Boiler Zhytomyr

Heating equipment of the Zhytomyr brand “Atem” is widely known in the countries of the former USSR. The plant's products are famous for their reliability, simplicity and affordable price tags. Let us highlight another important advantage - the manufacturer is as honest as possible with the buyer. The documentation for the Zhitomir solid fuel or gas boiler reflects the real operating parameters of the equipment, no overestimation of efficiency or other marketing techniques.

We decided to collect all the heat generators of the Atem model range in one publication and make a detailed review of each line of boilers. The task is to lay out the technical characteristics, identify the strengths and weaknesses of the units. At the end we will attach reviews from owners who use this equipment for heating private houses and apartments.

Range of gas parapet boilers

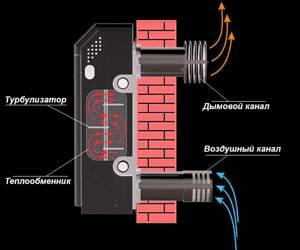

The parapet-type gas boiler “Zhytomyr” is an inexpensive device for organizing water heating of a small country house with an area of up to 150 m². It successfully combines elements of turbocharged and atmospheric boilers - a closed combustion chamber and a coaxial chimney in the absence of a blower fan.

The movement of gases through the coaxial chimney of a parapet heat generator occurs naturally, without a fan or smoke exhauster

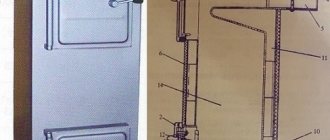

Principle of operation. The heat generator, suspended from the wall near the floor, burns natural or liquefied gas without pressurization. Combustion products are thrown out through an internal short pipe passing through the wall. Air enters the firebox through the external channel (outer pipe) naturally. New versions are equipped with 2 separate pipes - smoke and air.

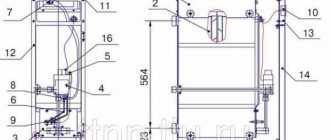

The line of parapet models "Zhitomir-M" includes 5 single-circuit and 4 double-circuit boilers, designated by the abbreviation AOGV-SN and ADGV-SN, respectively. Thermal power of the devices is 5, 7, 10 and 15 kW. Let's reveal the design features of heaters:

- the material of the main heat exchanger is steel, the secondary heat exchanger for hot water supply is copper;

- combustion chamber – completely closed;

- burner - tubular type, safety automatic - gas valve SIT 630 made in Italy;

- ignition – piezoelectric, from a button on the valve;

- 4 fittings DN40 for connecting the heating system - two on each side of the housing.

The boiler comes complete with a gas-air unit (otherwise known as a coaxial pipe), a flexible pipe for connecting to the gas main, fasteners and an asbestos sealing cord. The cost of a single-circuit unit with a power of 5 kW (heated area - 50 m²) is 270 USD. e., double-circuit 15 kW - 475 USD. e.

New version of wall heat generator with separate pipes for air and flue gases

Reference. Up-to-date information on the pricing policy and offered models of heat generators can be found on the official resource at: shop.atem.ua.

Specifications

The Zhitomir-M parapet boiler has the following operational parameters:

- fuel efficiency (EF) – 90%;

- minimum inlet gas pressure – 6.4 mbar, maximum – 17.6 mbar;

- operating pressure in the heating system – 1.5 Bar, maximum permissible – 2 Bar;

- coolant temperature at the outlet of the heat exchanger – no more than 90 degrees;

- the amount of water in the boiler jacket is from 5 to 19 liters;

- maximum pressure from the cold water supply – 6 Bar;

- The dimensions of the largest device in the line are 360 x 495 x 825 mm (LxWxH).

Natural gas consumption, hot water output and the size of the chimney duct depend on the power of the heater. The specified characteristics are presented in the table, in more detail on the manufacturer’s website.

Advantages and disadvantages

The most important advantage of Zhytomyr parapet boilers is the price that is affordable for people with average and low incomes. Heating installations can be freely purchased in Ukraine and the CIS countries.

