What is a condensing boiler and how does it differ from a regular boiler?

The main difference between a condensing boiler and a conventional one is the increased size of the heat exchanger. If you don’t understand boilers, then this phrase won’t explain anything to you. Therefore, I will now describe in detail the operating principle of both boilers and in 5 minutes everything will become clear to you.

For example, I’ll take the wall-mounted gas boilers that are installed in my home. In 2008, I installed a conventional Viessmann Vitopend 100 gas boiler to heat my house.

In January 2021, I replaced it with a Viessmann Vitodens 050 condensing wall-mounted gas boiler. Externally, the boilers look almost the same.

In the foreground is a Viessmann Vitodans 050 condensing boiler. In the background is an old Viessmann Vitopend 100

The operating principle of a conventional gas boiler

When gas is burned in the combustion chamber of the boiler, exhaust gases are formed, consisting mainly of carbon dioxide and water vapor at a high temperature. When these exhaust gases pass through the boiler heat exchanger, the heat from them heats the heat exchanger and the already cooled exhaust gases escape into the chimney.

For those who do not understand what a boiler heat exchanger is. If you have a car, then there is a heat exchanger with a fan that is installed inside the car and you call it a stove.

Hot coolant (antifreeze) circulates through the radiator, causing it to heat up and transfer heat to the air, which the fan drives through the radiator. The heat from the liquid (antifreeze) heats the air, this is called heat transfer.

Imagine that a radiator from a car stove was installed in a gas boiler. Hot gases fly through this radiator and heat the liquid inside with their heat. Only, unlike a stove in a car, in a boiler, heat from the air heats the liquid, and not vice versa.

As I wrote above, when gas is burned, water vapor is released. As these vapors cool as they pass through the boiler heat exchanger, these vapors condense. Drops of water appear, which settle on the boiler heat exchanger and begin to corrode it.

The boiler heat exchanger leaked. That's how corrosion ate it

Vapors form condensate at temperatures below +58°C. Therefore, when designing conventional gas boilers, engineers made sure that this temperature passed as quickly as possible.

If you watch the operation of a conventional boiler, you will probably hear that when the burner starts, the boiler immediately turns on at its maximum power. And after a few seconds, the burner flame decreases and the boiler operates in the configured mode.

19 mistakes that are made when installing water heated floors

This was done in order to minimize the occurrence of condensation.

How does a condensing boiler work?

The operating principle of a condensing boiler is exactly the same as that of a conventional gas boiler. But as I wrote above, the condensate heat exchanger is larger. If the heat exchanger is larger, then it will be able to remove more heat from the exhaust gases than a conventional boiler.

Large heat exchanger takes up half the space in a Viessmann condensing boiler

So it turns out that the efficiency of a condensing boiler is greater, since less heat escapes into the pipe when burning the same amount of gas. For comparison: the flue gas temperature of a conventional Vitopend 100 boiler is 105-132°C, and that of a condensing Vitodens 050 is 35-68°C.

There is one more point.

If a conventional boiler tries to quickly go through the condensation phase, then in a condensing boiler, everything is done the opposite. The more condensate appears, the more heat can be removed from it and transferred to the heating system.

Therefore, the most efficient operating mode for a condensing boiler is operation at temperatures below 58°C.

Principle of operation

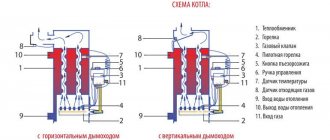

The unit operates in two stages:

- the return flow of coolant enters the condensation chamber . It is a heat exchanger in which the energy from the settling water vapor from the flue gases is transferred to the heating water (heating water). This causes the temperature of the coolant to rise slightly, which makes the heating mode of the gas burner more economical and gentle;

- From the condensation chamber, the OM enters the primary heat exchanger and then the whole process occurs according to the usual traditional method . Having received full heating, the liquid enters the secondary heat exchanger, giving up part of the energy for the preparation of hot water. It then enters the heating circuit or underfloor heating system.

For efficient operation of a radiator-type thermal circuit, it is necessary that the return temperature is not higher than the degree of heating of the condensation chamber heat exchanger, otherwise the operation of the first stage will become impossible.

IMPORTANT!

In Russian conditions, it is physically impossible to provide such conditions, so all that remains is to use condensing models to power the heated floor circuits. Such a limitation calls into question the feasibility of using these units in unsuitable conditions, since the difference in cost destroys all the benefits of fuel economy.

