Design features of a furnace made from wheel rims

A do-it-yourself sauna stove made from old machine disks is the best option. Compared to metal store-bought stoves, they are cheap, simple in design and can last no less time than store-bought stoves.

Furnace design features:

- Small size.

- Easy to assemble.

- The material used is strong, durable and resistant to damage.

- The round shape of the wheels is the optimal shape for a sauna stove.

- For kindling in the summer, only a couple of logs are required (preference should be given to pre-prepared oak firewood).

- The stove cools down quickly: in winter cold the process of cooling the stove takes approximately 2 hours.

- During the fire, you can wash in the bathhouse, since there is no accumulation of carbon monoxide in this design.

- Possibility to use different materials for heating the bath.

Thanks to the different sizes of wheels, you can choose the size of the future furnace. If you need a sauna stove of decent volume, then the ideal option is a sauna stove made from the disks of any model of truck.

Operating principle of a disk furnace

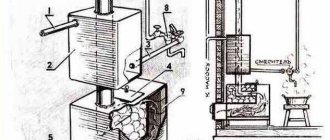

The operation of a homemade sauna structure made from car rims is based on the following principle: burning fuel transfers heat from the first to the second body. These two rims are welded to each other. The first disk has no bottom, the 2nd one has one. You can put stones in it.

A pipe is installed through both rims to remove products resulting from the fuel combustion process. The 3rd disk has a gas divider made of metal. It takes the place of the bottom. Thanks to the divider, the burned fuel is cleaned, resulting in the stove releasing even more heat.

At the final stage, the temperature of the heated carbon monoxide decreases in the 4th disk. The fourth disk is a tank with a tap built into it, as well as a lid. A homemade sauna stove made from disks works no worse than a factory one. And the service life is much longer.

Materials and equipment for manufacturing

A stove made from discs for a sauna is easy to make. To create it, you need the following construction supplies:

- Metal cutter or grinder.

- Welding machine, electrodes.

- Special elements for protection: leggings for legs, glasses for eyes.

- Two metal pipes 50 cm long, with a thickness of only 5 mm and a diameter of 16 cm.

- Iron sheet 8 mm.

- Large bolts and nuts.

- Fire resistant brick.

- Clay, cement for masonry.

- Iron sheet with a thickness of 8 mm.

- Large sized bolts and nuts.

- Fireproof brick.

- Clay, cement and concrete mortar.

- 4-6 channels.

To create a stove body for a bathhouse, you will need 4 wheel rims, preferably from a truck, for example, from a Kamaz. The diameter of such a furnace is half a meter. The thickness of the stove walls is 1 cm. These dimensions are quite sufficient for heating a small bathhouse.

Scheme of a sauna stove made from KAMAZ rims, drawing

It is best to use wheels from KAMAZ or other trucks to install a sauna stove. This will lead to a significant increase in service life.

The meaning of the design is the vertical arrangement of the disks on top of each other. Fastening is done by welding.

The design includes the following parts:

- The first disk is the firebox, where the fuel is placed.

- The second disk is a heater.

- The third is the heat exchanger.

- The fourth is a container for heating water.

Sometimes metal legs are added to the structure for stability of the stove structure.

Preparing tools

If you decide to make a hearth for a cauldron or a regular stove using car wheels, then you need to take care of the availability of tools, among them the following should be highlighted:

- welding machine;

- electric drill;

- chisel;

- sledgehammer;

- disks;

- paint brush;

- ruler;

- grinder;

- hacksaw for metal;

- hammer;

- file;

- pliers;

- roulette

It is noteworthy that almost any of the disk-based models made will be portable, which is very convenient, because this design can be used in a bathhouse or on the street. It is best to use stamped steel disks, the diameter of which varies from 40 to 50 cm. Their height can be 25 cm. The hearth for a cauldron, like a sauna stove, cannot be made of aluminum disks, or those made on the basis aluminum alloys.

DIY sauna stove made from wheel rims

To create a stove from disks for a bath, it is recommended to first prepare the material: thoroughly clean the machine disks from rust, dust, dirt, and paint residues. For this, sanding paper is used. After bringing the disks into proper condition, you can begin to build the structure.

Water container

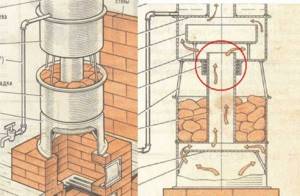

To create the last, upper part of the oven, you need a pair of car wheels. This compartment is designed to heat water.

Important! The tank must be sealed.

A grinder is used to cut out the central plates for fastening. Only the rims are left. After cutting out the central part, the remaining rims are firmly welded.

Cover the surface of the second tank with a lid. You can use a damper. For greater safety, it is recommended to weld the lid, leaving a small hole for pouring water. A metal plate is placed at the bottom of the tank.

When all welding activities are completed, holes need to be cut at the top and base of the tank for a chimney that will stretch across the entire tank. A thin tube is mounted on the sides, at the bottom level, always at an angle. It is closed with a tap designed to drain hot water.

The tank should be carefully checked for any cracks or holes through which water can leak. If defects are detected, they can be easily eliminated by welding.