Let us list the other advantages of chimneyless heat generators:

- Energy independence. The boiler does not require electricity, although it can work in conjunction with an external circulation pump.

- Small size and simple design.

- Reliability and safety provided by proven gas automatics from the EuroSIT brand.

- A full-fledged smoke channel is not required.

- The double-sided arrangement of the fittings expands the possibilities for connecting heating network pipes.

Important point. You should not perceive the listed nuances only in relation to Zhytomyr devices. The market is saturated with parapet clone boilers with similar pros/cons.

Diagram of the dual-circuit version of the heater

Despite the low threshold of permissible coolant pressure (2 Bar), wall-mounted boilers can operate as part of closed systems with a membrane expansion tank. The main thing is to maintain the specified threshold when filling with water and adjust the pressure inside the air chamber of the tank according to the instructions.

Since we profess the completeness and reliability of the published information, we will reveal the shortcomings of the Zhitomir-M heaters:

- The degree of automation of the boiler is minimal and includes only a set of safety functions - protection against attenuation, overheating and a critical decrease in pressure in the gas pipe.

- If the wall faces a windy passage, the burner may periodically go out. The problem is solved by installing an additional screen on the windward side of the chimney.

- The performance of the hot water heat exchanger is enough to serve 2 consumers with low consumption. If you turn on the shower and the kitchen faucet at the same time, the water temperature will become uncomfortable for washing.

- A constantly burning pilot light wastes fuel. This fact is critical for residents of Ukraine and other countries with high prices for main gas.

- Manual ignition mechanism.

All safety, heating and gas control functions are concentrated in the 630 SIT valve

The disadvantages of heat generators are not critical and are a consequence of the maximum simplification of the design and reduction in cost. At the same time, the service life of inexpensive Zhytomyr boilers reaches 15 years, taking into account minimal maintenance.

Floor-standing boilers "Zhytomyr-3"

The reliability of the stationary units of the model range has been tested by many years of practice. Heaters “Zhitomir-3” are among the most popular; they are recommended to be purchased by gas service technicians.

Explanation. Gas workers really “love” the floor-standing boiler models of the Zhytomyr brand. The design is simple and reliable, malfunctions occur extremely rarely, and accordingly, the technician has less work to do.

The line includes 18 devices - 9 single-circuit models KS-G-SN and 9 heat generators KS-GV-SN with an additional water heating heat exchanger. Main characteristics of boilers:

- range of covered powers - 7...60 kW, efficiency - 92%;

- the material of the main heat exchanger is carbon or stainless steel, the secondary coil is copper;

- burner – tubular micro-flare from Polidoro, combustion chamber – open type;

- there is a constantly burning igniter, which is ignited by a piezoelectric element button;

- operating coolant pressure – 1.5 Bar, maximum – 2 Bar, permissible pressure in the water circuit – 6 Bar;

- recommended temperature schedule - 60...80 °C, maximum - 90 degrees, at 95 °C the overheating sensor is triggered;

- removal of combustion products through a traditional chimney with natural draft.

Note. The KS-G-045SN and KS-GV-045SN units with a power of 45 kW are designed for higher coolant pressure: operating pressure - 2 Bar, maximum - 3 Bar.

Design Features

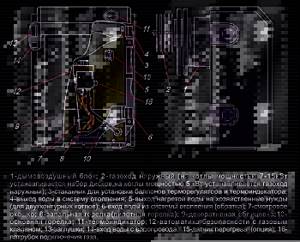

According to the requirements of the regulations, the Atem floor-standing boiler is equipped with an automatic safety system that interrupts the fuel supply to the igniter and the main burner based on four factors: a drop in gas pressure below 6.4 mbar, spontaneous extinguishing of the flame, lack of chimney draft and overheating of the coolant. The shutdown function is performed by an automatic gas valve, whose model depends on the performance of the unit:

- 7…16 kW devices are equipped with 630 SIT automation.

- Heat generators with a capacity of 22.5…31.5 kW are equipped with 710 MINISIT valves.

