Are you familiar with the situation where you have to repair an expensive part, but the budget for this repair is growing? Surely you know what costs can and should be considered unnecessary. For example, you have a gas boiler and you don’t want to pay up to 30 percent of the cost of the entire device to repair one single part. If you don’t know how to weld the heat exchanger of a gas boiler, just read our article and you will learn.

Thanks to this article, you will learn the procedure for repairing the heat exchanger - a part due to which boilers often break down. We talked about soldering heat exchangers in different ways. Using our recommendations, you can independently repair the failed part.

In domestic conditions, heat exchangers are repaired by soldering. Welding is literally used in manufacturing, sometimes with the help of robotic devices. Leave a heat exchanger with extensive structural damage to the craftsmen, but in the case of small holes in the part, soldering can help. Find out more about this.

Repair of heat exchangers of gas boilers: stages of work

Reliable and high-quality repairs of gas boiler heat exchangers are quite difficult to carry out on your own, but it is still possible. We'll talk about how to do this correctly below.

Causes of breakdowns

Modern models of mounted boilers may fail if the heat exchanger:

- a crack will occur as a result of thermal overstress, a sharp change in temperature or pressure;

- poor quality materials were used;

- The coolant used is not sufficiently cleaned.

Pipes before and after cleaning

Repair

When cracks appear, the breakout site must be soldered. Heat exchangers can be cast iron, steel or copper; most often in gas boilers you can find copper structures with the addition of nickel, zinc, manganese, silicon and aluminum. Accordingly, if you decide to carry out soldering yourself, you need to select solder from the same alloy.

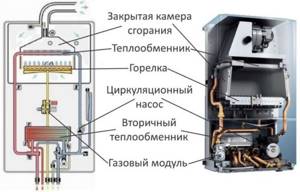

Gas boiler heat exchanger

Copper melts at a temperature of 1083 0 C, brass - at 900 0 C. Old gas boilers can be soldered with brass, but modern systems have a different copper composition, so you need to show considerable diligence in finding solder. He must:

- have the same soldering fluidity as the heat exchanger;

- be sufficiently viscous;

- have a melting point of at least 700 0 C;

- have a composition as close as possible to the composition from which the heat exchanger is made.

In general, choosing the most suitable solder is the most important part of the upcoming work.

Important!

You cannot solder with tin, the soldering will be of poor quality and after a couple of months the crack will recur. Only high-quality hard factory solder is used.

If you have already encountered similar work before, you can try to fix the leak yourself, but if you are not familiar with soldering, it is better to turn to professionals.

Soldering is carried out using a gas torch; to speed up and facilitate the entire process, several installations can be used at once. Solder is chosen in the form of a rod or wire - this is convenient because if it is necessary to add flux during work, the hot end of the solder is immersed in the flux, which instantly sticks to it.

Important!

When soldering with copper-zinc solders, intense evaporation of zinc occurs. In order to avoid this, up to 0.4% tin or silicon is added to brass.

Silver solders with zinc and copper are considered the best. They are used for soldering cast iron, steel and most refractory non-ferrous metals, the melting of which occurs at a temperature higher than the solder melts.

Copper-phosphorus solders, which also require the use of flux, since phosphorus itself is not suitable for heat exchangers. They can only be used when there is no shock or vibration load.

The place of future soldering must first be cleaned and heated to the required temperature. It will be difficult to warm up the heat exchanger in air, so you need to create the necessary environment in advance. It is necessary to control the upper and lower thresholds, the temperature threshold and the local cooling volume.

And in order for the soldering area to be reliably “sewn up”, upon completion of the work and complete cooling, it is advisable to cover the problem area with heat-resistant paint. Also, during the first week or two you need to regularly check the soldered part for leaks. If a repeated coolant leak occurs, it is advisable to invite a specialist to carry out the work, as it is obvious that the independent soldering was of poor quality.

Which material is better

Boiler heat exchangers are made of different metals, the selection of which is made by the manufacturer during the design of the heating source.

Basically, modern devices are equipped with heat exchangers made of steel, cast iron, copper and aluminum. They have different heat transfer coefficients, permissible temperature environments and resistance to corrosion processes. A floor-standing gas boiler with a cast iron heat exchanger is the most economical and durable.

