Home » Classification of gas boilers » Operating principles » Setting the modes of the Immergaz gas boiler

Heating equipment made in Italy by Immergas has long been known on the Russian market. It includes modern technologies and has the ability to connect other auxiliary devices, for example, a room thermostat or an outdoor programmer. Setting up a gas boiler Immergaz allows you to control the operation of the unit in two modes: via the remote control or using a panel located on the body.

…

- 1 Turning on the gas boiler

- 2 Setting the unit power

- 3 Programming settings

- 4 Other gas boiler settings

Turning on the gas boiler

Before turning on the gas boiler, you should check that the pressure in it is at the level of 1-1.2 bar and the gas supply valve is open. Then the Main handle must be moved to the “Remote control” or “DHW and heating” position. When one of the modes is activated, the top green indicator lights up.

If the unit is in the “Remote Control” mode and the remote control is connected to the boiler, the manual switches stop functioning. Setting up a gas boiler and turning on various functions is done from the remote control. When the remote control is activated, indicators 2 and 3 on the unit body are constantly lit, above which there are images of a water tap and a radiator. Indications of modes or failures are displayed on the remote control display.

If the knob is turned to the “Remote Control” position and the remote control is not connected, the heating knob will turn off, but the hot water knob will work.

When the “DHW and heating” mode , the heating knob is used to adjust the heating power, and the DHW knob is used to change the temperature of the water circuit.

…

If any light in the group, which includes 7 indicators located on the right, blinks, this indicates a malfunction.

How to properly set up a gas boiler?

Find out here the features of a wall-mounted gas boiler

Gas boiler temperature regulator - purpose and types

Gas boiler IMMERGAS Features

The company approached its fiftieth anniversary (which it celebrated in 2014) with its own technical development center, 15 assembly lines, and production output of just over half a million boilers per year. The main production is located in the town of Brescello in the heart of Italy.

However, there is a second production unit located in the Slovak Republic, at the city factory Poprad - production for the eastern countries of the European Union is established here, and the production of boilers is about 60 thousand units.

What boilers does Immergas produce?

Immergas condensing boilers are in high demand among consumers in Western Europe. They generate heat from the combustion of gas, and in addition they use heat from steam. The fact is that, according to the latest directive of the energy legislative body of the European Union, it is allowed to operate a high-efficiency boiler of the condensing type. It's all about the advantage that allows you to achieve savings in natural gas of up to 35% compared to the second type of traditional devices produced - atmospheric devices by the Immergas company.

The Russian consumer is still reluctant to overpay for condensation options, preferring to pay for excess gas consumption - fortunately, for us it is not yet at European prices. That is why cheaper traditional atmospheric boilers are the most popular for domestic consumers, which in turn are divided into:

- single-circuit - this Immergas gas heating boiler of the Eolo Mini X 3E and Nike Mini X 3E series is optimal in terms of price-consumer qualities and provides heat to cottages or private homes. By the way, immergas eolo is very popular in Russia. As a rule, they are produced with high productivity. But to provide hot water, additional equipment will be required in the form of an indirect heating boiler.

- dual-circuit models are easy to use. The fact is that this design allows you to heat the house and provide the hot water needs of your household. And due to the fact that the price between the modifications of single- and double-circuit models is practically unnoticeable, the 2-circuit versions of Immergaz have gained great popularity by combining the advantages of a gas water heater and the advantages of a heating device.

Immergas combustion chamber

In addition, the Italian manufacturer Immergaz produces boilers with traditionally two types of combustion chamber arrangement. Of course, these are models with closed and open gas combustion options. firebox

The classic option is a boiler with an open combustion chamber. Such Immergas models do not require special installation of a chimney; all combustion products are removed by natural draft. The Immergaz gas boiler, equipped with an open combustion chamber, can be found under the name “Nike”. Thus, the manufacturer offers the Immergaz Nike Mini 24 E boiler with two separate heat exchangers.

The power characteristic of immergas mini 24 is 24 kilowatts. As a rule, such models are less likely to suffer from various breakdowns. The “Nike Star 24 3R” model is equipped with a copper bithermic heat exchanger based on the “two-in-one” principle and with exactly the same power of 24 kW. The disadvantages of such models include that the combustion air is taken from the room, and the Gas Service imposes more stringent requirements for their installation and maintenance.

Closed combustion chamber immergas

The closed combustion chamber is technologically equipped in a series of Immergas boilers with the name “Eolo Mini”, including two heat exchangers - one for heating and the second for preparing hot water, as well as “Nike Star 24 3R” with a copper bithermal heat exchanger with the same power - 24 kilowatts each every.

The boiler provides protection against scale. After switching off, the pump continues to pump cold water for about 3 minutes, thus removing the thermal load. This function prevents the formation of scale and salt on the walls of the heat exchanger. The closed-type design of immergas star allows achieving good economical gas consumption. In addition, air supply and combustion products removal are carried out through a coaxial chimney, which leaves residents with the oxygen they need without using it in the combustion process.