- Boilers with a power of 40 kW and more are equipped with automatic gas blocks SIT 820 NOVA.

Reference. The latest series of Italian valves 820 NOVA is equipped with a connector for connecting weather sensors and room thermostats. You will find more information on the operation of gas boiler automation in our separate review.

The second important feature of domestic heaters is the design of the DHW circuit. The heat exchanger is a copper coil immersed in the water jacket of the apparatus. Therefore, the temperature of the water going to the hot water supply depends on the degree of heating of the coolant in the boiler tank.

In the summer, the operation of the water supply circuit is ensured by piping the boiler - a pipe jumper with a tap is placed between the supply and return. When the heating of the house is turned off, this tap opens, and the heating system is cut off by other fittings. The coolant begins to circulate in a small circle, as shown in the diagram.

For summer operation of the DHW circuit, the manufacturer suggests looping the supply with the return, maintaining the connection between the boiler and the expansion tank

Advantages and disadvantages

The main advantage of floor-mounted heat generators “Zhitomir-3” remains high reliability at low cost of equipment. A single-circuit boiler with a thermal power of 7 kW will cost approximately 300 USD. e., with a water circuit – 340 USD. e.

The remaining advantages of water heating devices look traditional for the Atem brand:

- simplicity of design and unpretentiousness in operation;

- non-volatile – the boiler does not require power supply;

- long service life;

- models with automatic SIT 820 NOVA can be connected with external control devices - thermostats and weather sensors.

Addition. The new generation of KS-G-SN models with a power of 10...30 kW is equipped with an Atem-Start lightweight ignition system. The start button is located on the front panel of the boiler.

The units are adapted to work in open-type gravity and pump heating systems. Use as part of a closed circuit with forced circulation is allowed, provided that the operating pressure of the coolant does not exceed 1.5 Bar (short-term - 2 Bar). Let us remind you: the KS-G-045SN modification can withstand 2 and 3 Bar, respectively.

The disadvantages are similar to those of parapet boilers, except for blowing the burner through a coaxial chimney. If the flue pipe is built correctly - the cross-section (diameter) and the height of the rise of the channel are maintained, then problems with draft will not arise.

Solid fuel units

In recent years, the Zhytomyr plant has mastered the production of boilers operating on solid fuel. There are 2 lines of heat generators available for the buyer to choose from:

- Classic heaters of the AOTV and AKTV series, designed for burning coal, anthracite and firewood.

- Pure wood-burning long-burning boilers “Zhitomir-D”.

The first line includes 18 models with a heat output of 12...25 kW with a steel fire-tube heat exchanger. The AKTV series is equipped with a cast iron hob, while the AOTV-V modifications are equipped with a copper coil that heats water for household needs.

Let us list the features and operating parameters of traditional coal boilers:

- combustion of fuel and emission of flue gases occurs due to natural draft in the outlet channel;

- the air supply and combustion intensity are adjusted manually with a special screw on the ash pan damper or with an automatic draft regulator on a chain (optional);

- the secondary copper DHW coil is located in the boiler tank;

- the manufacturer declares an absolutely real efficiency indicator - 78%;

- operating coolant pressure – 1.5 Bar, in versions with a round body – 1 Bar;

- the weight of the device is from 88 to 208 kg, the volume of the fuel chamber is 44–69 liters, depending on the power of the specific model;

- burning duration of 1 load of anthracite – 8 hours, firewood – 6 hours;

- The highest permissible supply coolant temperature is 90 °C.

Note. The heat generator comes with a poker and a scoop for scooping and cleaning the ash chamber.

In the operating instructions, the manufacturer directly states: solid fuel units are designed to operate in heating networks with natural circulation of water and an open expansion tank. In fact, adding a circulation pump is quite acceptable provided that the coolant pressure does not rise above 1.5 Bar.

