Why does it go out?

The main reason should be considered a gas supply interruption.

If the valve on the gas pipe is closed, or the pressure in the network is lost, the burner will go out. First of all, it is necessary to determine how much the gas pressure corresponds to the operating values. In addition, external influence factors are possible.

The burner flame largely depends on the room conditions and the presence of draft in the smoke removal system.

If there are drafts in the room, the draft may be weakened or completely disappear. then the combustion mode changes sharply and the flame goes out. Another possible reason is the occurrence of reverse draft, which may be caused by strong gusts of wind or drafts in the building.

Floor-standing gas boiler Siberia 11 single-circuit

Gas floor-standing boiler Rostovgazoapparat Siberia 11 is a single-circuit energy-independent boiler produced by the Rostov Gas Equipment Plant. The boiler is intended for heating only. Open combustion chamber with natural smoke removal. Piezo ignition. Italian EUROSIT automation unit, Polidoro burner, thermometer on the front panel. Operates on natural gas (to operate on liquefied gas, replacement of nozzles is required). Operable at reduced gas pressure. Power 11 kW. However, it is also possible to obtain domestic hot water using a single-circuit boiler. To do this, you need to connect an indirect heating boiler to the heating system. It is there that the water is heated to the required temperature. The result is a compact, convenient and very economical system that does not require an additional source of energy (for example, electricity), but operates directly from the heating boiler.

Recently, Siberia gas boilers are gaining more and more popularity and respect among... Show more

Gas floor-standing boiler Rostovgazoapparat Siberia 11 is a single-circuit energy-independent boiler produced by the Rostov Gas Equipment Plant. The boiler is intended for heating only. Open combustion chamber with natural smoke removal. Piezo ignition. Italian EUROSIT automation unit, Polidoro burner, thermometer on the front panel. Operates on natural gas (to operate on liquefied gas, replacement of nozzles is required). Operable at reduced gas pressure. Power 11 kW. However, it is also possible to obtain domestic hot water using a single-circuit boiler. To do this, you need to connect an indirect heating boiler to the heating system. It is there that the water is heated to the required temperature. The result is a compact, convenient and very economical system that does not require an additional source of energy (for example, electricity), but operates directly from the heating boiler.

Recently, Siberia gas boilers have been gaining increasing popularity and respect among consumers. This is facilitated by the presence of such significant advantages as:

14. Thoughtful development taking into account the harsh climate conditions of our country and the characteristics of gas and water supply, an ideal ratio of quality and price.

Structure of a floor-standing boiler The device consists of the following main parts: heat exchanger, cover, gas exhaust device, walls, pilot burner, main burner, frame, gas block. The automation of the Siberia boiler provides: stabilization of the gas pressure on the main burner, maintenance of the set water temperature, turning on the main burner when there is a flame on the ignition burner, turning off the device when the ignition burner goes out, in the absence of vacuum in the chimney.

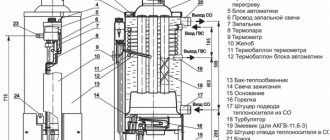

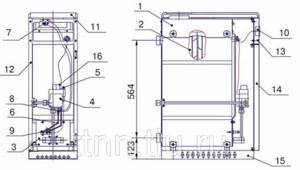

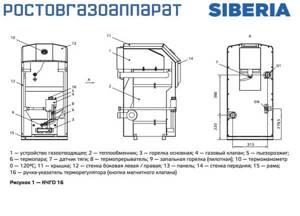

Design of the Siberia apparatus:

1 gas outlet; 9 ignition burner (pilot burner), 2 heat exchanger; 10 thermometer; 3 main burner; 11 cover; 4 gas valve; 12 side wall left / right; 5 cover with piezo ignition; 13 panel; 6 thermocouple; 14 anterior wall; 7 traction sensor; 15 frame; 8 thermal breaker; 16 thermostat indicator knob (magnetic valve button). Technical characteristics of gas floor-standing boilers Siberia

| Model | 11 | 11K | 17 | 17K | 23 | 23K | 29 | 29K | 35 |

| Rated thermal power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Reduced gas consumption | |||||||||

| natural, m3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| liquefied, kg/h | 1 | 1 | 1,21 | 1,21 | |||||

| Approximate heating area, m2 | up to 125 | up to 125 | 100–200 | 100–200 | 100–250 | 100–250 | 150–300 | 150–300 | 150–400 |

| Flue gas efficiency, %, not less | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Water temperature setting limit, °C | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 |

| Water consumption in hot water supply mode. when heated at Δt=35°C, l/min | 3,8 | 5,5 | 7 | 8 | |||||

| Connecting thread of fittings, inch | |||||||||

| for gas supply | G½ | G½ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ |

| Inlet/outlet | |||||||||

| to the heating part | G1½ | G1½ | G2 | G2 | G2 | G2 | G2 | G2 | G2 |

| to the water heater parts | G½ | G½ | G½ | G½ | |||||

| Internal diameter of the gas outlet pipe, dm, not less | 1,25 | 1,25 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Overall dimensions, mm | |||||||||

