Home / Gas boilers

Back

Published: 03/04/2020

Reading time: 7 min

0

2916

The Danko brand is known in the CIS countries for its gas boilers. The first Danko boiler was produced in the Ukrainian city of Rivne in 2002.

Today the company sells heating products on markets in Russia, Belarus and Moldova, significantly expanding the brand line.

- 1 About the manufacturer 1.1 Official website where you can see all models and factory instructions

- 6.1 The wick goes out

About company

is engaged in the production of heating equipment of various types - it produces gas, electric and solid fuel boilers, heaters and converters. The first products entered the market in 2002. The batch consisted of only 49 units of equipment. Today the company has about 850 thousand units of products sold. The production uses advanced equipment from foreign companies from Italy, Denmark, and Finland.

Operation and setup

Operating requirements are detailed in the user manual, which must be carefully read before using the unit.

The key to successful operation is competent and high-quality installation. Floor-standing models are installed on a non-combustible substrate (a layer of asbestos, on top of which a metal sheet is laid), and wall-mounted boilers are hung on brackets secured with anchor bolts.

Only strong load-bearing walls are suitable for installation; temporary and plasterboard partitions for hanging are prohibited.

Boiler tuning consists of adjusting factory settings designed to increase efficiency and stability of operation.

The boiler adjustment must be performed by a specialist from the warranty workshop. Doing the work yourself can damage the unit.

In addition, unauthorized work with gas equipment is an offense and can be punished within the competence of the gas service.

Floor-standing single-circuit gas boilers Danko

Danko is a brand owned by PJSC Agroresurs, which is based in the Ukrainian city of Rivne.

The company creates heating boilers, guided by the principles of equipment availability, resistance to weather and climatic conditions, technological features of gas and water supply.

The main direction that allowed us to successfully promote our products on the market was the exclusion from the design of all minor and unused parts and assemblies, of which there are too many on European models.

This not only reduces the price, but also reduces the risk of boiler breakdowns or failures, which can become a very serious problem in winter. The company's products are aimed at the mass consumer; the boiler power level is optimal for use in small and medium-sized private homes.

There are non-volatile models that increase the reliability of the heating system, but require some changes in the configuration of the pipelines to ensure natural circulation of the coolant.

Boiler installation

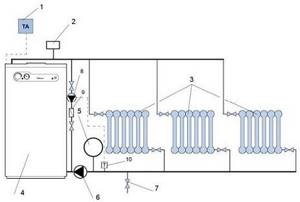

Installation of Danko gas boilers and connection to the gas main is quite easy. For comfortable operation, the housing includes left and right connections. When installing, it is very important to follow the following expert advice:

- The gas supply is regulated manually using automation. To increase the power of the unit, set the required mode using a rotating wheel.

- The Danko wall-mounted gas boiler is mounted using anchor bolts. During operation, the maximum weight of the device is 80-100 kg. It turns out that the fasteners must be very reliable to withstand such a load. With proper installation of the boiler, possible excessive fuel consumption and other problems can be eliminated.

- To minimize gas consumption, an external temperature sensor can be used. The operation of the device is to determine the ambient temperature, as well as auto-adjust the specified mode of the boiler equipment. The temperature sensor works in this way: it records the ambient temperature and transmits information to the controller. Automation detects changes and introduces them into the specified temperature regime. As a result, gas consumption becomes lower.

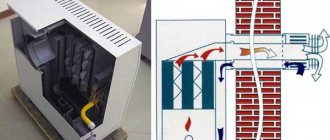

- Chimney – can be connected to a classic and coaxial smoke exhaust system.

Fire safety requirements for the installation of parapet devices are not as high as for atmospheric models. Therefore, in apartments it is recommended to install models with a closed combustion chamber.

The article described all the distinctive features of the brand’s heating devices, the installation of boilers, and examined their possible operating problems: why a Danko gas boiler goes out, goes out and takes up a lot of fuel. Take note of the recommendations of experts, reviews of owners, and the heating unit will serve you for a long time.

The use of gas boilers in dachas and private homes is an economical way to heat a home. Gas has lower consumption and cost than electricity, and is much more convenient to deliver than solid fuels. The most common at the moment are floor-standing models, such as the Conord (only this type is produced). Wall-mounted ones, for example, “Danko” (this manufacturer produces both types of structures), are also firmly in use.

For your information! The main problem when operating gas boilers is proper starting.