The circulation pump in the gravity system is placed on the bypass

In closed heating systems, TT boilers must be used with a buffer tank (heat accumulator). Otherwise, in case of overheating, the pressure in the pipeline network will reach 3 bar, which is why the water jacket of the unit may swell and crack. The warning equally applies to long-cycle heat generators “Zhitomir-D”, whose characteristics are presented below:

- the line includes 3 thermal units with a capacity of 12, 16 and 20 kW, the main fuel is wood;

- the minimum duration of work from 1 full bookmark is 8 hours;

- the firebox volume is increased to 140, 195 and 250 liters, respectively;

- boiler tank capacity – 78 l;

- unit weight – 200, 250 and 290 kg;

- other parameters are identical to heaters of the AOTV series.

Important point. The manufacturer strongly recommends using long-burning boilers in conjunction with an accumulating buffer tank that can hold 0.35–1 m³ of coolant.

The long-burning boiler "Zhitomir-D" has an enlarged firebox, which makes it high

Positive and negative aspects of operation

In terms of ease of use and reliability, Atem TT boilers differ little from other heat generators in the budget segment:

- the heat source operates without electricity;

- combustion duration and efficiency strongly depend on the quality of the fuel (wood, coal) and operating mode;

- cleaning the firebox and ash pan is not difficult; access to the fire tubes is through the front door;

- If the operating rules are followed and there is no overheating, the device will last 10-15 years;

- you can cook food on AKTV series boilers;

- burning wood is a priori more economical than using other energy sources (excluding natural gas in the Russian Federation).

The most important advantage of Zhitomir-D heaters is the large volume of the fuel chamber, which determines the combustion duration. It is very difficult to find boilers of similar capacity among equipment from other brands. The real competitor is the Lithuanian Stropuva 20 kW with a firebox volume of 260 liters, which is significantly more expensive.

For piping a unit with a large firebox, the manufacturer recommends a classic scheme with a buffer tank (heat accumulator)

There is no point in listing the disadvantages inherent in all wood and coal boilers. Let us note the specific disadvantages of Zhytomyr devices:

- The low threshold of the maximum coolant pressure does not allow the TT boiler to be safely operated as part of a closed heating system, where the water pressure can reach 3 Bar.

- According to the manufacturer's recommendations, the temperature in the return pipeline should not fall below 45 degrees, otherwise condensation will form in the firebox. With natural circulation, it is unrealistic to use a classic piping scheme with a bypass and a three-way valve that protects against cold return.

- Manual air supply control does not allow you to implement the optimal operating mode and maintain the desired temperature. The draft regulator only partially solves the problem. Request for the manufacturer: equip 2-3 models with an automation unit and turbocharging.

Video: operation of the Zhytomyr TT boiler

However, the Zhytomyr solid fuel unit can be connected to the closed system of a one-story house, where low water pressure is maintained. In case of overheating, we suggest installing a thermal relief valve, as shown below in the diagram. Read more information on safety valves in the corresponding topic.

When heated to a critical temperature, an additional valve begins to discharge coolant from the system, regardless of pressure. Cold water automatically flows into the boiler

Combined models

In addition to traditional heating equipment, it produces 3 combined series of boilers:

- Electric gas heat generators KS-G-SN / KE with a heat output of 10-12 kW.

- Units "Zhytomyr-9" burning coal and natural gas. Designation - KS-G-SN / AOTV, power - 10, 12 and 15 kW.

- Heating and hot water installation “two in one” KS-G-SN, otherwise – “Zhitomir-10”. The range of models covers the range of 7…30 kW.

Clarification. All types of combination boilers are produced in a floor-standing version.

The line of gas-electric boilers is built on the basis of Zhytomyr-3 units and does not differ in appearance from conventional floor-standing units. The design is complemented by a control unit and an electric heater placed inside the water jacket. 2 types of heating elements are installed - with a power of 4.5 and 9 kW. Important feature: both heating methods can be turned on one by one or simultaneously.

