Scheme and principles of operation of heat pumps

Structurally, the device is a complex of main and auxiliary elements:

- Impeller or impeller. Parts with blades that capture liquid and direct it to the heating system devices.

- Electrical engine. The element is needed to put the equipment into operation.

- Pumping chamber. The compartment is equipped with coolant supply and pressure pipes, which are connected to the system pipelines.

- Frame. Serves to protect the device from damage due to mechanical impact; it can be made of cast iron or heat-resistant plastic.

- Terminals. A box with terminals is needed to connect the unit to the electrical network, to receive power for all elements and control parts.

How the pump works: coolant flows through the supply pipe into the pumping chamber of the equipment, then the electric motor starts the impeller, the blades of which capture the liquid. After this, the pressure on the coolant increases, it is directed to the outlet pipe, which is connected to the main pipeline.

A simple circuit for a heating pump does not require any special skills during installation, and there will also be no problems in finding out the reason for the equipment stopping - there is no power, the impeller is clogged. The supercharger does not provide any additional functional features; it does not increase the pressure in the system; it is only needed to ensure normal fluid circulation in the devices.

Installation instructions for the circulation pump: important points

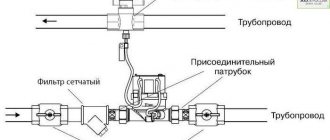

First, let's look at the materials associated with installing the pump - you should understand that technology is technology, and it tends to break down sometimes. As a rule, such situations occur at the most inopportune moment, for example, in winter, when the heating is working at full blast. Therefore, it is necessary to organize a so-called bypass, thanks to which the coolant can bypass the pump and thereby return to the natural circulation of the coolant while the breakdown is being repaired. To do this, you will need three ball valves with a diameter corresponding to the diameter of the pump, two tees, a pair of threaded turns and a filter to protect the pump from damage by debris.

Installation of a circulation pump for heating photo

It is better to assemble the bypass in such a way that the central line of the return pipeline remains intact, i.e. It is better to install on the bypass not a shut-off valve, but the pump itself with a filter and two valves on both sides. In this case, there will be no obstacles to the natural circulation of the coolant in the event of a pump breakdown.

We have sorted this out, now we assemble the necessary assembly dry without tow. We start with the pump - there should be an arrow on it indicating the direction of movement of the coolant. We direct the arrow to the boiler and screw on the filter on the right side of the pump, a tap on it (preferably with an American one) and then a threaded angle on which the tee is installed. To the left of the pump we screw on everything the same, except for the filter - it is not needed there. Between the two tees on the spare bypass branch we install a tap with an American connection, and fill the missing distance with a pipe with threads on both sides.

Installation of a circulation pump

That's it, the bypass is ready, now all that's left to do is cut a piece of the return pipeline according to its size, cut the threads and assemble everything in place using tow. And, of course, supply electrical power to the pump. After this, you can test the performance of the new, improved heating system - believe me, the result will surprise you. The system will not only consume less fuel, but your home will also become warmer!

These are the wonderful properties of a heating circulation pump. All this pleasure does not cost that much. One might say, commensurate with the excess energy costs, which it allows you to get rid of. But the payback period for such a product is approximately a couple of heating seasons, but then there is pure savings.

Author of the article Alexander Kulikov

Principle of operation

The volume of coolant changes when the temperature in the heated room changes.

The bellows also changes its volume. It is because of this that the control spool begins to move. Its movement is proportionally related to how the temperature regime changes.

The thermostat has a special valve stem that moves due to a sensing element that reacts to the environment.

What speed should I set on the heating pump at low boiler power?

Adjusting the power of the circulation pump is usually carried out in order to increase or, conversely, reduce its performance . The higher its speed, the faster the hot water passes through the pipes and the more heat it gives off. In turn, the lower it is, the slower the liquid passes through the system, the faster it cools and, accordingly, the heat transfer will be less.