Advantages

- The assembly is carried out in accordance with European technologies.

- Good technical characteristics - the manufacturer achieves a high level of efficiency and cost-effectiveness due to innovative technologies involved in production.

- Works stably and without noise.

- Can be used in a heating system without forced circulation - it operates energy-independently.

- Simple installation - you can handle it yourself, without the help of specialists.

- The kit includes instructions explaining how to light the device, how to connect it to the heating system, how to carry out repairs and maintenance, as well as other useful information.

- Equipped with reliable automation that ensures the safety of the equipment.

- The coil is made of copper. The water heats up quickly.

- The heat exchanger is made of steel. Characterized by high heat transfer.

- Three years warranty. Cast iron ones last an average of 25 years, steel ones – 15 years.

The main advantages of Danko heating equipment

The production line is equipped with modern foreign equipment such as (Finland), “IDEAL LINE” (Denmark) and “AMADA” (Japan). Such equipment allows you to assemble inexpensive boilers of European quality.

In addition, Danko brand heating equipment has the following advantages:

- Excellent technical characteristics, which are achieved by using innovative technologies in the production of boilers.

- Silent, stable operation of the burner.

- Possibility of using a heating system with natural circulation. This system makes the boiler completely energy independent.

- Detailed operating instructions contain tips on how to properly connect the boiler to an existing heating system and recommendations on how to carry out repairs if malfunctions occur.

- Easy installation and connection: you can tie the device yourself.

High efficiency and efficiency, ease of operation make floor-standing double-circuit boilers of the Danko brand very popular and deserve positive feedback from users.

Advice! All floor-standing units are available in two versions: with a cast iron or steel heat exchanger. This makes the product range even wider and allows the consumer to easily select the appropriate equipment for heating an apartment or country house.

Advantages and disadvantages

The advantages of Danko floor-standing boilers include:

- The design of the units is optimized for maximum efficient and economical operation in all conditions.

- Boiler components and parts are made of high-quality materials using modern equipment.

- Fuel consumption is reduced by one and a half times compared to products from other companies.

- The units are designed for a long service life.

- Attractive appearance, compact size.

- Relatively low price.

The disadvantages of Danko boilers can be considered:

- Demanding requirements for water quality, the need to use softening filters.

- Requires annual inspection and maintenance.

- There are often cases of random flame extinction due to the backdraft effect.

NOTE!

The disadvantages of Danko boilers can partially be overcome through proper installation, and are partially a specific design feature.

Possible operational problems

During operation, any equipment can fail, no matter how reliable the automatic protective equipment is. Danko boilers have a simple design, which allows you to correctly carry out minor repairs yourself. Let's look at the main malfunctions, why they happen and how to solve them.

How to start a gas boiler

Any Danko boiler can be lit semi-automatically:

- The regulator handle is placed in the extreme position.

- When the wheel is pressed in, gas is supplied to the burner and ignited by a piezoelectric element.

- After starting the pilot burner, you must keep the wheel pressed in for 5-10 seconds.

- If the burner goes out when you release the latch, you must repeat the previous manipulations again.

Advice! The question arises, why does the igniter go out? The burner is equipped with a thermostat that automatically shuts off the gas supply if the burner does not heat up properly.

Blows out the boiler

This problem occurs quite often, especially in windy weather. Most often, there is no malfunction here, and repair of the device is not required; you need to check the following factors:

- During installation, a check valve was not installed in the chimney. For this reason, backdraft occurs and the burner goes out.

- If the chimney is not installed correctly, it can become clogged with soot and other combustion products. In this case, it is necessary to clean the chimney.

If the constant extinguishing of the boiler was preceded by extraneous noise in the burner or increased gas consumption, the controller may have failed. It needs to be replaced or repaired.

Advice! Due to their design features, double-circuit boilers for floor or wall mounting are free from these disadvantages.

Ukrainian-made Danko boilers are a good alternative to expensive models of heating equipment from Europe. Durability, simplicity and reliability of design, full adaptation to harsh operating conditions - these are the main advantages of boilers from this manufacturer, as confirmed by numerous consumer reviews.

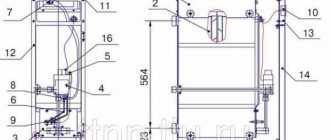

What series and models are floor-standing

The range of Danko floor-standing boilers is wide and includes several series.

