Principle of operation

The principle of operation for all models is approximately the same:

- Automation detects a drop in air temperature to a certain level.

- The pump turns on and water begins to circulate through the system.

- Then the burner lights up, which heats the coolant in the heat exchanger;

- After the coolant reaches the desired temperature, the burner turns off.

- The pump still runs for some time, pushing water through the system until it reaches the desired temperature.

The cycle repeats as soon as the coolant temperature drops below the required level by 1º C.

Water heating occurs according to the same scheme:

- The starting point is the opening of the hot water tap.

- The burner lights up.

- The secondary heat exchanger heats up from the coolant and raises the water temperature to the desired level.

- The flame goes out when the liquid reaches the permissible upper limit or after turning off the hot water tap.

How does a gas boiler work?

A double-circuit gas boiler can operate in 2 modes:

- heating - along the circuit with the primary heat exchanger module;

- hot water supply - along a circuit with a plate heat exchanger module.

Switching between modes occurs with a special three-way valve .

Most often,

room heating occurs according to the following scheme:

- when the temperature in the house drops below the set parameter, the automation gives a signal to the circulation pump to operate the system;

- water begins to move in the system, creating a vacuum in the return pipeline;

- simultaneously with the start of water movement, the burner is turned on;

- As water passes through the heat exchanger, it heats up and then begins to spread heat;

- “having passed” through all the radiators, the coolant cools down - this causes it to return to the boiler inlet with a lower temperature;

- then the water passing through the heat exchanger is reheated.

We recommend: Where can I install a gas boiler in a private home? Rules and requirements for equipment

When the selected temperature is reached (which is controlled by the temperature of the coolant or air), the burner turns off, and the water, driven by the pump, continues to circulate for a short time ( post-circulation mode ) until the heat exchanger cools down. After this, the boiler will be turned off until the temperature begins to drop. When the temperature decreases by 1°C, the boiler starts working again.

When heating water, the operation of the unit is almost the same - the only change is the inclusion of the burner as a result of water consumption . In this mode of operation (opening the tap causes the burner to ignite), the three-way valve closes the water inside the boiler. The hot water heats the secondary heat exchanger module, and from it the running water is heated. The system turns off after closing the tap.

Please note: Most dual-circuit models operate in only one mode - when the water is turned on, the heating of the room stops and continues only after the tap is closed.

Types of boilers according to installation method

According to the installation method, wall and floor structures are distinguished. The choice of heating device power depends on the area of the room.

Wall mounted

Wall mounted ones are small in size. They are usually placed in the kitchen. Thermal power ranges from 12 to 25 kW. The models are well suited for autonomous heating of an apartment.

Prices for a wall-mounted double-circuit gas boiler

double-circuit gas boiler

Floor-standing

The thermal power of such boilers reaches 35 kW, hence the large dimensions. Some models can be installed in a residential area, while others require a separate boiler room. This gas double-circuit boiler is well suited for heating a private home.

When installing any gas heating equipment, the following must be taken into account:

- distance from the top of the device to the ceiling;

- room volume;

- ventilation operation;

- presence of a gas meter.

The connection takes place according to an approved project under the supervision of gas company specialists who have a license for this type of work.

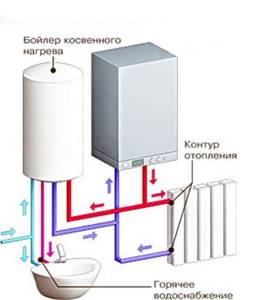

The advantage of a double-circuit gas boiler

The main advantage of a double-circuit gas boiler is that the heating and hot water supply circuits are compactly enclosed in a single housing. There is no need to equip the system with an indirect heating boiler, which takes heat from the coolant for technical needs. This saves usable space and minimizes inevitable energy losses.

Single-circuit gas boilers are more compact in size, but a lot of effort will have to be made to install hot water supply. With this scheme, you will need additional space for an indirect heating boiler and the device itself. That is why the double-circuit gas boiler has become widespread.