Electric-gas (left) and coal-gas (right) boiler

The coal-gas heat generator “Zhytomyr-9” has the following parameters:

- on the left side of the body there is a firebox with a volume of 47 or 70 liters for storing anthracite or firewood;

- to the right of the solid fuel chamber there is a gas firebox with a Polidoro burner and an SIT 630 automation unit, a common heat exchanger, and separate smoke exhausts;

- efficiency on gas – 92%, solid fuel – 78%, operating water pressure – 1 Bar (Max 1.5 Bar);

- work in a closed system is allowed, condition - installation of a safety group with a 1.5 bar safety valve;

- duration of 1 coal combustion cycle – 6…8 hours;

- There are modifications with a DHW water circuit.

Comment. When operating on coal and wood, the boiler produces less heat than on gas, which is noticeable in terms of efficiency. Example: the KS-G-016SN / AOTV-12 unit in the first case develops a power of 12 kW, in the second - 16 kW.

The operating algorithm is simple: while the coolant is heated by coal, the gas burner does not ignite. When the sensor detects a drop in temperature, the gas supply will open and the right side of the heat generator will start working. The main thing is that the pilot light is lit.

The gas installation “Zhytomyr-10” consists of two separate sections - a boiler furnace and an instantaneous water heater. Burners, safety devices and heat exchangers are completely separated. In fact, the gas water heater and the boiler are combined in one housing. The goal is to increase water consumption for hot water supply to a comfortable level without compromising heating efficiency.

Reviews about the operation of boilers

As you might guess, the vast majority of reviews are positive. When purchasing a heat source in a budget price category, the owners clearly understand the goal - to ensure reliable heating of the home with a minimal investment. Here are a number of statements from real users.

Azalea, Nikolaev Ukraine

We moved into a private house 8 years ago and immediately began repairing the heating. The old boiler, left over from the former owners, was replaced with “Zhitomir-3”. What I would like to note is that the device functions without interruption, the burner does not go out in strong winds. We wash and clean it every year, there are no problems in operation. We are happy with the boiler.

Layout of the universal device “Zhitomir-10” with independent heating of coolant and water

Alexander, Krasnodar, Russian Federation

I use a 25 kW Atem double-circuit boiler, floor-standing version. Fuel - main gas. Automation and heating work at a solid five, the hot water supply circuit is worthless. To wash properly, you need to set the regulator to 6-7, the batteries get unbearably hot.

Nikolay, Republic of Belarus

Since the heating system of the house is gravitational, I selected the appropriate 16 kW Zhitomir-3 boiler to replace the old Lemax. When starting up, I encountered a problem - the uninsulated chimney began to “cry” with condensation, with the old unit the gases heated up more strongly and a similar effect did not occur. 6 heating seasons have passed since installation, a malfunction occurred only once - the igniter went out. The gas worker advised over the phone to wipe the contacts of the traction sensor with alcohol, and that settled the issue.

Larisa, Perm, Russian Federation

The Zhitomir water heating boiler has been operating in our house for five years, no serious deficiencies have been found. The unit is simple, reliable and unpretentious; it does not need to be serviced by a service organization. We cannot install an open expansion tank, so we made a closed system. Until the gas pipeline was installed, 80 square meters of the house was heated with propane cylinders. True, we had to hire a specialist to switch the boiler to liquefied gas.

Conclusion

The range of heat generators of the Zhytomyr plant continues to be supplemented with new water heating devices - geysers, atmospheric and turbocharged boilers. It is unrealistic to consider each unit in detail within the framework of one publication, so we limited ourselves to a review of the most popular models. We hope that the brand will continue to maintain its reputation by supplying users with reliable heating equipment.

Range of gas parapet boilers

The parapet-type gas boiler “Zhytomyr” is an inexpensive device for organizing water heating of a small country house with an area of up to 150 m². It successfully combines elements of turbocharged and atmospheric boilers - a closed combustion chamber and a coaxial chimney in the absence of a blower fan.

