Hello! Is it possible to replace the valve in a brick kiln? Since the frame from the old valve has collapsed and the heat is escaping. Olga

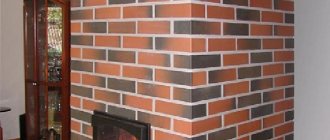

Changing the valve in the furnace is simple, although a little troublesome. We are probably talking about this model:

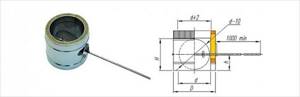

The simplest valve model for a brick kiln

Frames are not sold separately from them, so the first thing you need to do is buy a new bolt instead of the old one. If there is one valve on the stove, and there is room for a second one, higher up the pipe, then it is better to immediately install the second one. In general, it is necessary to install two valves - one or two rows of masonry, one above the other - this way the heat is retained better. The air gap principle. But sometimes this rule is neglected. Therefore, if you had one valve, it is better to immediately install a second one.

Sometimes valves are not installed on the pipe, but as gas flow regulators. But since we are talking about blowing out warm air, then, most likely, it is the valve on the pipe that is meant.

- Part of the masonry is being dismantled. Sometimes it is necessary to hang the pipe first. But this rarely happens. Most often, part of the masonry is simply dismantled from the front side. The dimensions of the window in the pipe for replacing the valve are regulated by ease of operation.

Everyone operates in different ways. Personally, in such cases, I simply clear out the seams in the masonry with an old dull kitchen knife - the stoves are laid on clay mortar, so this tactic is quite applicable. After clearing the seams to the depth of the brick, the brick is easily knocked out with light blows of a rubber mallet. This option is quite long - it is not easy to clear the seams. But it guarantees the safety of the brick. By the way, you only have to tinker with the first brick - the rest are easier.

Some people prefer to simply crumble the brick and subsequently replace it with a new one. Here it’s more convenient for someone.

- Then remove the old valve frame. It is placed only on the solution, without any wire, so it will be easy to remove.

Usually the seams and bricks in the area of the valve are heavily smeared with soot. The solution does not fit well on such a surface, but it is not difficult to help: just wipe the surface with the clay solution several times, as if rubbing it in. The clay solution removes soot as easily as rubber removes dirt from locks. Now you can safely repair the masonry - the mortar will firmly adhere to the brick.

- The new valve is placed on a sand-clay solution. The main thing is to choose the right fat content. When rubbing the solution between your fingers, you should feel solid greasy grains. If they seem dry and non-slip, then clay should be added. If they are too fat, with gaps, add sand.

It's a good idea to add some table salt. It will give strength to the “patch”. The proportion is as follows: a kilogram pack of table salt of any grind for 10-12 liters of clay solution.

- The brick and the place where it is installed in the furnace body are abundantly moistened with water. Otherwise, you will end up with a weak seam. And the solution will form lumps, the seams will come out with voids.

The seams are filled as tightly as possible. After some time, it may be necessary to re-grout the joints with mortar.

In the area of the valve, the furnace does not get particularly hot, so work can be done on a cold furnace. The oven can be operated normally immediately after repairs are completed.

Construction portal about construction technologies, repair and operation

Design of a furnace valve and its installation in a pipe

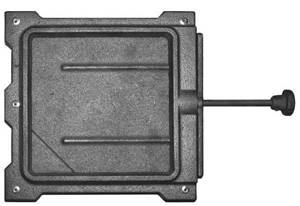

A stove valve is an integral part of any stove, the role of which is to regulate the draft in the chimney when the stove is already flooded and at the end of the fire in order to disconnect the stove from the chimney, as well as to switch the chimneys in combined stoves. The product consists of a frame and a slider. It performs its function by moving the slider in the grooves of the frame, as a result of which the cross-sectional area of the inlet of the chimney changes. This leads to a decrease or increase in vacuum.

