Cast iron stoves

A reliable cast iron wood stove is a worthy alternative to a traditional brick stove. It does not provide for the construction of a foundation and is placed in virtually any convenient place in the finished room, heats up faster, gives not only good heat, but also allows you to enjoy the play of the flame and the crackle of burning wood.

Compared to brick stoves, cast iron stoves cool faster, but this point, according to consumer reviews, is the slightest drawback, which can be reasonably omitted, knowing the advantages of this type of heating appliances.

Suitable boiler model for a bath

First of all, you will need to find or plan on your own the most optimal option for a boiler and heating installation. It is not difficult to assemble a sauna boiler with your own hands; you only need a minimum set of plumbing tools, a welding machine and cutter, sheet metal and steel pipes. A more difficult problem will be choosing your own drawings for a boiler in a bathhouse. At this stage of work, difficulties always arise with the characteristics and design of the boiler installation.

As a sample of a wood-burning boiler for a bathhouse, you can use two types of heating stoves:

- A low-power stove-boiler with 4-5 kW of heat, designed to heat a small steam room with an area of 4-5 m2 and produce 40 liters of boiling water;

- A large wood-burning boiler-stove with a thermal power of at least 20 kW, designed to heat a full-size steam room of 7 m2 and heat water in a volume of up to 70 liters.

For your information! Boilers of intermediate power, from 5 to 12 kW, for any bathhouse, including for a summer house or suburban area, can be obtained by simply scaling, increasing or decreasing the model you like. The two diagrams of boiler and furnace installations given below differ from each other in design, housing layout, organization of the combustion process and water heating for the needs of the bathhouse. Therefore, before making a boiler for a sauna with your own hands, it would be right to thoroughly understand all the details and determine how suitable the chosen option is for a steam room of a specific layout.

Gas boiler - effective, but not always safe

Gas equipment is advisable for use only in cases where there is a direct gas supply to the land plot where the bathhouse is located. Typically, gas boilers for baths are small in size and have low fuel consumption, but naturally, as mentioned above, you will still have to pay for the resource consumed. With proper installation and operation, there will be no gas smell in the room, and the system will operate stably. If there are signs of operational problems, then the owner’s task is to completely turn off the gas supply and call the emergency service.

When choosing a gas boiler for a bathhouse, you need to decide what kind of heating system will be implemented in the building: single-circuit (exclusively for heating) or double-circuit (not only heating will be provided, but also hot water will be supplied). There is also a three-circuit version of the gas heating boiler, which allows the supply of coolant to the floor heating system and the pool. You need to choose based on a pre-designed heating system diagram and your own financial capabilities.

Related Posts

- Secrets of stove makers: brick stove for a bath

- Manufacturing and connecting a sauna stove with a water heat exchanger

- How to choose a stove for an Ermak sauna: top 7 models with descriptions of technical characteristics and customer reviews

- Wood-burning stoves and their variety of designs

- Fire-battery 7b (thermophor)

- Cast iron stove for bath Vesuvius

- Buleryan oven: do it yourself

- How to weld a metal sauna stove

- Review of Siberia gas boilers

- Installing a stove in a steam room: location, fencing, protective screen

- Homemade Russian stove on the street under a canopy

- How to fold a Swedish oven with a stove

- Combined heating boilers with wood and gas

- Types and principle of operation of a gas boiler for heating a private house

- Fast and correct furnace repair

- How to make a long-burning stove yourself

- Stove for a Russian bath: top 10 and guidelines for choosing the best sauna stove model

- Do-it-yourself gas heater: options for the best homemade products

- Turbocharged or atmospheric gas boiler? which one should I take?

- Connecting and calculating a buffer tank to a solid fuel boiler

- DIY metal rocket oven

- How to install a stove in the house?