Steel

A stainless steel heating apparatus is technologically the simplest, both in manufacture and in operation. Therefore, it has the most affordable price, which affects the overall cost of the boiler.

Steel has good ductility, so this design in an environment of high-temperature hot gases is less susceptible to temperature deformation.

But at the same time, steel is affected by corrosion, both internally due to dissolved oxygen in the coolant, and externally due to acidic moisture in the flue gases, especially at the time of starting from a cold state. Therefore, these heat exchangers are not durable, have a lot of weight and create low boiler efficiency.

Aluminum

Many Western models are equipped with aluminum heat exchangers, to which experts attribute a great future in household heat and power engineering.

Soldering the heat exchanger

Repair of a copper heat exchanger of a gas mounted boiler

This model may leak on the left side, front or rear tubes, one or two out of four after 6-8 years of operation, this is a normal resource and it should also work after soldering if it is done well.

Heat exchangers can be steel, cast iron, copper: the latter are used in the automotive industry, air conditioners and in mounted boilers because, with significantly smaller sizes, they have more power but have the disadvantage that a leak appears, the loads it experiences are pressure + thermal stress, a crack appears, and leakage of coolant from the system, the first sign is the appearance of water at the bottom of the boiler in the form of drops that can change intensity and sometimes stop or flow intensely, due to the formation of salts at the crack site, this can be seen in the place where the salt cover is at the point from where the water flows :((((

The old Soviet speakers leaked after ten years, and it was not for no reason that the automation did not work, it was the norm and there were no problems with sealing because the copper was 1 mm thick, and today it is not copper and the thickness of a concert can, you can’t solder it with anything and anywhere you need experience and expensive solder, the skill of a craftsman, a master who does not work with heat exchangers all the time is no longer a master, well, you need to have different solders and different welding equipment on hand.

It has been noticed that boilers with good flame modulation, their heat exchangers are much less likely to fail; if the quality of the hot water supply is good, the heat exchanger does not overheat; if the boiler produces a stable hot water temperature, then the life of the heat exchanger is much higher. Ferroli DOMIcompact is not a problem; it can be 100% soldered, its average service life is 7 years, why are we talking specifically about these models? This heat exchanger flows only from the left, front or rear pipes on the side of the heat exchanger, heating or hot water in these places it is always possible to prepare the soldering area, the quality of the soldering largely depends on how it is prepared, but others also flow. When inspecting the boiler annually, draw the attention of the technician to this and ask him to check it according to the diagram in the boiler instructions and maybe lower it a little to save the boiler from excessive overheating. View more details on our website.

Heat exchanger cause of leakage thermal load diagram

Heat exchangers after repair: the right one is tinted with silver paint that is resistant to high temperatures, after such soldering it will no longer leak, time-tested.

We came across heat exchangers that needed to be repaired after they had been soldered somewhere, welded with argon, which cannot be done, not a single global company has thought of welding heat exchangers, if this happens it will be a new breakthrough in science and technology, but for now I am soldering them, and so advice if you we found a repairman and decided to send the heat exchanger for repair, and the master tells you let’s try it or you need to look at it, then you’ll think about whether it’s worth cutting up something worth 150 dollars. or ask if the master is ready to compensate you in case of bad luck and demand guarantees if everything is vague and not clear.

________________ Cases when repair is not possible or unreliable

Heat exchangers of all mounted boilers can fail, it happens when the heat exchanger flows above the burner between the absorber plates, namely under the plates, this plate with a hole in the shape of a heat exchanger pipe with a bend, this bend is equal to the gap between the plates (absorber) they are soldered to the heat exchanger pipe but this soldering does not serve for tightness, but only for transferring heat into the pipe with the coolant; if the plates are not soldered to the heat exchanger, there will be no heat removal and the plates will burn, and if there is a leak in the heat exchanger tube, it is not possible to remove the plate, and soldering on top of the plates is pointless. But we are not standing still, and on April 4, 15, there were the first heat exchangers with such a problem, and now we can say that here we are taking on such repairs when there is a leak above the burner between the plates, photos of such repairs will be presented the other day. Corrections 04/06/15

Pros and cons: whose victory?

After the first acquaintance with this type of heat generators has occurred, you can begin to consider their strengths and weaknesses in order to then assess the feasibility of purchasing a boiler that has a bithermic heat exchanger.