According to the type of installation, dual-circuit systems are divided into:

- floor-mounted energy-dependent;

- floor-mounted non-volatile;

- wall-mounted

Energy-dependent double-circuit floor-mounted boilers are used where there are no frequent power outages. The main disadvantage of this system is its large dimensions. An example of such a boiler is Mimax KSGV-12.5 with a power of 12.5 kW.

Floor-standing double-circuit gas boilers of non-volatile design are equipped with an automation system that operates without power supply. This system is relevant in rural areas and summer cottage areas, where power lines are used to transport electricity. Non-volatile automation works excellently.

Wall-mounted gas boilers are made in compact sizes. Their weight is reduced due to the use of copper for the manufacture of heat exchanger parts. All wall-mounted boilers are energy-dependent, as they are equipped with an electric pump and electronic automation.

The South Korean company Navien offers a Navien Deluxe 20 k device with a power of 20 kW. It is characterized by compact dimensions and enviable heat output.

Developers of boiler equipment, thanks to the use of modern technologies, managed to use the latent heat of combustion of gas, which accumulates in water vapor. Such a system is called condensation. Its advantage is obvious: in comparison with others, it has a higher efficiency.

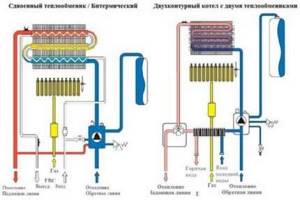

Types of heat exchangers

The boiler is called double-circuit because its heat exchanger consists of two modules.

By design, there are two types of heat exchangers:

- double;

- bithermic.

Twin

Dual consists of two circuits:

- Primary, which is a pipe with fins and is located above the burner.

- Secondary lamellar. It is located at the bottom of the structure.

Both contours are connected to each other and are one part.

Bithermic

Bithermal consists of two tubes located one inside the other. The outer one contains the coolant of the heating system, the inner one contains hot water supply.

Twin heat exchangers are easy to use. Water in the heating system circulates through a closed system, which slows down the process of scale formation. More of it is formed in the plate circuit, since running water enters it. If clogged with scale, the plate circuit can be replaced separately. The bithermal heat exchanger has to be completely changed in a similar situation.

About ease of use

What to choose for those who are not used to putting up with discomfort, but still want to comfortably use the benefits of civilization? For these purposes, single-circuit boilers are created as opposed to double-circuit boilers. Such a device is designed to heat heating fluid, but if you connect an indirect heating boiler to it, you can get a modern, efficient hot water system.

Further, with the use of a boiler, the following can be noted: the boiler begins to heat the water only from the moment it begins to cool for some reason. This means that it is possible to create a special recirculation system, i.e. movement of hot water in a circle. The water will bypass each tap and return to the boiler for further heating. In this case, we get hot water immediately after opening the tap - because the water will already be there. This is very important if you plan to build a large house with several bathrooms, and they are quite far from the boiler room

Types of burners

According to the burner control method, there are:

- single stage;

- two-stage;

- modulated.

Single stage

The least economical type of burner. In such a boiler there is no way to set the heating level to maintain a certain temperature. The device constantly turns on and off. This increases wear on parts and gas consumption.

Two-stage

They operate in two power modes: 100% and 50%. The ability to choose between two modes allows the automation to turn off the burner less frequently, which reduces fuel consumption and protects equipment from wear.

Modulated

The most economical type of burners. Automation sets the required power from 10% to 100%. Thus, the number of on/off switches is reduced to a minimum. Gas consumption is reduced by 10-15%. Heating of water for domestic use is also carried out more correctly. The only negative is the high price.

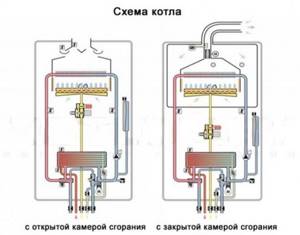

Scheme of operation of a double-circuit boiler

The presence of a hot water supply system slightly complicates the operation of a double-circuit gas boiler. The coolant heated by the burner, moving through the heat exchanger, ensures heating of the plate heat exchanger through which water from the water supply flows.

