Cinder blocks are special wall bricks obtained through vibrocompression of high-quality concrete mortar. Therefore, a house made of cinder blocks is stronger, more economical and warmer than other analogues. A good filler for this concrete will be blast furnace, fuel or volcanic slag, as well as broken brick, sand, crushed stone screenings, gravel, perlite, expanded clay and even sawdust, that is, many industrial wastes.

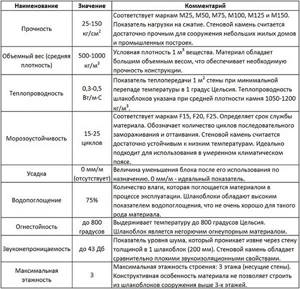

The technical characteristics of all cinder blocks depend on the fillers. Their density is 500 - 2000 kg/m2, frost resistance is up to 35 cycles, and the thermal conductivity of the masonry is 0.3 - 0.70 W/m - °C. But the thickness of a cinder block wall in central Russia should be almost 1 m.

High quality cinder block building

What is a cinder block, and what do cinder block houses look like in the photo

Cinder block is a building stone prepared by pressing from cement and filler. Mass production of cinder blocks is developed in regions with metallurgical production. It is there that waste from blast furnaces is actively used in the production of building materials. The first part of the name, slag, may have a non-literal meaning. It is understood as crushed stone, crushed glass or bricks, expanded clay, shavings and sawdust, ash, ash, sand.

The technical characteristics of this building material directly depend on the type of filler. Blocks made of crushed stone and pebbles are considered the most durable.

For your information! The strength of a cinder block building material is indicated by its brand and ranges from 35 to 125 kg/cm².

The minimum strength value, 35 kg/cm², is suitable for additional insulation of load-bearing structures or the construction of low fences. Grade 50-75 kg/cm² is suitable for internal partitions, 100-125 kg/cm² is material for foundations and load-bearing walls. Cinder block can be used in the construction of structures that have constant contact with water.

The material can withstand up to 50 freezing cycles without visible damage

Attention! The use of industrial waste in the manufacture of this building material makes it unsafe for humans. It is not recommended to use fresh slag as a filler; it must “weather” in the open air for at least a year.

Necessary construction tools and materials

To make building stone you will need:

- Filler – up to 65% of it should be slag. The rest can be replaced by quartz sand, broken glass, broken brick, expanded clay, and sawdust.

- For the binder, use cement of a grade of at least M400. You can also use M500.

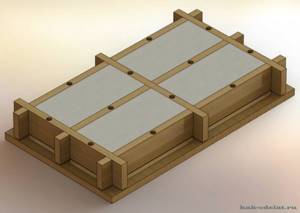

- Rectangular shape for blocks - made of plywood, plastic, boards, metal sheet.

- Concrete mixer.

If you need a lot of material, you should rent a vibrating table or vibrating machine.

Pros and cons of cinder block houses

Construction material made from industrial waste has its advantages and disadvantages. Before you make a choice in its favor, carefully study all sides of the coin.

| pros | Minuses |

| Suitable for the construction of low-rise residential and commercial buildings. | A long period of formation of blocks during the manufacturing process. |

| Wide range of applications due to the variety of block types. | Masonry made of this material shrinks after a few months. |

| Excellent heat-saving data, allowing the blocks to be used for construction even in the Far North. | Blocks may crack during laying. |

| This building material is easily cut into pieces. | High strength material requires additional insulation. |

| Hollow blocks significantly reduce the load on the foundation. | |

| High fire resistance, resistance to moisture and fungal growth. | Simple manufacturing technology has led to the appearance of low-quality material on the market. |

| The excellent vapor permeability of the blocks helps create a comfortable indoor climate. | |

| This building material is one of the cheapest. | The use of waste from boiler houses and blast furnaces makes this building material environmentally unsafe. |

| You can make cinder blocks with your own hands. |

Think before you decide to build with cinder block. Such houses require additional protective measures; their construction should be kept under strict control, taking into account the shrinkage and self-destruction of the blocks

No. 1. Cinder block: production features

Slag concrete belongs to the category of lightweight concrete blocks. This material first became known at the beginning of the 20th century, when Nicholas II was building a garage in the Winter Palace. At that time, cinder blocks, however, were made from coal combustion waste - slag, hence the name. Since then, production technology has changed somewhat, and the durability of the first cinder block buildings ensured that the material became quite popular.