Household models include the following lines:

- Danko SR or VSR . This is a series of single- and double-circuit domestic heating boilers with a 3 mm thick steel heat exchanger. Includes models with a power of 8, 10, 12, 15, 18, 20 and 24 kW. They are capable of heating houses with an area of 80 to 250 m2, which corresponds to the usual size of a private house.

- Danko SN and VSN . The units of this series have increased power, ranging from 30-48 kW. The main design features are the same - single- and double-circuit gas boilers with a steel heat exchanger.

There is also a series of Danko gas boilers with a cast iron heat exchanger. They are more massive and heavier due to the dimensions of the cast iron container, and have increased efficiency.

The ability of cast iron to transfer heat is higher than that of steel, which makes boilers more efficient and powerful.

There is a series of boilers for use in large industrial or public premises, the power of which reaches 96 kW. They are capable of heating up to 900 m2, and when connected in a cascade, the capabilities of the units increase accordingly.

Features of operation

Depending on the manufacturer and model, the device has a certain type of automation, which controls the entire combustion process, as well as its characteristics and, accordingly, operational features and certain rules when trying to ignite the boiler.

"Conord"

The main characteristics observed in the entire model range:

- The manufacturer produces boilers exclusively for floor-standing use, so any model from this company has a powerful casing of a fairly large size. It is protected by a layer of enamel, which prevents damage to the metal from moisture;

- since the manufacturer is domestic, the cost of its products is slightly lower than that of other brands;

- the efficiency of all boilers is on average 90%;

- the body and main structural components are made of steel sheets, the thickness of which is about 3 mm;

- Automation systems that provide control over gas combustion and operational safety require the boiler to be connected to a power supply.

The model range is quite wide, each model in it has various additional design elements. For example, there is an option for sale with warm water supply. It is equipped with automatic thermo-hydraulic type. For its operation, a constant stable connection to the network is required. The fuel supply is regulated by a thermostat: when the temperature sensor readings are required, gas access to the main burner is blocked.

For your information! High-quality automation ensures minimal deviations of the room temperature from the set one.

The productivity of the heating system is increased with a powerful burner when installed correctly. This is the only way to obtain a balanced mixture of gas and air. Good thermal insulation of the boiler, especially the chamber in which combustion occurs, also improves the quality of work. Low pressure will not interfere with the operation of this brand of unit. Thanks to all this, Conord allows you to warm up even in the most severe frosts.

Boilers of this brand also have a good multi-level security system:

- smoke exhaust sensor. It turns off the gas if there is no traction. It also does not allow the burner to be interrupted during strong gusts of wind, during which air moves in the opposite direction (“reverse draft”);

- temperature sensors. Shut off the gas when the temperature approaches the set limit;

- flame sensor. Interrupts the gas supply if there is no fire on the burner.

To know what other design and operation features there are, you need to be able to decipher the markings of a given brand. For example, KSts-GV-12 means that:

- this is a boiler (letter K);

- made of steel ©;

- cylindrical combustion chamber (letter C);

- the fuel for it is gas (this can be identified by the next letter G);

- “HW” means the presence of hot water supply;

- The numbers at the end indicate the maximum power output.

Radiator connection of serial type

This option is possible if a condensing gas boiler is used, because The operation of classical equipment is difficult at return temperatures below +55 degrees. The fact is that a cooled heat exchanger collects condensate on its surface. Gas combustion products contain, along with water and carbon dioxide, aggressive acids. In this case, there is a real threat of destruction of steel or copper heat exchangers.

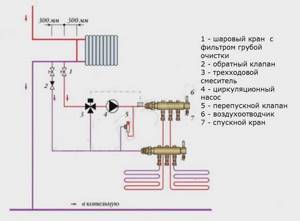

Condensing boilers have a different operating principle. A special stainless steel heat exchanger (economizer) is used to collect combustion products. As a result, additional heat transfer occurs and equipment efficiency increases. Because of this, the return pipe temperature level of +30-40 degrees is optimal. The heating system consists of two series-connected circuits - radiator and in-floor. The return pipe of the first is the supply pipe of the second.

DANKO boilers - operation and problems

The liquid in the system is significantly enriched with oxygen.

When heated, air evaporates, causing you to hear noise. If the unit settings are incorrect, the gas valve or bypass may howl. Today, gas boilers are very often used to organize heating systems for country houses, mansions, and cottages. Their popularity is associated with excellent performance, power, and affordability. In addition, blue fuel is considered the most economical in our territory, therefore servicing a heating system using gas is much cheaper than using other types of fuel. The efficiency of the heating system depends on the quality of the selected equipment.