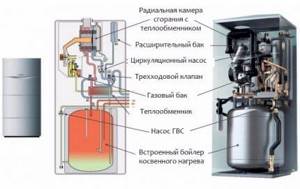

Design diagram of a double-circuit gas boiler with bithermal and two conventional heat exchangers. In the first option there is no need to use two heat exchangers

Simultaneous use of a dual-circuit model in heating and hot water supply mode is impossible. When the hot water tap is activated, the three-way thermostatic valve stops the circulation of coolant through the heating lines. The boiler switches to the mode of moving water along a circuit with a plate heat exchanger, which heats water for domestic needs.

If there is a significant consumption of hot water, the operation of the heating-oriented boiler may be paralyzed for a long time. The problem can be solved in two ways - to provide for the installation of a more powerful heating device or to include an indirect heating boiler in the arrangement.

If the hot water system is actively used, it is possible to install a double-circuit boiler with a built-in boiler. In this case, fuel consumption increases slightly due to the fact that during the pause between operating cycles of the heating system, the burner energy is used to maintain the water temperature in the additional gas water heater.

A certain supply of hot water in the built-in boiler allows you to use the DHW system without turning off the heating circuit. As a result, both systems operate alternately, without overheating the liquid and extending the life of the heat exchanger.

A boiler with a built-in standard boiler not only provides a sufficient reserve volume of hot water, but also helps to avoid long-term shutdowns of the heating circuit

The built-in standard boiler allows you to get hot water at the desired temperature at any time, the supply of which is provided automatically. While a flow-through DHW system takes several minutes to heat the water to the required temperature.

Combustion chamber types

The burner is located in the combustion chamber.

There are two types of cameras:

- Open or atmospheric. This design requires a good ventilation system, since oxygen enters it directly from the room in which the heating device itself is located, and combustion products are discharged into the chimney.

- Closed. Provide for a coaxial chimney leading outside. It is a “pipe-in-pipe” design. Through the outer pipe, air from the street enters the chamber, and through the inner pipe, combustion products are discharged to the street.

The operation of a boiler with a closed combustion chamber is more stable.

Disadvantages of closed systems:

- strong wind can blow out the burner;

- In winter, ice sometimes blocks the inflow and outflow of air;

- the turbine that provides air flow runs on electricity; without it, the boiler turns off.

Burners of a double-circuit gas boiler

The fuel burners of a dual-circuit gas installation have a complex structure and are controlled by electronic automation or a simpler mechanical analogue. The purpose of these devices is the correct formation and combustion of the gas-air mixture. In fact, the burners are the heart of the boiler.

Devices for mixing and burning gas-air mixtures are of the following types:

- Atmospheric. This is a classic option. In such a device, the mixture is depleted of oxygen. And in order to reach the specified power, the burner consumes more fuel.

- Diffusion. A distinctive feature of these devices is the formation of a gas mixture directly in the combustion chamber of the boiler. Such a system has good efficiency indicators, but will not compete with the next type of burner.

- Injection. These devices differ in that they contain complete or incomplete formation of the mixture immediately before combustion. Such burners consume less fuel.

- Regenerative. In this case, there is a significant increase in the efficiency of the installation due to preheating of the fuel: after mixing with the air of the combustion chamber, the combustion process occurs more intensely.

- Regenerative. Such devices are distinguished by the presence of a heat exchange device that heats the gas-air mixture before combustion in the boiler. This results in increased fuel economy.

- Supercharged. Such burners are installed in high-performance installations designed for high power and an extensive heating system. The intensity of combustion of the fuel mixture in pressurized burners is achieved by pumping it into the working cavity with an electric fan.

Additional functions

Depending on the connection to the electrical network, boilers are:

- volatile, that is, equipped with a control program, a circulation pump and other devices that run on electricity;

- non-volatile, having no equipment dependent on electricity.

Regardless of this, all devices have an automation system designed to monitor the following parameters:

- presence of draft in the chimney;

- gas pressure;

- flame control.

If at least one indicator does not meet the requirements, the boiler does not turn on.

Different models may have additional automation settings:

- Maintaining the set temperature level. There are two options for this program: one monitors the temperature of the coolant, the other monitors the temperature of the air indoors or outdoors, and in accordance with it regulates the power level of the boiler.