| height | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 |

| width | 280 | 280 | 280 | 280 | 380 | 380 | 380 | 380 | 380 |

| depth | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 |

Siberia boiler - Malfunctions and repairs

___________________________________________________________________________________________

- AOGV Borino, ZhMZ, Alpha Calor

- AOGV Lemax, RGA, Thermolux, Ishma, Thermo

- Repair and adjustment of Angara boilers

- Operation and settings of boilers Termotechnik

I am using a Siberia 11 gas floor-standing boiler with Eurosit 630 automatic control system. Recently, a malfunction appeared in its operation: if I turn off the main burner, the pilot burner also turns off at the same time. I checked the thermocouple and solenoid valve - everything is fine with them. I don't have a traction sensor installed. Observing the problem, I found out that when the main burner goes out, the pilot simply loses fire. The gas supply is not interrupted at this moment - I checked (if immediately after extinguishing the gas is ignited manually, the burner begins to work quietly). The flame itself on both burners is blue. I spent three days troubleshooting this problem and finally succeeded. It turned out that a lot of water had accumulated in the chimney pipe (about 10 liters). After I poured it out of there, everything began to work fine. The chimney itself goes out from the house onto the loggia, and then goes out onto the street. You need to thermally insulate the chimney. In the floor-standing boiler Siberia 17 with Eurosit 630 automation, problems arose with the automation from the moment it was connected. The point is this. When igniting, with the valve open, the wick lights up, but as soon as you turn it to the “work” position, the fire disappears. The specialists were unable to fix the problem and came up with the following. A spoon was placed under the valve, thereby securing it in a constantly open position. This is how the unit works, but another problem remains. Gas constantly leaks through two holes located under the burners. Its smell is strong throughout the house. Is it possible to somehow fix it without changing all the automation? Basically, gas shouldn't be getting into the holes if your machine has good draft, so check that first. It is also worth checking whether the pilot burner flame reaches the thermocouple. Perhaps she should come under fire more. The Siberia model with automatic 630 evrosit is installed, for some unknown reason it turns off randomly. It was installed at my parents' place, and when I came to help, I saw the following. The wick lights normally. Then after I set mode 1 it works as it should for about half an hour and then dies. In this mode, the main burner should not go out at all. You should clean the igniter from any dirt. My gas boiler Siberia (Eurosit 630) does not work properly in mode 4, because after reaching 65C, it turns off completely. Your pilot burner turns off the main burner, and this is precisely the crux of the problem. The position of the regulator in this case does not affect anything. The operation of the burner, for some reason unknown to me, depends on the direction of the wind. At certain moments, the flame begins to burn unevenly, and sometimes goes out. The problem needs to be solved urgently, since in winter, constant work on a “candle” is wrong. I tried to protect the chimney myself, even installing a special fungus, but it didn’t help. I'm already thinking about increasing the gas supply to the burner, but I don't know how to do it. The device operates on automatic 630 eurosit. If your flame escapes through the inspection window, then you should increase the air supply to the boiler. The automation of the gas floor-standing boiler Siberia 23 (eurosit 630) began to malfunction. If you compare the temperature of the water in the device at the moment when the automation turned it off with the readings of the thermometer on the handle, there will be a strong difference (up to 10 degrees). The device heats water above 55C only in one mode (if you set position 7). It is in this mode that a significant increase in the burner flame is observed, which produces heat. It is not possible to set the maximum gas flow. Changes can only be seen in mode 7. How can this be fixed? Repair or change automation. Two years ago, a Siberia TopLine 24 double-circuit boiler was installed in our private house. The first winter it worked in a gentle mode, since construction continued and the temperature in it was not raised above 50C. In the spring, the renovation was completed, and we began to live in the house permanently. When the second heating season arrived, I noticed instability in the pressure in the heating system. There is a constant need to either shed off the excess or add in what is missing. Is there any way to fix this? It’s better to set everything up once, or maybe install additional equipment, than to constantly tweak something in the system. Problems with blood pressure happen like this. The pressure begins to drop with high hot water consumption. Accordingly, the device stops. Pressurization required. You set it to the required value, the device starts working, and the pressure continues to increase until it stops again. Then you need to bleed off the excess. After the pressure normalizes to 1.5 - 1.8, the unit begins to operate stably. A similar thing happens if you need to increase the water temperature, for example, to 70C. A long power outage also causes a similar problem. I would like to understand how this can be fixed. You have an expansion tank in your system. Its cavity is divided into two parts by a special membrane. One holds excess pressure, and the second is filled with water (also under pressure). When working correctly, this membrane divides the device into equal parts, then there are no problems in operation, since it is the membrane that compensates for all pressure differences. Excess air is removed automatically through a special valve. Please note that if water flows from this valve, the expansion tank is no longer suitable and requires replacement. In your case, for some reason the expansion tank does not absorb pressure changes when the water temperature changes. All the cases you described are related precisely to this. It is possible that your expansion tank is simply too small for your needs and requires an additional one, or a new one with a larger capacity. Currently, my house is heated using a natural circulation system, KChM boiler 5-21 kW. I use coal, but by winter I plan to switch to gas. In this regard, the question arose which is more rational. Upgrade the KChM by installing a burner in it. Or purchase and install a gas boiler Siberia 23. In any case, I plan to supply hot water through an indirect boiler. Siberia is identical to AOGV, only designed to run on gas. If we compare the KChM, it is more economical. Although there have been cases where older steel units consumed less or the same amount of gas as modern ones. But more often than not, the gain in money is noticeable. But you must take into account that for Siberia 23 to work correctly, you need to install a very good chimney. And KChM, if necessary, can be used again on coal. You will have to evaluate all the pros and cons and choose something yourself. Personally, I would install a modern appliance with the necessary chimney upgrades. I want to install a system of a Siberia 17 floor-standing boiler, with forced circulation of coolant. I’m interested in this moment: what will happen to it if for some reason a failure occurs (for example, there is no electricity) and the pump that provides circulation turns off? Will there be a normal shutdown when the temperature in it reaches the set temperature? Or is there some kind of emergency way to stop its operation and the shutdown will only occur due to overheating? Is it possible to connect the pump via a thermostat, alternatively, Valtec VT. AC601.0? After all, if the device is turned off in a non-emergency mode, then its operation can be stopped by turning off the pump. The temperature sensor sends a signal to the pump, which turns off when the room is warm enough. Which in turn turns off the device. Or will this connection method lead to inevitable damage to the equipment? What will happen to the unit if the automation stops working as expected? Is it possible to install any backup circuits so that the gas is guaranteed to be turned off in the event of a breakdown? Will the Siberia 11 gas boiler be able to provide heat to a room of 100 square meters? m.? Is it possible to install an indirect heating boiler in the system? Will it fit properly, or is this a violation of operating conditions? This model has enough power to adequately heat a given volume. But there are some nuances with the boiler. The device itself does not care what equipment is installed in the system. Moreover, your main water consumption will go to the hot water system. Just see if you can choose the right size boiler. Your unit is not very powerful and the boiler is 100 square meters in size. m. it will heat for a very long time (for example, 30 kW heats from 10C to 60 in about 10 minutes, but in your case only 11 kW). If 100 liters is enough for all your needs, then you can try installing a boiler, otherwise you need to think about other options. I have a Siberia 17 floor-standing boiler installed. Is it possible to replace the Eurosit 630 automation installed on it with a Minisit 710? While reading the instructions, I came across the function of modulating the burner flame, and it interested me very much. Will this work in my case? I also have a question about gas consumption. Heated area 150 sq. m. (100 sq. m. the house itself and 50 sq. m. insulated attic). The heating system is not yet permanent. So far there are 4 aluminum batteries installed in the house and an additional one is in the attic. The weather outside is a slight minus (up to 04), and the house heats up no higher than 15C, with a gas consumption of 60 cubic meters in 4 days. Is this normal, or can something be changed? To optimize gas consumption, you will need to properly insulate your home, and calculate and install exactly as many radiators as required. An incorrectly installed system can also have an effect. To determine the problem, test all batteries. If there is uneven heating, especially if they are hotter closer to the unit, then look for an error. And yet, your current automation also has a modulation function. What automation should be installed on Siberia for its most correct operation? Typically, 630 Eurosit (up to 23 kW), 710 Minisit (up to 35 kW) and 820 Nova (up to 50 kW) are installed on Siberia. Nova has another useful function: you can attach a room thermostat to it. All of them can modulate the combustion process. An important advantage is the good price-quality ratio. Eurosit 630 is controlled by only one control handle, which can be used to activate the solenoid control valve and also adjust the temperature regime. It also allows you to turn off the device if necessary. To supply the house, I installed the Siberia 17 model with a water heater. The heating system is well implemented, all rooms are heated, there are no problems. With hot water supply, things are much worse. We have an 80 liter heater installed and this amount was enough. In winter, we set the temperature on the unit to 65-70C, and everything was fine. There was enough water. In the summer, the temperature on it had to be reduced, and now it does not have time to heat the water in the boiler - there is a catastrophic lack of water. How can problems be solved? Will installing an additional tank help? To solve this problem you need a faucet in the heating system. Shut it off and heat the water in the boiler before actively using water in the hot water supply. If you cannot connect a speaker, then using it is the most optimal solution. The pump and the supply valve itself are closed. 20 minutes of operation of the device only for heating and you can draw hot water. Do you think Siberia Top Line 24 requires installing an inventory generator or can a regular one be used? And another question: are there any nuances of grounding? We would recommend installing a regular one, since when installing an inventory one, some difficulties may arise. Good afternoon. I can’t find a function for setting the upper limit for water heating in Siberia 23. My device produces a maximum of 70C (supply water temperature 7C). The instructions say that it should give 85-90C. Make sure the incoming gas pressure is correct. Also check the gas valve, it tends to get clogged. There is also this trick: you need to turn off the water supply to the heating system and wait until the unit heats up to the required temperature. In the future, with the heating system open, it must maintain the selected temperature. I can’t figure out how the modulation mode works on the minisit 710 automation. What is the relationship between the set temperature (on the thermostat) and the temperature at which the gas supply begins to decrease? Does changing the maximum temperature settings affect the modulation range itself? The specified range from the start of modulation to gas shutdown is 13C. To heat the house, a Siberia 17 boiler was installed. Now we have built a bathhouse and want to use it to make an additional circuit for heating it. Will this project succeed? I don’t want to connect the bathhouse to the main circuit, since it will require a significant reconstruction of all the pipes in the house. The size of the residential building is 100 sq. m (an open two-pipe heating system with steel pipes and cast iron radiators was installed). To it I add a bathhouse with an attic with a total area of 70 square meters. m. Your unit is not capable of supporting such an area. A more powerful device is required.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alfa Kalor, Termotechnik. Adjustment of gas automatic equipment Eurosit 630. Replacement of thermocouple and maintenance of pilot burner.