- Construction of a frame bath with your own hands

- The operating principle of a double-circuit gas boiler. classification and advantages

- Types and sizes of Russian stoves: types, sizes, 5 construction recommendations

Read with this

- Secrets of stove makers: brick stove for a bath

- Manufacturing and connecting a sauna stove with a water heat exchanger

- How to choose a stove for an Ermak sauna: top 7 models with descriptions of technical characteristics and customer reviews

- Wood-burning stoves and their variety of designs

- Fire-battery 7b (thermophor)

- Cast iron stove for bath Vesuvius

- Buleryan oven: do it yourself

- How to weld a metal sauna stove

- Review of Siberia gas boilers

- Installing a stove in a steam room: location, fencing, protective screen

How to make a boiler for a bathhouse

Assembling a bath boiler with your own hands will not be difficult if you know how to use a grinder and a welding machine. The structure is welded according to a finished drawing or your own design is developed. It is only important to know what components a heating device for a bath consists of.

Construction of homemade boilers

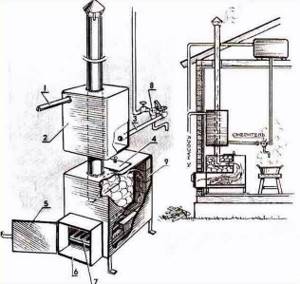

Homemade products differ in shape, which depends on the material of manufacture (pipe or sheet steel). The design of a heating device for a bath consists of the following components:

- The combustion chamber. Firewood is loaded into the firebox, and this is where it is burned.

- Chimney. The pipe is connected to the firebox and led through the roof of the bathhouse to the street to remove combustion products.

- Ash pit. The chamber is located under the firebox and is divided by grates. The coals of burnt firewood spill through the cracks into the ash pit. This chamber is also called a ash pan, since air enters the firebox through the ash pan to maintain combustion.

- The heater is installed above the firebox. The compartment is made in the form of a chamber with stones loaded inside.

- The water heating tank is located above the heater. There is a metal chimney running inside. It heats the water.

Now it’s worth considering the nuances of the design. The boiler is made slightly elongated so that the doors of the firebox and ash pan open into the dressing room. The building itself enters the steam room through the wall. The heater is not a mandatory unit. The steam room can be heated from the body and boiling water in the tank.

Advice! The heater is an integral attribute of the bathhouse. It's nice to take a steam bath in a steam room where you can splash some water on the hot stones.

When making a boiler, it is not advisable to save on the heater.

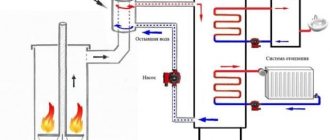

If the bathhouse is large and there are many rooms, a full heating system will be required. The heating device is equipped with another unit - a heat exchanger. The tank or coil is located in the firebox. A pipeline with radiators is connected to the heat exchanger. The system is filled with coolant, most often water or antifreeze.

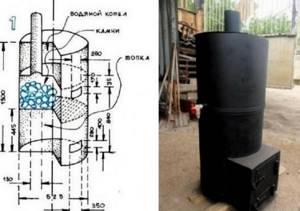

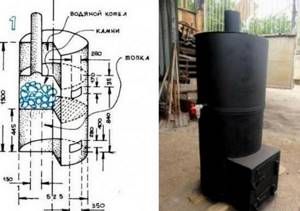

Cylindrical boiler

A cylindrical boiler is easier to manufacture due to fewer welded joints. The material will be a barrel or pipe with a diameter of at least 50 cm. It is advisable to select thick metal - about 6 mm. The service life depends on this.

To make a cylindrical model, cut a piece of pipe 1 m long. The ends are sealed with a plug. Where the bottom will be, 4 small legs are welded. At a height of 5 cm from the bottom, a rectangular ash pan window is cut in the pipe with a grinder. A door is made from a cut out piece of metal and attached to the pipe with hinges near the vent.

Grate bars are welded inside the pipe 10 cm above the ash pan. They can be made removable. The plates are welded to the pipe, and cast iron grates are laid on them. Another hole for the firebox is cut 10 cm higher from the grate. The door is similarly secured with hinges.