The minimum power of heating equipment is set mainly in the spring . At this time, it is already quite warm outside, but the house itself does not warm up enough and there is a need for a little heating of the room.

Pump speed modes may vary depending on the model and configuration. On average, the minimum is 30-35 l/min , the maximum is 80-90 l/min .

Why do you need to check the settings?

To ensure maximum performance of the device, before using it . This is done, as a rule, according to two parameters.

Noise insulation. There are several reasons why a heater may make a lot of noise:

- incorrect installation;

- air in pipes;

- voltage fluctuations;

- device malfunction.

To avoid these problems, it is better to entrust the installation to a specialist who will carry out comprehensive diagnostics and ensure the correct installation and functionality of the device.

Uniform heating. The main reason for uneven heating of radiators is insufficient power. Low speed contributes to the rapid cooling of the water, as a result of which the heat simply does not reach the end of the system.

Airiness or an incorrectly selected thermostat mode also leads to a similar problem . May affect the performance of the device and improper installation .

This is especially true for aluminum and bimetallic batteries, which must be installed as level as possible.

Automatic pump protection

The main reason for pump failure is its operation outside the permissible voltage zones. Operation without liquid is not permissible. When purchasing a pump, you should pay attention to the requirements for minimum and maximum voltage values in the network.

It will not be possible to constantly monitor these indicators, so a power stabilizer is built into the system. The maximum and minimum voltage values are set on it. If it is outside the permissible zone, the automation turns off the pump. On three-phase motors, asymmetry and phase sequence are monitored. Such stabilizers protect the system from voltage surges using a time delay. A reliable model is the Turbi.

Three types of combinations of protective control automation

- Start protection devices. They are fully ready-to-use devices. They are connected to the pump system, pressure switch, and volume sensors. There are many functions and parameters to control, but making changes to the settings is almost impossible.

- Relay blocks. They are common starters and popular in the market. The device protects the relay, but there are few functions, and an additional circuit breaker is required for connection.

- Microprocessor-based controls. The most complex protection devices. They allow you to monitor temperature, voltage, resistance and phase sequence through a computer. Protects against voltage surges and work without water. Mainly used in systems with deep pumps.

What type of automation should I choose for the pump? (video)

How to choose

When choosing a UPS for a heating system pump, you need to take into account a lot of nuances that will affect the final cost of the device. In this case, the following is taken into account:

- Number of phases. You can buy single-phase and three-phase models on the market, but only the first type is used in everyday life. Three-phase UPSs are designed for industrial needs;

- An important parameter is the power of the device, which is calculated based on the total power of connected consumers. In this case, the starting load of the equipment is taken into account, because it will be greater depending on the operating voltage. This characteristic can be found out from the pump passport; the load value is called “starting current”.

Note! When selecting a UPS for a pump, voltage drops in the electrical network are taken into account. If the increase or decrease in voltage is within 8-9%, then buy an uninterruptible power supply with an operating range of a voltage drop of 10% up or down.

IPB in the heating system

If you neglect this simple rule, then after a sharp jump or drop in voltage, the pump will run on battery power, which will quickly damage the UPS. It is advisable to purchase equipment with several useful functions.

For example, a cold start allows you to turn on the pump even when there is no power in the network. The device must have indicators indicating the battery charge level. A decrease in battery capacity to a critical point must be accompanied by a special sound signal.

Uninterruptible heating system Cyber Power CPS600E

In addition to all the listed nuances, it is necessary to pay special attention to the power of the pump. If you have installed a weak uninterruptible power supply, the built-in battery may not be enough for long-term uninterrupted operation of the system. According to experts, it is best to buy a device with an external battery connection, which will make it possible to select the required capacity of the pump’s backup power source.

Harness

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Uninterruptable power source

Uninterrupted power supply for the heating pump is, of course, an important point. However, you should not rush to choose a heating system until all their advantages and disadvantages have been studied. If your choice is a heating system with natural circulation of coolant, then you need to take into account that it also has some disadvantages. The main disadvantage is that if there is no automation or pump, the system may fail or, at least, will not be as efficient as it should be. Also, the absence of these components will negatively affect the amount of fuel consumed, which means that such a system will bring you considerable financial losses.