Setting the unit power

You can adjust the optimal power of the Imeergas gas boiler using the gas valve. Setting the operating power of a gas boiler is carried out as follows:

- set the DHW switch to the desired position;

- open the hot water tap;

- adjust the required power using the adjustable nut on the gas valve;

- adjust the heat output by turning it clockwise to increase it, or counterclockwise to decrease it.

The minimum heat output can be adjusted using a plastic screw located on the gas valve. The adjusting nut must remain motionless. It is recommended to turn off the power to the valve modulation coil and then turn the screw clockwise to increase the pressure or counterclockwise to decrease the pressure. After this, the power to the coil must be returned.

…

Note! The minimum power should not be less than that specified in the characteristics of the unit.

Brief information about the design of the heating system

Modern gas heating systems are complex systems. Their operation is monitored using a whole range of automatic devices, which you need to become familiar with before you begin repairing gas boilers yourself.

Basic elements of a security group:

- Draft sensors designed for 75 0 C. This device makes it possible to monitor the condition of the chimney. If normal smoke removal fails, the temperature rises and the sensor is triggered. Optimally, in addition to the traction sensor, a gas alarm is purchased.

- The monostat protects turbocharged gas units from poor removal of combustion products due to a clogged chimney or heat exchanger.

- The limit thermostat is designed to control the temperature of the coolant in a heating installation. When the water boils, the overheating sensor turns off the device.

- The flame control electrode, when detecting its absence, turns off the operation of the heating unit.

- The blast valve serves to control the pressure. When the pressure rises above a critical value, excess coolant is discharged in batches.

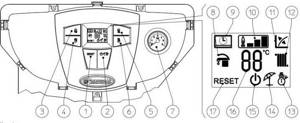

Programming settings

Immergaz boilers of the Zeus series allow the user to program their own settings, each of which has its own indication.

To activate the programming mode, set the main control to the Reset position and hold for 15-20 seconds until the top indicator flashes. Then you need to switch the main regulator to the “DHW and heating” mode.

First, the first programming level is activated, which will allow you to adjust the parameters. You can determine the programmable parameter using 10 indicators, indicated by the corresponding icons:

- 1 – minimum heating power;

- 2 – maximum heating power;

- 3 – heating switch-on timer;

- 4 – parameter of smooth power control;

- 5 – pause time before ignition when working with a thermostat or remote control;

- 6 – thermostat of the DHW circuit;

- 7 – circulation pump;

- 8 – heating of the DHW circuit;

- 9 – gas;

- 10 – operation of relays and safety sensors.

The activated parameter will flash. At the same time, the upper sensor will also blink. You can adjust the required value using the DHW heat exchanger temperature switch.

After selecting a parameter, move the main switch to the Reset position and hold it until the indicator of the corresponding parameter goes out. After this, the mode switch is released.

A second level of programming is now available. Activation of parameters is indicated by blinking of the corresponding indicators. The values are changed using the heating temperature controller. The selection is confirmed by moving the main switch to the Reset position. After this, the mode indicator should go out. Programming mode will turn off if there is no activity for 30 seconds or the main switch is turned to the OFF position.

The automatic gas boiler provides power modulation depending on the room temperature. By setting the maximum and minimum performance values, the unit will operate within the set power range.

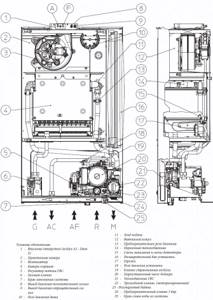

Gas boiler IMMERGAS Device

The manufacturer Immergaz guarantees that mass-produced wall-mounted 2-circuit boilers with the names “Mini” and “Star” can be found on sale exclusively in Italian production. The Nike range includes two traditional heat exchangers: one is made of copper alloy and provides heating to the heating system. The second is responsible for supplying hot water; the manufacturer installs it in a stainless steel boiler. The difference between the series called “Star” is that it is equipped with a bithermic heat exchanger, which combines two circuits. Each model in the series includes a gas valve from SIT, which has established itself as a reliable and high-quality supplier to many boiler equipment manufacturing companies. An even more famous world-famous leader in pump construction, the GRUNDFOS concern, was chosen as the supplier of the circulation pump.

On the right side, the Immergas gas boiler contains a flat, expansion membrane tank with a capacity of six liters, a smoke pressure switch and a fan. All gas and water connections are made of high-quality copper alloy guaranteeing a long service life of the product.

On the front panel, the display demonstratively displays the values of the selected boiler operating mode summer - winter, temperature readings, and pressure in real time. The immergas boiler controls its operation using a board with a microprocessor. As a result, the consumer sees the necessary information about the state of the equipment and possible errors in the form of codes.

