Cats don't sleep on cold radiators.

The efficiency of the entire heating system directly depends on the performance of the boiler. Malfunctions of the main heating equipment negatively affect the efficiency of the home heating circuit and lead to excessive energy consumption. That is why any breakdowns, even the most insignificant ones, are given special attention. People’s experiences are understandable if the boiler is working and the radiators are cold. After all, this not only reduces the level of comfort in the house, but also entails expensive repairs. To properly solve a problem, you need to understand its essence. Only a specialist can correctly determine the reasons why the boiler does not heat the batteries. Also read: “Why do radiators heat poorly?“.

Boiler malfunctions

Typical problems with the operation of heating equipment:

- malfunction of the built-in pump;

- the heat exchanger is clogged;

- The three-way valve does not work.

If the boiler is working and the radiators are cold, experts recommend, first of all, assessing the technical condition of the main heating element. More specifically, determine whether the circulation pump built into the device is working. This part is an invariable attribute of modern equipment and is designed to increase the efficiency of its operation. Very often, after a long period of inactivity in the summer, the pump can become clogged or become covered with a layer of limescale. As a result, it does not remove the heated coolant from the heat exchanger in a timely manner. The boiler is boiling, but the radiators are cold.

It is strictly prohibited to independently repair such complex equipment as a boiler. In this case, either a specialist from the service center or a repairman with the appropriate certificate or permit is called to your home.

Experts do not recommend using ordinary tap water as a coolant, as it is hard. When the coolant temperature increases, dissolved salts settle on the heat exchanger. As a result, the following problem arises: the boiler is working, but the radiators are barely warm. Scale reduces the thermal conductivity of the heat exchanger, so the water in the circuit does not heat up, although the heating element constantly works with excessive energy consumption. You can fix the problem by changing the coolant and cleaning the heat exchanger. This video will help you understand how to clean the heat exchanger correctly:

A double-circuit boiler heats water, but does not heat the radiators. Here you need to pay attention to the serviceability of the three-way electric valve. It is responsible for switching the bypass from heating circuit maintenance mode to DHW and CO mode.

Before making a heating register with your own hands, familiarize yourself with the technical base.

Why can't antifreeze be used for radiators? The answer is here.

How to repair the system

Initially, to determine whether the pump is faulty, you should check the operation of the rotor; to do this, you need to unscrew the plug nut at the end of the pump. When unscrewing, a small amount of water will flow out. Next, you need to insert a screwdriver inside and turn the pump shaft.

If air has accumulated in the pump, open the air vent and bleed it. The air vent looks like a cap that rises up and rotates around an axis. At the moment of descent, a certain hissing sound will be heard, as if you deflate a balloon. If all these manipulations do not help, you will have to replace the faulty part with a new one. Since repairs are quite difficult to perform, and the service is not cheap.

Important: If you do not have enough qualifications in boiler repair, it is better to invite a specialist from the service department. Since incorrect actions during your repair process can cause even greater damage to the boiler. And in the case of gas boilers, this is also life-threatening.

Problems with the heating circuit

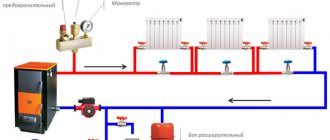

The pump must be selected according to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be sought in the wiring itself.

List of main heating circuit malfunctions:

- the filter on the return line or the needle tap (Maevsky tap) is clogged;

- insufficient power of the circulation pump;

- the rules for installing a heating circuit with natural circulation have not been followed.

Any of the above problems must be resolved before the start of the heating season. Otherwise, the room may be left without heat for several days, since the repair involves completely draining the coolant.

So, why doesn’t the boiler heat the batteries if everything worked fine over the previous years? The reason is a dirt plug that has formed on the heating circuit filter and completely blocks the coolant flow. It can be solved simply - the water is drained from the pipes or its circulation is blocked using bypasses, and the filter is cleaned. To prevent a recurrence of such a situation, it is necessary to completely replace the coolant with parallel flushing of the entire circuit.

Boilers with semi-automatic ignition.

Heating equipment equipped with automatic Eurosit 630 or similar is classified as semi-automatic, because the main burners are ignited by the flame of the wick, which burns throughout the entire operation of the boiler.

