For many of us, an autonomous heating system is truly a lifesaver, thanks to which we can make almost any home comfortable and cozy. A warm water floor is one of the most comfortable, efficient and convenient ways to heat residential premises. Despite the relative simplicity of the design and understandable operating scheme, even such heating systems can fail. Emergency situations in this case are rare, however, often quite unpleasant. The main problem that owners of private houses and apartments face in this situation is damage to the water circuit. Due to disturbances in technological processes and or as a result of mechanical damage to the pipeline, a leak appears.

If you experience malfunctions in the heating system, it means that your underfloor heating is damaged. If traces of coolant leakage are visible, the pressure in the system has dropped, it is necessary to urgently eliminate the situation. Otherwise, the situation threatens a new overhaul of the screed and reconstruction of the floor covering. We will consider in detail how to find damaged water floor pipes and what algorithm of actions in such a situation.

Reasons why underfloor heating may be damaged

In terms of its reliability and operational parameters, heated floors are one of the most reliable, practical and durable heating systems. Design features allow you not only to install heated floors in your home yourself, but also allow you to troubleshoot technical problems on your own. From a technological point of view, any underfloor heating system is worth the investment and effort, however, even the most reliable equipment can fail, and at a completely inopportune moment.

For reference: functionally, a properly installed heated floor can effectively do its job for a long time. According to the technology, a water floor works normally for 25-30 years, if all operating parameters are followed.

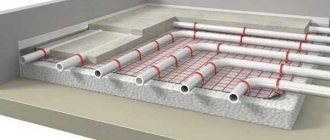

If the problem with a warm water floor is not critical, you can try to correct the technical failures that have arisen yourself. However, in order to do everything right this time, you need to have an idea of how the water floor in your home works. The main reasons why a coolant leak may be detected in a warm floor are commonplace. This is usually our negligence. In most cases, damage to the water circuit occurs during construction work.

When working with heavy mechanical tools, for example, a hammer drill, it is very easy to cause mechanical damage to a pipeline embedded in a concrete screed. If you do not know how the pipe is laid in the floor, then in this situation the probability of damaging the integrity of the water circuit is almost 100%.

During installation, careless behavior of workers can lead to the pipe receiving mechanical damage even before it is laid. An ordinary accidental blow with a hammer or a drop in gravity will cause microcracks to appear on the walls of the pipe.

For reference: such troubles often arise in an apartment with electrical wiring, when installing suspended ceilings, installing or dismantling interior partitions. The absence of a technological diagram leads to unauthorized damage to the electrical cable. The situation is similar with heated floors, both with water and electric cables.

Another reason why a break may occur is a defective water circuit pipe. This is in most cases due to the use of consumables of unknown origin during the installation process. The discrepancy between the pipe material and the technological parameters in which the heated floor is used often leads to a violation of the integrity of the pipeline.

For example: a pipe from an unknown manufacturer, with a missing certificate, may have uneven wall thickness. As the temperature of the coolant and operating pressure in the system increases, weak points in the pipeline can become a rupture point.

In this aspect, it should be recalled that unprofessional installation of the heating system often causes leaks. Poorly made connections become the cause of a violation of the integrity of the water circuit in 50% of cases.

Note: professionals recommend using whole pieces of pipe when laying a heated floor pipeline, trying to ensure that all fittings and joints are brought outside.

It is almost impossible to detect the extent of damage by eye. At first glance, the pipe may appear intact; the joints appear to be strong and reliable. When starting the heating system, the pressure in the pipeline increases (1.5-2 bar), which naturally forces the liquids to look for an outlet in weak points of the water circuit.

The last mistake that can cause damage to the integrity of the pipe is an incorrectly laid screed.

At first glance, there are many reasons why a heated floor can be damaged. Don't panic. In this situation, the main thing is to choose the right course of action and begin eliminating the accident.

Metal-plastic pipes:

When choosing press fittings, the manufacturer does not matter much. To choose it correctly, you need to know the diameter of your pipe and the thickness of its wall. When installing, pay special attention to whether there are rubber O-rings under the steel sleeves.

This type of fitting is crimped with a special tool.

Practice and time have proven that for pipes made of cross-linked polyethylene, fittings of all brands described below can be installed and this does not depend on the manufacturer of the pipe itself.

Rehau makes fittings of this type:

There are plastic and brass fittings. It is placed inside the pipe, on which the mating part is already put on in advance, and with a special tool it is put on the fitting itself, thus crimping the pipe.

Uponor provides another method. I like him much better. We also take the fitting from plastic or brass.

There are minor differences in the principle of operation of this method from the one described above. In this case, you need a special plastic ring that fits onto the pipe. Next, the ringed pipe is expanded with a specially designed tool, and a fitting is placed in the middle. After some time, the expanded pipe with the ring put on “sits” on the fitting and compresses it. This type of connection can easily rotate around an axis.

Any questions? Write to us!