Troubleshooting and repair of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Bosch gas heating boilers Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Settings for functions and modes.

Navien repair recommendations Deluxe Coaxial, Deluxe Plus, GA models. Errors and problems. Working with Xital remote control. System control. Adjustment of work by temperature and pressure.

Buderus floor-standing boilers Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vailant boilers Models Turbotec Atmotec pro/plus VU/VUW INT. Components and operating functions. Programs for adjustment. Gas system. Installation and installation. Maintenance and prevention.

Floor-standing boilers Protherm Repair of Bear models KLOM, KLZ, TLO, PLO with power from 20 to 50 kW. Breakdowns and problems. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and adjustment Models of gas floor-standing boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automation Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted boilers Protherm Repair of Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repairs and adjustments Repair and operation of Ciao, City, Novella, Exclusive boilers. Wall and floor models. Malfunctions and error codes. Operating functions and setting up service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of automatic pellet burner APG-25, 36, 42. Operating mode settings.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting up service parameters. Maintenance.

Heating boilers Alfaterm Description of floor-standing boilers of the Beta model and wall-mounted gas boilers Sigma. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - faults and repairs Wolf boiler installed. I noticed that over time the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks, but found nothing. What else should I check?

Junkers gas boilers After 7 years of operation, the Junkers ZW-23-KE gas boiler developed the following problems. When the hot water supply starts working, it either turns off or stops working...

Boiler repair Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, and it does not matter what the temperature is. To make sure this is so, I raised the temperature to...

Types of devices

All single-circuit and double-circuit AGVs produced by Zhukovsky have three main varieties, which allow customers to choose a heating column depending on their available budget:

- “Economy” modification - has a set of equipment necessary only for safe operation: domestic automation, temperature sensor, heat exchanger.

- The “Standard” variation is also capable of modulating the burner flame, is controlled by a foreign control system, and can turn off when overheated, preventing damage.

- The Comfort boiler complex is distinguished by the presence of a remote control unit, technology for maintaining the set temperature, and a room thermostat.

Heater parameters

The high efficiency of the AOGV - up to 92% - means that the installation of this equipment will bring maximum heating efficiency, and this is due to the original design of the jacket. Boilers can operate in heating systems with forced or natural circulation of coolant, provided that the pressure in the system is at least 1.4 Atm. Such conditions can ensure a liquid temperature of +40/+90C.

The disadvantage of this equipment can be considered to be too much power - even the lowest-power boiler produced by the Zhukovsky plant is designed to heat an area of at least 200 m2, which means that in small houses its installation will be impractical and costly.

The burner in any modification and brand of boiler is made of stainless steel, so its durability is guaranteed. The jacket for hot water supply is made of copper, the body of the unit is coated with polymer or powder paint. Standard automation has temperature sensors and regulators to control the temperature of the coolant and prevent overheating of the boiler. The package also includes a thermocouple that controls gas flow and an air flow stabilizer, which serves to compensate for differences in air pressure during gusts of wind, and shuts off the gas in calm weather. Certificate of conformity for gas boiler AOGB

| Names | AOGB-11.6 | AOGBK-11.6 | AOGB-17.4 | AOGBK-17.4 | AOGB-23.2 | AOGBK-23.2 | AOGB-29 | AOGB-35 | AOGBK-35 |

| Indicators | |||||||||

| Rated power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29,0 | 29,0 | 35,0 |

| Consumption of main or bottled gas | |||||||||

| Main, m3/h | 1,19 | 1,19 | 1,75 | 1,75 | 2,32 | 2,32 | 2,95 | 3,56 | 3,56 |

| Balloon, kg/h | 0,865 | 0,865 | 1,215 | 1,215 | – | – | – | – | – |

| Heated area, square meters | 120 | 120 | 100-200 | 100-200 | 100-250 | 100-250 | 150-300 | 150-400 | 150-400 |