- Post-circulation mode. When the burner turns off, there is a danger that the water in the heat exchanger will boil. This can lead to damage to the device, so the pump continues to circulate coolant through the system for some time until t drops to a safe level.

- Economy mode. Prevents freezing of the coolant during the absence of owners. It maintains the temperature at +5 º C. This is enough to keep the system in working order.

- Summer mode. Designed to prevent the system after the heating season ends. The automation turns on the pump once a day to drive water through the pipes and thereby prevent the occurrence of traffic jams and blockages of various types.

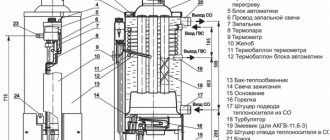

Design, structure and characteristics of equipment

A double-circuit gas boiler is a device in which heat energy is generated as a result of gas combustion. The resulting energy is used to heat the water used to heat the house, and is also supplied to the hot water supply system.

What does this unit consist of:

- gas-burner;

- heat exchanger;

- igniter;

- heating circuit;

- hot water supply;

- expansion tank;

- pump for liquid circulation;

- a chimney necessary to remove combustion products;

- automation - allows you to control the boiler and control the temperature.

When choosing a dual-circuit gas unit, it is important to know exactly what you need to pay attention to first. That is why it is worth familiarizing yourself with its device in more detail.

Types of heat exchangers

The main difference between a dual-circuit device is that it is capable of heating water for heating a room, as well as for hot water supply.

Attention! Both functions cannot work simultaneously.

That is why the device contains special heat exchangers, which come in the following types.

Twin

It consists of 2 modules, each of which is presented separately - primary and lamellar. In the primary, the water required for heating the house is heated, and in the secondary, the water intended for household needs is heated.

If you look at the structure of a dual heat exchanger, the first type of module is comparable to a tube with fins, and the secondary one looks like a set of plates. Both of these modules are interconnected, so they represent a single part, but the structures are located in two different boiler parts - the primary one on top and the plate one on the bottom.

Bithermic

In appearance, it looks like 2 tubes made of metal, which are inserted into one another. In the inner part of the 1st tube, the water used for household needs is heated, and the 2nd tube (outer) is necessary for heating.

A system equipped with a dual heat exchanger is considered the highest quality and most durable . The fact is that when heating water for domestic purposes, running water is taken, which leads to a large amount of scale in the pipes.

This situation contributes to frequent repairs of the unit or requires its complete replacement, which is not always easy to do.

And if in a double heat exchanger it is possible to replace only some parts of the hot water supply, then in the case of bithermal separation it will be necessary to install a new device, which will cost the owner twice as much.

It is also worth considering the fact that if the hot water system in a double-circuit gas boiler fails, the dual heat exchanger will continue to successfully heat the room, while the bithermic one will have to be repaired, since it will be completely unsuitable for use.

Heat exchanger material

When choosing a double-circuit gas boiler, you should pay special attention to the material of the heat exchanger:

- galvanized steel is the cheapest and fastest-fading material;

- Stainless steel is a more durable material, notable for its considerable price, but the efficiency of such a boiler is quite low;

- copper - this durable material is characterized by good efficiency, so the high cost of a device with a copper heat exchanger does not frighten many people who prefer to pay less for gas in the future.

Copper is considered the best option, so most modern and high-quality boilers have heat exchangers made of this material.

The boiler's automation helps prevent overheating, and excessive chemical activity can be reduced by using chemically neutral materials, such as polymer pipes.

Types of burners

Depending on the type of flame control, burners can be divided into the following types:

- Single-stage - there are no intermediate positions, the burner is either on or off. This is not the best operating mode, since the unit is turned on/off.

- Two-stage - there are 2 operating modes of the device - 50-60% and 100% power. The required power is maintained automatically. Based on the reduction in the number of on/off switches, these types of burners operate in a more economical mode and maintain the required temperature well.

- Modulating are the most expensive, but also the most economical types of burners. They are controlled automatically, and it is possible to set exactly the power that is required at a certain time - from 10 to 100%. Since a double-circuit boiler, equipped with a modulating burner, has a minimum number of on/off cycles during operation, it is characterized by increased durability. The positive thing is that in such boilers the fuel consumption is significantly lower than in other models.