Strong pops during startup indicate a malfunction of the ignition mechanism. The repairmen launched the Danko floor-standing boiler in the middle of this year. About six months later, a problem arose. I adjust the temperature, but it doesn’t hold it. I would like to know what is the reason? Perhaps the automation fails, and when the temperature rises by 60 degrees, the nozzles turn off. It is necessary to adjust the automation for correct operation.

The reason may also be that you have chosen the wrong power of the device in proportion to the heating area. I installed the same device in October of that year. It runs on liquefied gas. Almost 9 m3 was spent in 4 months. Currently, there is an excess of soot inside the device, and the main burner is also smoking.

Why does this happen? Excess carbon deposits in the combustion chamber indicate that the burner is poorly adjusted and the gas fuel is not completely burned.

There may also be an unsatisfactory composition of the gas mixture. To avoid soot from the burner, it is recommended to periodically perform wet cleaning.

I had this unit installed. During startup, the burner ignites and goes out immediately. Apparently there is no ignition spark. How can I fix this problem? It is necessary to check whether the sound of the ignition mechanism sparking is heard when the ignition cable is removed. If not, the ignition transformer must be replaced. If there is sound, replace the ignition electrode or gas burner device.

Just yesterday a problem appeared with the Danko 7 parapet boiler. Water began to drip from it. It worked properly for only 2 months. Tell me why the water is dripping?

Answers from Danko boiler service specialists

Apparently it is dripping due to high pressure in the heating system. There may also be destruction of the walls of the heat exchange device. Water hammer is also a cause of boiler leaks. We are going to implement the connection of the same device in the apartment. This device is connected to the system. The day before yesterday I noticed a malfunction in its operation. It starts to function, but does not warm the room. How can we explain this? There may be an accumulation of air in the radiators or a lot of scale in the heat exchanger.

It needs to be washed. We use the same device indoors. Until today it worked fine. Now it has a problem. The device overheats every day.

How to eliminate this accident? It is possible that scale has built up, causing the duct to become clogged. You must clean the unit.

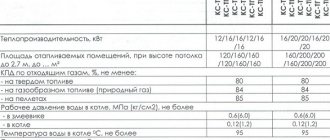

Specifications

Let's look at the parameters of Danko floor-standing gas boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Fuel type | Natural gas, conversion to liquefied gas possible |

| Heat transfer type | Convection |

| Functionality | Heating, hot water preparation |

| Efficiency | 92 % |

| Unit power | 8-48 kW |

| Power supply | Absent, some models are connected to a single-phase network 220 V 50 Hz |

The most reliable models with prices and technical characteristics

The product range contains more than 300 options for heating boilers with heating output from 2 to 1000 kW, which are installed for autonomous heating:

- natural/liquefied gas, solid fuel and pellets, electricity;

- open and closed;

- single-circuit and double-circuit;

- with natural and forced circulation;

- floor boiler;

- heat exchanger metal: steel, cast iron and copper.

- micro-flare burners made of heat-resistant non-corrosive steel.

All units are equipped with automatic safety systems:

- HONEYWELL - Netherlands;

- SIT - Italy;

- KARE - Poland.

The best solid fuel boilers for 150 m2:

- DANKO-12 VSR, power 12 kW, efficiency 91.5%, open combustion chamber, steel heat exchanger, mechanical control, centrifugal pump, price - 21,219 rubles.

- DANKO-20VSR, power 20 kW, efficiency 92%, open combustion chamber, steel heat exchanger, mechanical control, centrifugal pump, price - 32,685 rubles.

- OK-18V, power 18 kW, efficiency 90.5%, open combustion chamber, steel heat exchanger, centrifugal pump, electronic control, price - 27,172 rubles.

Popular Danko boilers operating on gas fuel for heating areas from 150 to 500 m2:

- DANKO-16LS, power 16 kW, efficiency 90.0%, open combustion chamber, cast iron heat exchanger, centrifugal pump, mechanical control, price - 38,001 rubles.

- DANKO-25LS, power 25 kW, efficiency 90.0%, open combustion chamber, cast iron heat exchanger, centrifugal pump, mechanical control, price - 47,531 rubles.

- DANKO-33LS, power 33 kW, efficiency 90.0%, open combustion chamber, cast iron heat exchanger, centrifugal pump, mechanical control, price - 60,238 rubles.

