Answers from Beretta boiler repair technicians

There is a problem - the Beretta Ciao 24 CSI boiler was installed in September. Now the green light blinks once every 0.5 seconds.

The boiler starts, the burners turn on, it runs for 30 seconds, then it sounds like water and air flowing through the pipes or boiling, and immediately turns off, waits 3-5 minutes and everything starts all over again.

But about once an hour it starts up in normal mode for about 10 minutes (all batteries heat up). And it’s cold in the house, the house is about 100 meters, one floor, two circuits are done.

There may be problems with the DHW flow sensor - spontaneous activation.

Tell me what could happen to the Beretta Chao boiler? 5 years without maintenance, in summer mode the pressure for some reason jumps from 1bar to 3 and drains.

The expansion tank does not work - there is no air, it could have bleed in 5 years - pump up the air to 0.8 bar, but first drain all the water from the boiler, and while pumping air - so that the outlet is open to drain water from the boiler.

Question: Where is the room temperature sensor installed and how to use it?

It is installed at a distance of 3-5 meters from the radiator in the most important room (not in the kitchen - there the stove disrupts the thermal regime), at a height of 150 cm from the floor level.

The temperature is set on the sensor, upon reaching which the boiler switches to summer mode; when it drops from the set one (usually by 1°C), the boiler turns on again and heats the heating system.

Problem with the Beretta Ciao CSI 24 boiler - in heating mode it starts up for 20 seconds, turns off (the light flashes once every 0.5 seconds), after 3 minutes it starts up again for the same 20 seconds.

It really happens that it starts up for 10-15 minutes (but this happens once every hour or two). There is a mode when it is guaranteed to start (“from the pusher”). I turn off the boiler, then turn it on and at the same time turn on the hot water tap.

In this case, it works for 10-15 minutes, and all batteries heat up normally (the light in this case blinks once every 5 seconds). Can someone tell me the reason?

Green indicator light.

Flashes once every 5 seconds – the boiler is in standby mode, there is no flame.

Flashes once every 0.5 seconds – temporary shutdown of the boiler for one of the following reasons, which can be eliminated independently without outside intervention: the hydraulic pressure switch has activated (waiting time approximately 10 minutes); the flue gas pressure switch (Ciao N CSI) or the smoke exhaust thermostat (Ciao N CAI) has triggered (waiting time approximately 10 minutes); transitional stage of waiting for ignition.

At this stage, the boiler waits for operating conditions to be restored. If after the set time the boiler does not resume normal operation, it will stop completely and the indicator light will turn red.

Boiler Beretta Chao, 1 month. Before connecting the remote temperature sensor it worked fine, now after disconnecting the sensor it will not start on its own.

The green and red indicator lights up - the pressure in the system has disappeared, after pumping it starts. What is the reason?

First of all, you need to check the expansion tank for the presence of air (nitrogen). Secondly, look for where the water disappears from the heating system.

Problem with the Beretta ciao csi 24 boiler. Cold starts without problems. After reaching the set temperature it turns off. Each subsequent attempt will start 5-8 times.

Error codes and their interpretation

Let's look at the main error codes (pictures) of Beretta boilers:

| Code | Decoding |

| A01 | Boiler stop due to lack of flame on the burner |

| A02 | The boiler is blocked by the thermostat signal (overheating) |

| A03 | Exceeding the permissible flue gas pressure |

| A04 | Low coolant pressure in the heating circuit |

| A05 | DHW temperature sensor failure |

| A06 | Heating circuit temperature sensor failure |

| A07 | Thermal relay does not open |

| A11 | Parasitic flame (a flame is recorded on a switched-off burner) |

| A24 | Fan failure |

| ADJ | Requires setting of upper and lower boiler power limits |

| E33 | Incorrect connection of phase and neutral power supply |

| E35 | Pressure switch failure |

| E37 | False flame, chimney problems |

| E38 | Smoke sensor short circuit |

| E39 | Broken smoke sensor contacts |

| E40 | Unstable supply voltage |

| E42 | Short circuit of the direct line pressure sensor of the heating circuit |

| E43-44 | Opening of contacts or short circuit of the pressure sensor on the return line of the heating circuit |

| E46 | Coolant overheating |

| E48 | The fan is running wild |

NOTE!