We recommend: Types of gas boilers.

How to choose a reliable heating and water supply for a private home? The most economical choice is a boiler equipped with a modulating burner. It allows you to set the required room temperature, as well as heat the water to the required values.

Automation

To ensure safe operation of the boiler and facilitate its performance, gas boilers must be equipped with automatic control . Parameters that are monitored using it:

- flame control;

- gas pressure;

- presence of draft in the chimney.

If one or more of the above parameters does not correspond to the norm, the boiler will not turn on.

But in order to increase comfortable living conditions, as well as to simplify operation, it is worth choosing models that have extensive customization options . Additional functions of gas boilers include:

- Ability to set a stable temperature for room heating and water heating. This function can be achieved thanks to two types of automation. In one case, the water temperature is controlled, and in the second, the air temperature.

- Possibility of heating fluid for heating systems with different temperature conditions . This may be required, for example, if heated floors are installed. In pipes laid under the floor, a higher temperature can be given, while in heating radiators it can be lowered.

- Combustion process control - flame modulation, electronic ignition, soft start.

- Timer for turning on hot water supply at a specified time. This function will allow you to set water heating for a certain time, so that in the morning, before going to work, you can take a shower and not have to wait for the boiler to heat up.

- Post-circulation of the pump - after the liquid reaches the set temperature and the burner turns off, the pump continues to operate for a certain time, which will allow the circulating water to “remove” energy from the cooling heat exchangers.

Also, do not forget about automatic security systems that will prevent the occurrence of various emergency situations and notify you if the equipment fails.

Criterias of choice

When purchasing, be sure to familiarize yourself with the technical characteristics specified in the device passport.

We pay attention to the following indicators:

- Thermal power. Usually the manufacturer gives its minimum and maximum value. For example: 8.0-24.9 kW.

- Water heating speed. The technical characteristics do not indicate the actual t of water, but the value of its rise from the moment it enters the plate circuit until it exits to the mixer. For example, t of water in the system is 17° C, with a given ∆ t of 25° C at the outlet it will be 42 º C.

- Heat exchanger material and type.

- View of the combustion chamber.

- Burner type.

Korean heating boilers

Korean-made boilers combine modern technology and reliability.

They are equipped with protection systems against voltage surges, increased pressure and temperature in the collectors. The boiler also has a built-in natural gas leak detector. If it is detected, the boiler automation will shut off the gas supply to the burner device. Navien is a leading manufacturer of boilers. It produces boilers operating on various types of fuel with different numbers of circuits. The equipment is equipped with burner devices that operate even at low natural gas pressure. In addition, a voltage stabilizer is built into the boiler, which protects the system from overloads.

The Olympia company specializes in the production of double-circuit boilers equipped with a weather control system. The power range of models of this brand is quite wide, which allows you to choose a boiler for a room of any size. All boiler models are equipped with the latest automation system, which allows you to smoothly regulate the operation of the equipment and even protect the system from freezing. Domestic boilers.

Danko boiler equipment regularly receives good reviews from users and experts. From the model range presented by the company in the range from 7 to 15 kW, you can easily select a boiler for heating a small country house or apartment, subject to permission. The boiler unit is equipped with a gas filter, a steel heat exchanger and an economical micro-torch burner.

Another company that produces competitive boiler equipment is OJSC Borinskoye ISHMA BSK. A distinctive feature of these boilers is that they are produced with a built-in circulation pump. In this case, the boiler can operate both with and without a working pump. This is very convenient when there are frequent power outages.

Boiler power calculation

For rooms where the ceiling height does not exceed 3 meters, the following formula for calculating boiler power is applicable:

MK = S * UMK/10.

Where:

- МК – boiler power;

- S – area of the room;

- UMK - specific boiler power per 10 sq.m.

Depending on climatic conditions, each region of the Russian Federation has its own UDC indicators:

- 0.7 - 0.9 kW - for the Southern Federal District;

- 1.0 - 1.2 kW - for central Russia;

- 1.2 - 1.5 kW - for Moscow and the Moscow region;

- 1.5 - 2.0 kW - for northern regions.