| Efficiency ≥ 90% | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 | 90,0 |

| DHW consumption when heating water at 35°C, liters per minute | – | 3,5 | – | 3,5 | – | 7,0 | – | – | 10,0 |

| Thread on fitting, inches | 1/2 | 1/2 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 | 3/4 |

| Inlet/outlet | |||||||||

| To the heating system | 1/2 | 1/2 | 1/2 | 1/2 | 2 | 2 | 2 | 2 | 2 |

| To the DHW system | – | 1/2 | – | 1/2 | – | 1/2 | – | 1/2 | – |

| Diameter of gas outlet pipe, ≥ decimeters | 1,15 | 1,15 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Dimensions, cm | |||||||||

| Height | 86,5 | 86,5 | 86,5 | 86,5 | 85,0 | 85,0 | 85,0 | 85,0 | 85,0 |

| Width | 41,0 | 41,0 | 41,0 | 41,0 | 33,0 | 33,0 | 38,0 | 38,0 | 38,0 |

| Depth | 41,0 | 41,0 | 41,0 | 41,0 | 55,0 | 55,0 | 55,0 | 55,0 | 55,0 |

| Weight, kg | 43,0 | 47,0 | 49,0 | 52,0 | 56,0 | 72,0 | 65,0 | 80,0 | 82,0 |

| In models with a power of 23.2 29 and 35 kW - rectangular housing |

Single-circuit unit AOGV - design and dimensions

Technical characteristics

Let's look at the parameters of Siberia floor-standing boilers:

| Options | Values |

| Boiler type | Gas convection |

| Installation type | Floor |

| Fuel type | Natural or liquefied gas |

| Functionality | Preparation of coolant for heating systems, heating of hot water for the DHW circuit |

| Efficiency | 90 % |

| Serviced area (maximum) | Up to 500 m2 |

| Boiler power | 11-35 and 16-50 kW kW |

| Power supply | Absent |

| Burner type | Atmospheric (open type) |

| Burner material | Stainless steel |

| Heat exchanger material | Stainless steel or cast iron |

| Ignition type | Piezo |

| Chimney diameter | 125 mm |

| Weight | 56-200 kg |

| Dimensions | 850×280×560 mm, 850×380×560 mm |

| Guarantee period | 24 months |

| Service life with proper maintenance, maximum | 25 years |

Special features of the automatic system

As mentioned above, all products are automated and have a number of special features:

- The Italian Eurosit system controls the temperature;

- The automated system has a piezoelectric ignition function;

- Automation blocks make it easy to control the system;

- Mechanism of draft and flame control;

- The automatic system optimally consumes gas through the optimal choice of burner function;

- No need to control the process of the combination valve;

All systems are independent of energy, so there is no need to connect to the electrical network, and this is very important for Russia. Constant network failures disable all heating systems

Burner: basic operating functions

The Siberia heating system burner differs from its competitors in its operating features:

- The system is made of stainless steel, so even at low gas pressure there is no burnout.

- The burner is made in Italy.

- The system is made from environmentally friendly materials, so there are no harmful substances in the exhaust gases.

- The burner is very easy to use. You don't need any skill to replace or clean the system.

- At the time of replacing the igniter and the main part of the burner, the system runs on liquid fuel.

A few words about the power that each system has its own. To figure out how much power is required for an area, you can calculate it - take 10 square meters. m per 1 kilowatt. This calculation says that the system will work to its maximum, so add 0.3 to the resulting figure. If you need to warm up a room of 100 sq. m., then you better choose the 11th model Siberia. Moreover, when choosing a heating system, you need to choose design features - material, location, finish. For less insulated rooms, you need to calculate 1.5–2 kW per 10 square meters. m., for warm rooms - 0.5–0.7 kW.

If you want to use the Siberia boiler not only for heating, but also for supplying hot water, then it is better to buy boilers with the letter name K. If you buy the boiler model K, then such a system can provide all the hot water needs for several people. If more than three people will use hot water, then you need to buy a powerful boiler.

How much space is needed to install the boiler?

wall and floor heating systems can be used

The boiler room may not be heated

It is also important to consider that more powerful Siberia models make noise during operation. Some manufacturers produce powerful floor systems with excellent heat and sound insulation, which are installed outside the boiler room - in the hallway or kitchen

Additional details of the system are:

Additional details of the system are:

- Cranes;

- Expansion tank.

How to save on heating?

Without the slightest loss in comfort, you can reduce fuel costs by 10%. Especially if you have a private house and you are going to carry out major renovations. The initial costs can be recouped even with basic tariffs, and the price of fuel will rise. Your invested money will pay off even faster.

The very first thing you can do is reduce the heat loss of the building. This is a whole range of works, installation of doors and windows, insulation of walls

After all the work has been carried out, thermal monitoring must be performed: it is important to check that heat does not penetrate through the cracks. There are special companies that check losses using thermal imagers

And the owner of a private house can purchase a remote thermometer

It is also very important to choose a boiler based on power and positive reviews. The more square meters you need to heat, the more carefully you need to pay attention to the heat calculation. And the owner of a private house can purchase a remote thermometer

And the owner of a private house can purchase a remote thermometer

It is also very important to choose a boiler based on power and positive reviews. The more square meters you need to heat, the more carefully you need to pay attention to the heat calculation. On the heating systems market, the Siberia brand is one of the best

Systems with high power are very expensive, but consumer reviews are still positive. They evaluate the quality of use and technical properties of heating devices

The Siberia brand is one of the best on the heating systems market. Systems with high power are very expensive, but consumer reviews are still positive. They evaluate the quality of use and technical properties of heating devices.