Types of gate valves

The valve for a fireplace or stove comes in several types:

- Retractable horizontal installation . In this case, there is a plate inside the gate that extends, as a result of which the cross-sectional size of the ventilation or chimney pipes changes. This type of damper is used when installing brick chimneys; they are distinguished by their horizontal arrangement. The plate has special small holes - even in the closed position they do not completely block the air duct. This feature allows you to avoid future fires.

- Classic butterfly valve . Such a damper operates due to rotational movement inside the air duct. Such a gate installation consists of a metal body and a removable rotating disk. If used for a long time, it may become faulty, but replacing the part will not be difficult. You can perform this procedure on your own. Even in the absence of certain skills, you can do the entire design of a classic-type throttle installation with your own hands. This type of gate valve is easy to use and does not require constant monitoring by the property owner.

- Air gate valve for chimney . Refers to control parts that control the amount of fuel in the combustion chamber. Workflow management is carried out automatically.

Furnace valve design

The furnace valve is a structure consisting of three parts:

- Cast iron body - frame (sometimes steel is used instead of cast iron) with side grooves.

- The locking part is in the form of a panel damper, thanks to the movement along the grooves of which the sealing of the chimney is controlled.

- The control part on the panel damper is in the form of a handle. This makes it easy to operate the panel damper manually.

The shape of the valve must completely coincide with the shape of the chimney; according to this parameter, they can be rectangular, square, or round.

Functional purpose of the gate

To understand the purpose of this part for the chimney structure, you need to understand what a damper in a stove is. The damper provides a change in the traction force in the unit by adjusting the combustion of fuel in the firebox.

This element has an important advantage - it has low resistance relative to the remaining gas bubbles, which must be removed outside the room. When the chimney is inoperative, then the damper is completely closed.

A few words about rectangular valves

A rectangular valve can be of various sizes from small to very large, when the length of the valve reaches up to 600 mm. Large options are usually suitable for Russian stove chimneys, fireplaces, barbecues, etc. The purpose of the design is the same - to block the flow in the air ducts.

The smallest furnace valve has dimensions of 13x13 cm, and the largest is determined according to the individual requirements of the consumer. The most popular size for these structures is 26x13 cm, since these are the dimensions of the chimney of an ordinary Russian stove.

Thanks to square or rectangular stove valves, you can not only stop the air exchange in the pipe, but also adjust the intensity of the fire by changing the chimney draft and throughput. For this purpose, simply close the damper not completely, and then gradually pull the handle towards you, thereby controlling uniform combustion in the firebox.

Why do you need a chimney damper - what is a damper, types, installation rules

A damper is a damper, a valve for a stove chimney, designed to improve draft in it. This part is made of metal. It is installed at the stage of construction of the chimney pipe and ventilation passage.

Draft is of great importance for the functioning of the heating unit. When it is strong enough, the fuel burns completely, resulting in reduced costs. When the draft is poor, a fire can occur at any moment, and to prevent this, install a damper for the stove or fireplace.

The valve prevents the division of mechanical inclusions released during fuel combustion, which are gas bubbles and particles. Due to this property of the gate, it is used when heating a room with gas, coal, oil products, etc.

Round furnace valve or view

A round-shaped stove valve is otherwise called a view. This is a special valve with a slightly different design than the regular version.

The view consists of the following parts:

- The housing is in the form of a plate, which can be round or square with a round hole.

- A shut-off element in the form of a disk that closes the hole and blocks air exchange in the pipe.

- The control part, in the form of a regular handle in the center of the disc valve.

You cannot use a view to control air exchange, since you need to remove the damper from the air passage manually, which is almost impossible in a heated stove, in addition to exhaust gases. The design is used exclusively as a locking element, often as an additional damper for a complete result before igniting the stove and after it goes out.

It is recommended to install both types of cast iron stove valves far from the firebox.

Technical characteristics of the gate

For the manufacture of gate valves for stoves and fireplaces, stainless steel is most often used - steel that is least susceptible to corrosion processes. The thickness of the metal should be one millimeter.

The surface of the part is ground to an absolute smoothness, which has no defects, so that it can be easily cleaned from dirt and soot deposits that accumulate over time. This circumstance contributes to the appearance of good draft in the chimney pipe, since there is no resistance to the exit of gas particles.