What are the savings from using a condensing boiler?

I have two wall-mounted gas boilers, a regular one and a condensing one. It is clear that one throws water vapor into the pipe, and the second removes heat from it. Let's figure out what the savings are between them, because a condensing boiler costs more than a regular one.

You need to start with the heating system. It can be high temperature and low temperature. If the heating system has a temperature above the dew point, then it is high temperature. If lower, then low temperature.

When heating is done by competent installers, they come up with a system configuration based on the parameters of the heat source. Ideally, the heating system should be calculated and designed.

Agree, it would be stupid to install radiators under each window based on calculations of 10 watts per square meter if your heat source produces a temperature of, for example, +45°C. In winter you will simply freeze.

Since a condensing boiler operates at low temperatures, it makes sense to install it on low-temperature heating systems. And if, for example, for comfort in your home, the temperature of the radiators must be at least 70°C, then there is no point in installing a condensing boiler. You'll just overpay for it.

When operating at temperatures above 55°C it will operate with the same efficiency as a conventional gas boiler.

But if you have a low-temperature heating system, for example, heated floors, then a condensing boiler is what you need. The first advantage of its use is the savings of the boiler itself at the gas combustion stage.

Do-it-yourself piping of a solid fuel boiler

The second huge plus is the opportunity to save on the configuration of the heating system. The condensing boiler can be directly connected to water heated floors without spending money on mixing units. Without which, water floors cannot be connected to a conventional boiler.

How much did I save

As I wrote above, in 2021 I replaced a conventional boiler with a condensing boiler. I live in a private house with an extension. The area of the house and the extension are approximately the same. The house has radiators and the extension has water-heated floors. The gas boiler is controlled by a mechanical thermostat.

This thermostat controls my condensing boiler

After replacing one boiler with another, gas consumption decreased by approximately 20%. Previously, we paid 4,000 rubles per month, but after installing the Viessmann Vitodens 050 condensing boiler, we began to pay 3,000 - 3,200 rubles per month.

Equipment advantages

The list of advantages of condensing boilers is very extensive, which explains the high popularity of this type of heating system. Key advantages include:

- Economical. If we compare condensing boilers with conventional convection models, they consume 35% less fuel, which can significantly reduce the cost of heating the room.

- Environmentally friendly. The percentage of reduction in harmful emissions reaches 70% compared to traditional gas installations.

- Possibility of installing plastic chimneys due to the low temperature of the exhaust gases. Plastic models are significantly cheaper than classic steel ones.

- Quiet operation, which increases the comfort level of indoor living.

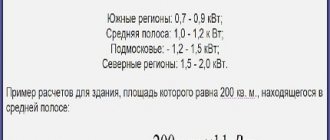

As for fuel consumption, it is determined by both the power of the equipment and the load placed on the boiler. To completely heat a home of 250 square meters, a 28-kilowatt boiler with a fuel consumption of 2.85 m3/h is quite suitable. For comparison, classic gas units will require at least 3.25 m3/h. As a result, over a six-month period of operation, savings of about 3 thousand rubles will be obtained.

Another important advantage of the system is the minimum volume of harmful emissions. During the combustion of an organic fuel mixture, carbon dioxide is formed, which produces carbon dioxide. In addition, any fuel contains chemical compounds of sulfur, nitrogen, phosphorus and many other elements, which also produce acids when in contact with water.

Conventional gas boilers emit water vapor with various impurities into the air, polluting it. Condensing units do not have this disadvantage, because all acids do not leave the condensate.

Disposal of condensate into a septic tank

Quite often my customers (I install heating systems) ask: can condensate be drained into a septic tank? They’ve read all sorts of things on the Internet or other installers have told them the passions and now it’s generally unclear where to drain the condensate.

You know, I’ve been working in construction for 20 years and I realized one thing: we must try to stay away from people who know everything. It is those who say that they are super professional and know everything who screw up the most. At least that's what I'm encountering.

My approach is simple: why do I need to know everything if every piece of equipment has instructions for its use? If you have a question about condensate, then most likely this is written in the manufacturer’s instructions for the boiler. I have a Visman boiler, I open the instructions for it and read:

During heating mode, condensate with a pH value between 4 and 5 forms in the condensing boiler and in the chimney. The condensate must be discharged according to regulations.