Today, cinder blocks are made from cement and sand; clay, lime or gypsum, as well as various plasticizing additives, can be added. The filler is no longer slag, but crushed stone, granite screenings, expanded clay, broken bricks, perlite, broken glass and sawdust. In terms of environmental friendliness and harmlessness to health, the best fillers are expanded clay, sawdust, crushed stone and shell rock. Production is carried out on vibroforming equipment.

If in the 70s, when cinder block began to be actively used in construction, garages, sheds and other utility and utility rooms were built from it, today the advantages of the inexpensive material make it possible to use it for the construction of houses and even industrial buildings.

Related Posts

- Bricklaying in winter

- Is it worth replacing wallpaper with paint in an apartment: what to paint with, is it possible to do the work yourself, and what paint to choose for the wall

- Mortar for laying a stove: varieties, composition, mixing methods

- Types and standard sizes of cinder blocks

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- DIY bricklaying device and how to use it

- How to plaster a stove to prevent it from cracking: types of putty for stoves and execution technology

- 10 tips for those planning a kitchen renovation

- Secrets of strengthening brick and block masonry walls with reinforcing mesh?

- How to update old tiles in the bathroom

- How to glue fiberglass correctly?

- Alabaster: what is it? how to divorce? where to apply?

- How to make fire clay

- Laying foam blocks with glue in winter

- How to calculate wallpaper: how many rolls and glue are needed to cover a wall. methods for calculating and determining the quantity of materials

- House made of monolithic foam concrete

- Plastic fastening clips for plaster beacons

- How to cut metal using a grinder

- Brick and mortar consumption calculator for masonry

- Do-it-yourself aerated concrete laying technology

- How to seal the joint between the bathtub and the wall? 8 popular options

- Stages of renovating a children's room

- The door handle creaks: causes of the problem and solutions

- Caring for matte and glossy stretch ceilings

- Insulation of a veranda in a wooden house

Read with this

- Bricklaying in winter

- Is it worth replacing wallpaper with paint in an apartment: what to paint with, is it possible to do the work yourself, and what paint to choose for the wall

- Mortar for laying a stove: varieties, composition, mixing methods

- Types and standard sizes of cinder blocks

- Do-it-yourself insulation of walls with polystyrene foam - detailed instructions

- DIY bricklaying device and how to use it

- How to plaster a stove to prevent it from cracking: types of putty for stoves and execution technology

- 10 tips for those planning a kitchen renovation

- Secrets of strengthening brick and block masonry walls with reinforcing mesh?

- How to update old tiles in the bathroom

What can reduce the advantages of cinder block houses, and how to solve problems with disadvantages

We found out what cinder blocks are and their advantages and disadvantages. How to make the most of the useful qualities of this building material and minimize losses? The main way is to choose the right product, avoiding widespread defects. How to do it:

- Buy blocks only from a reputable seller. Such a retail outlet must have quality certificates for the product indicating all its technical characteristics.

- Find out what filler is used in the production of blocks. Do not buy material with granite screenings for residential buildings; it may have an increased radioactive background.

If possible, check the product with a Geiger counter.

- A high-quality block must have clear geometric shapes. Carefully inspect the batch for cracks and chips, selectively measure several elements to see if they correspond to the declared parameters.

- A simple test of the block’s strength is to stick an ordinary nail into it. If the nail goes in without using a hammer, don't buy it. Try to manually break one product - if the production technology is violated, the blocks crumble with little effort.

- Transport purchased building materials only on pallets.

Build a secure shed to store blocks

Choosing suitable plaster: types and features

Any plaster solution is suitable for cinder concrete. For external walls, we use cement-sand with a small amount of lime.

Composition of the solution

• Cement – part; • Fine sand, cleaned, sifted – 3 parts; • Lime – 0.2 parts.

Experienced plasterers add detergent to the solution (dish soap, melted laundry soap, washing powder diluted in water). This additive gives the solution plasticity. It is possible to use ready-made plaster composition.