Error codes for Siberia boilers

_________________________________________________________________________________________

Error E01 No ignition. The gas mixture is not supplied to the gas burner unit. The shut-off valve appears to be closed. Open the valve located on the gas supply pipe. When the initial switch-on is performed, it is recommended to remove air from the pipeline line. Check the pressure parameters of the gas fuel supplied to the burner unit. The required pressure is from 18 to 20 Mbar. After this, check the accuracy of the adjustment of the maximum and minimum pressure of the gas mixture at the injectors. Setting values are specified in the operating manual. If necessary, we adjust the boiler. The gas valve is faulty. If malfunctions are found, install a working gas valve. The ignition electrode is not functioning properly or is damaged. It will need to be inspected for the presence of soot. Adjust the spacing between the burner assembly and the ionization electrode if necessary. The gas fittings are damaged. Check the coils in the gas valve to determine a possible break or short circuit. If any abnormalities occur, replace the gas valve. The gas valve is stuck. Install a piece of hose onto the fitting located in front of the valve and create high pressure. Insufficient ignition power. Adjust the ignition power using the service menu. Incorrect operation or damage to the electronics board. The ignition transformer stopped working. Reset the device. When the error starts again, the electronic board must be replaced. Check grounding. The body should have no potential. Excessive moisture is a source of boiler shutdown. Clean the firebox, ionization electrode and gas burner unit from moisture. Failure to perform the functions of the flame control electrode. The control board has detected a flame, but there is no combustion. Inspect the electrical cable of the ignition electrode. Poor contacts and breaks may be present. Inspect the circuit from the ignition electrode to the electronic board for a short circuit. The ionization electrode touches the burner assembly. Damage to the control board. It must be changed. Error code E02 The Siberia boiler has overheated. The temperature of the safety thermostat is about 105 C. If there are no ignition messages at the moment, then the error will not be detected. The gas burner goes out due to the increased temperature of the heating circuit, but the heat exchanger does not stop heating. In the heating cycle 90C, for the DHW phase 95C. The automation device turns off the boiler if, within 15 seconds, the temperature of the safety thermostat is above 105 degrees. When the thermostat sensor registers a temperature of more than 105 degrees during heating or antifreeze protection, the boiler automation will issue a break for approximately half a minute. If during this period of time the temperature of the thermostat sensor and temperature sensor does not drop to one hundred degrees, the automation system indicates an error. The device shuts down during a request to ignite the burner unit. If during the ignition stage the safety thermostat detects a temperature of more than 105 degrees, the boiler goes into standby mode for 10 seconds, and only then displays a fault message. The temperature sensor of the heating line or the safety thermostat is triggered, turning off the device. The emergency thermostat will turn on at temperatures above 105 degrees. Wait for the device to cool down and reset it by pressing the reset key. There is a problem or incorrect operation of the overheating thermostat. Replace it. Poor circulation of the heating circuit fluid. For the main circuit, measure the pressure. Its values in an unheated system are 1.2 bar. Presence of air in heating pipes. Remove unnecessary air from the Siberia boiler system through the bleeder valve. No circulation. Fully open the shut-off and control elements that block the necessary water circulation. The circulation pump is not operating correctly. The pump stopped reaching the required speed. Test the voltage and characteristics of the electrical network. When a power outage occurs in the electrical network, the boiler is connected to the electrical network using a transformer-stabilizer. Diagnose the resistance of the stator winding of the circulation pump electric motor for a break or short circuit. The pump operates uninterruptedly, but the pressure is insufficient. Apparently the impeller is damaged. If damage is found, the pump should be replaced. The pump does not rotate, but the flow to it is stable. Let's inspect the pump, most likely there is a jam. Unscrew the plug, then rotate the rotor shaft of the electric motor. There is no power supply to the circulation pump. Problems with the control board. The boiler needs to be restarted. When the failure continues, replace the control board. The combustion products thermostat has overheated. Wait for the thermostat to cool down, then restart. Error code E05 Malfunction of the NTC sensor of the heating circuit. The occurrence of a short circuit or break in the electrical circuit of the NTC sensor of the heating circuit. If the electrical circuit of the sensor is broken, the signal is lost, so the electronics board will send a command to stop the operation of the burner device. Error E06/E12 Malfunction of the hot water supply temperature sensor. If there is a damage or short circuit in the electrical circuit of the hot water supply temperature sensor with a period of five seconds, the burner device will not be able to ignite at the DHW stage. The operation of the Siberia gas boiler will continue in the heating cycle. Malfunction of the DHW thermistor functions. Error code E04 Indicates low pressure inside the system. The main sources preceding this malfunction: a decrease in fluid pressure in the heating circuit. Lack of contact between the control board and the minimum pressure switch. The pressure switch is faulty. First you need to know the pressure gauge readings. In many cases, the problem can be eliminated using a make-up tap, which is designed to fill the heating system with coolant. When the failure recurs, there is most likely a water leak. The hydraulic pump, main heat exchanger, safety valve, worn gaskets, make-up valve and other parts may leak. Leaks can be determined visually by hydraulic components. Error E03 No traction. For stable and safe operation of the device, it is necessary to create a draft to remove combustion products so that they do not penetrate into the room. The smoke output is monitored by electronics, and if some problems occur, the draft sensor will work and the Siberia boiler will be blocked. The main reasons contributing to the lack of traction: the narrowed size of the outlet channel, a design flaw, clogging, ice on the inner wall. A narrowing of the chimney diameter may cause a weakening of draft. Exceeding the maximum length of the chimney pipe - We advise you to carefully study the instructions for using the gas boiler and check that all necessary requirements are met. A horizontal section of the chimney pipe that is too long often causes a lack of draft. Traction sensor malfunction - If a vacuum forms in the inlet tube, you can hear a characteristic click. There is no contact between the traction sensor-relay and the electronic board, there is condensation, as well as incorrect connection of the tubes to the pressure switch. Fan damage - The fan impeller is clogged. There is not enough lubricant on the fan shaft, so it does not generate the required speed. Lost contact between the electronic board and the fan. Error code E35 Problem with ignition. This situation is displayed if there is no ignition or the burner flame is extinguished. It is necessary to check the contacts between the ignition unit and the flame electrode, and also between the gas valve and the board. One of the factors of flame failure is lack of draft.

_________________________________________________________________________________________

_________________________________________________________________________________________

- How to troubleshoot problems and malfunctions on the Junker boiler

- How to troubleshoot basic problems with Buderus Logano G334 boilers

- Errors and malfunctions of Rinnai boilers

- Diagnostics of major breakdowns of Ariston Matis gas boilers

- Causes of problems during operation of Baxi Eco Nova boilers

- Recommendations for repairing Buderus Logano G124/125 boilers

- Causes of problems with Baxi Main Four boilers

- Diagnostics of breakdowns of Beretta Novella boilers

- Possible breakdowns during operation of the Beretta geyser

- How to properly adjust and repair an Electrolux gas water heater

_________________________________________________________________________________________

_________________________________________________________________________________________

- Tips for adjusting and repairing Gorenje geysers

- Immergaz boiler error code values

- Problems with Junkers geysers - Recommendations for repair and maintenance

- Causes of problems with Bosch Gaz 4000 boilers and how to fix them

- Diagnosis of the main problems with Ferroli Torino gas boilers

- How to identify and eliminate malfunctions in a Ladogaz gas water heater

- Recommendations for operation, repair and settings of the Mora gas water heater

