What is an indirect heating boiler?

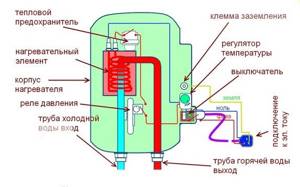

The boiler structure consists of:

- housings;

- insulation,

- tank;

- thermometer;

- heat exchanger (coil);

- magnesium anode (protects against corrosion).

There are anodic and cathodic methods of anti-corrosion protection. More popular are anode.

An indirect heating boiler is a tank of water from which heat is released from the heating system.

Heating is carried out in the following way: the process of water flowing from the boiler occurs through the heat exchanger, it heats the walls of the heat exchanger, and from them the water that is in the container is already heated.

An example of an indirect heating boiler device

Operating principle and types

A characteristic feature of the operation of an indirect heating boiler is that this device only works in conjunction with external heating sources.

The coolant moves from the source along the coil. Thanks to the pump, the coolant circulates and directly heats the water in the boiler. Cold water enters the boiler through water supply pipes.

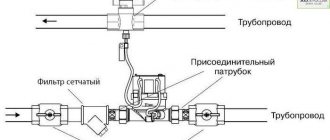

Special pipes are designed to allow it to be connected to a coolant supply source. After the coolant passes the entire cycle through the coil, it again enters the heating system through the outlet pipe.

The heat exchange process occurs most efficiently in coils with a large diameter. But in this case, in order for the coolant to heat up, the power of the heat generator must be stronger.

Operating principle of an indirect heating boiler

When choosing a boiler, it is important to take into account the characteristics of the room in which it will be located.

Connection diagram for an indirect heating boiler

There are the following types of indirect heating boilers:

- Wall-mounted indirect heating boiler. It is attached to the wall at a short distance from the floor, it is small in size and has limited capacity.

- Floor-mounted indirect heating boiler. It comes in different sizes and can be used for industrial purposes, but you need a separate room to place it.

- Vertical boiler. The most common type, because It is quite compact and saves space.

- Horizontal boiler. It is very spacious and can be used in enterprises; with such an installation, maintaining the required water level is much easier, so there is no need to install additional pumps.

- Boiler with coil. It can be single-circuit or double-circuit; the first option is in great demand.

- Boiler with recirculation. Thanks to it, water is supplied to the tap instantly, however, in order to establish circulation, there must be a third input in the heater tank.

- Storage boiler. The most optimal option, thanks to which you can not only heat water, but also keep it hot.

- An indirect heating boiler with a heating element is called a combined boiler: this device combines two heating principles: direct and indirect.

You can read about direct and combined heating boilers here.

Water heater device

The device has a simple design. Externally, the equipment resembles a cylinder.

The heater consists of the following elements:

- outer casing;

- a layer of thermal insulation (to maintain a high temperature inside);

- internal capacity;

- heat exchanger;

- magnesium anode;

- thermostat.

Thanks to a layer of insulation between the outer casing and the inner tank, the boiler retains heat for a long time. The water temperature decreases by 3-4 degrees every day (depending on the model and outside air temperature). The thermostat ensures that the set parameters are maintained, and the heat exchanger ensures rapid heating.

The heat exchanger is located in the internal container and has a spiral shape, which ensures fast and uniform heating of water. The device is protected from galvanic corrosion by a magnesium anode. All reactions occur with this element without affecting the working parts. It is worth considering that the magnesium anode is subject to increased wear and tear; this part must be replaced regularly.

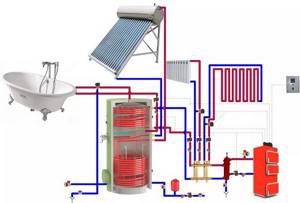

Manufacturers offer water heaters that operate only from an external heat source, as well as combined models with an electric or gas heater. You can also purchase boilers in which the working fluid is heated from solar panels.

Indirect water heaters are convenient in the summer. After the end of the heating season, you can switch to alternative heat sources.

Advantages and disadvantages

An indirect heating boiler is a device that has many advantages, but along with them there are also some disadvantages.

Let us note the pros and cons of these devices.

Pros:

- high performance;

- can heat water in large quantities;

- efficiency: little money is spent on heating water;

- ease of installation;

- allows you to supply hot water in several directions at once.

Minuses:

- The high cost of the device itself and installation work, as well as the heating boiler, which will need to be installed in advance. Therefore, the initial costs will be considerable.

- Long first heating process. However, this drawback is short-term and you will encounter it only when starting up the system, at the beginning of the heating season.