For the heater, another piece of pipe is cut. The length is calculated individually so that the end extends into the steam room of the bath. The blank for the heater is welded over the firebox. At the same time, the chimney pipe is welded. The end of the heater facing the steam room can be equipped with a door. A water tank is installed above the heater.

Advice! It is better to make all components in contact with water (tank and chimney) from stainless steel.

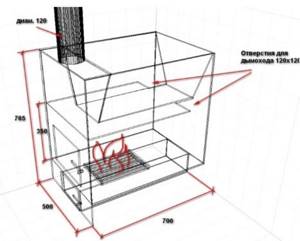

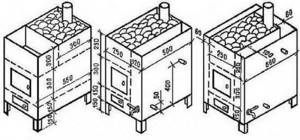

Rectangular boiler

The manufacturing scheme of a rectangular heating device for a bath is similar to a cylindrical design. The only difference is that the pipe forms a finished body, where all that remains is to cut out the firebox and ash pan. The rectangular body will have to be welded from separate pieces of sheet steel.

Another important point is the cylinder’s resistance to deformation when heated. To ensure that the rectangular walls remain smooth, stiffening ribs are welded inside the body on the firebox side.

The video shows an example of making a boiler:

Do-it-yourself boiler for a bathhouse: drawings

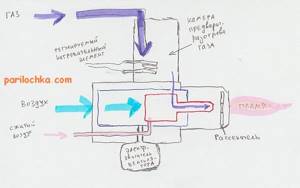

Gas and solid fuel boilers can be made according to one drawing. The nodes are almost the same, but there are nuances. In a gas boiler, burners are installed instead of a grate. The firebox is reduced, and due to it the size of the heater is increased. An ash pan is also not needed, but a small blower is made to supply air to the combustion chamber.

Attention! The design of a gas boiler for a bathhouse is designed so that the automation and all connections to the burner are located in the dressing room. The control unit is covered with a protective casing.

The drawing of a diesel fuel boiler for a bath is similar to its gas counterpart. The difference is the installation of a different type of burner.

Tools and materials

When making a boiler, you cannot do without the following tools:

- apparatus for electric or gas welding;

- grinder with cutting discs for metal;

- hammer, chisel, pliers.

The materials needed for the boiler are metal (pipe, barrel or sheet steel). You will also need a tap for the water tank and hinges to hang the doors. Consumables for welding work depend on the type of apparatus (electrodes, carbide, oxygen, wire).

Boiler installation rules

Even before starting to prepare the boiler, a place is prepared for it in the bathhouse. Due to the heavy weight of the metal structure, a foundation of concrete or brick is provided. A hole in the ceiling and roof of the bathhouse is cut strictly above the chimney exit from the boiler to avoid bends. The knees become clogged with soot faster, and traction worsens.

Advice! It is better to make the passage of the chimney through the ceiling of the bathhouse from a two-layer “sandwich” pipe.

Due to the thermal insulation of the internal channel, the outer casing does not heat up. The chimney is safe even when touching flammable roofing materials of the bathhouse.

Advantages and capabilities of the steam generator

The main advantage of using a steam generator in a bath and sauna is its ease of use and maintenance. In addition, powerful models of devices are able to work without a traditional heater. Other undeniable advantages of using steam guns include:

- Economical consumption of electrical energy.

- Easy to adjust supply intensity and initial temperature of steam generation (a special dashboard is designed to control all processes and equipment operating parameters).

- High speed of heating water in the tank and supplying warm steam (a couple of minutes after switching on).

- Safety of use in the bathhouse.

- Automatic control and maintenance of specified operating parameters. (the intensity of steam generation and output is monitored and controlled by sensors and a microprocessor).

- Compact dimensions and light weight (allow the steam generator to be placed even in a small bathhouse).

The disadvantages of steam generators for baths and saunas are the high cost of quality products from reliable manufacturers, as well as energy dependence.