- DANKO-41LS, power 33 kW, efficiency 90.0%, open combustion chamber, cast iron heat exchanger, centrifugal pump, mechanical control, price - 68,814 rubles.

- DANKO-50LS, power 50 kW, efficiency 90.0%, open combustion chamber, cast iron heat exchanger, centrifugal pump, mechanical control, price - 85,492 rubles.

Characteristics of Danko pellet boilers for a heated area from 150 to 1500 m2:

- DANKO-150 TEM, power 150 kW, efficiency 88.0%, fuel supply, steel heat exchanger, centrifugal pump, mechanical control, price - 330,400 rubles.

- DANKO-100 TEM, power 150 kW, efficiency 88.0%, fuel supply, steel heat exchanger, centrifugal pump, mechanical control, price - 296,200 rubles.

- DANKO-75 TEM, power 150 kW, efficiency 89.0%, fuel supply, steel heat exchanger, centrifugal pump, mechanical control, price - 330,400 rubles.

- DANKO-50 TEM, power 150 kW, efficiency 88.0%, fuel supply, steel heat exchanger, centrifugal pump, mechanical control, price - 267,100 rubles.

- DANKO-25 TEM, power 150 kW, efficiency 89.0%, fuel supply, steel heat exchanger, centrifugal pump, mechanical control, price - 182,300 rubles.

- DANKO-17 TEM, power 150 kW, efficiency 88.0%, fuel supply, steel heat exchanger, centrifugal pump, mechanical control, price - 152,200 rubles.

Additional systems

In the design of gas heaters, the manufacturer has additionally provided:

- water temperature sensors - triggered when boiling, turning off the system;

- a protective block that shuts off the gas supply when the wick goes out;

- a block that stops equipment operation in the absence of traction;

- draft control unit - to adjust the flame;

- multifaceted protection unit – turns off the device in case of any type of threat;

- intelligent block - for distributing liquid flows.

User manual

The boiler operates automatically. The user is only required to maintain the cleanliness of the body, fill and drain water from the system and start the boiler when necessary.

Temperature adjustment is carried out in operating mode, according to the user’s own feelings. The boiler is started either using a piezo ignition system or manually using the principle of a gas stove. To turn on the boiler using piezo ignition, you need to turn the knob to the ignition position.

The thermostat knob must be turned until it aligns with the “asterisk” icon and at the same time pressed in all the way.

Press the piezo ignition button several times to light the burner, but hold the thermostat knob for another 10-15 seconds . If the attempt is unsuccessful, repeat the procedure.

To service and repair the boiler, you should call a technician from the service center. Independent tampering with the structure will automatically void the warranty agreement.

Care tips and advice

Proper maintenance of the boiler, performed regularly, will help keep it in working condition for a long time and avoid various accidents and accidents. Otherwise, the unit may break even in the first year of operation. Performing several operations will prevent this from happening:

- even during normal operation of the boiler, you need to contact one of the organizations carrying out work in this area, so that a technician inspects the device for gas and water leaks, the condition of the sensors and chimney, and, if necessary, carries out repair work;

- You should always monitor the water pressure inside or at the outlet of the system. If it drops below 0.8 bar, then water needs to be added;

- The addition of water to the system is usually carried out directly through the boiler, where there is a special tap. In this case, the pressure of the added water must be greater than the pressure of water from the boiler. The supplemented water should only be cold (up to 35°C).

For your information! To spend winter evenings warm and comfortable, you need to properly care for your boiler and also know how to light it.

Depending on the model and manufacturer, this process will be slightly different due to differences in design. This can be clarified in the instructions supplied with the device.

Installation

It is necessary to take into account the rules for installing gas equipment:

- The power is selected according to the heating.

- There must be at least 25 cm between the housing installed on a fire-resistant horizontal platform and a non-combustible wall.

- The device can be installed near fire-resistant walls if they are sheathed with steel sheets.

- The width of the passage in front of the facade is from 1 m.

- To improve water circulation, the installation should be lower than the level of heating devices.

- The expansion tank is located at the very top of the system.

- The minimum length of the chimney is 5 m.

- If the chimney is located outside, it must be insulated.

- The diameter of the smoke outlet must exceed the diameter of the smoke outlet pipe.

- At the junction of the boiler and the chimney, it is necessary to seal it with a solution of cement or clay.