Reasons and methods for eliminating water boiling in boilers with semi-automatic ignition.

Faulty coolant temperature sensors.

The temperature of the water in the heating circuit is controlled by sensors (thermistors), which are located in the supply and return lines of the boiler. A working sensor changes its resistance when the coolant temperature changes. For example, at 25 0C it will be approximately equal to 10 kOhm, and at 45 0C - 4.913 kOhm. According to the type of design, the sensor can be surface-mounted (reads parameters through the copper wall of the pipe) or submersible (contacts the coolant without an intermediary). If probes are not inspected in a timely manner, then a non-metallic coating forms on the contact surface, impairing heat transfer and causing their damage.

To study the condition of the thermistor, a tester is connected to the sensor contacts in the ohmmeter position. If it commits:

- the resistance is in the range of 1 - 30 kOhm, which means the sensor is working;

- 1 or 0, the probe must be replaced.

Procedure for replacing the temperature sensor:

- Depending on the type of probe, it is unscrewed or removed from the pipe.

- Before installing a new sensor, for overhead thermistors, thermal paste, for example, MX 4, is applied to the prepared base, from which dirt, oxides, and grease are removed. For immersed probes, the seat is cleaned, and fum tape is wound onto the mounting thread.

If the probe breaks down in automatic boilers, a fault code will be displayed on its dashboard. Also, the coolant may overheat due to a pump malfunction and filter contamination. Methods for identifying and eliminating such problems are described above.

Good afternoon Yesterday we installed 2 additional radiators (white aluminum) into the heating system in a private house, installed them, opened the valves, let the water in, and as the radiator filled with water, they bleed the air through the vent hole as usual. After the work was done, the pressure in the system decreased and, as usual, water was added from the central water supply system (our house is connected to a water supply system that runs next to the house and we add water to the heating system from the central water supply system, everything is connected so that the valve opens - the water has gone). After all this, the boiler began to heat up and boil very quickly (in our house there are 3 circuits in the heating system, through which the first and second floors of the house are heated, each circuit has a pump (3 pieces) and one pump is installed in the return line. So Now, all the pumps are working, the air in all the radiators has been bled, and the boiler continues to heat up very quickly, literally from one piece of firewood thrown in. I beg you to help in any way you can, I’ve been suffering for 2 days now, I don’t understand what the reason is.

Unfortunately, knowing almost nothing about the heating system of your home, we cannot help with specific advice. It’s like in medicine: to make a diagnosis, the doctor must receive test results and examine the patient. And we don’t even know the “anatomy”; you didn’t attach a diagram to the question. You need to know not only the general location of the heating devices, but also the structure of the boiler room, the location of the air vents, etc. But even knowing these parameters, trying to determine the nature of the problem in absentia is largely guessing from the tea leaves. There can be many local reasons for the malfunction of the system; we will outline the correct, in our opinion, algorithm for finding and eliminating them:

A manual air vent (Maevsky tap) must be installed on each radiator

Poor circulation can also be caused by general contamination of the system; first of all, the batteries become clogged. The heating device can be removed and blown with compressed air or washed with a powerful stream of water.

The diagram shows that automatic air ventilators on combs (5, 11) and Mayevsky taps (13) are placed on all heating devices without exception. This was done for a reason, but to eliminate situations similar to yours.

Cats don't sleep on cold radiators.

Why are the radiators cold when the boiler is running?

Low efficiency of the heating system can be the result of malfunctions of both the circuit itself and the main heating element. In the case of a heating device, it is necessary to pay attention to the three-way valve, the functionality of the pump and the technical condition of the heat exchanger. Typical problems for heating wiring are a clogged filter, insufficient power of the circulation pump and lack of slope of the pipes of the circuit with natural water circulation.

The heating system is a complex structure consisting of several elements combined into one circuit and put into operation through a chain reaction.

But it happens that the system fails and the water in the batteries becomes cold. The reason for this may be problems with the return line.

DIY Baxi boiler repair Video tutorial

Burner flame does not reach maximum power

The cause of the malfunction may be incorrect pressure setting in the heating system, a malfunction of the gas valve modulator, or a breakdown of the diode bridge.

Remedy: adjust the system parameters using the boiler operating instructions.