Installing a UPS for the heating pump will be an excellent solution to prevent such problems.

By installing a UPS for the heating circulation pump, you don’t have to worry if the electricity suddenly goes out, since such equipment is equipped with automation. Such equipment has a battery for the heating pump, which will ensure uninterrupted operation of the pumps and other volatile components of the heating system if the electricity suddenly goes out.

There is another method that will create all the conditions so that the components of the heating system do not lose their functionality. We are talking about a diesel or gasoline generator. This method is more reliable, but at the same time, more expensive. However, even generators have their drawbacks: some such devices can produce short-term voltage surges at the output. This may cause a malfunction of some automatic components of the boiler or heating system.

Automation for circulation pump

The general definition includes several types of elements - thermostat, relay, uninterruptible power supply unit. All these components are necessary to regulate the temperature of the coolant supplied to the main line, as well as to ensure uninterrupted operation of the pump.

It is worth knowing that a thermostat for a circulation pump can also be useful for an apartment - the device is connected to a radiator and is used to regulate the circulation of coolant through the battery. In some apartments, this control option is considered the only possible one.

Thermostat

Combines the functions of a valve and a thermoelement and controls the temperature of the coolant.

How a circulation pump with a temperature sensor works:

- First, information is determined from the temperature sensor, on which the entire operating principle is based.

- The indicators are compared with the configured settings. They must be entered in the side menu of the device. Here the difference is the pump start temperature and hysteresis - this is the name of the temperature lag interval when starting and turning off the equipment.

- As soon as the heating process has begun, hysteresis is added to the temperature indicators for starting the pump into operation, and when the coolant cools, the hysteresis is subtracted.

It turns out that if the owner sets the temperature at +50 C, the hysteresis at +5 C, then the water must first warm up to +55 C in order for the heating circulation pump control unit to start the device into operation. And to turn off the equipment, the coolant must cool to +45 C.

The device, supplemented with hysteresis, is considered convenient to use. It turns out that the equipment will not be constantly turned on and off to maintain the heating accuracy to one degree. When choosing a thermostat, it is better to give preference to the minimum hysteresis in the firmware +/- 1 degree, and the maximum +/- 10 degrees.

Important! If the thermostat for the heating circulation pump is adjusted taking into account data on the external temperature in the room, then the boiler adjustment should take into account changes in the temperature of the coolant. Install the device next to the boiler.

Uninterruptible power supply

It is impossible to control the circulation pump without power supply, so ensuring the supply of direct current is the main task of the owner. The easiest way is to install an uninterruptible power supply (UPS) or get a generator.

Many owners try to do without additional equipment, creating a heating system with the possibility of gravity circulation of the coolant. This is a good solution, but at the slightest violation of the pipeline laying technology, the system will stop. In addition, when installing a heating main in a 2 or more storey building, the gravity circuit may fail, so you cannot do without a pump.

When installing a power supply, you don’t have to worry about the operation of the system - the equipment is equipped with automatic control and a battery for the heat pump. The support complex will ensure the operation of both the pump itself and other energy-dependent components of the system.

It is only important to select a UPS with the required battery capacity, for which you should read the information in the data sheet. As a rule, manufacturers indicate the storage capacity and the possible operating time of the devices. To find out the exact information, you should take into account the power of the pump for the heating system.

On/off relay

A relay is installed to turn on the heating pump to maintain the operation of the device in automatic mode. The principle is simple - when the pressure level in the heating main decreases, the relay will start the device into operation, and when the pressure increases, it will turn it off. It turns out that as soon as the consumer stops disassembling water, the pressure level in the system rises to the upper limit and the timer for the heating pump turns off the unit. As soon as water collection starts, the pressure in the line drops to the lower limit level, and the pump starts working again.

