Home / Gas boilers

Back

Published: 03/21/2020

Reading time: 5 min

0

2952

South Korean offers the domestic market a wide range of boiler units of varying thermal power and installation options.

Navien boilers are adapted to work with Russian communication networks and real climatic conditions, so the installation of a Navien boiler will work in Russia without loss of efficiency.

- 1 How to install a wall-mounted boiler step by step 1.1 Connect the chimney

- 2.1 Chimney connection

How to install a wall-mounted boiler step by step

Installation of Navien gas boilers is carried out in accordance with the gasification project, carried out according to technical specifications issued by the regional department of the gas service and approved by regulatory authorities: architecture, SES, fire inspection and others, in accordance with the requirements of directive materials for the safe operation of gas equipment.

Step-by-step installation of a wall-mounted boiler:

- The choice of installation location and preparation of the wall for placing the Navien boiler is carried out according to the project. Since the weight of the structure is 25-35 kg, the wall on which the device will be mounted must be solid or additionally reinforced to withstand the load.

- Install an anchor bolt to securely fasten the structure.

- Install thermal insulation and a buffer panel, for example, rubber, on the wall to prevent vibration of the Navien Deluxe boiler and background noise.

- Install the Navien unit strictly in a horizontal position, maintaining a distance of at least 60 cm on all sides for repair and maintenance.

- Connect to an electrical line with a voltage of 230 V. The socket for connecting the device must be individual and located at a distance of no more than 300 mm from the housing. Boiler equipment must be grounded.

- Connect the unit to the gas pipeline directly. No other gas equipment should be connected to this area. The installation site must be firmly secured to prevent independent dismantling of parts.

- Connect to a water supply with a diameter of 15 mm or 1/2″. A shut-off and control valve is installed at the entry point of cold water into the unit. The water pressure should be in the range from 1 kgf/cm2 to 6 kgf/cm2. Otherwise, you will need to apply methods to increase/decrease the pressure in the water supply.

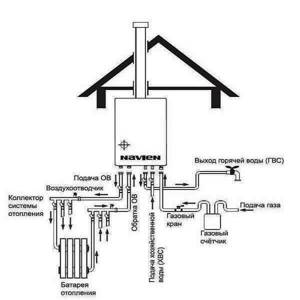

- The unit is connected to heating systems. When connecting pipes to the battery, a manual or automatic air vent is installed on the top part to remove air from the network.

- All connection areas are secured using mounting couplings or mounting nuts.

- Perform thermal insulation of pipes and collectors.

- Install the thermostat on the wall in a heated room, with a distance of 1.5 m from the floor.

Connecting the chimney

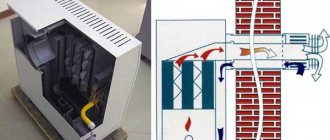

A Navien boiler with a natural smoke exhaust system is installed in a room with reliable fresh air ventilation, capable of providing 3 times air circulation.

The cross-section of the chimney must correspond to the smoke pipe of the Navien gas boiler. The diagram of the chimney and its geometric dimensions must correspond to the diagram specified by the manufacturer in the technical documentation of the boiler.

The main requirements when installing elements of the chimney system:

- Along the entire length of the chimney, its diameter must be without kinks, equal to or greater than the smoke pipe of the unit.

- The chimney is installed vertically. If the diagram contains horizontal sections, then their length should be no more than 2 m. An inspection is installed in this section to clean the smoke exhaust system.

- The cross-section of the chimney is made round, since in rectangular and square structures there are stagnant zones in which soot accumulates and draft decreases.

- The metal of the chimney is stainless steel.

- A deflector is installed on the chimney.

- In the lower part, in the area of the tee or support, install a plug with a condensate drain.

Installation features

Before purchasing a gas boiler you must:

- Prepare the installation site. Atmospheric apparatus requires a separate room, at least 2x2 m in size, with exhaust ventilation.

- The device must be powered from a stabilizer connected to a circuit breaker or outlet that has an emergency shutdown feature.

- The boiler body must be grounded, so you need to connect a grounding wire to the installation site.

- The wall where the device will hang, if it is flammable, must be sheathed with non-flammable material.

After purchasing a boiler, the difficult task of connecting it arises. The factory operating instructions recommend engaging an authorized service center specialist for this.

But if you have skills in working with pipes and taps, you can try hanging it on the wall and connecting the device yourself. The factory instructions describe this in detail.

