forced water circulation. A gravity flow circuit will very quickly lead to overheating of the element and destruction of the plastic pipe.

To avoid such situations, a thermostat is installed in the heater, connected to an emergency shutdown device. Experienced electrical engineers use for these purposes thermostats with temperature sensors and relays that turn off the circuit when the coolant reaches the set temperature.

Homemade structures are characterized by rather low efficiency, since instead of free passage, there is an obstacle in the way of water in the form of wire particles. They almost completely block the pipe, causing increased hydraulic resistance. In emergency situations, damage and rupture of the plastic may occur, after which hot water will certainly lead to a short circuit. Typically, such heaters are used in small rooms as an additional heating system during the cold season.

The heating system is an important component of any home. It can be called the “heart” of the home, because it is warmth that creates comfort and atmosphere. The market is replete with different types of gas boilers because they are considered the most efficient. However, the gas main can be located quite far away, so in this case electrical equipment comes to the fore. Induction boilers are quite popular. The advantage of this type of heating is that an induction furnace from a welding inverter can be easily made with your own hands. Based on eddy currents, it is also possible to construct an induction heater for metal, using a welding inverter as the current source.

Pros of technology

It is used in a wide range of industries due to its low cost (depending on the type and modification) and high efficiency. Mainly used in the alloy manufacturing industry, where ultra-pure alloys can be produced through the use of an induction heater.

Note!

Do-it-yourself wind generator: TOP-170 photo reviews of finished devices. Detailed DIY instructions for beginners

Do-it-yourself spot welding - the best master class on making homemade spot welding with step-by-step photo diagrams of do-it-yourself work

Do-it-yourself tennis table: TOP-150 photos of the best manufacturing ideas. Master class on creating a tennis table at home

An environmentally friendly technology that does not pollute the environment in any way, and at the same time is cheap to produce.

It is actually possible in any shape, which allows you to evenly distribute heat over the entire area, eliminating local overheating.

In fact, if you compare this technology with similar ones, it has no disadvantages. Except for one thing: it involves the need to connect the inductor and the workpiece. If this is not done, the heating will be insufficient in most cases.

Is it really possible to save money on induction heating?

The popularity of using equipment in everyday life is due to good energy savings. When installing induction cookers in the kitchen, the owner no longer needs to turn on the ventilation, because... the surrounding space practically does not warm up. The heating surface does not require complicated cleaning since it is made of glass.

Due to the increased heating rate, the operating time of the system is reduced, which also allows you to save on electricity.

How to make it yourself

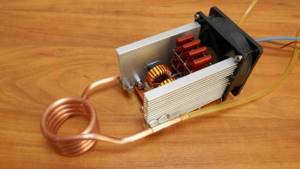

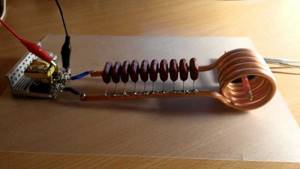

Let's consider the second method of making a powerful induction heater with your own hands. Unlike the first method, there will be much fewer components, but its power will be higher due to the use of slightly different components and connection type.

We will need:

1. Welding inverter; 2. Generating welding current (from 15 A); 3. Copper wire.

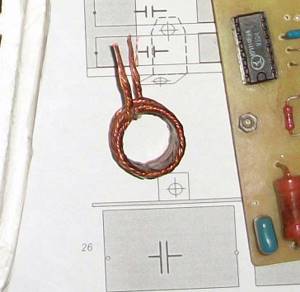

It is recommended to use polymer materials as the core. This is due to the fact that they are able to withstand fairly high temperatures when heated. In our case there will be a polymer pipe with a diameter of 50 mm.

It is necessary to wind the wire around the core and connect it to the inverter terminals so that there is no twisting.

What is induction and its principle

Electromagnetic induction was discovered more than a hundred years ago. It allows you to generate heat using high-frequency currents - this technology is actively used for metal smelting. This technology has also reached household consumers - we can see its implementation in the kitchen in the form of induction electric ovens. Induction ovens allow you to quickly heat food and are small in size. Another advantage is their long service life.

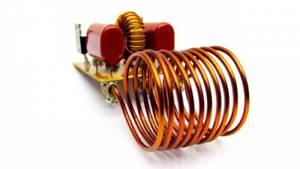

An induction heater is a powerful coil that is supplied with high frequency alternating current. A metal core is placed inside the coil, which is heated by eddy currents. Thus, there are no conventional heating elements here, and the heat is generated exclusively through induction heating.

Magnetic induction is used in the metallurgical industry. Here it allows you to get rid of coal and gas furnaces, which are large in size. Today, metallurgical shops have small induction furnaces that quickly heat metals and alloys to high temperatures. They are safe for people and reduce the time spent recycling metals.

An induction coil can be used to quickly heat metal to very high temperatures.

In the domestic sphere, magnetic induction works in induction cookers and electric induction boilers. What are the advantages of such heating?

- There is no direct contact between the heated body and the induction coil.

- Lack of scale in induction boilers, which is due to the absence of conventional heating elements.

- Long equipment life.

- Fast heating of coolants and metal structures.

- High equipment efficiency.