The boiler starts and immediately stops working

The reason is low gas pressure in the gas pipeline.

Remedy: reduce the incoming gas pressure to five mbar (standard - twenty-five mbar).

Weak heating in the hot water supply system

The reason for this is the incomplete opening of the three-way valve or its breakdown. To confirm a valve malfunction, you should allow the system to cool, close the shut-off valves of the heating system, then turn on the boiler in hot water supply mode. If the valve is faulty, then heating in the heating system will occur simultaneously with the DHW.

When igniting a “popping” sound is heard in the boiler

This noise appears due to: insufficient gas combustion (minimum pressure adjustment is necessary); changes in the distance from the gas supply to the igniter during careless transportation of the Baxi boiler (the gap should be adjusted by setting it to 4-5 mm); excessive draft (use a damper to reduce the draft in the boiler).

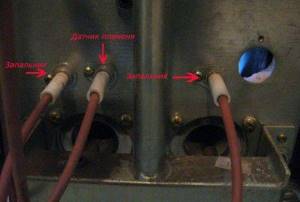

How to adjust the gap between the burner and the igniter

Open the front panel and completely remove it from the boiler. Remove the damper from the inspection hole. Behind it is an igniter

To change the gap size, you need to unscrew the screw that secures the igniter electrode, then remove it and carefully bend the electrode. Then we install it in place and close the hole flap

A sharp decrease in coolant temperature in the circuit

The reason for this is: clogged filters (they need to be cleaned or replaced); damage to pipes, radiators, their clogging or freezing (the malfunction must be identified and replaced or the defective section of the pipeline must be cleaned).

How to clean the primary heat exchanger with your own hands (video)

We drain the water by unscrewing the tap on the boiler on the right. If possible, drain the water from the heating system. For cleaning we use a device called Jelly. We connect the pipes of the device to the heating pipes of the baxi. Unscrew the cap on the device and fill in cleaning liquid. We turn on Zhel in the electrical network. Over the course of a couple of hours, use the knob on the device to switch the direction of the washing liquid “forward - backward”. After two hours, turn off the device and unscrew the tap to drain water from the baxi boiler. We remove the hoses, making sure that the washing liquid flows back into the device. We connect the boiler to the system and fill it with coolant. Cleaning the boiler will remove scale from its parts and prevent clogging and breakdowns.

Cleaning the secondary heat exchanger (heating circuit)

We use the washing device again. We connect it to the boiler and turn it on. The gas tap should be closed and the hot water tap should be opened. And after that, turn off the cleaning device. Thus, the liquid will be driven along a short circuit of the system.

Before installing the boiler, operating it or repairing it, be sure to consult a specialist. Despite all the positive qualities of baxi boilers, they, like all equipment, have their own margin of safety and service life. In this article, we looked at the main types of breakdowns, and also saw how to repair Baxi boilers with your own hands. We wish you and your boilers success.

“Baksi” is the name given to the line of gas boilers from the Italian company. If you are faced with the task of ensuring a comfortable microclimate in the room, then Baksi boilers are the best solution. The installations of this manufacturer have many advantages. The most important thing is that Baxi boilers are economical. In addition, they can be used for a long time and do not make noise during operation. These units perform well during use and are also easy to use. The reasonable price of this equipment makes it accessible to most consumers.

What is return in a heating system?

The return is a coolant located inside the heating system. During operation, it passes through all heating devices and gives off heat to them. Then, already cooled, the coolant returns to the boiler , where it is heated and begins a new cycle.

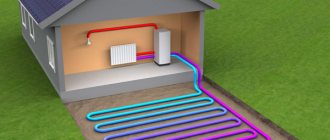

Photo 1. Heating diagram with a circulation pump and expansion tank. The arrows show the movement of the coolant.

water and antifreeze act as a coolant . It is put into operation either naturally (under the influence of gravity) or forcibly (using a pump).

Causes of problems with return flow in the batteries of a private or apartment building

There are several reasons why the return flow is not warm enough or even cold. Common problems are:

- insufficient water pressure in the system;

- small section of the pipe through which the coolant passes;

- incorrect installation;

- airiness or contamination of the system.