- Repairing the Zota Carbon boiler - Types of faults and options for eliminating them

- Recommendations for troubleshooting errors and malfunctions in Bosch boilers

- Help with troubleshooting problems and errors on Electrolux boilers

_________________________________________________________________________________________

_________________________________________________________________________________________

- How to eliminate errors and malfunctions on Ferroli boilers

- Typical breakdowns during operation of Ferroli Domiproject boilers

- Causes of the main problems with De Dietrich Zena gas boilers

- Boiler repair Zota Master - What malfunctions occur and steps to eliminate them

- Decoding Celtic boiler error codes

- Boiler repair Buderus Logano G221 - Types of problems and methods for eliminating them

- Causes of malfunctions in the operation of Buderus Logano S131 boilers and methods for their repair

- Questions about troubleshooting storage water heaters

- How to troubleshoot problems when operating storage boilers

- Malfunctions of electric water heaters and tips for eliminating them

- Malfunctions of electric boilers and recommendations for repairs

- Hermann Habitat boiler error codes

- Tips for troubleshooting basic storage water heater problems

- Help in troubleshooting problems with storage boilers

- Possible malfunctions and breakdowns during the operation of geysers

- How to repair a gas water heater if a malfunction occurs

- Tips for repairing Ariston boilers - Methods for eliminating basic faults

- Symptoms of malfunctions in the operation of Baxi boilers and an algorithm for eliminating them

- Methods for eliminating malfunctions and breakdowns on geysers

- Errors in gas boilers Proterm Gepard

- Elimination of breakdowns and malfunctions during the operation of geysers

- Causes of malfunctions and repair of geysers

- Repair of geysers in case of malfunctions

- Hermann boilers - Methods for eliminating errors and malfunctions

- Elimination of errors and malfunctions during the operation of Arderia boilers

- Ariston Egis boiler error codes

- Causes of malfunctions in Immergas gas boilers

- Symptoms of problems with Proterm floor-standing boilers and options for their repair

Main advantages

According to the manufacturer, Siberia gas floor-standing boilers are a new generation of heating units designed to provide heating and hot water supply to the home. Compared to imported competitors, boilers of this brand have the following advantages:

- A wide range of models that can satisfy any consumer demand.

- Automated control system, which ensures ease and safety of use.

- Economical.

- Trouble-free operation even in the harshest operating conditions.

- Availability of service support.

- Affordable price.

Now, analyze each point of the above advantages in more detail, because only the reliability of the facts will allow the domestic consumer to consider the equipment of this brand as a candidate for purchase.

How to properly turn on and off a heating boiler

Problems with blood pressure happen like this. The pressure begins to drop with high hot water consumption. Accordingly, the device stops.

Pressurization required. You set it to the required value, the device starts working, and the pressure continues to increase until it stops again. Then you need to bleed off the excess. After the pressure normalizes to 1.5 - 1.8, the unit begins to operate stably. A similar thing happens if you need to increase the water temperature, for example, to 70C.

A long power outage also causes a similar problem. I would like to understand how this can be fixed.

Today, the Russian heating equipment market is flooded with heat generators from various manufacturers, among which German and Italian brands have always been the leaders. However, in the last decade it has become clear that imported boiler systems have not only advantages, but also disadvantages, including: high requirements for coolant quality and operating conditions. In this vein, the domestic consumer has no choice but to pay attention to boiler units of domestic brands. Compared to imported competitors, boilers of this brand have the following advantages:.

You have an expansion tank in your system. Its cavity is divided into two parts by a special membrane.

Contents: 1. How to start a gas boiler: preparation 2. Useful tips When arranging a heating structure, many homeowners prefer installing double-circuit gas boilers.

One holds excess pressure, and the second is filled with water, also under pressure. When working correctly, this membrane divides the device into equal parts, then there are no problems in operation, since it is the membrane that compensates for all pressure differences. Excess air is removed automatically through a special valve.

Please note that if water flows from this valve, the expansion tank is no longer suitable and requires replacement. In your case, for some reason the expansion tank does not absorb pressure changes when the water temperature changes.

All the cases you described are related precisely to this. It is possible that your expansion tank is simply too small for your needs and requires an additional one, or a new one with a larger capacity. Currently, my house is heated using a natural circulation system, KChM KW boiler. I use coal, but by winter I plan to switch to gas.

In this regard, the question arose which is more rational. Upgrade the KChM by installing a burner in it. Or purchase and install a Siberia gas boiler. In any case, I plan to supply hot water through an indirect boiler. Siberia is identical to AOGV, only designed to run on gas. If we compare the KChM, it is more economical. Although there have been cases where older steel units consumed less or the same amount of gas as modern ones.

But more often than not, the gain in money is noticeable. But you must take into account that for Siberia 23 to work correctly, you need to install a very good chimney. And KChM, if necessary, can be used again on coal. You will have to evaluate all the pros and cons and choose something yourself.

Personally, I would install a modern appliance with the necessary chimney upgrades. I want to install a system of a Siberia 17 floor-standing boiler, with forced circulation of coolant. I’m interested in this moment, what will happen to it if for some reason a failure occurs, for example, there is no electricity and the pump that provides circulation turns off? Will there be a normal shutdown when the temperature in it reaches the set temperature?

Gas boilers from Siberia

Siberia boilers are the brainchild of Rostovgazoapparat CJSC. The company produces a wide range of heating and water heating equipment; installations produced under the Siberia brand are far from the only models in the company’s arsenal.

The main advantage, which determines stable demand and high-quality operation of boilers, is a deep knowledge of the conditions and operating features of heating equipment in the countries of the former USSR.

The manufacturer has eliminated the most problematic areas in the design, creating energy-independent units capable of operating in the most difficult conditions. This advantage can only be truly appreciated by residents of Russia who have an understanding of winter frosts and the danger of being left without heating.

The company produces units that are optimally suited for use in small and medium-sized private houses, of which the vast majority are in our country. Low gas consumption and active use of natural physical processes make it possible to increase efficiency and simplify the design of units.

All Siberia units are floor-mounted. This makes it possible not to load the walls in residential premises and expands installation possibilities - floor-standing boilers can be placed anywhere, unlike wall-mounted structures.

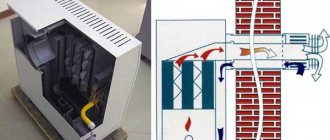

Since the units are non-volatile, the type of gas burner is the same for all - open (atmospheric) type elements with natural smoke removal are installed (a conventional stove-type draft is used). This circumstance puts forward some requirements for the room - it is necessary to ensure high-quality ventilation and eliminate drafts.