A modern steam supply device is a compact mechanism, simple and comfortable to operate.

Modern devices generate steam with a temperature of 35 to 95 degrees, which allows the user to maintain an optimal microclimate in the steam room, depending on individual settings and personal preferences. In one room, using a steam gun, you can create the atmosphere of a Turkish hammam, a traditional Russian bath or a Finnish sauna.

On a note! Since steam generators are operated in a bathhouse under conditions of high temperatures and air humidity, they are subject to strict safety requirements. The operating parameters of the steam gun are automatically monitored; if they deviate from the norm, the device is disconnected from the power supply.

Gas cast iron stoves for baths

Not everyone wants or has the opportunity to heat the stove with wood. Therefore, a reasonable question arises: is it possible to purchase a gas cast-iron stove for a bath?

Unfortunately, we found only options that would require converting a wood-burning cast-iron stove into a gas stove. There is no point in doing this type of re-equipment on your own. A gas burner must be installed by a professional and the burner must be certified and inspected by your gas inspector.

In general, gas stoves require permission for installation, the reason for which is their special fire hazard - if you can expect just a fire from a wood stove, then the gas also explodes . That is why we advise you to take into account the legislation and equip stoves with gas burners in accordance with all standards. We have an article in which we talk about all the nuances of installing a gas stove in a sauna.

Liquid fuel boilers

Devices running on diesel fuel are almost as easy to operate as gas ones. This is largely influenced by the fact that an ordinary container, such as a canister or a small barrel, is quite sufficient for storing fuel. A large volume is not required - diesel fuel begins to lose its quality over time.

A boiler that uses liquid fuel must be installed outside all rooms visited by people as part of bathing procedures. This is due to toxic and very unpleasant fumes that permeate any room.

Sometimes, to reduce the costs and effort of constantly purchasing fuel, owners of large bathhouses install large tanks underground that are filled with a significant volume of fuel at a time. Of course, such an operation can only be done under the supervision of professionals, but if performed correctly, this approach can justify itself.

Sheet iron heating device

A similar stove with a metal boiler for a bathhouse is the most difficult to produce. This is due to the fact that there will be no prepared workpiece. Fundamentally, such a device is no different from the one described above. It also contains 4 compartments: an ash pan, a firebox, a heater and a tank.

The production of such a furnace will take longer. You will especially have to tinker with the water tank, which should be practically sealed. But the result will be a product no different from what was produced at the factory.

Selecting a steam generator for a bath according to the type of water supply

There are two options: you can use the steam generator by connecting it to the water supply network or to a separate container. The second option was specifically created for buildings that do not have a water pipe. These are dachas and small country cottages.

Connecting to a water supply makes the steam generators automatic. That is, everything happens without human participation. However, it should be noted that the low quality of tap water creates conditions for the deposition of salts and sediments on the walls of the tank and heating element. All this reduces the life of the unit. Therefore, you have to install filters or come up with cleaning systems, which increases the cost of a steam generator for a bath.

The second design option is called autonomous or semi-automatic. For it to work, you will have to install an additional container, which will need to be filled manually with water. In principle, this is its only disadvantage. But you can control the quality of the water being poured. By the way, you can fill the tank with distilled or simply well-purified and settled water. These are low-power sauna units, which is why they cost less.

How to buy a suitable stove in our online store?

Our company is the official dealer of well-known domestic manufacturers of stoves with cast iron fireboxes. We guarantee convenient terms of cooperation:

- We provide delivery by our transport throughout Moscow and the region or transfer it to transport companies for delivery throughout the Russian Federation.

- All models in the catalog are offered at competitive prices.

- Our specialists will not only help with the selection, but will also provide turnkey installation with a guarantee.

To contact us, call or request a call back.

Water heating

For areas where there is no hot water supply, stoves that have their own means for heating water are relevant. Regardless of what material the stove is made of, it will be either heat exchangers or water heating tanks . In both cases, the source of heat is the fuel on which the unit operates.