If a problem with cold return occurs in an apartment, then the first thing you should pay attention to is the pressure. This is especially true for rooms on the upper floors . The fact is that the principle of operation of the return flow is to quickly and continuously circulate liquid through the system. And if its speed drops , then the coolant will not have time to push out cold water and the batteries will not heat up.

Control board errors

The control board should be considered as the cause of hot water problems when all other checks have failed. The cause may be a malfunction in the flame modulation circuit. The boiler control unit constantly adjusts the burner power depending on the conditions, and if there is a fault on the board, the boiler can spontaneously reboot or turn off when it reaches maximum power, which in most cases is required precisely in the hot water preparation mode.

It is also possible that boards may be configured incorrectly as errors. But this only applies to those cases where problems appeared after its replacement. BAXI boards are universal and require customization for a specific boiler.

Italian Baxi gas boilers occupy a strong place in the heating equipment market due to their high efficiency, stable operation even in adverse conditions and thoughtful stylish design

.

But, despite their high reliability, sometimes

malfunctions occur

in the operation of Baksi boilers caused by violation of operating conditions or failure of individual boiler elements. Most often, you can eliminate them yourself, without calling in specialists.

The Baxi line of gas boilers includes a number of models that differ in volume, type of installation, and functionality. However, the principle of their operation is generally similar.

The most popular boiler models:

- Baxi Luna (Baxi Luna);

- Baxi Slim (Baxi Slim);

- Baxi Main four (Baxi Main for);

- Baxi Main 24 fi (Baxi Main 24 fi);

- Baxi Nuvola (Baxi Nuvola);

- Baxi EKO four (Baxi Eco for, Baxi Ecofor).

By installation type

Gas boilers are divided into

wall-mounted and floor-mounted.

Wall heater is fixed

using special brackets

in any convenient place,

which makes wall-mounted models very popular. Chambers with a closed combustion chamber, for example, Baxi Main 24 fi, have increased efficiency and environmental friendliness in a small size.

Coolant volume

in the heat exchanger depends on the model, in the most powerful it

reaches 80 liters

.

In terms of functionality,

models

can be single-circuit

- for heating, or

double-circuit

- in addition to the heating system, they also supply the hot water circuit.

Work

They can use

both natural main gas and liquefied gas

from cylinders, making it possible to install them in non-gasified areas.

The boilers are completely volatile

and require connection to an alternating voltage network.

Operating principle of gas heating equipment:

- Sensors analyze the temperature in the room, and when the minimum value is reached, they send a signal to turn on the circulation pump.

- The pump turns on, creating a vacuum in the return pipe, and the heated water enters the heating system.

- The microprocessor sends a signal to ignite the burner at low power, it gradually increases, and the coolant is heated to a temperature specified by the user.

- Then the boiler operates in modulation mode - it maintains the temperature within the specified limits, turning on when it drops.

At any of these stages, a malfunction may occur, which the boiler notifies using coded errors.

Possible malfunctions of the Baxi Main for, Baxi Main 24 fi, Baxi Eco for boiler:

- the burner goes out immediately after switching on or during the heating process (error codes e01, e04);

- ignition of the boiler is impossible;

- overheating occurs (error code e02);

- The water pressure in the system drops (error code e10);

- extraneous noise is heard during operation;

- there is popping noise in the combustion chamber;

- the coolant does not heat up to the set temperature;

- One of the sensors fails (different error codes may appear).

The most common causes of certain malfunctions, according to service center specialists, may be:

- wrong

- errors when connecting the boiler to the electrical network;

- water getting into the circuit board, burner or electrical part of the boiler;

- low quality of network water or other coolant;

- sudden drop in gas pressure;

- The network voltage drops or increases unacceptably.

The resulting malfunctions can be easily eliminated by adjusting the boiler, but sometimes it is necessary to call a specialist to replace boiler parts.

What problems arise in the apartment due to cold return

Violation of the return flow entails certain problems and troubles.

Firstly , in this case the batteries do not heat up properly , or even do not work at all. Accordingly, the room itself becomes cold, which is certainly not encouraging.

Secondly dissonance occurs of the supply and discharge of liquid.

This entails the accumulation of condensate on the walls of the boiler, which begins to react with carbon dioxide released from fuel combustion. The consequence of this process is the formation of acid, which corrodes the walls of the boiler , thereby destroying it.