The circulation of the coolant is also natural by default, which creates the need for proper installation of the heating system in compliance with the required slope of the pipelines.

However, it is possible to install an external circulation pump, which increases the speed of movement of the heating agent and significantly increases the overall efficiency of the boiler.

There are single- and double-circuit models. The former are intended only for preparing coolant in the heating circuit, the latter simultaneously heat batteries and hot water for household needs.

The second type of design is more preferable in a private home, but the gas consumption of such boilers is slightly increased.

Siberia boilers: features, advantages, disadvantages, model range

An important advantage of units from Rostov manufacturers is their high efficiency. This figure reaches 90%. Depending on the model, produced under the Siberia brand, they can be used to heat houses with an area of 100 to 500 square meters. m and several floors.

The units are available with open and closed heat exchangers. The coolant heated in the heat exchanger in single-circuit boilers enters a three-way valve, and in double-circuit boilers into a secondary heat exchanger. A design feature of Siberia boilers is the separate regulation of water and heating. This allows them to be used in the summer only for domestic hot water.

All models of Siberia boilers are non-volatile and are configured to operate with low gas pressure. If necessary, they can be easily converted to use liquefied gas. Gas burners have pilot and main stages. The first is used for ignition, which is done manually using a special piezo button.

The manufacturer provides a guarantee of up to 25 years for its equipment. The units have a floor-mounted installation option and can be single- or double-circuit.

They are presented on the market in two heat exchanger versions:

- steel;

- cast iron

The power of the boilers included in the model range can range from 11 to 50 kW. The power range of models with a steel heat exchanger is from 11 to 35 kW, with a cast iron one - from 16 to 50 kW.

The latter are produced only in a single-circuit version and are intended only for heating rooms. The heat exchanger material and unit power are displayed in the boiler markings.

The Siberia line of cast iron boilers includes 4 types of units:

- KCHGO 16;

- KCHGO 25;

- KCHGO 40;

- KCHGO 50.

The letter “H” indicates the material used to make the heat exchanger, and the numbers indicate the power of the unit. A similar type of marking is used for boilers equipped with a steel heat exchanger.

In addition to them, the manufacturer produces Siberia floor-standing boilers with a block of electric heating elements operating from a single-phase electrical network with a voltage of 220 V. Such equipment is marked with the letter “E”.

Expert opinion

Grebnev Vadim Savelievich

Heating system installer

All models of Siberia gas boilers are equipped with atmospheric gas burners with natural smoke removal. Such designs require high-quality ventilation in the room. A mandatory requirement for the room where a gas boiler is installed is the absence of drafts.

Specifications ↑

Features of this brand at the moment

The manufacturer itself positions itself as a competitor to Slovenian gas units “Proterm”. This can be seen in some design and technological solutions, as well as in the adopted standard outlet openings for various purposes. Siberia, of course, generally loses to Proterm in power, build quality and efficiency, but very seriously all the “disadvantages” are covered by an affordable and more than acceptable price.

Due to the desire to comply with foreign analogues and the best domestic representatives of gas boiler equipment, the implementation of technical and design innovations has led to very great difficulty in setting up the boiler. That is, if previously any user could adjust the equipment to suit himself, now only a specialist can do this. True, we must pay tribute that after high-quality tuning, the boiler noticeably reduces energy consumption, while leaving thermal indicators unchanged. It should also be noted that another, to a certain extent, weak point of the Siberia boilers is the automation, or rather, some of the sensors included in its composition. This applies to:

- draft sensor (this is a problem with all domestic boilers);

- flame cutoff sensor (an unconfigured pilot burner often cuts off the pilot flame when the wind is strong enough, but the sensor does not manifest itself in any way and gas continues to flow to the burner.

In Fig. samples of Rostov heating equipment products are presented below, you can familiarize yourself with the technical characteristics of its basic model:

The Siberia boiler is presented below, compare the technical characteristics

What to look for when choosing?

Before purchasing a dual-circuit model, you should pay attention to five important indicators:

Combustion chamber type

There are devices with an open and closed combustion chamber. Appliances with an open chamber take air from the room, and combustion products are discharged through the chimney. For safety reasons, such a chimney must be at least 4 m in height. Since this consumes oxygen from the room, ventilation in such a house must be well organized.

With closed combustion, air is taken from the street, and combustion products are discharged outside at this moment. Thus, the oxygen in the room does not burn and the overall atmosphere is much more favorable. Models with a closed chamber are suitable for those who have poor ventilation in their home. They can also be installed in the kitchen or bathroom. Devices with a closed combustion chamber are the only possible option for apartment buildings.

Boiler type

There are classic (convection) and condensation devices.

Classic wall-mounted gas boilers with two circuits, the 2020 rating of which will be given below, generate heat only by burning gas. On average, their efficiency ranges from 85 to 95%.

Condensing appliances generate additional heat by condensing water vapor that is produced naturally during the combustion process. Thanks to this, the boiler efficiency increases and can range from 100 to 110%. Taking this into account, the condensing model can reduce gas consumption by 10 - 15%. This savings will be especially noticeable when using heated floors. If you really want to save on heating and water heating, then take a condensing model. Such models will definitely be included in our rating of wall-mounted double-circuit gas boilers in terms of reliability.

Heat exchanger material

The heat exchanger of the device can be made of the following materials:

- Cast iron. Used in the cheapest models. It generates heat quite well, but the efficiency usually does not exceed 90%. Boilers with cast iron heat exchangers are heavier and bulkier, which complicates their installation.

- Stainless steel. Suitable for budget and middle class. Stainless steel is quite durable and can be easily repaired if necessary. However, heat transfer is less than that of copper.

- Copper. Copper heat exchangers are installed in mid- and expensive-class models. They are durable and dissipate heat well.

If you want to take a classic model and are going to install it yourself, take it with a stainless heat exchanger. For underfloor heating and hot water supply, we recommend choosing a condensing type device with a copper heat exchanger.

Boiler power

On average, 1 kW of device power can heat about 8 m2 of area. Divide the total area you need to heat by 8 and get the required power. Add 1 kW for water heating. If you want to more accurately calculate the power of the device, use the formula that we provided for single-circuit boilers.

Availability of built-in boiler

A separate type of double-circuit boilers can be additionally equipped with a boiler for heating and, most importantly, storing water. Sometimes it is very convenient to have such a boiler, since if there is a strong drop in pressure in the pipeline, the boiler may simply not heat the water, but the water in the boiler will always be hot. Purchasing a model with a built-in boiler makes sense only in cases where there is a frequent drop in pressure in the city water supply. Otherwise, it's a waste of money.