Troubleshooting a heated water floor

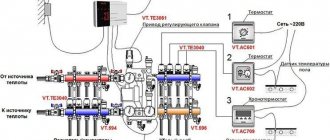

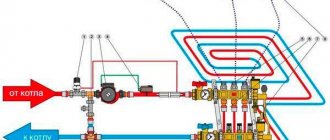

When a break in a heated floor is identified, repair work is carried out according to a specific algorithm. The important thing here is that almost all the main elements of the heating system are within reach. The procedure to follow in a situation where it is necessary to eliminate a leak in the water circuit is as follows:

- the water supply to the water circuits stops. For this, all supply valves on the manifold are used (you do not know in which circuit the break occurred);

- if the damage is caused by the operation of the tool, then it’s easier for you, you know where the leak is located;

- the leakage area is cleared of screed and construction debris;

- Remains of concrete should be removed and access to the damaged pipe should be done carefully. You need to work with a hammer drill step by step, breaking off small fragments of the screed within a radius (10-15 cm) of the damaged area.

Now that you have the location of the damage in front of you, the whole task comes down to pressure testing the water circuit. For this purpose you will need a hacksaw or metal scissors. The edges of the cut pipe are thoroughly washed to remove dirt, shavings and debris. The edges of the pipes are unfolded using a special reamer. This is done to align the hole and whatever happens after. The fitting did not slip off when put on. Only now can you put a fitting on the cut pipe and press it into place. Next, the other end of the damaged pipe is prepared and pressure tested in a similar manner.

In place of the damaged area, a prepared piece of pipe of identical diameter and size is installed, not much longer than the length of the removed fragment.

Having completed the installation and eliminated the break point, you can begin to introduce water into the pipeline system. If everything is in order and no side effects are observed in the operation of the water circuit, you can begin to restore the screed.

Important! After completing the restoration work, you should draw up a clear plan - a diagram that will indicate the location of opening the screed and installing a new connection. This precaution will allow you to know the location of the break in the event of further maintenance work or during renovation of a residential premises.

In the video you can see how to fix a water circuit leak.

No repairs will be needed if...

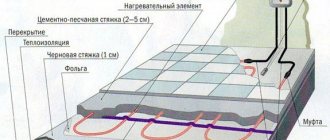

When installing a heated floor, it is especially important to take into account several rules, which will not be superfluous to know.

- The reason for poor heating of an electric floor is often the incorrect choice of the type and power of the heating cable and insufficient thermal insulation.

- It is better to go shopping for the necessary equipment and materials together with a specialist who will install the heated floor.

- Choose a heating element size in accordance with the length of the room, since cutting the cable reduces its strength.

- It is prohibited to lay the heating cable in places where furniture will be located due to the risk of overheating of the wire.

- Before laying the heating cable, thoroughly clean the floor surface. Do not step on the cable during installation.

- The temperature sensor is installed in a corrugated tube so that it can be accessed in case of necessary repairs.

- There should be no voids around the heating element, which could cause the cable to overheat.

- It is necessary to draw up an installation diagram to avoid accidental damage to pipes or cables.

- Check the wires after installation by measuring the resistance.

- Turn on the system after the screed has completely dried.

- Measure the resistance before and after installing the heated floor system. It must correspond to the data in the technical passport.

How can you identify a hidden water floor break?

In a normal situation, when you yourself see the location of the cliff, the procedure is simple and clear. What to do in those cases when you don’t have the slightest idea where your leak is. Linoleum, tiles or other types of flooring skillfully mask the location of the leak, while water freely flows into the subfloor, destroying the structural elements of the house or, worse, flooding the neighbors below.

To find the location of a water circuit break, there are a lot of primitive and simple methods, starting with filling the system with colored liquid and ending with supplying high pressure air into the pipeline. The release of colored liquid or a stream of air will indicate to you the approximate problem area where you should look for a leak.

The examples given are not so complicated at first glance, however, to do this you will have to drain the water from the entire heating system, which at the height of the heating season can lead to significant discomfort.

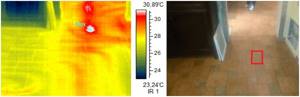

Today, in such situations, a completely different, simple and effective tool is used - a thermal imager. In this case, such a device will allow you to find break points with high accuracy, down to a millimeter. Typically, technicians from companies that service heating equipment use similar equipment. Thanks to a thermal imager, you can not only detect the location of the defect, but also receive detailed recommendations for troubleshooting. Then everything goes according to the thumbnail diagram, opening the screed or tiled covering, cleaning the damaged area and eliminating the failed fragment.

Finding damage to the heating cable

In non-working electric heated floors, one of the reasons for the failure of the heating cable may be a break, damage to the core, short circuit of the wires to each other or to the shielding shell. With this type of damage, the heated floor will still not work after replacing the regulator with the sensor; it is also possible that the RCD or differential circuit breaker will be knocked out.

To find places where heating cables are damaged, we use high-voltage burning, magnetic induction and thermal imaging methods.

Breakage of the heating cable in the heating system of the open area at the entrance to the shopping center due to the installation of a bumper.

After drilling the floor to install a dowel-nail, the following problem may occur with the heated floor.

Repairs to heated floors under tiles can be carried out using a thermal imager. Location of damage to the heating cable on the thermogram.