Advantages of boilers with bithermic heat exchangers

The list of advantages of such units includes:

- compactness due to the minimum space occupied by the “pipe within a pipe”;

- the ability to use only hot water, which is important in the summer;

- a chance not to encounter cold water in the hot water supply, since the liquid is already partially heated;

- maximum efficiency, cost-effectiveness due to more accurate heat consumption;

- quite high efficiency (only 1-2% less than that of conventional boilers), the same rate of heating of liquids;

- lower price (by 10-15%) of units due to significant savings in material, lack of control valves, and a three-way valve.

Reducing the risk of element failure can be added to this category. Since the design of a boiler with a bithermal heat exchanger is simpler, there are fewer parts in it, which means that the likelihood of component failures is also not as low as with more complex heating devices.

Disadvantages of bithermic equipment

Everything in the world has pros and cons, this is also true for boilers with combined heat exchangers. Before choosing a device, you need to find out what the weaknesses of such devices are. These include:

- the complex shape of the pipes, their small size, are potential reasons for the rapid formation of salt deposits if the water quality is poor and the set temperature for the heating system reaches 95°;

- liquid temperature: when opening a hot water tap, owners risk being severely burned if the highest possible values for the heating system coolant were selected for installation;

- a gradual decrease in the efficiency of equipment with bithermal elements: this is due to clogging of the circuits over time, but it can and should be dealt with;

- overgrowing of the DHW circuit, after which further operation of the equipment is impossible; boilers with separate heat exchangers are devoid of this unpleasant feature;

- when using DHW, heating of the liquid for radiators, heated floors, etc. stops.

The last drawback is still relative. To feel a drop in room temperature, you need to use hot water for a very long time, and this “waste” is hardly possible with installed meters. This list includes the need for precise adjustment of boilers with bithermics for hot water supply.

Owners who “missed out” on the formation of deposits that are almost incompatible with the life of the boiler run the risk of encountering a significant disadvantage. Replacing this element will require paying a significant amount: sometimes installation and purchase takes almost half the cost of the unit, often even more.

Repair of gas boilers in Rostov-on-Don

- Boiler repair

- Gas wall boilers

Boiler repair in Bataysk and the region

SERVICEDOM | Bataysk, Rostov region

We repair heating and hot water equipment.

Installation of boilers in Rostov-on-Don

Today, gas boilers produced by foreign manufacturers generally have a number of significant advantages: - elegant design that corresponds to modern trends; — .

Repair of gas boilers and water heaters

Repair and maintenance of gas boilers and water heaters in Stavropol and the region, no further than 50 kilometers. All types of repair work, including board repair (control modules), prevention and consultation. Original.

In stock / Service

Gas boiler repair

Repair of gas boilers. Repair of geysers. Cleaning geysers. Installation of geysers. Maintenance of gas boilers. Repair of gas stoves. Safe, inexpensive, using high-quality .

In stock / Service

Boiler repair call a technician, spare parts Baxi control board

"Sun Energy" LLC |

Delivery to Rostov-on-Don Repair of heating boilers BAXI - control boards, we will help replace spare parts if they break down Chelyabinsk. The technician will replace the sensors, board, heat exchanger, fan, and transformer for an additional fee.

Repair of gas boiler control units

Ivanov V. L. IP | Delivery to Rostov-on-Don

Repair of control units for gas boilers in Novocheboksarsk. Repair of control boards for gas boilers. Electronics repair. Repair of power supplies st. Molodezhnaya, building 6A, office 200, above Pyaterochka, .

In stock / Service

Boiler repair

German warmth | Delivery to Rostov-on-Don

The most important factor ensuring uninterrupted operation and safety of heating equipment is annual maintenance. also provides services.

In stock / Service

Gas boiler electronics repair in Novocheboksarsk

Ivanov V. L. IP | Delivery to Rostov-on-Don

Repair of gas boiler control units, electronics repair. st. Molodezhnaya, 6A, office 200, 2nd floor. Novocheboksarsk (above Mag. Pyaterochka, intercom 7). Tel. IP Ivanov Vladimir Leonidovich.