The heating device should not work at the limit. In addition, in addition to its direct heating function, it heats water, so we add another 40% of the power to the result obtained.

Types of gas boilers with two circuits

The operating features of gas equipment are largely determined by the design version of the heating device. Modern boilers are available in two form factors - floor-mounted and wall-mounted.

When choosing a design option, you need to focus on the size of the heated area and the activity of using the hot water system. You need to understand that wall-mounted boilers are more compact, but at the same time they have much less power.

The double-circuit wall-mounted gas boiler has a compact size and modern design, but is only effective when heating small areas with moderate hot water consumption

The choice of a wall-mounted double-circuit boiler may be justified if the heated area does not exceed 200 sq.m, and the total productivity of the hot water system does not exceed 14 l/min.

The small size of a wall-mounted boiler, although it seems like an advantage, actually hides many disadvantages. Compactness is achieved through the use of thinner heat exchanger tubes. In addition to the fact that they have a shorter service life, there is a possibility of clogging.

In floor-standing installations, more massive and reliable cast iron heat exchangers are used. This not only increases the reliability of the heating device, but also extends its service life.

Review of popular manufacturers and prices

You can buy a double-circuit gas boiler in specialized stores. Before purchasing, it is advisable to familiarize yourself with the prices and technical characteristics of the product on the manufacturer’s website. This will allow you to choose the most suitable device model for maintaining heat in the house.

Protherm Jaguar 11 JTV

This is a wall design.

Characteristics of Proterm:

- power 12 kW;

- the largest heated area is 120 sq. m;

- has a closed combustion chamber;

- the material of the primary heat exchanger is copper, the secondary one is stainless steel;

- hot water supply productivity (∆ t = 30 º C l/min) - 10.7;

- volatile, indicators are displayed on an electronic display;

- price — 31,605 rub. on the manufacturer's website.

Baxi SLIM 2.300 Fi

Baxi is a floor-standing convection boiler with an atmospheric burner.

Peculiarities:

- power 29.7 kW;

- DHW productivity (∆ t = 25 º C l/min) – 17;

- the presence of a built-in boiler of 60 liters;

- price — 154,680 rub. on Yandex Market.

Bosch GAZ6000W WBN6000

This is a Bosch wall model.

Key Features:

- equipped with a closed combustion chamber;

- has a power of 18 kW;

- hot water heating performance (∆ t =25 º C l/min) - 8.6;

- modulating gas burner;

- price — 30,370 rub. on the website of the Hitboiler online store.

Prices for Bosch GAZ6000W WBN6000

Bosch GAZ6000W WBN6000

Ariston CARES X 24FF NG

Ariston is a wall-mounted convection boiler.

Distinctive features of this model:

- m power 25.8 kW;

- DHW productivity (∆ t = 25 º C l/min) - 13.5;

- has a closed combustion chamber;

- energy dependent;

- price — 38,176 rub. on Yandex Market.

Navien GA 35 KN

Navien is a floor-standing boiler.

Has the following characteristics:

- thermal power 35 kW;

- DHW productivity (∆ t = 25 º C l/min) - 20;

- closed combustion chamber;

- steel heat exchanger;

- heated area up to 350 sq. m;

- price — 37,639 rub. on Yandex Market.

Vaillant atmoTEC pro VUW240/5-3

The wall-mounted atmospheric boiler Vailant has:

- thermal power 8.0 - 24.9;

- water heating power at ∆ t = 30 º C l/min - 11.5;

- primary heat exchanger made of copper, secondary heat exchanger made of stainless steel;

- modulating burner;

- price — 62,230 rub. on Yandex Market.

Buderus Logamax U072 -24 K

Buderus is a wall-mounted energy-dependent convection boiler.

Its main characteristics:

- power 24 kW;

- water heating capacity (∆ t = 30 º C l/min) 11.4;

- closed combustion chamber;

- heat exchanger made of Al-Si alloy with increased corrosion resistance;

- price — 28,300 rub. on Yandex Market. Find out the technical specifications of polypropylene pipes for heating by following the link.