Instruction DWA-A 251 “Condensate from condensing boilers”, on the basis of which local regulations on wastewater treatment are usually drawn up, defines the conditions for the discharge of condensate from condensing boilers into the local sewerage network.

If you look at this German instruction DWA-A 251 and translate it, it says: condensates from natural gas combustion systems with a power of up to 200 kW are usually sufficiently neutralized by mixing with domestic wastewater.

Let’s say that I don’t trust the Germans or don’t know how to use the Internet and a translator, how can I decide whether condensate can be drained into the sewer or not? The instructions for the boiler indicate that the acidity of the condensate pH is between 4 and 5. For example, tomato juice has an acidity of 4.1. Beer has a pH of 4.5, while black coffee has a pH of 5.

How much does a room thermostat reduce heating costs?

What will happen to the septic tank if you pour coffee or tomato juice into it? Probably nothing will happen to him.

I have been draining condensate into a septic tank for over a year now and have not noticed any problems.

Rating of the TOP 10 best condensing gas boilers of 2020-2021

This rating includes the best condensing gas boilers in terms of quality and reliability.

| Place | Name | Price |

| TOP 5 best condensing double-circuit gas boilers | ||

| 1 | BAXI Duo-tec Compact 24 20 kW | Find out the price |

| 2 | Protherm Lynx 18/25 MKV 18 kW | Find out the price |

| 3 | BAXI LUNA Duo-tec MP 1.60 55 kW | Find out the price |

| 4 | BAXI LUNA Duo-tec MP 1.35 33.8 kW | Find out the price |

| 5 | Viessmann Vitodens 111-W B1LD031 35 kW | Find out the price |

| TOP 5 best condensing single-circuit gas boilers | ||

| 1 | Protherm Lynx 30 MKO 30 kW | Find out the price |

| 2 | BAXI LUNA Platinum+ 1.32 34.8 kW | Find out the price |

| 3 | Vaillant ecoTEC plus VU INT IV 346/5-5 30 kW | Find out the price |

| 4 | BAXI LUNA Platinum+ 1.24 26.1 kW | Find out the price |

| 5 | BAXI Duo-tec Compact 1.24 24 kW | Find out the price |

Errors during boiler installation

When we installed a condensing boiler at my home, we made several mistakes. The first mistake is the lack of a break in the stream at the condensate drain. I did it consciously. But since it’s at my house, I turned a blind eye to it.

When I do heating and get paid for it, then I do everything right. So that there are no conflicts and claims. We installed a condensing boiler at our home on January 2nd. The shops were closed, so I temporarily stuck the hose from the boiler into the sewer pipe.

The hose from the condensing boiler was stuck into the sewer pipe

But nothing is more permanent than something done temporarily. This is the second year that my hose has stuck out like this.

A break in the jet is needed so that when the sewer is clogged, crap does not go into the boiler. There were precedents. The customer complains that the boiler is not working, the installer opens it, and it is clogged with feces. This can happen if the drain is clogged and there is no break in the flow.

Siphon with jet break. Don't forget to make a water seal. Or install a valve with a dry seal so that the smell does not come from the sewer

The second mistake I made was with the chimney. For conventional boilers, the slope of the chimney should be towards the street, for condensing boilers it is the opposite. We removed a regular boiler and installed a condensing boiler. I knew about the incorrect slope of the chimney and planned to correct it later. If you are interested in what this led to, then read the article on my Yandex Zen channel .

Burner Premix

The burner is also an important component of any boiler, including a condensing boiler. List of tasks for which she is responsible:

- Ensuring precise proportions of mixing fuel with oxidizer (air).

- High-quality mixing of gas components.

- Ensuring environmentally friendly combustion.

The first two points are necessary to increase the completeness of fuel combustion and, accordingly, the overall efficiency of the boiler. We will analyze them in detail below.

The third point ultimately involves reducing emissions of harmful substances into the atmosphere. In the burners of modern condensing boilers, this is achieved due to relatively low combustion temperatures, which reduces the amount of nitrogen and sulfur compounds formed. To achieve the required power levels when the temperature drops, the flame area in such burners is usually quite large.

The most common are two options for organizing the combustion surface. Cylindrical: And flat:

|

|

| cylindrical premix burner | flat burner premix |

An increase in the combustion surface also provides a larger area of infrared radiation when the burner operates at low power modulation.