In stock / Service

Gas boiler repair

"Termogaz" Service LLC |

Delivery to Rostov-on-Don Repair of gas boilers of any complexity, incl.

emergency repair. We work with leading European manufacturers Vaillant (thermogaz ru/remont-vaillant/), Viessmann (thermogaz ru/remont-viessmann/), .

Strengths and weaknesses of opponents

In order to be able to correctly and objectively compare both devices, we now need to give the pros and cons of boilers with separate heat exchangers.

Advantages of units with non-combined elements

Any new product initially causes mistrust, so familiar equipment is always in an advantageous position. What is attractive about conventional double-circuit boilers when you compare them with new units?

- Comfortable water temperature in any conditions. In this case, the owners are guaranteed not to encounter very hot water when opening the tap, so they are not in danger of getting burned.

- Relatively simple installation of uncombined dual-circuit equipment. Often such an operation is carried out independently, refusing the services of professionals.

- The existence of a second heat exchanger is already a plus. Since one of the elements will be used less often, its service life will increase.

- Self-repair. This possibility exists in a number of cases when the breakdowns are not too serious.

- Price of individual heat exchangers. In any case, it is lower than the cost of a “pipe in pipe”.

The minimal risk of clogging is another advantage that opponents of bithermal devices cite as an argument. Separate heat exchangers require less frequent maintenance of traditional equipment. But this plus does not apply to all boilers.

Disadvantages of separation of heat exchangers

The main complaint about this type of devices is their large dimensions. It is not always easy and quick to find a device that would fit perfectly into the space that is intended for it. In addition to size, there are other disadvantages. This:

- the presence of additional elements that “willingly” come out and work: first of all, this applies to very “capricious” three-way valves;

- the price of conventional double-circuit equipment, however, it is justified, since more complex boilers have a larger number of components;

- it is impossible to thoroughly rinse the secondary plate heat exchanger, since the distance between its elements is only 2-3 mm.

Both devices are imperfect: each of them is superior in some ways and inferior in others to its competitor. Therefore, the choice of boiler depends on the conditions under which the equipment will operate. Moreover, a significant role in this case is played not by any shortcoming of the device, but by one, most important factor - the quality of the water used.

The role of coolant in systems

The main complaint about devices with bithermal heat exchangers is their rapid overgrowth. However, this is not a problem with the equipment, because providing good quality fluid is the task of its owners.

Heating requires a prepared coolant - free from iron, excess salts, and other inclusions. This is the best cleaning option. But there is a minimum program: it consists of softening the water, adding antifreeze or other additives that prevent the appearance of scale on the walls. Distilled water is considered the ideal liquid for working in a heating system. But since the liquid circulates in the circuit in a closed circle, over time it is deprived of salts even without proper cleaning.

If we consider hot water supply, then the heat exchangers of single-circuit boilers suffer in the same way from poor quality of the liquid if they have a large channel cross-section. When there are suspicions that the water is hard, it is necessary to install a filter, or a whole complex - a station that will prevent lime and salts from entering the hot water supply system.

REPAIR OF GAS HEATERS

• repair of geysers; • installation of a geyser; • commissioning of a gas water heater; • Maintenance of geysers; • cleaning the geyser; • heat exchanger soldering; • replacement of a gas water heater; • Heating installation; • Gas boiler repair.

It's free and doesn't oblige you to anything. We will call you back within 30 minutes.

By clicking on the “Get consultation” button you consent to the processing of your personal data.

We comply with all rules, regulations and safety requirements. Let's prepare a project. Let's connect the components: chimney, draft regulator, thermostat and fan, automation.

* You do not pay for equipment diagnostics if you agree to carry out repair work. ** Village of Kotovskogo (Kryzhanovka, Leski, Fontanka) / Tairovo (Sauvignon, Chernomorka) +50 UAH. The final turnkey cost depends on the brand of equipment and the installation location.

Maintenance of geysers

is an important part of proper care of the gas water heater and its safe operation. During maintenance, equipment is thoroughly inspected and cleaned. In order for the gas instantaneous water heater to work correctly, the manufacturer strongly recommends annual maintenance.

Soldering the heat exchanger

- a reliable and durable way to eliminate leaks, returning the column to good working condition with a guarantee. If the heat exchanger is damaged, it is not necessary to immediately replace the heat exchanger. Very often it is possible to repair the heat exchanger and solder the breaks. We use only high-quality alloys when soldering the geyser heat exchanger.