Construction of a double-circuit gas boiler

The correct choice of a double-circuit gas boiler is based on its characteristics, which depend on the design features.

Main installation components:

- Fuel burner. Its function is to form a high-quality fuel mixture, the combustion of which releases the energy necessary to heat the working fluid.

- Heat exchange device. Its purpose is to extract heat from the combustion products of a gas burner. Double-circuit boilers can be equipped with a secondary plate heat exchanger or a bithermal heat exchange device.

- Smoke exhaust system. It performs the function of removing reaction products from the combustion chamber. The system can be either passive or active (using a fan).

- Circulation pump. Its task is to ensure constant movement of the working fluid along a closed heating circuit, regardless of the difference in system levels. It is the circulation pump that ensures rapid heating of the room.

- Membrane tank. It is used as a container to collect water displaced during heating. Most often it is called an expansion tank.

- Frost protection. This system is not installed on all boilers. It is needed for equipment operating in energy saving mode.

- ACS. An automated control system monitors the operation of the installation and carries out diagnostics in real time. And the presence of an indicator panel allows you to carry out all the necessary boiler settings and receive diagnostic messages. The system also has built-in blackout protection.

Modern double-circuit boilers, which are widely used abroad, are condensing boilers. They can significantly reduce energy consumption by extracting latent heat of combustion.

When gas oxidizes, carbon dioxide and water vapor are released. Part of the energy is spent on the formation of the latter. It is precisely this that is extracted in condensation-type boilers, which makes it possible to increase the efficiency of the installation. Despite the high cost of this solution, it has gained great popularity abroad.

Condensing double-circuit boilers are poorly represented on our market due to low demand for this product. Since their design is quite complex, their price is appropriate. However, no one is immune from rising resource prices, and soon condensing models will be installed everywhere.

Prices: summary table

| Model | Efficiency, % | Max gas consumption, m3/hour | DHW capacity, l/min at t 30°C | Cost, rub. |

| BAXI ECO-4s 24F | 92,9 | 2,73 | 9.8 at t 35°C | 43 200-47 500 |

| Vaillant turboFIT VUW 242/5-2 | 93,5 | 2,66 | 11 | 45 000-53 200 |

| Viessmann Vitopend 100-W A1JB010 | 91 | 2,77 | 11,2 | 54 000-61 000 |

| Bosch Gaz 6000 W WBN 6000-24 C | 93,2 | 2,8 | 11,4 | 39 800-42 000 |

| Buderus Logamax U072-24K | 92 | 2,8 | 11,4 | 43 500-52 500 |

| Ariston ALTEAS X 24 FF NG | 93,7 | 2,73 | 9.6 at t 35°C | 64 200-69 000 |

Do you need a boiler?

A double-circuit boiler is capable of independently preparing hot water and does not require additional devices . This is a common view, and it is generally correct.

However, many users are not satisfied with the DHW supply mode in their homes. This usually happens due to a large number of water taps, numerous families, etc. For these cases, there is a way to connect an external drive as a buffer capacity.

Hot water fills the container and is replenished as needed.

The boiler's DHW supply can be adjusted so that the flow rate is minimal . This will ensure high temperatures and stabilize the supply of hot water to consumers.

Advantages and disadvantages

When choosing a suitable heating device and water heater for plumbing, you should consider the pros and cons of the devices in question.

The advantages of these boilers include:

- the presence of a second heat exchanger allows you to effectively organize the process of heating the medium for the water supply and for the heating circuit;

- most devices are equipped with automatic devices - this function increases productivity and reduces fuel consumption;

- a variety of models of two-level devices allows you to solve the issue of organizing heating and water supply in any area;

- an automatic device adjustment system allows you to create a comfortable mode in the room, which cannot be done with centralized heating;

- durability (with proper use).

Negative properties include:

- installation of a floor-standing device will require the allocation of a separate, specially equipped room;

- the costs of installing large and complex systems can reach impressive amounts;

- for uninterrupted operation of the boiler, water with certain characteristics and without foreign impurities is required;

- the need to obtain special permission to install some devices.