As a rule, manufacturers of equipment that does not have automation installed provide recommendations on the selection of components, but there is an option to buy a heat pump with all additional devices. To make it easier to regulate the flow of coolant into the batteries, experts recommend installing thermostats on all radiators. In addition to maintaining a comfortable temperature in the house, timely adjustment will help reduce energy costs.

Important! When choosing thermostats, you should evaluate the setting scale. The smaller the gradation of divisions (1-5 degrees), the more accurately the temperature of the liquid circulating along the line will be set.

Line interactive

Such devices are manufactured in conjunction with an off-line switch and a voltage regulator that operates in automatic mode. The main advantage of this uninterruptible power supply is the ability to ensure normal operation of the circulation pump when the voltage in the electrical network increases or decreases. The downside of the UPS in question is the certain period of time for switching to the battery during power outages.

Linear-interactive uninterruptible power supply for heating is one of the options for ensuring the safety of the heating system

The efficiency of such devices occupies an intermediate position between simple and cheap off-line UPSs and expensive high-quality devices with on-line double voltage conversion. In practice, line-interactive uninterruptible power supplies are used for continuous operation of desktop computers and monitors, circulation pumps and other devices.

According to the method of obtaining the voltage at the output of the battery, such devices are divided into two main types:

- Voltage generation using a pure sinusoid. Such installations are often used as an alternative to double voltage conversion;

- Obtaining voltage from an approximated sinusoid. Such UPSs are operated in conjunction with a personal computer.

Principle of operation

A recirculation pump is not at all necessary, but it significantly increases comfort and even the quality of hot water. Its main task is to pump water through a pipeline in a closed loop from the boiler to the intake points and back. For this purpose, devices with low productivity, low noise and low energy consumption are specially developed. The main requirement for pumps is resistance to high temperatures, stable operation provided that the water is heated to 65°C.

Taken together, recirculation pumps for hot water are still different from pumps for heating. The latter are designed for temperatures up to 90°C and with significantly higher productivity. Interchangeability is irrelevant in this case. If desired, the heating pump can be used in DHW recirculation, but the pump cannot be used the other way around.

A circulation pump is especially in demand in houses with an area of more than 200 square meters, where the boiler is located in a separate room or basement, and there are several water intake points located throughout the house. You will have to wait a long time for cold water to drain from the pipes, which significantly increases consumption. If the water in the boiler heats up to 65-80°C, then almost all pathogenic bacteria die, but in the pipes where the water cools, they are able to actively multiply.

Regular pumping of water through pipes eliminates these problems in the bud. However, due to heat loss in the pipes, the load on the boiler or water heater increases, so the installation of a recirculation pump has a lesser impact on savings and is primarily responsible for the comfort of residents.

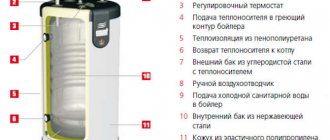

To use a recirculation pump, the DHW distribution throughout the house must be carried out in the form of a closed circuit connected to the boiler. All water intake points are already connected from it. If you take water from the top of the boiler, then this will be considered the beginning of the circuit, then the pump is installed at the second entrance to the boiler, located in the lower part of the storage tank at the same level as the entrance to the cold tap water supply.

The circulation pump must be installed together with a check valve, which will prevent the reverse flow of water in the circuit, because in this case only cold water will flow through the pipes, tied to the bottom of the boiler and the inlet water supply.

Characteristics

The list of main characteristics of circulation pumps:

- productivity, m3/hour (liter/min);

- pressure created, meters or Pa;

- power consumption, W;

- control method (by timer or temperature sensor).

The recirculation pump requires little power and performance. It is necessary to pump water only in tubes with a small internal volume, and at low speed. A device with a capacity of only 0.2-0.6 cubic meters per hour is sufficient to constantly maintain the water temperature in pipes up to 40-50 meters long.