- The entire structure requires quite a lot of space. Therefore, such equipment is more suitable for private homes where there is a room that can be allocated for a boiler.

Features of the cottage layout

How, in fact, is the water supply system in a private house simpler than in an apartment building (of course, in addition to the total number of plumbing fixtures)?

There are two fundamental differences:

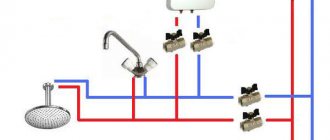

With hot water, as a rule, there is no need to ensure constant circulation through risers and heated towel rails.

In the presence of circulation connections, the calculation of the hot water supply network becomes noticeably more complicated: the pipes need to pass through themselves not only the water disassembled by the residents, but also the continuously circulating masses of water.

In our case, the distance from the plumbing fixtures to the boiler, pump or connection to the route is small enough to not pay attention to the speed of supply of hot water to the tap.

The heated towel rail is heated by continuous circulation through the hot water risers.

The water supply in a private house is routed according to a dead-end pattern, which implies a constant load on individual sections of the distribution. For comparison, the calculation of a water supply ring network (which allows each section of the water supply system to be powered from two or more sources) must be performed separately for each of the possible connection schemes.

How to choose an indirect heating boiler?

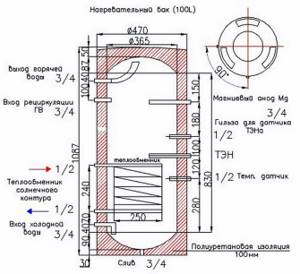

Sectional view of an indirect heating boiler

If you want to buy an indirect heating boiler , then when choosing it, be sure to consider the following points:

- Tank capacity: be sure to calculate the water your family uses. On average, one person uses 100 liters of hot water daily. Considering the number of members in the family, you can choose a boiler that suits your volume.

- Assessment of the economic feasibility of the purchase: an indirect heating boiler is justified only if the water consumption is at least 1.5 liters per minute. Typically, this water consumption is typical for 4-5 people or more.

- Warm-up time.

- Thermal insulation material: lower-priced units use foam rubber as thermal insulation, while more expensive boilers are equipped with high-quality materials such as mineral wool or polyurethane foam.

- Dimensions: do not forget that such equipment is quite large in size and is mounted next to the heating boiler. Therefore, when choosing it, you need to take into account the size of the room in which it will be located.

- Stainless steel boilers, unlike enamel ones, are capable of heating water up to 90 degrees.

- Boiler power: it determines whether it can simultaneously heat the room and operate the boiler.

- Presence of protection elements (thermostat, safety valve, etc.): you must pay attention to the presence of these elements, because It is they who perform the function of protecting against pressure drops inside the tank and excessive heating of the water.

- Warranty period: first find out whether there is a service center in your place of residence or nearby that repairs boilers from the manufacturer of your choice.

- Manufacturer: it is better to buy indirect heating boilers from manufacturers with good reviews.

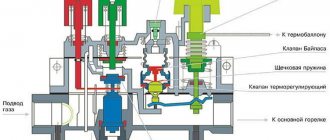

The principle of operation of the boiler thermostat.

When choosing a boiler, you must pay attention to the power of the heating source. Because a unit with low power will not be able to heat the water to the required temperature.

Operating principle of an electric instantaneous water heater

Flow heaters have a simple design. For almost all models, a single concept is used, in which the liquid passes through the body of the thermal equipment, receiving heat from the heating elements. The moment the user opens the tap, a special pressure switch is activated, followed by a heater. Its task is to quickly heat the water to a given temperature.

The design has a breaker, the function of which is to forcibly turn off the power. This occurs when pressure drops in the system or the degree of water heating is exceeded. An additional fuse is a stabilizer. Its task is to ensure normalization of pressure when critical values are reached.

Design features

The main component of electric water heating devices remains the heating element. The alloy of this part provides heat transfer when electric current passes through it. The spirals are insulated to prevent corrosion, for which they are placed in a special plastic block. When the heating element heats up, the generated heat is taken away by the cold water passing through it.

Loading

The design of the active unit eliminates residual heat generation. This is due to the small volume of passing liquid and the mass of the device itself. There is no scale formation on the spirals, which significantly extends the service life of the products.

Note! If you look at a cross-section of a water heater after many years of use, you will notice only a slight coating on the surface of the spirals. In flow-through installations of a closed modification, the spirals of heating elements are enclosed in copper or brass modules

This structure ensures fire safety

In flow-through installations of a closed modification, the spirals of heating elements are enclosed in copper or brass modules. This structure ensures fire safety.