Attention! Add the plastering mixture to the mortar, making sure there is no lime in the mixture.

Characteristics and sizes of different types of cinder blocks

Different types of fillers and shapes divide blocks into several main types. Some of them are suitable only for the construction of garages, fences and other outbuildings. There are blocks that are used for insulation or cladding, and there is a high-strength material that can withstand heavy loads. How not to make a mistake in this diversity?

Durable monolithic cinder blocks

A solid element made of filler and cement fill is characterized by increased strength. It can be used in any load-bearing structures: supports, foundations, columns and basement structures.

This material is not used for the construction of walls, as it has low thermal insulation characteristics

Foundation blocks made of slag concrete are especially in demand. But you need to remember that they can shrink and need reliable protection from the effects of groundwater.

Lightweight hollow cinder blocks

Blocks can have voids in their structure - oval, round, square or rectangular. The size of such voids is approximately a third of the volume of the building element.

Such blocks are used for internal partitions and load-bearing walls.

The most common question is: how many bricks can fit in the volume of a cinder block? Standard block dimensions: 39x19x18.8 cm. Thus, there are approximately 6 single bricks in one volume. If we compare the thermal conductivity of the material, then one block is equal to 12 bricks.

Decorative cinder blocks

There are two types of decorative material made from slag:

- Colored element - to make it, dye is added to concrete. This material can be used to make a fence, decorate a wall or support.

- Facing block - has a more complex manufacturing technology that allows you to imitate the surface of natural stone or plaster. The outer layer of the elements is covered with a protective layer.

Decorative cinder blocks are rarely used - there are a lot of other materials for facade finishing that look more presentable

Laying methods

Laying walls made of cinder block material is possible in several ways.

1) In two stone blocks.

2) One and a half blocks.

3) In one cinder block.

4) Half a stone.

The solution must be laid no more than one and a half centimeters thick. If the layer is thicker, the thermal insulation properties of the finished structure may decrease. To increase these properties, it is better to leave the voids inside the blocks unfilled. The solution is placed only at the joints of the blocks and where it is needed. When the wall is ready, the voids in it are filled with very fine slag, which is then carefully compacted.

In any case, the construction process is much faster than if you used ordinary bricks. This is due to the size of the material and the ease of its use. So, the brick is smaller in size, so you will need twice as much of it. Consequently, more movements will have to be performed. And a lot of cement will also be used. This means that cinder block saves money. When the process of constructing the walls is completed, you need to begin their hydro- and thermal insulation. This is necessary to prevent moisture from reaching the surface of the material.

This is especially important to do before you install the roof.

Once the walls are completely weatherproofed, the roof frame is installed. It is constructed after all work related to the building frame is completed. To prevent condensation from forming between the ceiling and the roof of the house and moisture from collecting, vapor and waterproofing materials should be laid between them. When the roof installation is completely completed, it is necessary to perform a vapor barrier on the ceiling. It, like the entire roof, must be insulated inside with basalt or mineral wool.

What type of cinder block is best to use for building a house?

Each of the listed types of slag building materials has its own purpose. Hollow blocks are used for walls. If the percentage of voids is within 30, you can use the blocks to build a house of two or three floors. If there are more voids - only in one-story construction. Such elements retain heat well, but, unfortunately, are not durable.

For internal partitions, you can buy custom-sized blocks. They are narrower, only 9 cm wide

Hollow elements are not suitable for the base and foundation of a building. Only monolithic products can be used here. Properly selected building material will help you build a good, strong and durable house. So if you still doubt whether you can build a house from cinder blocks, leave your doubts. Of course, it is possible, you just need to be careful when selecting high-quality building materials.

How to paint a cinder block

After finishing with plaster, the walls can be painted with regular facade paint. If a fence is made from cinder blocks, it is enough to prime and paint it. It is better to paint the seams with a different color. If the paint is not intended for facade work, it will quickly fade.

You can make the last layer of plaster from colored acrylic mortar, and then the walls don’t need to be painted.

It is better to paint the walls inside the house with acrylic or latex water-soluble paints. They do not smell when painted, wear-resistant and moisture-resistant, environmentally friendly.

Finishing the walls inside the building is the simplest type of repair work.