How to close a furnace valve, operating rules

The operation of the furnace valve itself is quite simple, but it is definitely associated with some risks that threaten human health. If you close the structure in a stove that is still burning or if the fuel is not completely burned, then exhaust products can enter the room, poisoning the air.

Therefore, the use of a valve, which allows you to save heat in the furnace for longer, should be used extremely wisely, that is, the structure should be closed on time. It is known that due to the cast iron valve, the heat in the stove and, accordingly, in the room remains for a long time. The use of fuel such as coal increases the temperature inside the furnace by approximately 60-70 0 C.

Sometimes, in order to save fuel, the valve is closed earlier, before it is completely burned, which is extremely undesirable. After all, human health and life are higher than any savings. Closing the damper earlier than necessary increases the risk of carbon monoxide poisoning. Carbon monoxide is a combustion product that is poisonous. Therefore, to avoid such situations, you need to use the chimney valve correctly, following some rules:

- Before closing, be sure to stir the coals to avoid the presence of completely unburnt pieces.

- During the initial attenuation of the coal, when the blue flame is no longer visible on the surface, the damper should be slightly closed, but it is not recommended to close it completely. After all, the presence of coals does not mean that they are completely burned out. If there is a need to seal the pipe, this should be done after complete combustion of the coals.

- Next, you need to open the ashpit so that a draft is formed, and the remaining coals are completely turned into ash and ash.

Photo for publication of the names of the elements of the Russian stove

Polatya door was the same name as the continuation of the stove, on which one could lie, put things, dry shoes and lay out vegetables for drying, such as onions. Added by Alexander from Samara.

A bed is not only a sunbed built between the stove and the wall, but also a wooden flooring built under the ceiling, above the stove. The tents were also located in the corner between the walls. You can dry vegetables on the floors. This is what V.I. writes in his explanatory dictionary. Dahl: “half (from half

) - in general, a platform or platform, a flooring raised above the floor and head; then: a platform in a peasant hut, from the stove to the opposite wall (above the doors, and to the bed, or on the other side, to the kuti); three corners of the floors are adjacent to the walls, the fourth to the golbts, or chamber pillar, and the flooring lies, to one side of the pillar, on the chamber beam, and to the other - on the voronets; this is a kind of mezzanine, mezzanine, useful for the sake of cramped conditions in the hut and for warmth; dormitory. In the old days, people also lived in boyar mansions.”

Podtopok is a small stove for heating a Russian stove (usually under a hearth) or on the side of the hearth.

Flood in a Russian oven

Stove with heating

Additional heating in the furnace

The information was supplemented by Yuriy, a visitor to the KaminTeplo blog.

Podshestok - a cold stove under a pole; small kitchen utensils were stored in it.

Podpechek, under-oven - a cavity under the hearth and bottom of the stove, where firewood was most often stored, dried before heating, and where pets lived.

Half-door - a small door for cleaning out soot, a door for an ash pan. The half-door was installed to provide access to the view.

Hailo - a hole for releasing flue gases into a chimney.

The throat is a hole above the hearth; if the hearth is open, then the stove simply does not have a mouth.

A hole is a window, for example, a window in the bottom of a stove, if the stove is not a classic one, but for example, a heated stove with a flood chamber.

A counter is a long box, a bench for storing utensils next to the stove.

Dushnik, samovar - a hole for connecting a samovar with a lid.

Sand backfill is a backfill of any heat-intensive material over the roof of the furnace; sand was most often used.

The need for valves and views in the chimney

The damper is an integral part of the stove, which closes the chimney after it is fired. In combined stoves, such as cooking and heating stoves, this design allows you to move between smoke exhaust channels.

The damper is usually installed in the chimney when laying the stove, secured with several rows of bricks. Often two valves are installed, especially in rooms in cold climates, when temperature changes are more significant, which leads to rapid heat exchange.