Errors of type “A” require a restart of the boiler, and errors of group “E” disappear after the cause is eliminated without the need for a restart.

Repair of BERETTA boilers in Moscow and the Moscow region!

Repair of BERETTA boilers in Moscow and the Moscow region is carried out on the same day. Most services send specialists to the area only on the second or third day after the order is received, which is very inconvenient in the cold season. Repair of the BERETTA boiler can be truly high-quality if you entrust the work to specialists who know the specifics of the equipment.

The Italian manufacturer offers high-quality equipment, which, with proper care, can become a reliable assistant. A distinctive feature of the manufacturer is the huge number of innovations introduced into the equipment. The equipment of this brand is widely used in three dozen countries, showing excellent quality of work. A huge selection of devices operate on all types of fuel, have standard and compact sizes, can be condenser type or equipped with different types of burners. Every building owner can find the right option. Most of the devices are incredibly economical. The quality of each device is checked and controlled. Only after successful checks the equipment is sent for sale.

Failure of reliable equipment is most often associated with improper installation, system design, and lack of proper attention to maintenance. We also repair DIETRIC gas boilers.

How to run self-diagnosis

The self-diagnosis system is a network of sensors located on all important and critical parts and components of the boiler.

They do not need to be started, since they operate in continuous mode, from the moment they are turned on until the unit stops operating.

Therefore, launching self-diagnosis of a gas boiler as a separate function is impossible . Moreover, if it occurs to someone to stop the operation of the system, then no result will be obtained - it is impossible to stop the process using standard methods, and turning off the sensors is regarded by the control board as the same error, causing the boiler to block.

The self-diagnosis system is an integral part of the gas boiler operation process, ensuring the safety of the equipment and notifying the owner or repairman about the location of the defective unit.

Replacement of BERETTA boilers in Moscow and Moscow region!

Replacing a BERETTA boiler can be the beginning of a long period of high-quality heating if you entrust the solution to real professionals. The company's employees have undergone specialized training, studied all the features of the European brand, having an excellent understanding of all the intricacies of the equipment. Replacing BERETTA boilers in Moscow and the Moscow region will be the start of productive operation of high-quality equipment, provided that the installation is performed by qualified specialists. The favorable cost of services will be another advantage for customers.

High-quality heating equipment can fill a space with warmth for many years. Proper care and installation are key conditions for the proper operation of complex devices. It is always wise to entrust complex tasks only to the most qualified specialists who are ready to help on the first call. “Gorelka+” helps customers out even in the most difficult moments.

Causes of breakdowns of a wall-mounted or floor-standing gas boiler

Gas boilers rarely break down . This occurs as a result of natural wear and tear of the equipment, or due to manufacturing defects . Other cases of breakdowns are necessarily associated with the following factors.

Contaminated water in double-circuit

The boiler may break due to water. At risk, first of all, are dual-circuit devices used not only for heating, but also for hot water supply .

The fact is that rust from the pipeline and other fractions clog the thin tubes of the heat exchanger over the course of a year.

A coarse filter will help you avoid troubles related to water quality . It is installed when mounted on a liquid supply pipe. For greater safety, you can add a fine-grain filter , or install a full cleaning system.

Electricity is the source of the problem

Household appliances are resistant to voltage surges and power outages. But a gas boiler is more delicate equipment. A power surge will cause the boiler to shut down or damage the electronics. A malfunction of the device or a power outage will lead to freezing of the heating pipes.

To avoid dire consequences, install at least one of the additional devices.

- A stabilizer is a device that will solve the problem of power surges. Its size is small and can be installed both in an apartment and in a private house.

Photo 1. Electronic voltage stabilizer Resanta Lux for a heating boiler. The device is mounted on the wall.

- Uninterruptable power source. Will equalize the input voltage. Allows the boiler to operate for some time in the absence of electricity. Suitable for use in both apartments and houses.

- Gasoline generator. It does not affect the stability of the network in any way, but can save you during a long-term power outage. Used only in the private sector.

Attention! When purchasing a generator, check whether it is truly single-phase .

