This heating device is an important component of the installation of a heated floor. It regulates the set degrees that are in the underfloor heating installation.

A module (collector) is a required fragment of an aggregate for greater performance. The combination of a heated floor itself has many advantages compared to conventional heating. Many people use this heating method, most of them abroad.

Unlike the standard steam-type heating method, using a heated floor heats the room evenly, filling the room with warm air, and does not create a draft.

At the same time, there is a significant saving of 20% when using heating and heat energy consumption.

The totality of this installation does not take up space in the room, since the working part is hidden in the coating and is not noticeable.

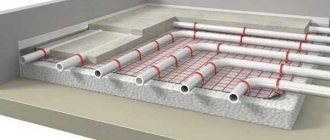

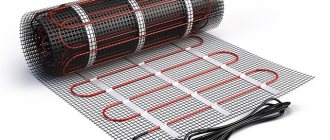

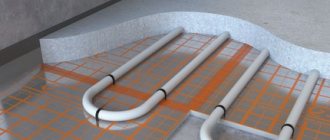

Fact. The substructure is a bundle of thin hoses that is embedded invisibly under the outer covering of laminite, parquet or linoleum.

Thin pipes are filled with water or a specialized liquid.

The substructure is a bundle of thin hoses that is embedded invisibly under the outer covering of laminite, parquet or linoleum.

Key principles when choosing a reservoir

Before choosing a mechanism for installing heating, you will need to clarify the compatibility of these key components.

This is shown by the following characteristics:

- for starters, the price of the key distribution mechanism for heated floors.

- then its reliability and environmental friendliness.

Fact: Hot and cold flows are mixed in the connecting link of the module, its key part.

Modern mechanisms and connections are likely to be improved for greater convenience and practicality of the heated floor.

the mechanism is selected for a given heated floor, taking into account the required pressure for directed fluid flow.

Hot and cold flows are mixed in the connecting link of the module, its key part.

When producing the module, the metals used are brass and other metals that do not rust. This is of significant importance and is an important characteristic when purchasing a tool; it affects the maintenance of a particular type of tool.

Manifold assembly

Having selected all the parts for the heating system, you can begin assembly. The faucet can be installed in an external or internal cabinet, but remember that external cabinets can only accommodate a system up to 16 cm wide.

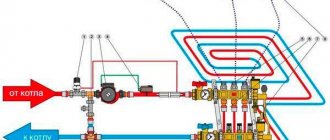

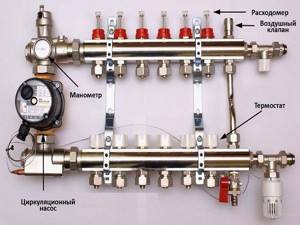

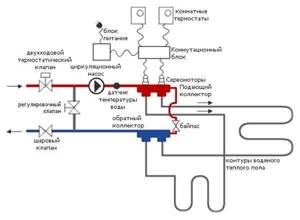

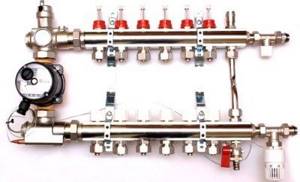

The diagram of the underfloor heating collector is shown in the photo. Read it carefully and assemble your system according to this diagram.

Conclusion

A collector is a necessary thing for arranging a heating system in a house; only the price can scare you, but connecting a heated floor to a collector will significantly reduce energy costs for heating water.

Requirement of a module with a bunch of thermal control

The presence of a significant number of varieties of additions to the main equipment, for greater convenience and testing, such as degree meters, connections with an air release function, flow monitoring and other auxiliary devices.

Fact. Modules using a device for calculating flow rate act as an equivalent mixing link. With the help of two degree sensors, it is possible to bypass energy deprivation.

In each of the heating units, a separate degree name is determined using a brass-based comb tool and a flow meter.

Modules using a device for calculating flow rate act as an equivalent mixing link

This device contains:

- temperature head, in a unit with an embedded probe;

- temperature-static dilution valve;

- case for a specialized temperature meter;

- device for air outlet.

The temperature-static valve distributes the heated water and its quantity. In this case, the combination works correctly, without failure in the heating installation.

Fact. With a large number of different and multifaceted converters, the choice of a specific, required mechanism becomes more complicated.

When purchasing a design for a room heating composition, pay attention to the following:

- the size of the room, apartment, house or room in which the system will be installed;

- what set of functions should be in the mechanism, and their capabilities;

- The cost of the purchase and its justification, price-quality.