What is better - buy cinder blocks or make it yourself

You will find many admiring reviews from buyers of equipment for making cinder blocks. They say that with the help of a small vibrocompression machine you can not only build your own house for literally pennies, but also start a profitable business. Don’t rush to buy a device, not everything is so simple.

A small machine for making blocks costs between 18-30 thousand rubles

On the one hand, if you have a source of material for the blocks, for example, a boiler room nearby, why not use this opportunity? In this case, you will get the main filler for free, since boiler houses are happy to get rid of waste. Another good option is connections with a sawmill.

Chips, sawdust and shavings can also be used as filler. You can use improvised material for tying

It doesn't have to be concrete. Lime or clay, gypsum - all this is also material for cinder blocks. Now for some practice. First, it is not so easy to properly balance the composition of the mixture. Too little binding material, too much filler, or the wrong consistency—the blocks will be brittle. You will have to spend some time and money until the right composition is found. Secondly, if you do not use free material, but purchase it, the blocks will not be much cheaper than factory ones, and maybe even more expensive. A large manufacturer purchases raw materials in bulk, in large volumes. In the end, it costs him less.

People who have tried making cinder blocks in practice talk about profitability in the range of 15-20%

And lastly, even if you have a concrete mixer to prepare the mixture, you will have to spend a lot of time and effort on the production of this building material. It is necessary to transfer more than one ton of sand and crushed stone, wait until each batch is worked out, and until it stands in order to become suitable for masonry. What is the result: savings of 15%, a large percentage of defects due to lack of experience, a sore back and a lot of wasted time. Think again about whether the benefit received is so significant.

How to prepare the solution and what is its consumption

For plastering, the composition is selected according to the purpose of the room and operating conditions. If the building is not heated, a cement-sand-lime mortar is used. It enhances protection against humidity and temperature fluctuations.

Stages of solution preparation

1. Preparation of lime dough. You will need water, the composition is mixed in a ratio of 1:3. 2. Everything is mixed and left in a closed container for a day. 3. Lime dough is mixed with sand in a ratio of 1:3, pour everything with water and mix. This is a strong solution. If more strength is required, add more sand (1:5).

Attention! To plaster the walls of the material, we use a lime-clay solution.

It contains:

• Lime dough; • Clay mass; • Sand.

Important. The preparation of clay dough follows a similar recipe to lime dough.

Lime-gypsum mortar is used. To prepare it, you will need to add gypsum mass. Gypsum, diluted in water, is mixed with a lime composition, and the wall is plastered without waiting. The solution quickly hardens in the container.

Polymer composition - after drying, a smooth surface is formed, which is most often taken for a unique finish: it does not require gluing or wallpapering. The only drawback is the cost. It is more expensive than an ordinary finishing mixture.

Masonry techniques.

The brick is laid in the same way. There is a bandage of rows and reinforcement with masonry mesh. Levels are also monitored and identical tools are used. In addition to the devices, there is a rubber mallet (hammer), which shrinks the cinder block onto the solution by tapping. The material requires a much larger amount of mortar, since a bucket of mortar is used to lay 4 cinder blocks. It would be a good idea to rent a concrete mixer. This will reduce physical costs and save energy. Masonry occurs with voids down. The evenness of the rows is maintained by stretching a cord along the rows. The base should be waterproofed before laying.

How to build a cinder block house with your own hands: main points

Construction of cinder block buildings is a simple process. Such structures are much faster and easier to build than with conventional brick. The main thing is to make the calculations correctly and follow the general construction rules.

How to calculate the number of cinder blocks for building a house

Savings in construction are achieved not only by using cheap building materials, but also by correctly calculating their quantity. It’s better to buy additional blocks if there aren’t enough of them, than to rack your brains about where to put the extra ones. What indicators are included in the calculation? The first is the thickness of the cinder block wall. It depends on the region of residence. For the south and central Russia, it is permissible to install external walls with a thickness of 20 to 40 centimeters. For northern regions, at least 60 centimeters are required.