Pump consumption is also low and ranges from 5 to 20 W. This is enough for stable operation and completion of the assigned task.

It is more important to select the correct pressure generated by the pump. More often, in a house or, especially, an apartment, the wiring is carried out one floor at a time, then a pressure equivalent to 0.5-0.8 meters of water column is sufficient. However, if it is necessary to ensure trouble-free circulation of water in a house with several floors, then the pump must cope with the rise of water to a given height, and with a margin. Pump performance directly depends on the actual installed load.

Controller for boiler circulation pump KG CS-07

The KG CS-07 controller is designed to control the pump that circulates water in the central heating system. The regulator's job is to turn on the pump if the temperature exceeds the value you set, as well as turn it off if the boiler cools down (as a result of extinguishing). This avoids unnecessary pump operation, which saves energy (depending on the degree of use of the boiler, savings can be even 60%), and also extends the service life of the pump. Thanks to this, the reliability of the pump increases and the costs associated with its operation are reduced. The thermostat is equipped with an anti-stop system. Another useful feature is the beep sound, which indicates that the temperature is too high. The signal starts when the temperature at the point where the sensor is installed exceeds (90 ° C). The thermostat is also equipped with an anti-freeze system and turns on the pump when the temperature drops below 5 degrees C. Below this temperature, the pump runs all the time.

Power: 230/50Hz +/-10% Power Consumption: 2W Ambient Temperature: -10 to 50°C Pump Output Load: 6 Temperature Measuring Range: 0 to 99°C Adjustable Temperature Range: 5 to 80 °C Temperature sensor strength: -10 to 120 °C Sensor cable length: 1.2m

Thermostat CS-07C

The CS-07C thermostat can be used as a thermostat or underfloor heating pump controller. The device can regulate the temperature of turning the pump on and off. The pump turns on when the user-set temperature (O) is exceeded and will turn off when the user-set temperature (U) is reached. CS-07C is equipped with an anti-stop function that prevents the pump from sticking outside the heating season every 14 days for approximately 15 seconds. Another useful feature of the controller is an audible alarm that signals when the temperature is too high. The signal appears when the temperature in the place where the sensor is installed exceeds (90 degrees C). The controller is also equipped with frost protection and starts the pump if the temperature drops below 5°C; below this temperature the pump runs all the time. Power: 230/50Hz +/-10% Power Consumption: 2W Ambient Temperature: -10 to 50°C Temperature Measuring Range: 0 to 99°C Adjustable Temperature Range: 10 to 75°C Temperature Sensor Strength: -10 to 120°

Instructions for the boiler pump controller can be downloaded below in the specifications section

Boiler fan:

In some models of pyrolysis or conventional solid fuel boilers, it is convenient to use forced air exhaust fans and smoke exhausters. From the Polish manufacturer MplusM, they are represented by the series RR 152-3030 LH, R2E 150 AN91-06, R2E 180 CG 82-05+kond, R2E 210 AA 34-05+KPL. You can find out the cost of MplusM smoke exhausters with different characteristics by clicking on the link below.

To control the boiler in automatic mode, according to the specified parameters of temperature, time, etc., a control unit or controller must be connected to the fan. This device, with a built-in microprocessor, will control the operation of a boost fan or smoke exhauster, according to specified programs in the database or based on user settings. All controllers for fans or smoke exhausters are equipped with several factory programs for controlling fan operation. Some of them have advanced functionality. You can not only set the time for turning the fan on and off based on the coolant temperature, but also set the fan speed (boost power) at each stage of the heating boiler operation. The most popular controller models: ATOS, Comfort Eco, KG Elektronik CS-19. The price of boiler controllers depends on the quantity in the order.

For example, the price of the control unit is

For the undemanding buyer or those with limited financial resources, manufacturers produce budget versions of kits for connecting to the boiler (fan + controller). These kits are affordable but limited in functionality. For example: Boiler control unit PK 22+fan NWS 75