For structures used in small rooms, it is enough to use a plastic device. There are no special requirements for this type of building.

With a large number of different and multifaceted converters, the choice of a specific, required mechanism becomes more complicated.

It is definitely not expensive to purchase a distribution device for heating; upon purchase, it includes a sensor for calculating flow and checking and regulating temperatures.

Fact. With the feasibility of distribution adjustment and error-free degree adjustment, the reliability and productivity of such devices is increased.

Main and auxiliary purposes

Separating and mixing water is the main purpose of the mechanism in a flooring system. In addition, he performs support assignments. Often there are two closing valves, one for each one coming and going, so the system is warmed up, checked, and drained. In addition, the converters are equipped with release valves.

With the feasibility of distribution adjustment and error-free degree adjustment, the reliability and productivity of such devices is increased

Auxiliary appointments

Additional meters are installed on the mechanisms; such meters are installed on one current or more to monitor all or part of the installation. For this purpose, a flow metering sensor is used. Flow metering is done to equalize the resistance pressure of cold and hot liquids, and due to the difference in the distances of the nodes. All sources recommend that the pipes in their bundle be made of the same size. But such wishes are not always likely to come true. Since when the building is turned on, the heat will flow along a short path, and without heating a separate section of the room, because such a substructure has the lowest pressure. To avoid this, sensors are installed to record flow. With its support, currents are inspected in each node of the substructure, opening or closing a passage for the flow of warm water.

At the outlet of the installation system, closing valves are installed. With valves, there is a possibility to control the connections, the connection of the device, and at the same time we control the degrees in the aggregate and in the room.

Purpose and design of the collector group

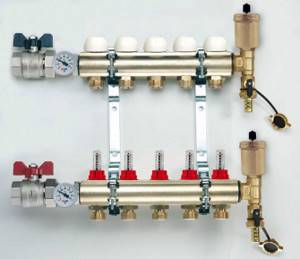

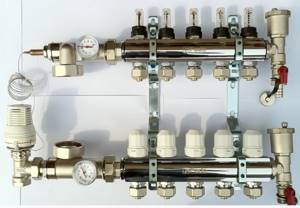

Let's consider the design of a water heated floor collector. The main element is the collector itself (comb). This is a thick piece of pipe with a large number of pipes for connecting forward and return pipes from the underfloor heating circuits and from the boiler.

Monitoring and control devices are also connected here: pressure gauge, air valve, distribution valves, tap for draining coolant from the circuits (selection of components for a heated water floor). Complete drainage of water may be required to repair a water-heated floor collector, boiler or other significant element of the system.

Pipes from the circuits are connected to the combs through valves designed to regulate the water supply. The system consists of two combs: for hot coolant and for return. They are placed in a manifold cabinet or in a specially designated niche. The hot comb is installed above the return one.

The collector unit may have several combs connected in series or parallel. A parallel connection is used when installing two or more circuits (about the layout of a heated water floor). The coolant distribution is controlled by two-way valves.

The materials used to make the combs are polypropylene, stainless steel, and brass. The most economical option is a manifold for a warm water floor made of polypropylene: it is easiest to make it yourself.

Automatic room temperature control device

The temperature control device is an unimportant component of the installations. But it is very convenient, instead of constantly turning on and off heating units, it is possible to install this mechanism and it will perform this work automatically, install temperature meters. Determine the temperature in the house required for comfort. And it will be supported using this tool.

The temperature control device is an unimportant component of the installations.

Such degree meters (sensors) monitor the given degrees of air or in the module. For control, remote meters are installed in the system, which are added to the essential degree meter.

Important. Install and check the functioning of the sensors and structure before the final pouring of the floor.

Adjustment equipment

The fundamental operating principle of a water heated floor collector: when installing (water heated floor installation technology) a large number of circuits, they try to ensure that their lengths are as proportionate as possible. In this case, the coolant flow in circuits operating from the same comb is approximately the same.

But this is not always achieved: the heated area of the bathroom (how to make a warm floor in the bathroom) and the fireplace room is obviously different. In addition, in short circuits there is less hydraulic resistance of the pipes, which means more intense circulation.

To balance the heating of various circuits and ensure optimal heat transfer from each, a manifold for a warm water floor with flow meters is installed. Those. install a thermostat, balancing valve or rotameter on the comb at the outlet of each circuit.