The Immergaz gas boiler is equipped with multi-level protection.

equipped with reliable protection: possible overheating is blocked by NTS temperature sensors. The draft sensor will protect against operation of the device in case of poor smoke removal. The boiler has permanent frost protection, anti-blocking of the pump and three-way valve. With an optionally purchased room thermostat, the operation of the boiler will be balanced based on the room temperature.

Remote thermostats can be either simple CRONO 7, CAR V2 - mechanical or electronic type, or intelligent MINI CRD with the advantage of weekly programming. Thanks to the use of modern composite materials, it was possible to reduce the weight of the product by more than 10%, while maintaining strength and long service life.

Boiler Immergas Nike and Eolo Mythos 2E (4R)

MYTHOS is a series of 2-circuit boilers, as we have already mentioned, produced at enterprises in the Slovak Republic. Two separate heat exchangers guarantee the supply of hot water and heating of your home. The price niche occupied by boilers is slightly lower than expensive competitors. The use of composite materials contributed to the price reduction.

Slavak Mythos have two modifications:

- equipped with a fan-turbine Eolo Mythos 24 2E (4R) and Eolo Mythos 10 2R correspond to powers of 24 and 10 kW;

- traditional-atmospheric Nike Mythos 24 3R power 24 kW.

Specifications

Following the instructions, the manufacturer suggests using 130 mm pipes to equip the smoke exhaust pipe of an atmospheric boiler with an open firebox. The Immergas turbocharged boiler removes combustion products using a 60/100 mm coaxial chimney. The consumer has the option to build a separate smoke exhaust with a diameter of 80 mm.

The European manufacturer does not equip the device with a chimney, trying to offer the lowest possible price on the heating market. By the way, today it is not difficult to buy a chimney separately, comparing the length you need with the upcoming installation. The boiler is simple to operate; the main thing is to make the initial settings correctly; later everything will be done by the electronics. Reliable protection, protects against power surges.

Advantages

- The Imergaz boiler is quite easy to operate; simple adjustments do not take much time. An informative display helps you set up the boiler in a matter of minutes;

- High Italian quality of the assembly line and components used;

- Noise performance is below average;

- Due to the use of composite materials, the Imergaz boiler was able to reduce weight and reduce its size;

- Extended warranty is 5 years;

- Wide service network;

- Fast heating, not accompanied by increased gas consumption;

- Self-diagnosis helps you deal with minor issues on your own.

- The Immergaz boiler receives positive feedback from both consumers and installation organizations.

Flaws

- Probably, the high cost can be attributed to the disadvantages, but given the European quality, you shouldn’t be so categorical;

- The sensitivity of the automation board to voltage changes in the network; you should additionally purchase a voltage stabilizer.

- Traditionally, expensive spare parts that may have to be made “to order”;

- The chimney will have to be purchased separately, which entails additional costs.

Today we made a brief review of Immergas boilers. Reviews that can be found on the Internet from users of the product characterize it as high-quality and economical equipment. Of particular note is the long service life and extended warranty. Thanks to their reliability, Immergas boilers have won high positions in the ranking of Italian manufacturers. Many argue that Immergas boilers occupy first place in the European Energy Union.

Repair and operation

Many modifications of boilers have an LCD screen; error codes are always displayed on it if they occur. The codes can be quickly deciphered by simply looking at the instructions included with the specific gas unit.

Fault code 16, which means the fan does not turn on, indicates that the circuit is open. To do the repair yourself, you need to diagnose the fan, subsequently repair the circuit, and routinely tighten the contacts, and then all problems with the boiler will be solved.

To do this, press the Reset key. This happens after a long period of equipment downtime. All that remains is to bleed excess air from the system and restart the ignition.

If you need to switch your boiler to summer mode, then press the button with the image of an umbrella and set the most comfortable temperature for yourself. If it suddenly becomes cool and there is a need for heating, then simply turn on the winter mode - the icon with a snowman. And also select the desired coolant temperature.

Video review of the Immergas gas boiler, see the following video.

history of the company

The company began its existence in 1964. In 1965, the company developed and produced its first gas boiler. Since 1967, having received the first patent, the Immergas company begins to gradually develop and expand. Here are the company's main milestones:

- Since the mid-70s, the company has focused on the production of household units for heating residential premises. The first model with a built-in water heater tank goes on sale.

- In the 80s, a wall-mounted model of a boiler with a boiler was developed and produced.

- Since 1994, the Immergas brand entered the world market, where it successfully gained a foothold. All over the world, Immergas wall-mounted boilers have positive consumer reviews.

- In 2000, the company relied on innovative energy-saving technologies and developed condensing heating equipment. Such equipment is very environmentally friendly and economical.

- Following the development and introduction of condensing boilers, Immergas focused its potential on hybrid systems capable of supporting a complete cycle of cooling, heating and hot water production for an entire house.