But we must not forget that in any case, you will need to call a gas service specialist to conclude a service agreement and obtain a special permit to operate gas equipment.

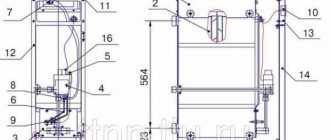

Installation of a Navien floor-standing boiler

A floor-standing gas boiler is a potentially dangerous object and, in accordance with the current requirements of SNiP, must be installed only in a special room - the furnace room according to the project. These requirements cannot be ignored, since the user does not receive permission to operate the unit from the gas service.

The combustion room must have a reliable ventilation system. For Navien gas boilers with a power of up to 150 kW, it can be installed on any floor, and more powerful equipment only on the ground floor or in the basement.

Their installation in residential premises, bathrooms and toilets is prohibited. The combustion chamber should not have a cavity or niche to avoid the accumulation of combustion products and the formation of explosive mixtures.

A reliable cement base is laid under the gas unit. Structural elements of the building in the area where the unit is located must be protected from the possibility of fire.

Typically, thermal insulation is carried out using roofing sheets laid on a fire-resistant pad, such as asbestos sheets above 3 mm thick.

The protective structure must extend beyond the dimensions of the boiler along the entire perimeter by at least 100 mm. The minimum gap from the wall of the unit to the thermally insulated walls should be 100 mm.

In front of the front of the device, a free passage of at least 1.0 m is left for maintenance. The space in front of the Navien boiler is covered with an iron sheet with an area of 1x1 m.

After installing the boiler, it is connected to auxiliary equipment and in-house utility networks: circulation pump, fan, safety group, drainage line, make-up line, heating and hot water system, gas pipeline and smoke exhaust system.

Piping diagrams are indicated in the design documentation for the boiler room and technical materials of the manufacturer. Installation and adjustment work is carried out by a specialized organization that has the right to conduct this type of operation. Work on gas equipment is carried out by Gorgaz specialists.

Chimney connection

The chimney ensures fire and sanitary safety in the house, and also contributes to the efficient operation of the unit with standard efficiency values.

The dimensions of the flue are set by the manufacturer of the boiler equipment so that the necessary vacuum is created in the combustion chamber to allow air to leak into the combustion mouth. The location of the chimney outlet is determined before installation work is carried out so that it can be combined with the boiler smoke pipe.

For boiler units with a power of up to 35 kW with an open combustion chamber, the minimum diameter of the chimney is chosen to be 140 mm, for more efficient units over 160 mm.

Closed-type Navien boilers are equipped with a coaxial chimney of the type that comes with the device or is specified by the manufacturer in the technical documentation.

When installing a boiler and its chimney system, it is important to maintain the slopes of the structural elements, insulate the points where it passes through the building structures, and install a condensate drain and deflector.

After tying the chimney elements into a complete structure, check the natural draft in the boiler firebox by holding a lit match to the viewing window of the ignition device.

Navien boilers: new heating options

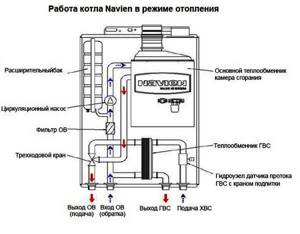

The Navien wall-mounted double-circuit boiler works perfectly at low water pressure up to 0.1 bar, so it is widely used in residential areas with minimal water pressure in the water supply, as well as in cases of constant power failures. The buyer receives a long service life of a wall-mounted double-circuit boiler, thanks to a heat exchanger made of reliable steel, which prevents rust and corrosion.

The Navien wall-mounted double-circuit boiler operates on the basis of the APS mechanism, which guarantees stable combustion and reduces gas costs. The mechanism controls the amount of gas that penetrates the burner, ensuring total combustion of fuel, reducing its consumption. A fan with controlled rotation speed promotes safe combustion. Therefore, the Navien wall-mounted double-circuit boiler can be used in apartment buildings. The convenient location of the APS mechanism prevents condensation.

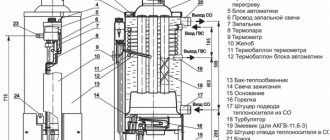

Features of the Navien boiler design:

- circulation pump;

- universal separate heat exchanger;

- tank;

- automatic control system;

- the ability to operate the boiler on natural and liquid gas;

- convenient choice of heating mode. You can choose any temperature that will be present in the house;

- timer function. You can set any time for stopping the boiler operation. The Navien boiler will work for half an hour during the set time with further shutdown. If you set the time to 4, then heating will be carried out for four hours, half an hour at a time;

- With one function you can save fuel consumption and, at the same time, maintain the temperature when you are not at home.