Where you can and where you can’t install a gas boiler

The rules for installing a gas boiler provide the following requirements for installing a HEATING boiler, regardless of whether it also provides DHW or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications that a ceiling of 2 m is acceptable. This is incorrect. 8 cubic meters is the minimum free volume.

- The furnace room must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with flammable materials and the presence of a false ceiling or false floor are unacceptable.

- The combustion chamber must be provided with an air flow through a through, non-closed vent with a cross-section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly called a chimney); using ventilation ducts for this is unacceptable - life-threatening combustion products can reach neighbors or other rooms.

- The length of the horizontal part of the flue should not exceed 3 m within the combustion chamber and have no more than 3 rotation angles.

- The flue outlet must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since combustion products form chemically aggressive substances when cooling, the chimney must be made of heat- and chemically resistant solid materials. Use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A durable fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- There should be no cavities in the room in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment/house:

- The slope of horizontal sections of pipes must be positive, but not more than 5 mm per linear meter of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler that has everything provided for: rules are rules.

- The condition of the heating system must allow it to be pressurized under a pressure of 1.8 atm.

The requirements, as we see, are strict, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a water heating one, if:

- You live in a Khrushchev block or other apartment building without a main gas duct.

- If you have a false ceiling in your kitchen that you don’t want to remove, or a permanent mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which in principle can be removed, and then there will be no mezzanine, gas workers turn a blind eye.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment, which only the owner can do.

In all other cases, it is possible to install a hot water boiler in an apartment; wall heating is possible, but floor heating is very problematic.

In a private house, you can install any boiler: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside to serve as a furnace room, then the authorities will only have less reason to find fault. You can install a high-power floor-standing gas boiler in it to heat not only the mansion, but also the office premises.

For middle-class private housing, the optimal solution is a wall-mounted boiler; it does not require, as for a floor one, to install a brick or concrete tray with sides of half a meter. Installing a wall-mounted gas boiler in a private house also avoids technical and organizational difficulties: a fireproof closet under the furnace can always be fenced off, at least in the attic.

Basic malfunctions, why does the boiler go out?

The main malfunction of the Danko floor-standing gas boiler is spontaneous extinguishing of the burner.

It can be caused by various reasons:

- Stopping the gas supply (in the main line, or simply forgot to open the gas tap on the boiler itself).

- There were problems with gas equipment - breakdown of automation, failure of the gas valve, other problems.

- Reverse draft in the chimney, strong wind or drafts inside the room.

If the gas supply is interrupted, you should contact the gas service and obtain the necessary information. If problems arise with gas equipment, you must call a technician from a service center who is authorized to perform such work.

Dealing with drafts or backdrafts is more difficult, since they are often caused by external reasons that cannot be influenced. In any case, it is necessary to ensure high-quality and stable air exchange in the room, to eliminate drafts and sudden changes in the direction of air flows.

It is also necessary to monitor the condition of the chimney and promptly clean it from soot and soot.

Important Operating Instructions

In terms of operation, gas boilers with a closed combustion chamber are considered safer. Their firebox does not communicate with the room air. However, the power of such boilers is significantly inferior to the power of boilers with an open combustion chamber. Therefore, in private households a second type of boiler is often installed.

The choice of future coolant depends on the goals and operating conditions of the system. If the boiler is expected to be turned off frequently, then it makes sense to think about using antifreeze

The operation of such boilers requires compliance with safety precautions. So, to install a powerful floor-standing boiler, it is customary to use a separate room with a certain size. The boiler is mounted at some distance from the walls. Nearby walls should be protected with fire-resistant material to prevent fire.

A ventilation system must be installed in the boiler room. There should also be a source of natural light. The width of the entrance door must be at least 80 centimeters. The chimney is laid in accordance with the instructions for the boiler and from heat-resistant material. The chimney must rise above the roof ridge by at least half a meter.

One safety measure is to install carbon monoxide detectors. The gas detector will promptly detect the leak of a volatile toxin and warn users about it. It can also be configured so that the ventilation is automatically turned on and the gas supply is turned off. Modern automation allows the implementation of a variety of smart systems.

If the temperature, pressure or gas sensor fails, you must immediately turn off the boiler and call a service technician. Using a boiler without these devices is fraught with serious negative consequences.

SNiP requirements state that a gas boiler must be connected to the main line using a copper pipe or a bellows hose. In this case, a faucet must be installed

If signs of a gas leak are detected, you must immediately turn off the gas tap and open the windows to ventilate the room. Do not turn on the light and try to illuminate the room by lighting matches or a lighter.