During installation/installation

For geysers, we use only high-quality, proven materials, take into account all the manufacturer’s recommendations and provide guarantees.

When we install a gas water heater, you receive a bonus: delivery of a new water heater is free.

Installation, start-up and commissioning are carried out by experienced craftsmen with valid permits for gas-hazardous types of work.

Competent service is the key to stable heating operation

Real photos of our works:

The SERVICE No. 1 company is a reliable partner who values its reputation.

Important aspects of our approach to providing equipment repair services:

Types of services.

We will solve your problem comprehensively. From repairing parts to fine-tuning the entire heating system.

Free consultation and diagnostics.

Our specialists will readily answer all your questions before and during work.

Guaranteed stable performance.

We use only high-quality, original parts. Own s/h.

- You rest - we work.

We fix 90% of problems on site on the same day.

The choice of price is yours.

We will announce the cost before work begins. You choose your own set of services.

You can come to our service center.

Our office is located at: Odessa, Uspenskaya 76.

We carry out - repair of heating equipment: gas, wall-mounted, floor-standing, solid fuel boilers; repair of laptops, tablets, smartphones, computers, replacement of matrices, keyboards, batteries, hard drives, drives; repair of small household appliances.

We have been diagnosing, repairing and servicing boiler equipment for more than 8 years. During this time, we have accumulated extensive experience in the repair and operation of boilers of various brands. More than 600 clients annually enter into a contract with us for the maintenance of boiler equipment.

Why do they trust us and recommend us to neighbors, friends and acquaintances?

Authorized Service Center.

We are an authorized service center for boiler equipment of the brands

Vaillant, Protherm, Viessmann, BOSCH, Ferroli , Ariston. If a warranty case arises, the boiler will be repaired by our specialists free of charge, within the framework of the manufacturer’s warranty obligations.

Own warehouse of spare parts.

The required quantity of original spare parts for authorized brands is maintained in stock. When you call our specialist to diagnose the equipment, the engineer will immediately take with him the necessary spare parts, which will significantly reduce the repair time.

Qualified specialists.

Our employees undergo annual training conducted by boiler equipment manufacturers, which is confirmed by certificates. Each specialist undergoes timely certification and has certificates allowing him to work with gas and electrical equipment.

Special conditions for collective applications.

Among our clients are residents of cottage villages and apartment buildings with individual gas heating. For such clients we can offer special conditions. To receive a discount on services, it is enough to submit a collective application (from 4 houses/apartments).

Comfortable cooperation.

In order to conclude/extend a maintenance contract, you can come to our office at Balkovskaya 120/1, office: 525, or leave a request by phone

(050) 508-61-79

and our engineer will come for service immediately with a prepared contract. Payment for all services is possible in cash or by bank transfer. If you need to pay by bank card, the engineer will take a mobile terminal with him.

Maintenance of geysers is an important part of proper care of a geyser and its safe operation. During maintenance, equipment is thoroughly inspected and cleaned. In order for the gas instantaneous water heater to work correctly, the manufacturer strongly recommends annual maintenance.

Repair of electronic control boards for gas boilers of all brands and types in Odessa and the region by prior arrangement. Fast quality with a guarantee. Visiting the customer’s home, assessing the cause, working within a short time frame. Sale of new boards.

Our main task is to bring your device back to life!

And we are making every effort to cope with this task as quickly as possible, while complying with all technical standards.

We guarantee:

Same day repairs

Depending on the complexity of the problem, repairs take from 20 minutes to 1-2 days.

Work guarantee

If the installed parts break, we will replace them free of charge.

Troubleshooting

Experienced craftsmen can easily cope with any problem.

We install only branded, certified parts.

Even if you do not order repairs from us, we will carry out diagnostics for free.

What is more profitable: repair or replacement?

The choice depends on operating conditions, operating life of the model, and types of damage. If, after a visual inspection, no defects are identified in other parts of the structure, you can stop at repairs. The appearance of numerous signs of defects indicates the need for replacement.

It is difficult to independently determine the degree of maintainability. The solution is to call a specialist for a comprehensive analysis. He will help you find damage and advise you on the choice of soldering technology for the Etra heat exchanger (ET) or another company.