Violations of installation instructions

Installation of complex equipment by a non-professional will entail serious consequences. In frequent cases, the following problems occur:

- During the installation process, grounding was neglected . This leads to the accumulation of static on the device body. When an electric arc occurs, the boiler automation often fails.

- After installation, the air was not released from the system . The resulting plug will lead to rupture of the coolant pipes and breakdown of the pump.

- Violations in the piping of a gas boiler system with a cast iron heat exchanger will cause a split in an important part of the apparatus.

User manual

Beretta boilers are operated automatically, which does not require constant human intervention.

The user is only required to adjust the heating mode according to his own feelings, switch the boiler to winter or summer mode (turning off or starting the heating circuit), maintaining the cleanliness of the body and periodic maintenance (by service workers).

All serious problems can only be solved by calling a specialist - eliminating constantly occurring errors or incomprehensible phenomena that occur with the boiler in operating mode.

In addition, the user independently fills the system with water (or recharges as necessary).

The process consists of supplying liquid through the make-up tap and filling the system until the water pressure reaches 1-1.5 Bar. This is below the operating pressure, but when heated, the water will expand and due to the increase in volume, the pressure will reach the desired value.

Download instructions Download instructions

for Beretta gas boilers

.

The boiler starts automatically when the required temperature of the coolant in the system is set.

It is prohibited to pour water into a hot boiler due to the risk of destruction of the heat exchanger . It is necessary to wait until the boiler cools down and only then add water.

Possible malfunctions and DIY repair methods

Any malfunction of a gas boiler must be dealt with by a specialist. However, it is not always possible to use the services of a specialist, and the breakdowns can be trivial . Let's look at problems that can be solved independently.

The house smells like gas

Typically, the smell of gas appears when it leaks from the threaded connection of the supply hose . If there is a smell in the room where the boiler is installed, you need to open the window and turn off the boiler . Then follow the instructions:

- Prepare the necessary things: soap solution, FUM tape, open-end or adjustable wrench.

- Apply the solution to all threaded connections. If bubbles begin to inflate, the leak has been identified.

- Close the gas valve.

- Use the key to open the connection. Wrap FUM tape around the external thread and put everything back together.

- Reapply the solution and resume gas supply.

- If the leak is fixed and the smell of gas has disappeared, remove the remaining solution.

Attention! When the leak cannot be found, turn off the gas and call a specialist .

Fan doesn't work

If during operation of the boiler the sound produced by the turbine disappears or decreases, this indicates a malfunction of the blower fan. For repair you will need: a screwdriver, a new bearing, a cloth, and grease.

- It is necessary to turn off the boiler and turn off the gas.

- Remove the turbine.

- Use a cloth to clean dust and carbon deposits from the turbine blades

- Inspect the electric fan coil for blackening. If everything is ok, move on or replace the fan.

- Disassemble the fan housing. a bearing installed inside the turbine shaft ; it needs to be replaced. Some fans have a bushing instead of a bearing. In this case, it needs to be lubricated.

The turbine may also not work due to low mains voltage or a faulty control board. The first can be eliminated with the help of a stabilizer, but the second can only be eliminated by calling a specialist.

The chimney of a floor-standing boiler is clogged

Problems with the chimney occur only with floor-standing boilers . This is due to its size and vertical position. Mounted units do not require chimney cleaning.

The chimney, consisting of metal parts , is cleaned with a metal brush. It needs to be disassembled and the accumulated soot mechanically removed. A solid chimney is cleaned with special vacuum cleaners or chemicals. But for this you need to call a professional.

Photo 2. Three ways to arrange a chimney for a floor-standing gas boiler. The first option is the most difficult to clean.

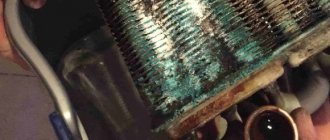

High temperatures

Overheating of the boiler is associated with contamination of the heat exchanger . To clean the device you will need: a special solution of hydrochloric acid, an adjustable wrench, FUM tape, a metal brush. Then follow the instructions:

- Turn off the boiler, turn off the gas and water.

- Remove the heat exchanger using an adjustable wrench.

- Clean it with a brush.

- Pour the acid solution into the heat exchanger through the pipe . If foam appears, it means there is a lot of scale inside.

- Pour out the solution and repeat the procedure.

- Rinse.