When considering how a boiler works, it is necessary to distinguish between the type of control. Hydraulic manipulation occurs manually through six power stages. More precise electronic control of equipment operations. Such a system operates autonomously; the degree of heating of water in the boiler is controlled at a user-specified temperature. This principle is better than hydraulics, since all processes are controlled electronically, regardless of pressure.

Due to prevailing stereotypes, the name “boiler” is often associated with an electric water heating tank. Although there are other versions of household appliances that provide autonomous hot water supply to private houses and apartments. Under certain conditions, the use of gas appliances and indirect heating containers is much more profitable and comfortable. To choose a storage water heater, it is worth comparing the operating principle of different types of boilers, connection nuances and operating features.

Calculation of tank capacity

In order to calculate the required volume of the boiler, it is necessary to determine how much hot water is consumed at a time or in a short period of time.

When taking readings, be guided by the morning time, when children are getting ready for school or kindergarten, and adults are going to work. After all, at this time everyone takes a shower, washes their face, brushes their teeth, which means that the most water is consumed at this time of day. If for some reason you do not have the opportunity to take readings, then you can use the table, which shows the hot water consumption indicators for various devices.

| Name of water consumer | Water consumption, l | Average temperature of consumed water, C° | Water consumption at 60 C°, l |

| Kitchen sink | 10-20 | 50 | 8-16 |

| Bath | 150-180 | 40 | 90-180 |

| Shower | 30-50 | 37 | 16-27 |

| Sink | 10-15 | 37 | 5-8 |

| Hand wash | 2-5 | 37 | 1-3 |

Having calculated these measurements, a reserve volume of 10-15% must be added to the resulting figure. This way you will get a boiler volume that will be optimal for your family.

Shapes, sizes and type of boiler control

The modern market for the equipment in question provides consumers with a huge selection of different types of electric boilers.

- Various volumes - most often they buy models from 10 to 100 liters.

- Various shapes: round, flat, square. Round water heaters with a volume of up to 30 liters are very popular; they are usually installed in the kitchen. If you need a larger model for the bathroom, then the flat version will take up less space. It can easily be mounted on a free wall or above the toilet.

- Vertical and horizontal. Most often, consumers prefer the first option. Before choosing, you should decide on the installation location. Horizontal models are best installed above a door or other plumbing equipment.

- By type of control: mechanical and electronic. The second option has the possibility of more precise settings, setting automatic shutdown or on. Such models are often equipped with a small screen.

Connection

An indirect heating boiler can be connected via an electrical and hydraulic system.

Hydraulic (two-pump) is considered more effective. One pump is intended for heating the living space, the other is used for indirect heating of the boiler itself.

The electrical connection diagram assumes a mode switching system - a relay.

During the process of installing a boiler, many ordinary people encounter difficulties and make mistakes:

- Inappropriate location for the equipment: firstly, it must be placed as close as possible to the boiler and to the outlet of the central supply.

- Incorrect connection to the cold water source: in order for the device to operate as efficiently as possible, it is important to maintain a sequential connection of the coolant inlet (top) and outlet (bottom).

- Incorrect pump connection. As a result, this error entails negative consequences: the motor axis is not horizontal and because of this, the bearings will quickly fail.

DIY indirect heating boiler

To make an indirect heating boiler with your own hands with high quality, first of all, you need to familiarize yourself with the structure and operating principle of this unit.

It is much easier to make a boiler if you have a drawing on hand indicating all the overall dimensions, shape and location of all elements.

Drawing of an indirect heating boiler

Using the drawing and having all the necessary tools at hand, creating the described design will not be difficult. However, the success of the work will depend on the calculations, so it is very important to make them correctly.

Power calculation

This parameter depends on three indicators:

- Circulation speed.

- Temperature of water in the tank.

- Coolant temperature.

To calculate the power of the water heater, you need to take the following parameters as the norm: a 1 atm circulation pump that can distill 200 liters of liquid per hour, the highest coolant temperature is 85˚C. This is the information without which you cannot start working.

Tank calculation

The area of a 120 liter container is calculated using the formula:

S = V/h = 0.12/0.9 = 0.133 sq.m. V is the volume of the container, measured in liters; H – height. For models of famous brands, on average it is 0.9 m.

Then, from the area of the base circle, you need to calculate the radius:

R = √S/π = √0.133/3.14 = 0.205 m = 20.5 cm

The diameter of the circle itself will be 41 cm.