What series and models of the company exist?

There are three model lines:

- AOGV. Single-circuit floor models used only for space heating. They have 5 models with power from 11 to 35 kW. They are simply marked Siberia 11, Siberia 17, etc.

- AKGV. Double-circuit units providing heating and hot water supply. They have the same power models, the marking contains the letter “K” (combined) - Siberia 17K, Siberia 23K, etc.

PLEASE ATTENTION!Both groups (AOGV and AKGV) are equipped with a primary heat exchanger made of stainless steel. Double-circuit ones have a secondary plate heat exchanger for heating hot water

KCHGO. Increased power models with cast iron heat exchanger. The power range is between 16-50 kW.

The power of the boiler determines the area that it is capable of heating: 11 kW - 110 m2, 35 kW - 350 m2, etc.

Device

The design of Siberia floor-standing boilers consists of:

- Primary heat exchanger.

- Secondary heat exchanger (for dual-circuit units).

- Three way valve.

- Gas equipment (valve, stabilizer, filter, etc.).

- Piezo ignition unit.

- Gas burner (pilot and main).

- Gas pressure stabilizer.

- Control devices - thermometer and pressure gauge.

The main functions are performed by the burner and the heat exchanger, where the coolant is heated.

Then it is either immediately discharged to a three-way tap (single-circuit models), or it first passes through a secondary heat exchanger and heats the hot water.

After this, the liquid in the mixing unit receives the set temperature and is discharged into the heating circuit.

The movement of flows is carried out by gravity, under the influence of thermal movement of layers of liquid.

Smoke and combustion products are removed using the same method..

Choosing the right boiler

The most important characteristic that influences the choice of a floor-standing boiler is the power, which must correspond to the area of the heated room. The calculation is done in specialized organizations that charge quite large sums for their services. In fact, you can estimate how much power of a heat generator is needed to heat a particular room on your own without complex calculations: to heat a 10 m2 room you need 1 kW of boiler plant power. The formula is correct for rooms with ceiling heights of up to 3 m. As practice has shown, for normal operation of the boiler unit, you need to add 30% to the resulting value.

Note! For poorly insulated rooms, the power of the boiler installation should be calculated: 2 kW per 10 m2 of area. For warm buildings located in the southern regions of our vastness, this figure is 0.5 (0.7) kW/10 m2

The second characteristic that you should pay attention to when choosing a floor-standing boiler is the number of circuits. If you want to use the installation not only for heating the room, but also to obtain hot water for household needs, then pay attention to dual-circuit models

They are designated by the letter “K”. Depending on the performance, each such boiler can produce a certain amount of hot water per unit of time.

At a water temperature of 35°C, the nominal flow rate is:

- 11 K – 3.8 l/min;

- 17K – 5.5 l/min;

- 23K – 7 l/min;

- 29K – 8 l/min.

The third selection criterion is the heat exchanger material. Above we indicated all the advantages and disadvantages of devices with steel and cast iron heat exchangers.

Advantages and disadvantages of the model

The advantages of Zhukovsky AOGV 23 boilers are:

- Reliability, simplicity of design.

- Independence from the power supply system.

- Simple and intuitive controls.

- Designed for use in Russian conditions.

- Designed to work in harsh climatic conditions.

- The service life is 14 years (or more).

- The cost of boilers is much lower than that of European analogues.

The disadvantages of the units should be considered:

- The heat exchanger of the units is made of steel, which is inferior in thermal conductivity to cast iron.

- The appearance of the boilers is inferior to European models.

- The mechanical automation of the boiler is quite weak.

- The dimensions and weight of the unit require installation in a separate room.

NOTE!

Most of the shortcomings are, to one degree or another, common to all atmospheric models, so they can be attributed to a specific design feature.

The most common problems and breakdowns

It is clear that there is no perfect equipment and it breaks down or does not work as it should. In most cases there are specific reasons for this. Based on the operating experience of Siberia boilers, we can identify several characteristic problems that owners often encounter:

- Low heating of water for domestic hot water supply by Siberia double-circuit floor-standing boilers. There's nothing you can do about it - it's not their strong point. If you look at the technical specifications, the maximum hot water flow is very small. And this is at normal gas pressure. If the pressure is low (which usually happens in cold weather), then the water will be slightly warm.

- The water at the boiler outlet does not heat up to the stated 90°C (if you turn the regulator even to the very last, 7th position). There are several possible reasons. The first is low gas pressure. When the pressure drops below 130 mm. water the column's power decreases proportionally. When you call the gas service (they are responsible for the nominal pressure), ask them to clean the inlet filter. If it is clogged, the pressure will be low. The second possible reason is a burner clogged with soot and dust. It needs to be cleaned once a year. If this is not done, the efficiency decreases and the Siberia boiler heats worse.

- The pilot burner does not ignite the working burner. Again, there may be several reasons. And the first is low gas pressure in the pipe. But this time it is below 50mm. water pillar At this pressure the boiler does not start. The second reason is a clogged gas valve. The third is a smoked burner. In all cases, we clean the valve and/or burner. Fourth, the thermocouple sensor is located too far away (you can see it visually, if it doesn’t reach the flame, that’s the reason). In this case, you need to loosen the thermocouple mounting nut and move the contacts a little closer. Fifth - weak traction.

- After a summer of inactivity, it is difficult to start the boiler. During downtime, air collects in the gas supply pipe. Until it is “corroded”, it will not be possible to light the boiler. When igniting for the first time, open the window/vent and monitor your health. Take a break between launch trials. During this time, the burner will be ventilated and the Siberia floor-standing gas boiler will start up faster.

As you can see, there are a lot of problems, but most of them are related to the peculiarities of the work of public utilities in our country. Of course, there are reasons in the equipment. But this is a small part of the total number of cases of non-working equipment. In order for the Siberia floor-standing gas boiler to work without problems, it is worth fulfilling all installation requirements and carrying out regular maintenance.

User manual

Operating Siberia boilers is not difficult at all . The owner’s only task is to maintain the cleanliness of the unit and the absence of soot, soot or ash inside the unit. Changing the mode is done by turning the knob to the desired position.

In order to light the boiler, you need to press the handle, pushing it all the way, while simultaneously pressing the piezo ignition button.

Hold in this position for some time (up to 1 minute) until a flame appears on the pilot burner.

Then the control knob is switched to the desired operating mode, which will cause the flame on the main burner to light up and heating of the coolant will begin.

The system is filled with water with the make-up tap open. The process lasts until water flows from the signal pipe, after which the tap is closed.