The gas boiler must be serviced at intervals specified by the manufacturer. Information about the necessary procedures is indicated in the instructions for the device. For example, you need to clean the chimney, remove scale from the heat exchanger, or clear the fumes from the burner. Then the boiler will last a long time, and the risk of serious malfunctions will be significantly reduced.

When using a gas device, do not turn it on at maximum power for a long time. This may result in the release of steam, which is unacceptable.

Sometimes the boiler begins to make unusual noises and vibrations. This may be due to the operation of the fan. We warn you that all actions that require disassembling the boiler casing automatically deprive the owner of the right to warranty repair or replacement.

However, the owner of the unit needs to monitor the operation of mechanisms and systems that protect the boiler from fire. It is necessary to maintain the temperature in the circuits at around 50 degrees, which significantly reduces the likelihood of mineral deposits forming on the internal surfaces of pipes and devices.

Price range

Danko floor-standing boilers represent a wide group of models, which expands the price range. If you do not take into account powerful samples intended for heating large areas, then the cost of floor-standing boilers is in the range of 20-67 thousand rubles.

The price of a particular model depends on the set of functions and design features.

Before purchasing, you need to decide on the type of chimney, since this is an important factor influencing the choice of a particular model.

NOTE!

The chimney is not included in the basic package and must be purchased separately.

Conord product line

In the company’s line you will not find wall-mounted boilers, so to supply the home with heat, users prefer Conord floor-standing gas boilers, which may have various auxiliary options.

Floor-mounted units are available in four series. All units are made of durable high quality steel. To make the device more stable, its surface is coated with heat-resistant powder, which acts as protection against high temperatures and loads. Let's consider Conord heating devices from the following series:

- KSC-G-S;

- KSC-G-N;

- KSts-GV-S;

- KSts-GV-N.

Series KSts-G-S

In this series you will find a high-quality single-circuit floor-standing gas boiler Conord, which is equipped with a functional gas supply regulator. Italian automation is responsible for controlling the operation of the equipment, which makes the operation process safe, reliable and efficient.

KSC-G-S units are suitable for heating rooms with an area of 80-300 m². However, for this it is necessary to select a boiler of the correct power

To ensure that the boilers meet the requirements of the heating scheme, it is necessary to pay attention to other indicators. For example, the operating pressure of devices included in the KSts-G-S series is in the range from 0.2 to 1.9 Bar, the minimum temperature regime of the coolant is 60°C, and the maximum is 90°C

Series KSts-G-N

The most functional boilers are produced under this marking. They are equipped with a cylindrical heat exchanger, which is made of durable cold rolled steel. Thanks to this, the device works very efficiently, heating the coolant occurs in the shortest possible time and very evenly. This series includes single-circuit boilers that are suitable for supplying heat to rooms with an area of 100 to 300 m².

Gas boiler with steel heat exchanger Conord KSts-G-N

Heating devices Conord KSts-G-N can operate in difficult operating conditions - they are designed for systems where the operating pressure reaches 5 Bar. In order for the heating process to be optimized, the boilers are equipped with high-quality thermo-hydraulic automation. The described series is considered more functional and versatile, which certainly affects the price. The cost of devices starts from 16,000 rubles.

Series KSts-GV-S

Here is a budget double-circuit gas boiler Conord. In addition to the heating circuit, the package includes another one, which is used to provide the house with hot water.

The boilers have Italian Sit automatics; they are capable of effectively heating a room with an area of 120 to 300 m². By purchasing equipment from this series, you will solve two problems at once: you will provide your home with heat and you will have a supply of hot water for household needs. Boilers are considered universal; they can be installed in any circuit.

Series KSts-GV-N

Among the products manufactured under this marking you can find a good double-circuit gas boiler Conord. Among other features inherent in the units of the described Russian manufacturer, this one has a unique smoke collector shape, as well as thermo-hydraulic automation.

Reviews of the gas floor-standing boiler Conord KSts-G-8

In the end, it is worth noting once again that Conord gas boilers are high-quality heating equipment that copes well with heating (if we are talking about single-circuit models), as well as with the supply of hot water (double-circuit models). The devices are distinguished by their reliability, wide functionality and good heat transfer performance. Numerous reviews from owners are direct confirmation of this.

You can also pay attention to German, Japanese, Korean, Czech, Russian and Ukrainian gas boilers.