The surface material itself is a cellular structure made of metal or ceramic.

|

|

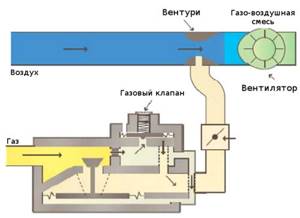

The cellularity ensures additional mixing of gas with air. But the main mixing and control of its proportions in modern boilers occurs before the burner - in the “gas valve / fan / Venturi tube” assembly. Its schematic image is presented below.

Such systems are generally called “Premix”, that is, a pre-mixed system. Precise maintenance of the air-gas proportion is ensured by approximately equal pressures at the mixing point. Moreover, this proportion is maintained over a wide range of mixture flow rates and boiler modulation.

Thus, the general scheme can be described point by point:

- The fan creates high draft, providing precise air flow according to the required power.

- The Venturi tube ensures equalization of gas and air pressures at the mixing point.

- The gas valve maintains the optimal gas-air ratio over a wide range of fan speeds.

- The resulting gas-air mixture enters the burner surface, where additional mixing occurs.

- The mixture enters the combustion area. Moreover, combustion occurs at a temperature low enough to ensure low emissions of harmful substances, but at the same time with a high total power.

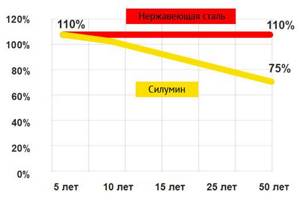

To summarize, we can say that the design of a condensing boiler and the principle of its operation are not that complicated. However, each individual element requires great attention when designing. The correct choice of heat exchanger material, its geometry, and reliable components of the gas-air path are the key to efficient operation and longevity of the boiler. Compared to any traditional boiler, a condensing boiler provides greater efficiency in all operating modes. A heat exchanger made of stainless steel ensures a long service life of the equipment (up to 50 years) without loss of efficiency for any quality of fuel and coolant.

Let's look at how the principles and technical solutions described above are used in HORTEK gas condensing boilers.

The range of HORTEK boilers consists of three lines of equipment:

| HORTEK Q - domestic wall-mounted boilers with a capacity of 25-60 kW with options with a built-in DHW boiler | HORTEK XL - wall-mounted boilers of the industrial series 60-120 kW with the possibility of installation in cascade up to 960 kW | HORTEK HL - floor-standing boilers of the industrial series up to 910 kW with the possibility of installation in cascade. |

Chimney problems

We replace the boiler we already have with a condensing one, and leave the chimney the same, so why bother and waste time and money. And it’s completely wrong, because the condenser boiler needs a different, special chimney made of acid-resistant materials. Well, one can interpret this necessity by saying that the materials must use lead or something similar, the same, also frightening, only in reality everything is a little simpler. Or much...

Photo: gazplus.ru

In fact, it is necessary to use exclusively ceramic or plastic chimneys. Iron ones are not allowed, but they don’t seem to make lead ones. In design, chimneys for condensing boilers are practically no different from those that have been developed and presented on the entire world market for simple gas boilers with a closed combustion chamber. After all, all the same, combustion products will be forcedly emitted, so there could not be any major changes.

Here! Forced smoke removal provides great opportunities for additional connection of two-pipe systems to coaxial chimneys. The boiler can also be connected to the air intake system from the room. Who is doing this? There is a standard steel chimney - put a condenser in it! Or as it’s still fashionable to say now – tough! That is, into tin, from which chimneys can be made.

Types of equipment - just in case

Today on the heating equipment market there are both gas and liquid fuel household boilers, which may have a condensing design. They are available in both wall and floor versions. Wall-mounted ones are not so powerful, they have an average rating of 20 kW, and floor-mounted ones are more serious units, which are characterized by a power of 30 kW or more.

With all this, boilers can be either single-circuit or double-circuit, and are intended either for heating only, or for heating and hot water supply. The problem of choosing among all types and types is relevant today, since it is the incorrect selection of equipment that not only increases its cost, but also reduces efficiency.

Heat exchangers for HORTEK boilers

The fundamental solution for all of the above boilers is to use heat exchangers only made of acid-resistant stainless steel AISI 316. From a design point of view, all heat exchangers are a set of smooth tubes communicating through manifolds. This solution made it possible to ensure high resistance to contamination both on the coolant side and on the flue gas side. In addition, the flow distribution in the heat exchanger is designed for high coolant velocities, which further increases resistance to clogging. Thanks to these factors, the efficiency of boilers with such heat exchangers remains at a constant level throughout their entire service life.