- Safety for others.

Electromagnetic induction heats quickly and very efficiently - the efficiency of the same induction boilers reaches 98-99%. also no direct contact between the coolant and live parts, which significantly increases the safety of the equipment .

Let us recall that in heating elements and electrode electric heating boilers, direct contact of heating elements and coolant is used.

Making an induction water heater with your own hands is not as difficult as it might seem at first glance. Many people with knowledge in the field of electrical engineering and “straight hands” skillfully create induction heaters used for heating residential buildings. Let's figure out how such heaters are created and what we need to assemble the equipment ourselves.

First

The wire must be cut into pieces approximately 5 cm long. Fill the core with these pieces, which is then sealed with wire mesh. Install the adapter from the pipe where the heater will be connected to the heating. Next, you need to wind a wire around the heater, the length of which should be about 16 m.

After this, the core is connected to the heating, the heater itself is connected to the inverter. Please note that before testing, you need to make sure that there is water inside the device. If you turn it on without water, it will overheat very quickly and melt.

Second

Regarding the first option, this one is much simpler, but requires additional costs. A long pipe is used as a base. Approximately a meter of paint must be removed from its surface. When the paint is removed, the cleaned area should be covered with electrical fabric in 3-4 layers. Next, copper wire is wound on top of the fabric, forming a coil.

The assembled device is isolated, all that remains is to connect it to the inverter.

Mandatory safety precautions

Any work performed with electricity, especially if the work in one way or another involves the participation/use of water in the process, requires full compliance with safety requirements.

Safety precautions must always be observed, with special care in cases where the device is assembled independently, using independently acquired skills and knowledge.

In addition, before starting any work, it is initially necessary to thoroughly study the theoretical part. This will allow you to understand the upcoming work in more detail and eliminate possible errors and misunderstandings.

In this article, we looked at several ways to make a heating device with your own hands. Photos of the induction heater, instructions and recommendations for use can be found on the Internet.

Please note that in the case of homemade induction heaters, they cannot be installed in residential areas. This is caused by electromagnetic radiation that comes from both inside and outside the coil. In fact, it will heat not only the core, but also metal objects and devices that are exposed to the magnetic field.

It is recommended to use only with a galvanized screen to eliminate this possibility.

Operating principle

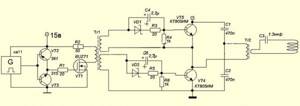

To obtain such currents, a so-called inductor is used, which is an inductor coil containing only a few turns of thick wire.

The inductor is powered by a 50 Hz alternating current network (sometimes through a step-down transformer) or from a high-frequency generator.

The alternating current flowing through the inductor generates an alternating magnetic field that permeates space. If there is any material in this space, then currents will be induced in it, which will begin to heat this material. If this material is water, then its temperature will increase, and if it is metal, then after a while it will begin to melt.

There are two types of induction furnaces:

- furnaces with magnetic core;

- ovens without a magnetic core.

The fundamental difference between these two types of furnaces is that in the first case the inductor is located inside the melting metal, and in the second - outside. The presence of a magnetic circuit increases the density of the magnetic field penetrating the metal placed in the crucible, which facilitates its heating.

Induction heater

An example of an induction furnace with a magnetic core is a channel induction furnace. The circuit of such a furnace includes a closed magnetic circuit made of transformer steel, on which the primary winding is located - an inductor and a ring-shaped crucible in which the material for melting is located. The crucible is made of heat-resistant dielectric. Such an installation is powered from an alternating current network with a frequency of 50 Hz or a generator with an increased frequency of 400 Hz.

Such furnaces are used for melting duralumin, non-ferrous metals or producing high-quality cast iron.

Crucible furnaces that do not have a magnetic core are more common. The absence of a magnetic circuit in the furnace leads to the fact that the magnetic field created by industrial frequency currents is strongly dissipated in the surrounding space. And in order to increase the magnetic field density in a dielectric crucible with material to be melted, it is necessary to use higher frequencies. It is believed that if the inductor circuit is tuned to resonance with the frequency of the supply voltage, and the diameter of the crucible is commensurate with the resonance wavelength, then up to 75% of the energy of the electromagnetic field can be concentrated in the crucible area.

Induction furnace manufacturing diagram

As studies have shown, to ensure efficient melting of metals in a crucible furnace, it is desirable that the frequency of the voltage supplying the inductor exceeds the resonant frequency by 2-3 times. That is, such a furnace operates at the second or third frequency harmonic. In addition, when operating at such higher frequencies, the alloy is better mixed, which improves its quality. A mode using even higher frequencies (fifth or sixth harmonics) can be used for surface carburization or hardening of metal, which is associated with the appearance of a skin effect, that is, the displacement of a high-frequency electromagnetic field to the surface of the workpiece.

Conclusions on the section:

- There are two options for an induction furnace - with a magnetic core and without a magnetic core.

- The channel furnace, which belongs to the first version of the furnaces, is more complex in design, but can be powered directly from a 50 Hz network or a high-frequency network of 400 Hz.

- The crucible furnace, which belongs to the furnaces of the second type, is simpler in design, but requires a high-frequency generator to power the inductor.