The movement of gases through the coaxial chimney of a parapet heat generator occurs naturally, without a fan or smoke exhauster

Principle of operation. The heat generator, suspended from the wall near the floor, burns natural or liquefied gas without pressurization. Combustion products are thrown out through an internal short pipe passing through the wall. Air enters the firebox through the external channel (outer pipe) naturally. New versions are equipped with 2 separate pipes - smoke and air.

The line of parapet models "Zhitomir-M" includes 5 single-circuit and 4 double-circuit boilers, designated by the abbreviation AOGV-SN and ADGV-SN, respectively. Thermal power of the devices is 5, 7, 10 and 15 kW. Let's reveal the design features of heaters:

- the material of the main heat exchanger is steel, the secondary heat exchanger for hot water supply is copper;

- combustion chamber – completely closed;

- burner - tubular type, safety automatic - gas valve SIT 630 made in Italy;

- ignition – piezoelectric, from a button on the valve;

- 4 fittings DN40 for connecting the heating system - two on each side of the housing.

The boiler comes complete with a gas-air unit (otherwise known as a coaxial pipe), a flexible pipe for connecting to the gas main, fasteners and an asbestos sealing cord. The cost of a single-circuit unit with a power of 5 kW (heated area - 50 m²) is 270 USD. e., double-circuit 15 kW - 475 USD. e.

New version of wall heat generator with separate pipes for air and flue gases

Reference. Up-to-date information on the pricing policy and offered models of heat generators can be found on the official resource at: shop.atem.ua.

Specifications

The Zhitomir-M parapet boiler has the following operational parameters:

- fuel efficiency (EF) – 90%;

- minimum inlet gas pressure – 6.4 mbar, maximum – 17.6 mbar;

- operating pressure in the heating system – 1.5 Bar, maximum permissible – 2 Bar;

- coolant temperature at the outlet of the heat exchanger – no more than 90 degrees;

- the amount of water in the boiler jacket is from 5 to 19 liters;

- maximum pressure from the cold water supply – 6 Bar;

- The dimensions of the largest device in the line are 360 x 495 x 825 mm (LxWxH).

Natural gas consumption, hot water output and the size of the chimney duct depend on the power of the heater. The specified characteristics are presented in the table, in more detail on the manufacturer’s website.

Advantages and disadvantages

The most important advantage of Zhytomyr parapet boilers is the price that is affordable for people with average and low incomes. Heating installations can be freely purchased in Ukraine and the CIS countries.

Let us list the other advantages of chimneyless heat generators:

- Energy independence. The boiler does not require electricity, although it can work in conjunction with an external circulation pump.

- Small size and simple design.

- Reliability and safety provided by proven gas automatics from the EuroSIT brand.

- A full-fledged smoke channel is not required.

- The double-sided arrangement of the fittings expands the possibilities for connecting heating network pipes.

Important point. You should not perceive the listed nuances only in relation to Zhytomyr devices. The market is saturated with parapet clone boilers with similar pros/cons.

Despite the low threshold of permissible coolant pressure (2 Bar), wall-mounted boilers can operate as part of closed systems with a membrane expansion tank. The main thing is to maintain the specified threshold when filling with water and adjust the pressure inside the air chamber of the tank according to the instructions.

Since we profess the completeness and reliability of the published information, we will reveal the shortcomings of the Zhitomir-M heaters:

- The degree of automation of the boiler is minimal and includes only a set of safety functions - protection against attenuation, overheating and a critical decrease in pressure in the gas pipe.

- If the wall faces a windy passage, the burner may periodically go out. The problem is solved by installing an additional screen on the windward side of the chimney.

- The performance of the hot water heat exchanger is enough to serve 2 consumers with low consumption. If you turn on the shower and the kitchen faucet at the same time, the water temperature will become uncomfortable for washing.

- A constantly burning pilot light wastes fuel. This fact is critical for residents of Ukraine and other countries with high prices for main gas.

- Manual ignition mechanism.

The disadvantages of heat generators are not critical and are a consequence of the maximum simplification of the design and cost reduction. At the same time, the service life of inexpensive Zhytomyr boilers reaches 15 years, taking into account minimal maintenance.