The second important indicator is the dimensions of the building (width, length and height of the building)

How to calculate the amount of cinder block in 1 m²: to lay one row you will need 12.5 pieces of standard size blocks. If the wall thickness is 40 centimeters, two rows are required, which means we multiply the number of elements of one row by two - we get 25 pieces. If a 60 cm wall is required, multiply by three.

Even a second grader can calculate the total area of the wall: you need to multiply the length by the height. For example, if the wall of a house has dimensions of 10×4, then we have 40 m² of masonry. Laying in two rows: 40 × 25 = 1000 blocks. Do I need to subtract the area of door and window openings? If you are planning regular, medium-sized windows, do not subtract them from the total area.

Cinder blocks are fragile and break frequently, so consider this a bonus for the fight

How to lay a foundation for a cinder block house

A cinder block house requires a high, moisture-proof foundation. It is necessary to protect the wall material from contact with groundwater. For one-story and two-story buildings without reinforced concrete floors there is no need to make a reinforced foundation.

Cinder blocks themselves are not heavy and do not place an increased load on the foundation, but the base needs to be reinforced in any case

Expert's point of view

Dmitry Kholodok

Technical director of repair and construction

Ask a Question

The foundation must stand for at least a month before the construction of the walls begins. Only during this period will the solution completely rise and the base will gain the required strength.

Related article:

Types of foundations for a private house. How to choose the right type of foundation and materials for it, step-by-step instructions for building a house with your own hands - read in our publication.

How to properly lay a cinder block on a foundation: video instructions

Blocks are first placed in the corners on the moisture-insulating layer of the foundation. The correctness of their location is carefully checked by the building level. Only after setting the corners is the cord stretched between them, and the masonry of the walls will be built along its line. In practice it looks like this.

How to build the walls of a house yourself - features of laying cinder blocks

The peculiarity of construction work with cinder blocks is that they can only be carried out in good weather at a temperature not lower than +15°C. To preserve the thermal insulation properties of the material, you need to make seams no thicker than one and a half centimeters and under no circumstances fill the voids in the blocks with mortar. The elements are laid offset by half a stone.

The verticality of the masonry should be constantly checked with a building level

Reinforcement needs to be done in every fourth row. To do this, recesses are made using an electric mill, pieces of reinforcement are inserted, and cement mortar is poured. This technique allows you to make the walls much stronger.

Roofing and interior finishing

An important point in the construction of a cinder block building is the installation of the roof. This must be done as quickly as possible so that rain or snow does not fall on the walls. If for some reason you do not have time to cover the roof before the downpour begins, use at least temporary moisture protection: polyethylene or any other covering material.

It is better to insulate cinder block walls from the outside

In any case, the facade of the building will need decorative finishing. If internal insulation is required, a vapor barrier is first installed, and mineral wool or polystyrene foam boards are installed on top. The walls in such a house can be plastered, covered with plasterboard and OSB boards.

How to insulate a house?

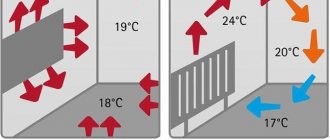

To make your home comfortable in cold weather, you need to take care of the insulation of the building. Experts say that it is better to insulate a building from the outside, as this guarantees 70% of the effect; sometimes internal insulation is not even required.

Before internal insulation, a vapor barrier layer is installed on the walls and ceiling of the building, after which mineral wool or expanded polystyrene can be used. Vapor barrier is not needed for finishing external walls.

If you want to save on insulation, then use polystyrene foam. This is the cheapest material; later it is plastered and painted. You can also buy expanded polystyrene, which has a low level of water absorption, so there is no need to install a vapor barrier layer.

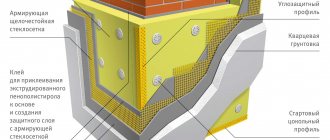

Wall insulation with foam plastic and decorative work are carried out in 5 stages:

- The walls are being plastered.

- Styrofoam is attached.

- Reinforced mesh is being installed.

- Work is underway to level and finish the walls.

- The building is being painted.

For painting, it is better to choose acrylic or silicone plaster. And if you are not limited in finances, then for insulation it is better to purchase polyurethane foam - a modern material that is applied to the walls by pouring or spraying. The result is a coating without seams; it does not allow cold air and moisture to pass through.