On a note! There is a difference in where the heat is taken from - from the stove body or from the chimney. In the first case, you reduce the efficiency of the furnace, in the second, you increase it. In addition, water has a very high heat capacity, which means a large heat consumption to heat it.

Cast iron stoves with heat exchanger for baths

A heat exchanger consists of pipes or a register of pipes, or other structure through which water continuously flows (under the influence of convection and gravity or from artificially created pressure). Being in direct contact with the heat source, the exchanger heats up new portions of water. It can be placed inside or outside the stove body, or it can be a coil that wraps around the chimney.

Cast iron stove with heat exchanger on a pipe.

When purchasing a stove, you should ask whether the manufacturer has ready-made heat exchangers suitable for the model you are purchasing. For example, “Sudarushka M” can be equipped with cast iron heat exchangers if the owner does not want to purchase a tank, which is also optionally supplied with the stove.

Cast iron stove with sauna tank

There are companies that are more concerned with consumer convenience. Thus, at PetrozavodskMash, almost all cast iron products can be equipped with a tank of the required volume at the consumer’s request.

Cast iron stove with sauna tank.

In any case, the manufacturer's website will usually indicate whether they have tanks in stock, whether they fit your model, and other information. True, the tanks may end up in the “accessories” section.

By the way! Tanks come in two varieties: some are somehow hung on a stove or chimney, while others are hung in an adjacent room, communicating with the stove through pipes. In the latter case, a heat exchanger will be needed to heat the water.

You will find more detailed information in the articles: stoves with a tank and with a heat exchanger for wood stoves.

Varieties

Models of steam generators differ in the method of pouring water into the equipment. Some models are filled manually, others automatically. If you choose the second option, you need to take care of connecting the steam generator to the water supply system. Most industrial models are equipped with a temperature control system that operates automatically.

Depending on the application, the following types of devices are distinguished:

- Industrial, which are often installed in public bathing establishments: baths, saunas.

- Household. The power of the units is lower compared to the previous type. For personal use.

Water is heated in different ways:

- Electrode. The collected water reaches the required temperature under the influence of electric current. Charged particles move along the electrodes.

- TENOV. Special tubular electric heaters are installed inside the structure, which ensure heating of the liquid to the desired temperature.

- Induction. The principle of operation is similar to that of a microwave oven. The water is heated by an inductor.

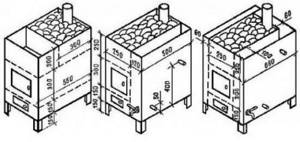

Types of structures

Sauna boilers usually have the shape of a metal cylinder or rectangle. In front they have a furnace and blower door, in the back there are heating circuit outlets, and on the side there is a heater door located on the protruding neck.

Cylindrical shape

To make a cylindrical boiler, you can use metal pipes with a diameter of at least 50 cm, barrels with a volume of up to 200 liters, 50-liter cylinders for transporting propane. These products are seamless and already have a cylindrical shape, which is more preferable than rectangular in terms of aerodynamics (air flow) and heat transfer. The orientation of cylindrical boilers can be either vertical or horizontal.

Rectangular

Devices of this shape have a large number of seams, and the cutting of their parts must be carried out with extreme precision. For a person without welding skills, assembling such a structure will be problematic. The orientation of a rectangular boiler does not play a significant role. For greater stability, it can be placed horizontally, if the area allows, of course. A vertical arrangement will save space, but will require additional measures for securing.

What materials to make the boiler from?

During operation, the structural elements of the boiler are exposed to high temperatures, so thick metal must be used to assemble it to prevent burnout.

If a suitable pipe or container could not be found, then such a device can be made according to the drawing from sheet iron.

Metal sheets

For the walls of the unit, sheet steel grade St3 with a thickness of 5 mm is suitable, the bottom should be even thicker - at least 10 mm.