The optimal layout of a warm water floor collector is that two regulators are installed on each circuit, on the supply pipe and on the return pipe. In this case, the input device doses the supply of heated water to this section of the floor, and the return device opens/closes the circuit as the liquid in the pipe cools.

To avoid airing, it is recommended to install an automatic air vent in the system, and the supply and return combs must be connected by a bypass to a bypass valve. When the circuits are closed, the bypass valve, together with the air valve, normalizes the pressure in the system.

There are flowmeters with a measurement function, as well as universal ones that combine measurements with adjustments.

Installation Guide

The structure is connected after the installation for warm liquids has been completed and the cabinet has been built in. At the request of the owner of the home, the cabinet can be mounted in the wall or placed on the wall, depending on convenience. But taking into account the practical connection of outlet pipes to it.

In accordance with the sequence, the installation resumes with installation on the valve module together with the degree meter.

The structure is connected after the installation for warm liquids has been completed and the cabinet has been built in

Important. It is practical to immediately buy a design kit that contains the necessary components for its installation.

At the same time, the installation of this unit is simplified, in addition to the connection of a hose with a heated liquid, and the opportunity to turn off the appropriate unit without incurring losses to other flows.

To fasten devices, valves and valves, use a compressor fitting or specialized connectors, brass-based nuts, a support sleeve and a clamping ring.

The connectors are not always the same diameter, but they use a fitting - an adapter.

In the common conventional method, the entire installation and its principle are shown by a simple module, with closing and opening valves.

The connectors are not always the same diameter, but they use a fitting - an adapter.

Based on this, installation in a simple way is shown as follows:

- With the help of valves, terminals for the outflow and inflow of water are added to it;

- the module is connected to the pipes with collector fluids.

The newest units have a regulation mechanism for heating construction; it contains the following components:

- three-way diluent or pump mixing flow;

- a device for releasing air from the structure mechanism;

- faucet for draining from the structure;

- a circuit that allows heat to pass through a mechanism, a pump.

Such a project will allow for detailed control of plant performance.

To fasten devices, valves and valves, use a compressor fitting or specialized connectors, brass-based nuts, a support sleeve and a clamping ring.

Manifold parts

For stable operation of the mixing unit you will need:

- Mixing valve, which we will talk about below;

- A pump that allows you to control water pressure (for more details: “How to choose a pump for a warm water floor - differences in details”);

- Shut-off and balancing valves;

- Sensors: pressure gauges and thermal head with thermometer;

- Air accumulating in the system interferes with stable operation, so it must be vented using an air vent.

- You will need various plumbing connectors: tees, fittings, etc.

Collector cabinet

For those whose heating structure is located in a separate room, this component is not required. For others, all components need to be hidden somehow, an inflated number of pipes, pumps, mechanisms; for this they use cabinets (pedestals) with fasteners.

They come in both built-in and outdoor versions, where they use materials for the side walls of the cabinet to easily make holes for other parts. There are functions for adjusting the size of the legs, changing the shape of the cabinet itself, and changing the direction of opening the door. The cabinet is attached through the legs or the rear component.

The cabinet is attached through the legs or the rear component.

Some cabinets are made of galvanized material and are spray painted, as a result of which they will not spoil the basic appearance of the room. The walls of the cabinet must be dense to prevent deformation if the functioning of the structure is disrupted.

In reality, it is not possible for all bundles and bundles of pipes to equally consist of the same distance and construction load.

As a result, it turns out that the underfloor heating pipes are of unequal length, resulting in uneven heating of the room or house. As a result, it is inevitable to use valves to regulate the water supply in the device.

Tips for installing a warm water floor collector

Using a factory kit eliminates a number of common mistakes when installing a unit. The finished manifold group for underfloor heating is already equipped with the necessary valves and other important elements.

Be sure to consider the following recommendations:

- The calculation of the thermal load on the circuit is calculated before installation, and based on the data obtained, the balancing valve is adjusted;

- The cabinet for the mixing unit is placed in a place located at the same distance from the connected pipes;

- The dimensions of the collector box should be selected according to the dimensions of the device;

- Under the block, be sure to provide space for bending each contour;

- For a possible increase in water circuits, it is worth leaving several free pipes;

- The most efficient heating system is obtained by introducing a powerful circulation pump;

- When installing multiple pumps, be sure to use check valves.