Starting the boiler

After connecting the boiler with the chimney system and utility networks, the heating networks are tested and the operation of the electronic systems and power supply of the unit is checked. The first start-up of gas equipment is performed by a representative of Gorgaz.

After the gas line is checked and is in good condition, I begin recharging the heating system with sequential air discharge through the air vents. After reaching the operating pressure in the heating circuit, start the boiler through the remote control panel.

All modes are configured on the control panel. Adjustment of the temperature regime in the system is carried out by pressing the “+” or “-” buttons when the “heating” option is selected, indicated by an image in the form of a battery. The LCD display shows the entered temperature value.

The control program has the ability to set the operating mode of the heating system based on the internal ambient air temperature. To do this, the user must click on the symbol of a house with a thermometer inside.

During the setup process, the temperature display will flash, and when the value is set, the display will become constant.

Gas boilers from Nevien

The South Korean concern KyungDong NAVIEN is known for its equipment for heating and hot water supply of residential and industrial premises.

Gas boilers make up a significant share in the company’s overall product range, although they are not the main type of product.

They are distinguished by their specialization for Russian conditions, are able to work with unstable or low pressure of gas and water, and automatically correct voltage fluctuations in the power supply network up to 30%.

This makes them the most preferable option compared to European models, and the low price increases the demand and popularity of Korean units.

Tips for use

The user must never interfere with the operation of the gas systems of the boiler and gas mains. These works are performed only by a gas specialist. If gas leaks or malfunction of equipment installed on the gas line are detected, the user must immediately close the main gas valve to the boiler, thoroughly ventilate the room and call the emergency service.

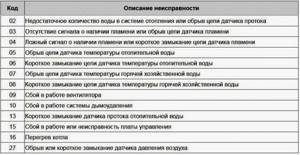

Navien gas boilers are very reliable equipment; if used correctly, breakdowns occur very rarely. In addition, the device’s software control unit has a good diagnostic system, which will not only determine the cause of the failure, but will also notify the user in a timely manner.

Device and design

The design of Navien boilers has a number of features:

- circulation pump;

- universal separate type heat exchanger;

- tank;

- automated control system;

- possibility of using liquid or natural gas as fuel;

- ease of setting the heating mode - you can select the required temperature that is most comfortable for your home;

- it is possible to set a timer - you can set the time after which the boiler will stop working; the boiler can operate for 30 minutes at a specified time and then switch off;

- Using just one function, you can easily save on fuel and at the same time maintain the desired temperature while you are away.

Basic errors and malfunctions

Service center specialists claim that 80% of problems during the operation of a gas boiler unit occur due to phase zeroing due to incorrect connection of the plug from the boiler to the socket. If the installation is correct, the system itself resets errors and starts the installation.

Unsatisfactory operation of the boiler is often associated with low parameters in the gas line; you can check this yourself by placing an ordinary kettle on the gas stove; if it boils for a very long time, the problem is with the quality of the gas.

A sharp increase in coolant in the circuit is usually associated with poor circulation in the circuit. You will need to check the filter at the pump inlet and that there are no leaks in the heating system.

When noise and vibration appear during operation of the boiler unit, it is necessary to diagnose the operation of the fan. The balancing of which may be disrupted due to dust adhering to the blades.

After cleaning it, the noise usually disappears. During diagnostics, the condition of the bearings is checked and their lubrication is renewed.

Navien gas boilers are reliable and multifunctional devices that operate with high energy performance. They are significantly lower in price compared to models from the EU, and are practically not inferior to them in quality and energy efficiency.

Filling the boiler and heating system with water

Error code 02 indicates that there was an attempt to start the boiler, but there is no water in the system, or there is not enough water. What to do:

- The appliance is unplugged and the gas supply is cut off.

- At the bottom of the boiler, among many elements, you need to find a make-up valve. Turning it counterclockwise opens it, and turning it clockwise closes it.

- When the tap is open, monitor the pressure gauge. You need to close the tap when it shows 1.3 - 2 bar.

- Now the boiler is connected again, gas is supplied and the start is made.

Don't worry if error 02 appears again. This may be caused by the fact that after bleeding the air (which is automatically done at startup), the water level is again insufficient. The filling operation must be repeated.