The view is installed in the chimney in the same way, but is usually used in Russian stoves. This valve is closed from the outside using a special door. If it is necessary to ventilate and cool the oven, all this can be done with the view door closed.

The design of the stove view makes it possible to eliminate the installation of an additional valve, because it completely copes with sealing the smoke exhaust pipe. When using the second valve, it is installed below the view.

Damper for a brick chimney.

In fact, it is more correct to call this unit not a gate, but a gate valve

chimney

For some reason, many people think that large valves need to be installed in the chimney.

Then this huge, oversized tongue sticks out onto the floor of the room and spoils the appearance of the entire stove.

Here I want to tell you how to correctly install a damper of the required size in a brick chimney.

Installing a chimney damper is a responsible and important undertaking.

The efficiency of a heat-intensive furnace depends on the quality of installation and the tightness of the valve.

After a heat-intensive stove is heated, its chimney must be hermetically closed with a valve.

If the chimney damper is not sealed, the heat accumulated inside the stove will be lost through it, and the stove will cool down faster.

According to modern fire safety standards, a small hole must be left in the valve to allow carbon monoxide to escape.

A small part of the heat is lost through this hole, but safety is still more important.

Gates are made of steel and cast iron.

Steel chimney damper.

Steel valves are mainly used for steel chimneys.

Due to high temperature expansion, steel valves can jam.

Cast iron chimney damper.

For brick chimneys, cast iron chimney valves are more often used

The valve should be selected in accordance with the cross-section of the chimney.

The most common sizes of brick chimneys.

- Quadruple chimney - there are 4 bricks in the chimney section, the size of the channel of such a chimney is 130 * 130 mm.

- Brick chimney five – 5 bricks in the chimney cross-section, channel size 260*130 mm.

- Shesterik brick chimney – 6 bricks in the chimney cross-section, channel size 260*260 mm.

How to install a valve on a chimney

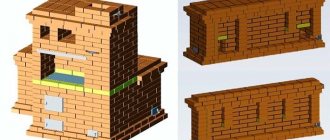

The valve is usually installed during the construction and assembly of the stove. The process is carried out in several stages:

- Laying bricks around the fittings in a selected location at a certain stage of chimney construction. In this case, the dimensions of the hole left must completely coincide with the dimensions of the valve. Often, wire is installed in the corners of the body, mounting it into the body of the masonry.

- Installation of the valve frame with fixation of the upper part using cement mortar.

- Applying cement mortar around the perimeter of the frame and wire about 1 cm thick, followed by laying a row of bricks.

- Installing a damper in the chimney.

A conventional cast-iron stove valve is locked with a panel damper, which is mounted in the frame body through a slot. It can be installed after mounting the frame. The damper on the view is closed manually, so a special door needs to be installed above the body of this design, with which you can control the lid.

After this, installation of the chimney continues accordingly.

Clay-sand solution

The amount of sand in the clay-sand solution is determined depending on the fat content of the clay (fat - 2-4% sand, medium - 15% sand, lean - 30% sand). To achieve the highest quality masonry, sand must be taken sifted through a sieve with 3x3 mm cells.

Proportions of clay-sand solution:

- Fatty clay: 1 bucket of clay, 2.5 buckets of sand.

- Medium clay: 1 bucket of clay, 1.5 buckets of sand.

- Skinny clay: 1 bucket of clay, 1 bucket of sand.

To prepare the solution, place several buckets of crushed clay in a container and fill it with water for 24 hours. Then the required amount of sand is added to the soaked clay in portions, constantly stirring until a homogeneous consistency.

Summer flap and its meaning

Often in stoves there is such an element as a summer damper, which has a specific purpose. The summer damper is used in fireplaces or Russian stoves, which are heated irregularly or periodically at long intervals. For example, in stoves in a country house or village house, when it is heated only in the summer season.

The summer valve has some design features and a special location, which makes the combustion process much easier after prolonged cooling, even in the most severe weather conditions.

The operation of this design is carried out in this way: The stove must be lit with the summer valve open, then, when the flame in the firebox flares up and some of the firewood has completely burned out, the valve must be closed to prevent heat loss.