Arrangement of the heater and the upper part of the firebox

The third and fourth discs are designed to create a heater and firebox roof. The middle of one disc needs to be removed, while the other needs to be left as is.

Place the disks on top of each other and cook. The hub of the untouched disc is located in the center. It will act as a lattice. Stones are placed on top of the open container. There is no need to close the container.

To make a heater, natural stones with an even, rounded shape are perfect. These include basalt, peridotite and others. Their price is quite high. For a budget option, ordinary river pebbles are good. These stones have already been hardened by exposure to the sun and water. It is recommended to choose stone types with a dark color and uniform structure.

Important! Stones are subject to destruction under the influence of high temperatures. This creates obstacles for the full release of smoke. The contents of the heater must be changed periodically.

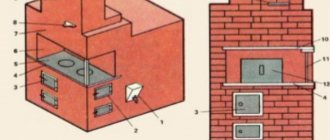

Foundation and brickwork

After collecting the main elements of the stove body from the sauna disks, we begin to create a strong base that is resistant to high temperatures. The material used is a concrete screed. Brick is perfect for lining the outer surface of the foundation. The base must dry. Only after this can you work on the lower part of the structure.

For example, a stove with a masonry size of 62*62 cm will require 60 red heat-resistant bricks. They are held together with clay or cement and placed in a square shape. Be sure to leave room for the blower hole for the door. At the top – the grate is attached.

Stove assembly

You need to assemble the parts of the stove from the rims for the bath sequentially.

Connect the metal part to the lower brick part. Cut doors from a sheet of metal for the opening of the firebox and vent. Close them with the resulting doors. To make it convenient and safe to use the stove, it is recommended to make handles for each door in advance. Larger bolts can be used.

The firebox requires an additional metal latch and a loop made of the same metal so that the fuel cannot fall out of the stove and the wood can burn quietly, giving off heat to the room.

Between the heater and the firebox there is a central hole in the hub. A second pipe is welded to it and secured by welding to the top of the chimney.

The stones are placed in the heater as follows: the bottom row is large and medium-sized stones, and the top row is smaller stones. To create a durable structure, metal channels are welded to the rim of the heater and the water tank. They are attached to the top of the stove at a slight angle.

The pipe must be led into a chimney equipped with heat-resistant bricks. The presence of a damper is mandatory. It will take no more than an hour to heat water in such a stove.

The stove is a friend on a hike and in the country

Don’t be lazy - spend 3-4 hours of free time and become the owner of an amazing and very functional stove made from wheel rims. Its advantages are obvious:

- light;

- portable;

- heats up quickly and releases heat;

- budget;

- any fuel is suitable for it;

- does not burn out.

A mobile stove made from old wheel rims will become indispensable for use in a bathhouse. And if you build a stove with a place for a cauldron, the device will be a great addition to outdoor gatherings or meetings with friends in the country. By placing a cauldron on it, you can safely prepare delicious soup or porridge, and by removing the cauldron and placing a grate on top, you will get excellent kebabs.

Fire safety rules when installing homemade stoves

The oven, made from old car rims, creates heat using infrared radiation. To transform the infrared flux into heat, you will need to make a furnace casing from metal sheets. They are fixed at a distance of 7 to 10 cm from the heater. The same size gap between the floor and the stove.

There are general rules for the safe operation of disk sauna stoves:

- Place a concrete or iron slab on the floor. In this case, this structure must extend beyond the edges of the furnace by more than 60 cm in four directions. This will help eliminate the possibility of a fire if coal or other fuel falls out.

- The chimney and stove made of metal should not touch easily and quickly flammable materials. In this case, it is recommended to use special insulation gaskets.

- Before lighting the stove, be sure to check the draft in the channels. If it is absent, warm up the chimney a little or clean the chimneys and ash pan.

- Liquid firelighters should not be used because they can easily cause fire to be thrown into the room from the firebox.

How to use such a stove?

Before using this oven for the first time, let it sit for about 3 days. Next, you can carry out the first test fire. It is advisable to warm up the potbelly stove for at least 3 hours in a row for the first time with a full load of fuel. The doors and vent must be open at this time. During this period, all surfaces of the furnace will be fired. You can immediately detect minor defects in welds and correct the situation so that in the future the stove does not smoke during use. True, they can be eliminated no earlier than a day after the fire-test, so that the device cools down well.

You can decorate the oven at your own discretion. In the instructions above we told you how to make a permanent furnace. But in reality, you can simplify your task somewhat. An example is in the video above.

You can use such a potbelly stove in the same way as a regular one from a store. Be sure to follow the operating rules and ensure maximum fire safety.

Also remember to clean your chimney regularly. The recommended frequency is at least once every 1.5-2 months. If the diameter of the pipe is very small, then it is better to clean it at least once every couple of weeks.

Please follow safety precautions when using this oven.

Making a potbelly stove from car wheels is not as difficult as it might seem at first glance. The main thing is to have the appropriate skills and some free time. But such temporary “investments” will certainly pay off handsomely and save you some money, with which you can buy something useful for your car.