You will learn how to properly cover a roof with corrugated sheeting by reading the following article. And this article tells you how to cover a roof with roofing felt.

What is better to choose for construction: brick or cinder block

A slag concrete house has its pros and cons, but, compared to a brick one, it, oddly enough, wins. Cinder block has a porous structure and holds heat much better than brick. Brick also has excellent thermal insulation qualities, but it will take a very long time to heat a cold house made of this material.

A slag concrete wall weighs less than a brick wall, which means there is no need for a reinforced foundation. The construction of brick walls will take more time, and the cost of work will be much higher. Again, the cost of a cinder block is lower than the cost of a brick.

Cinder block is inferior to brick in terms of durability of the building, but with proper external and internal finishing it will serve more than one generation of home owners

Related article:

Dimensions of red brick , varieties and areas of application, weight depending on purpose, quantity in a pallet, price per piece of a particular brand and type, video about production - in our publication.

Review of popular projects

1. House with an attic 10x15.

The total area of the cinder block building is 220 m2. Approximately a third of the first floor is occupied by a garage and technical rooms. On the opposite side of the house there is access to a wide terrace. The spacious living room and kitchen are located nearby, which is very convenient for receiving a large number of guests.

In the center of the attic there is a large hall with a floor-to-ceiling window. The project also includes a bedroom, an office, 2 children's rooms and 2 bathrooms. All rooms are separate, the doors open into the hall. The office and one nursery have balconies.

2. 10x10 house plan with garage.

The location of the attic is provided only above the residential part of the 1st floor. In addition to the garage, downstairs there is a narrow hall, a toilet, and a small kitchen. The living room has a stove, a built-in corner staircase and access to the terrace. On the top floor there are 2 bedrooms and a bathroom.

The house is designed for a small family of 2-3 people.

3. Project of a cinder block house on 2 floors 10x10.

The total area of the building is 180 sq.m. The house is divided into many living rooms. It also provides the necessary technical and auxiliary premises: boiler room, kitchen, wardrobe, 3 bathrooms (one downstairs and 2 upstairs). This is a spacious, ergonomic home for a large family.

What determines the cost of building a house?

The final price of a cinder block building is made up of many factors:

- House design taking into account engineering and communication systems. Ordering a plan from an architectural studio starts from 25,000 rubles.

- Excavation of soil under the foundation of a house to a depth of 0.7-1 m. A cube of earth costs 400-500 rubles.

- Construction of a monolithic strip foundation (reinforcement + filling). For a wall 0.4 m thick, a base width of 0.5 m is required. Material costs are about 8,000 rubles per cubic meter. If you hire a team, then the project estimate needs to be increased by 10-15%. Laying a turnkey strip foundation costs 17,000-19,000 rubles per cubic meter of concrete work.

- Filling with crushed stone and sand will cost 600-800 rubles/cube including delivery. At this stage of construction, you can include the arrangement of the basement.

- Purchase of slag concrete 390×190×190 mm. To lay walls in one block per 1 m2 you need 12.5 pieces. If walls made of double cinder blocks are specified, then 25 pcs/m2 will be required. The approximate cost of a block is 30-35 rubles plus 8-10% for battle and defects.

- Cement and sand. According to the laying plan, a cube of mortar is enough for 4.3 m3 of wall. To do this, you need to buy 6 bags of M400 cement and a cubic meter of sand, which will cost 1800-2000 rubles.

The estimate includes the costs of roofing, floors between floors, windows, and doors. The general list also includes materials for insulation, interior and exterior decoration. The most expensive part is the installation of heating, sewerage, gas, water and electricity.

Some nuances influence the final cost:

1. Walls made of cinder concrete cannot withstand the load of a concrete floor. Therefore, in a house project it is usually planned to install an armored belt made of longitudinal beams.

2. When constructing walls, it is necessary to reinforce every second row of blocks with steel bars. This increases the cost per cube of masonry by 300-350 rubles.

3. To make the structure lighter and cheaper, you can use hollow cinder blocks. Since they have increased fragility, they are suitable only for the construction of 1-2 storey houses, garages or installation of an attic.

Thus, the approximate price of a turnkey house is about 20,000-25,000 rubles per 1 sq. m. meter of area.