Stoves with a summer damper installed in them have a number of advantages, for example, by pulling out the summer damper and ash pan, you can use the stove at any time of the year as a classic open fireplace. With the help of a damper you can easily get rid of excess heat in the room. However, it should be remembered that it is recommended to heat such a stove for no more than 20 minutes, since the temperature can rise significantly, which is a feature of such fireplaces.

The stove valve belongs to the category of shut-off valves installed in the exhaust air duct of a heating device.

The design of the chimney duct valve resembles a conventional frame-type valve. Moreover, the requirements regarding the tightness and strength of the device remain unchanged.

Advantages of gate valves

Gate valves, which make up a significant part of the range of many manufacturers of pipeline fittings, have a number of advantages, the most significant of which are given below in the form of short abstracts.

- Gate valves have a short overall length, for example, compared to cranes.

- The design of a gate valve is relatively simple, which, on the one hand, determines its ease of installation (for example, the possibility of replacement without cutting into a pipeline) and ease of operation, and on the other hand, reliability.

- Reliability indicators largely depend on the parameters of the working environment ─ its aggressiveness, temperature, concentration of mechanical impurities.

- Gate valves are unpretentious and not capricious equipment; their maintenance and repair do not require very highly qualified personnel.

- Gate valves from the best manufacturers, who use high-quality components and modern materials in their manufacture, have such important properties as durability, resistance to wear and exposure to aggressive environments.

- The service life of gate valves can be measured at three or more decades, determined by the service life of the body. For other components it is smaller, but also very impressive. For example, for rubber products - at least 5 years. The same is the average service life between major repairs of a gate valve.

- The absence of stagnant zones and the ability to self-clean allow you not to think about slag and dirt.

- An important parameter is the minimum hydraulic resistance of the medium. For example, gate valves manufactured by ARMATEK have a coefficient of hydraulic resistance of no more than 0.3 when the blade is fully open.

- Gate valves have unique technical capabilities, including fast operation and high tightness. Including tightness of the highest class A according to GOST R 54808-2011. Pipeline fittings. Standards for tightness of valves."

Technical parameters and a wide range of functionality ─ a range of sizes, pressures and temperatures that meet all needs ─ make gate valves truly universal pipeline fittings, in demand in a wide variety of technology areas.

Furnace valve design

Like any other shut-off valve, the valve for the chimney duct consists of three elements:

- The device body is a cast iron (less often steel) frame with guide grooves in the side faces.

- The shut-off element is a shield damper that moves in the grooves of the housing and seals the chimney duct.

- The control mechanism is a regular handle built into the panel damper. The simplicity of the design of the control unit is explained by the fact that, in most cases, the valve in the chimney is controlled manually.

Making a damper with your own hands

You can make any type of damper yourself, but only from steel. Cast iron gate valves are manufactured by forging.

The manufacture of a retractable valve is done in the following way:

- Frames are cut out of two steel sheets, the internal dimensions of which are similar to the parameters of the chimney cross-section;

- the damper itself is cut out, 3–5 mm smaller in size than the frame;

Main components of a gate valve

- The structure is welded.

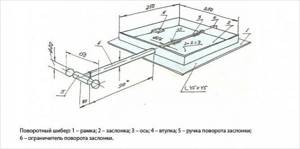

The manufacture of a rotary valve proceeds as follows:

- a circle with a diameter corresponding to the overall dimensions of the chimney is cut out of sheet steel;

- the axis of rotation is prepared. For this element, it is recommended to use a small diameter pipe with internal threads. The length of the workpiece should be 6 mm greater than the diameter of the valve;

- the axle is welded to the damper.

Setting the damper rotation axis

The cost of ready-made dampers is not high, so it is recommended to do it yourself only in exceptional cases.

Installing a stove valve in the chimney duct

Square and round valves are installed in the stove chimney channel directly during the construction process.

The process itself looks like this:

- At a certain stage of pipe construction, a valve frame is mounted on top of the brickwork layer. Moreover, a wire can be attached to the holes in the corners of the frame body, which is passed into the body of the masonry.