And the last thing you need to know is the circumference:

L = 2*πr= 2*3.14*0.205 = 1.28 m

Having calculated all these parameters, you can start welding.

Stainless steel is difficult to weld and can only be dealt with using argon arc welding and alternating current.

The boiler needs periodic cleaning.

Coil calculation

Most often it is made of copper, so you need to get a thin tube measuring 42 * 2.5 mm. 42 is the outer diameter, the inner diameter in this case will be 37 mm.

First you need to calculate the length of the coil:

L= V/S= V/πR2 = 0.0044/3.14*0.01852 = 4 m

After this, you need to find out the length of one turn. Having determined it, you can find out the approximate diameter of the coil.

For example, let’s take a coil with a radius of 15 cm.

L = 2πR = 2*3.14*15 = 94.2 cm

As a result, you get 4 full turns.

Don't forget a supply of copper tube approximately 20-30 cm long. It may come in handy during boiler installation.

To twist the coil, you need to use a log; its diameter should be smaller than that of the boiler tank. The free ends of the coil must be fixed at right angles. 2 sections of the coil, 6-8 cm each, should extend beyond the container.

Thermal insulation and assembly

Polyurethane foam, mineral wool, polyurethane, etc. can be used as thermal insulation.

On top of the applied thermal insulation, for a better effect, the boiler can be “wrapped” with a thin sheet of metal or foil insulation.

When making an indirect heating boiler yourself, the assembly process includes the following steps:

- In a stainless steel tank we make 3 holes with a diameter of 3/4″ and connect ball valves to them. The first tap (at the bottom) is responsible for water supply, the second (at the top) is for water intake, and the third is for draining water and maintaining pressure.

- We insert the coil and see how it turned out. We make holes in the walls of the tank for the ends of the coil and solder the threaded fittings. We solder threaded fittings to the ends of the coil. This is necessary to secure the coil in the tank.

- We check the tightness of the coil using a soap solution and a compressor. We treat the coil with the solution and close one hole and supply air through the other.

- Close the boiler tank with a tight lid. It can be made from two sheets of steel and polyurethane (placed between them). Don't forget to weld the rim and attach the handle.

- We insulate the structure. We use glue, wire or other options for securing the insulation.

- We check the boiler for leaks by connecting it to the water supply.

Review of manufacturers

| Manufacturer (country) | Boiler models | Capacity of manufactured boilers, l | Average price, rub. |

| Protherm (Slovakia) | FE 120/6 BM; WH B60Z, FS B100S; FE 150/6 BM; FE 200/6 BM; FS B300S; FS B400S; FS B500S | 60-500 | 28 000-70 000 |

| Baxi (Baxi) (Italy) | Premier PLUS 100; Premier PLUS 1000; UB 80; UB 120; Premier PLUS 200; Premier PLUS 150; UB 120 INOX; Premier PLUS 300; Premier PLUS 400; Premier Plus 2500 | 80-2500 | 30 000-700 000 |

| Buderus (Buderus) (Germany) | Logalux L135; Logalux S120; Logalux SU400/ 5 W; Logalux L160; Logalux SU300/5 W; Logalux SU200/5E W; Logalux SU160/5 W | 120-1000 | 20 000-500 000 |

| Vaillant (Germany) | actoSTOR VIH QL 75 B; uniSTOR VIH R 120/6 V; uniSTOR VIH R 200/6 V; uniSTOR VIH R 150/6 V; uniSTOR VIH R 300; actoSTOR RL 400-60; actoSTOR RL 500-120 | 75-500 | 27 000-200 000 |

| Thermex (Termex) (Russia) | ER 100V (combi); ER 120V (combi); ER 150V (combi) | 100-150 | 20 000-30 000 |

| Bosch (Bosch) (Germany) | ST 120-2 E; ST 160-2 E; 160-5 C; WST 200-5 C EC; WST 300-5 C; WST 400-5 C; WST 500-5 C | 120-500 | 30 000-70 000 |

| Drazice (Drazice) (Czech Republic) | OKC 100; OKC 80; OKC 160; OKC 200 NTR; OKC 250 NTR; OKC 250 NTR/BP; OKC 400 NTRR/1 MPa; OKC 750 NTRR/1 MPa; OKC 1000 NTRR/1 MPa | 80-1000 | 20 000-170 000 |

Thus, an indirect heating boiler allows you to provide hot water to all consumption points at the same time. The main thing is to choose the right tank volume.