How to calculate the cost if you decide to build a house from cinder blocks yourself

There is nothing special about budgeting for a cinder block home. We talked about calculating the amount of wall material, so calculating the cost of building materials for this part of the construction will not be difficult. But remember that, in addition to the walls, you will need to invest in the foundation, roofing, interior and exterior decoration, and necessary communications.

You won't find a calculator that will do the full calculation for you. The budget will depend on the prices of materials in the region, the cost of construction services, or, if you are going to do this work yourself, the purchase of the necessary tools.

If you don’t have a plot for a house, add the cost of purchasing it to your total budget

In a word, if you want to estimate future costs, look among your friends and acquaintances for those who have recently mastered a similar construction project. Inquire about turnkey costs from local construction companies. You can safely reduce their amount by a third - approximately how much it will cost you to build such a house with your own hands.

Making a mold for cinder block

Without a special brick-making press, it is advisable to make cinder blocks if you have started a small-scale construction of a garage, summer kitchen, or bathhouse. To build a large house, you will need a large number of cinder blocks and the process of their production will take a lot of time and effort.

You can assemble the mold for pouring cinder blocks with your own hands. It is a parallelepiped with side dimensions of 40x20x20 cm. The given dimensions are again standard and you can change them at your discretion.

molds for cinder blocks with metal walls

The mold for pouring cinder blocks is often made from solid wooden boards; metal sheets can also be used. The boards should have a smooth surface for easier removal of the block. It consists of four side boards, that is, of two identical-sized pairs of boards, all four boards should be the same in height and a fifth board for the bottom of the mold. They also make molds without a bottom, but the floor of the room or street where the molds will be poured must be prepared, level, hard and clean. To speed up the process, they knock down and make a mold for several cinder blocks, 5-10 pieces at once, with partitions inside.

wooden molds

Prices for turnkey construction of cinder block houses

The cost of building a turnkey cinder block house in June 2018 is in the range of 18-20 thousand rubles per m². If you order an individual project, you will have to pay an additional 20-35 thousand rubles for it.

The price may increase if your site is located in a hard-to-reach place or the necessary communications do not pass near it

When is it necessary outside and inside, and when only on one side?

In order for the house to warm up evenly and not release warm air, it is necessary to create a layer of insulation on the outside or inside of the wall.

Regarding cinder block, there are only 2 options for insulation: only on the outside or on both sides of the wall.

Installing thermal insulation on the outside of a building is a standard method of maintaining temperature and not damaging building materials. According to the laws of physics, cold air will pass through obstacles: finishing material, a layer of insulation, and only after that it will hit the cinder block. The external covering of the house will act as a filter and condensation will not form on the walls.

Advantages of insulating cinder block outside the building:

finishing materials will create a barrier and protect the blocks;- usable space inside the house is preserved;

- the wall becomes a kind of battery, the ability to retain heat increases by 70%, and the ability to return it appears;

- eliminating the risk of fungus;

- the service life of the material increases, since it is not subject to freeze/defrost cycles;

- the dew point shifts, moisture evaporates from the finishing material;

- insulation and finishing protect the supporting structure from mechanical damage and precipitation.

If you create a thermal insulation cushion only inside the house, when passing through bare cinder concrete, cold and warm air will mix and form a dew point. The walls will become covered with moisture, the insulation layer and interior decoration will get wet, and the process of rotting will begin. As a result, a wet wall will appear in the house, where microorganisms will quickly multiply and the microclimate of the room will be disrupted.

Inside the building, it is customary to cover the cinder block with plaster and finishing material . Insulation may only be needed in northern regions, as an additional barrier against the cold that can accumulate heat.

Cost of work in the Russian Federation

The cost of work depends on the type of insulation, the volume of work, the complexity of installation and the qualifications of the craftsmen.

| Name of works | Moscow and Moscow Region, rub/m2 | St. Petersburg and Leningrad Region, rub/m2 | Krasnodar region, rub/m2 | Kazan, rub/m2 |

| Insulating a cinder block wall from the outside | 2000 | 2000 | 1900 | 1900 |

| Insulating a cinder block wall from the inside | 1600 | 1600 | 1500 | 1600 |