- Next, a fastening solution with a thickness of at least 1 centimeter is applied on top of the wire and frame, on which the next row of bricks is laid.

It should be noted that a typical rectangular cast iron stove valve is locked with a panel damper passed through a slot in the frame body. This element can be installed after installing the valve frame, and during the installation of shut-off valves in the masonry. The view flap opens and closes manually, like a regular lid.

Therefore, it is necessary to install a special oven door above the body of the view frame, by opening which you can “control” the lid.

Features of operation of dampers

The process of operating the shut-off elements of a chimney is associated with a certain risk: after all, if you close the valve while the fuel is burning, carbon monoxide and combustion products will go into the living room.

Therefore, the use of chimney valves must comply with the following safety regulations:

- Firstly, the damper should not be locked completely, despite the possible leakage of warm air through the chimney. After all, safety comes before savings.

- Secondly, if the need to seal the air duct does arise, such action should be organized only after complete combustion of the fuel. The presence of coals is not a sign of complete combustion - only ash should remain in the firebox.

- Thirdly, in order to avoid heat leakage through the stove chimney, the air duct damper should be closed only in conjunction with the door of the supply chamber (blower).

Making a rotary gate yourself

When using a chimney, it may be necessary to replace the damper, and a standard damper is not suitable for this design. In this case, the damper is made independently according to the dimensions of the pipe.

To work you will need metal scissors, a drill, a grinder and a welding machine.

- A frame for the damper is welded from steel corners with a flange size of 35–45 mm. The size of the parts corresponds to the diameter of the pipe.

- Holes are drilled in the frame to secure the axle. For a gate with straight rotation, they are located in the horizontal plane, and for an angular one, they are located diagonally.

- Bushings are welded from two sections of half-inch pipe, which ensure rotation of the axis.

- The damper is cut to the size of the frame; the material is a steel sheet 2–3 mm thick.

- An axis on which the damper will be mounted is inserted into the holes in the frame. The second part of the metal piece will become the adjustment knob.

- The plate is inserted into the frame and fixed to the axis by welding.

- For safe use, there must be a 1mm gap between the flap and the frame.

- To ensure the plate is fixed in the open state, a limiter is installed.

Drawing of a rotary gate valve

Note! The choice of damper model depends on the design of the chimney and the type of heating system, but its installation is mandatory. The device allows you to regulate the draft level and keep the heating system in working condition.

Installation features

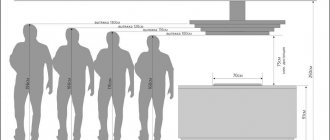

- When installing the gate at the stage of laying brickwork, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should stand straight, without blocking the outline of the chimney;

- In stainless steel chimneys, the valve is installed using the “pipe-to-pipe” technology. It is necessary to coordinate its dimensions with the diameter of the channel;

- An important nuance - the damper is installed on an uninsulated section of the chimney;

- The height from the firebox to the damper should not exceed 1 m (for metal channels);

- Pipe height from the floor to the valve - 1.8 - maximum 2 m (for brick);

- The damper in the grooves should move freely;

DIY making

Option 1. Manufacturing a rotary gate from stainless steel

We offer detailed instructions for manufacturing the damper already with a finished stove heating, when the design is completed, but the damper mechanism was not provided.

To make and install a gate valve with your own hands, you will need the following materials:

- grinder, cutting and grinding abrasive wheel;

- drill;

- tap;

- oil for lubricating the tap when cutting threads;

- hammer;

- vice;

- pliers;

- welding;

- core;

- electrodes for stainless steel;

- compass;

- roulette;

- permanent marker.

The materials you should immediately prepare are:

- stainless steel sheet 1.5 -2 mm thick.

- stainless steel tube with an internal diameter of 6 mm;

- 2 bolts 8mm,

- nail (or metal rod).

When all the tools and materials are prepared, you can begin to carry out the work.

- Measure the inside diameter of the pipe and mark it on the stainless steel sheet using a compass.