After the start of the heating season, you can often encounter the problem of uneven heating of radiators. The most common solution is to de-air the system using a Mayevsky tap or other techniques. Unfortunately, some owners of apartments and private houses are faced with a situation where they have vented the air, but the radiators remain cold. Let's figure out what options for eliminating the problem exist and how to apply them.

Reasons for the battery not heating up

Air locks are the main reason for insufficient or uneven heating of radiators, but there are other reasons for this unpleasant phenomenon. These include :

- Poor circulation of coolant through the system pipes.

- Incorrect battery connection (for example, when the supply is connected to the bottom hole and the return to the top).

- Clogged inside the pipes and the battery itself.

Let's consider each possible option in more detail.

Insufficient water pressure in the system

As you know, all heating systems are divided into two main types: gravity (gravity) and forced. In the latter case, a water pump is installed, which drives the coolant through the pipes, thereby ensuring uniform heating of the radiators throughout the house.

In the gravitational scheme, movement is achieved due to the difference in density of cold and hot water. In this case, the boiler should be installed at the lowest point, and the expansion tank at the top. This option for installing a heating system can answer the question of why one battery is hot and the other is cold. The thing is that hot water warms up radiators located in close proximity to the boiler, while those located far from it lack coolant movement and do not heat up.

Reasons that may result in overheating of a solid fuel boiler

Even at the selection and purchase stage, it is important to take into account the performance characteristics of the heating device. Many models that are on sale today have a built-in overheating protection system. Whether it works or not is the second question. However, it is necessary to adhere to certain knowledge and skills, hoping to create an effective and safe autonomous heating system at home. The reliable operation of the heating unit depends on the operating conditions. In case of obvious violations of the technological parameters of heating equipment and abuse of standard safety rules, there is a high probability of an emergency situation.

For reference:

exceeding the temperature in the combustion chamber of the permissible parameters can cause boiler water to boil. The result of an uncontrolled process is depressurization of the heating circuit and destruction of the heat exchanger housing. In the case of hot water boilers, an explosion may occur if overheated.

Possible negative consequences can be prevented at the stage. Correct piping of the heating apparatus will be the key to your safety and reliable operation of the unit in the future. In detail, in each case the protection system of a solid fuel boiler has its own specifics and features. Each heating system has its pros and cons. Eg:

- When it comes to solid fuel boilers with natural coolant circulation, it is necessary to take care of the safety and performance of the heating equipment even during installation. The pipes in the system are metal. Moreover, the diameter of such pipes must exceed the diameter of the pipes used to lay the circuit with forced circulation of the coolant. Sensors installed on the water circuit will indicate possible overheating of the coolant. The safety valve and expansion tank play the role of a compensator, reducing excess pressure in the system.

A significant disadvantage of a gravity heating system is the lack of an effective mechanism for adjusting the operating modes of solid fuel boilers.

- Great technological opportunities for consumers are provided by working with forced circulation of coolant in the system. Just the presence of a second circuit significantly increases the ability to regulate the heating temperature of the boiler water. The only drawback in the operation of such a system is the running pump, which can cause difficulties during the operation of the heating system.

This is due to the fact that when the power is turned off, the pump stops performing its functions. Stopping the circulation process and inertia of solid fuel heating boilers can lead to overheating of the heating unit. If the boiler equipment is not equipped, a situation with a power outage is fraught with extremely unpleasant consequences. Effective protection against overheating of a working solid fuel boiler should be based on the mechanism for removing excess heat generated by the heating device.

Cats don't sleep on cold radiators.

Incorrect battery connection

Incorrect or ineffective connection of the radiator is also the reason for its poor heating. The best option is to supply water to the top hole of the battery and exit through the bottom. In this case, both connections must be on the same side.

Options for connecting the battery to the system

The cross method involves the return outlet on the other side of the radiator. This is also an efficient option that allows only 2% heat loss. There are other connection options, but they have more noticeable losses.

Incorrect radiator connection

An incorrect connection can completely deprive you of heat . This includes the case when the supply is installed in the lower hole, and the outlet in the upper. If such installation errors occur, they should be eliminated as soon as possible.