- Reinstall , having previously wrapped all threaded connections with FUM tape.

Sensor malfunction

Problems usually arise with the combustion electrode. If the burner flame goes out after a few seconds and the boiler gives an error, then the problem is in the combustion sensor. Turn off the boiler and turn off the gas.

To repair the electrode, you will need sandpaper , which can be used to clean the sensor probes without removing it. If the damage remains, the sensor is replaced.

Self-shutdown

There are two problems that lead to spontaneous shutdown of the boiler. The combustion sensor is broken or the chimney is clogged . Repair of both faults is described above in the article.

Common heating boiler malfunctions

Regular preventive maintenance of heating boilers should be carried out at least once a year.

The causes of malfunctions can be different: from water leakage to breakdown of main parts.

What determines the longevity of a boiler?

Each factory heating unit has a passport with the specified requirements and instructions for the correct operation of the equipment. Compliance with all passport requirements guarantees safe, efficient and durable operation of the unit.

The durability of the boiler depends on compliance with boiler operating standards and on the quality of the water, which acts as a coolant.

How to extend the service life of the boiler

Pay attention to the boiler every day and do not ignore any changes: noise, instrument readings, cracks, combustion features or combustion products

It is important to promptly follow the operating rules (specified in the passport) and carry out preventive maintenance (preferably before the start of the heating season)

Each change in the operation of the unit has its own reason, so contact the specialist in a timely manner.

The most common malfunctions in the operation of domestic boilers:

- Leakage of water or coolant.

- Formation of soot on the walls of the combustion chamber or chimney.

- Reduced unit performance.

- Water hammer inside the boiler.

- The burner does not turn on.

- The burner turns on and then locks out.

- The fuel burns unevenly with pulsations.

- While the burner is operating, the ignition is switched on.

- Soot formation.

Causes of malfunctions

Water leakage may be due to the collection of water vapor condensate. This is a common occurrence after the boiler is started. The second reason for water leakage may be a violation of the sealing of threaded connections or a crack in the pipeline.

The formation of soot can lead to a narrowing of the chimney flow area, as a result of which the stable operation of the boiler will be disrupted. To do this, it is necessary to carry out cleaning work through a special hatch, and to prevent re-clogging, it is necessary to check the draft.

The draft and blast air are adjusted using a gas analyzer. For example, for an oil-fuel boiler, combustion products must contain: CO up to 200 ppm; O2 from 3.5 to 5.5 ppm; CO2 from 11.5 to 13.5 ppm.

An excessively high temperature in the combustion chamber indicates poor draft, so adjustments must be made.

Excessive consumption of fuel may indicate a deterioration in its quality or the formation of scale on water heating surfaces. To prevent damage, the boiler should be descaled and an electromagnetic converter installed to reduce water hardness.

If the temperature of the coolant at the boiler outlet does not rise, there may be several reasons: the draft and blast are incorrectly adjusted, scale formation, or a malfunction in the system automation.

Water hammer inside the boiler can occur due to low-quality gas fuel or “airing” of the heating system. To troubleshoot problems, it is necessary to adjust the draft and install an automatic air vent.

The operating instructions describe all problems with the boiler.

The burner does not turn on - there may be several reasons: if it is a liquid fuel unit, the voltage to the engine may have gone out, the parameter is not normal, or the blocking does not allow starting for safety reasons.

The burner turns on and then locks out. Reasons: the ignition electrodes are not adjusted, the insulation of the electrodes is broken, the software controller is faulty, fuel supply is impossible (clogged, missing, malfunctioning).

While the boiler is operating, the ignition is switched on. The cause of this phenomenon may be a dirty photocell or faulty automation.

Uneven pulsating combustion can be caused by too much blowing air pressure.

The formation of heavy soot indicates an incorrect draft/blown setting or poor fuel quality.

Why you shouldn't do it yourself:

- Unqualified repairs can aggravate the situation and the unit will become life-threatening.

- If you act carelessly, other elements of the unit may be damaged.

- It is possible that the wrong cause has been identified, and eliminating the wrong cause will not lead to a fix.

- The technician will perform the repair with a guarantee.

Autonomous heating is convenient, efficient and practical, but do not forget about regular preventive technical inspections.