Types, types

Boiler heating is classified depending on the type of installation. There are single-circuit and double-circuit models of heaters, they differ in mountings:

- floor;

- hanging.

Wall type

The advantage of a mounted boiler is ease of installation, the ability to install it in the room where it will be used. Compact, compared to the floor-standing type.

Flaws:

- low efficiency;

- heating a small house, a small room.

Floor type

The view works on the principle of two in one. Helps provide space heating and hot water supply. The two circuits are independent of each other. There are models with a built-in “Winter-Summer” mode.

Flaws:

- large area for equipment installation;

- complex installation.

Floor view

Difference from single-circuit

The difference between the models is that heating in a dual-circuit system is combined with the organization of hot water.

Single circuit systems include:

- heat exchanger;

- burner;

- controlling system.

Double-circuit models are more complex. Heating units:

- additional heat exchanger;

- circulation pump;

- three-way valve;

- sensors;

- electronics for work automation.

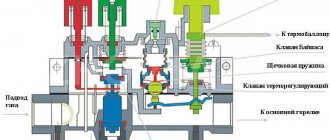

The boiler operates in 2 modes:

- Heating the coolant to turn on the heating. The burner burns gas that heats the coolant. Ignition and the strength of the fire are regulated by simple mechanics and electrics. The coolant is pumped by a pump.

- DHW mode. After turning on the tap, the coolant circulates and the pressure sensor turns on. The three-way valve is automatically connected. When the tap is turned off, the supply stops.

Provided that a single-circuit boiler is installed in the house, the water supply is organized by an additional indirect heating boiler. It is cheaper to use double-circuit heating; the systems help to heat any volume, while maintaining a constant set temperature.

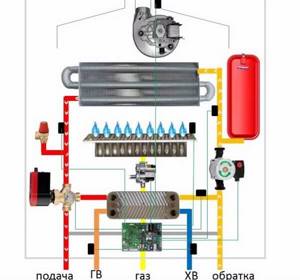

The principle of operation of a boiler with two circuits - the movement of cold water is highlighted in blue, hot water is highlighted in red

Construction of double-circuit boilers

The device of a gas boiler consists of several parts. So, different boilers can heat a small or large room at the same speed. They also differ in energy consumption. What the boiler consists of and what its components are needed for will be described in detail below.

There will be no problems with it in the summer. One of the circuits can be turned off at any time so that it does not work during a period of time when it is not needed. The connection is not very different from a single-circuit one. The difference is that you need to connect a three-way valve instead of a two-way or one-way valve.

Automation

Automation, in addition to energy-saving functions, has a number of positive characteristics:

- no overheating;

- increase in service life;

- reducing the chance of a gas explosion;

- saving electricity;

- automation of the unit operation;

- short work cycle;

- shutdown in case of unexpected situations.

Note! The downside is that in the event of a failure, it is not immediately possible to notice malfunctions in the system.

Burner

The burner is the basis for heating water. It burns fuel and thereby generates heat. When choosing a burner for a double-circuit gas boiler, pay attention to the following characteristics:

- Efficiency - how efficiently gas is burned;

- low toxicity;

- performance of the heat sensor;

- quiet operation.

Note! Due to the level of combustion by-products released, the type of chimney is selected based on the type of burner.

Coaxial chimney

The chimney is necessary to remove combustion products, mainly carbon dioxide, from the boiler. A poorly functioning chimney can lead to waste buildup in the home and carbon monoxide poisoning.

A coaxial chimney is two pipes of different diameters located one inside the other. While one pipe, using a special fan, pulls out combustion products, the other, using the same fan, draws in air in the required amount for combustion to occur. The outlet of such a chimney can be directly in the wall and take up little space. Such a chimney prevents combustion products from entering the room, and also uses oxygen exclusively outside the building.

Heat exchanger

The heat exchanger is the very mechanism by which the water heating system is heated. Despite the fact that heat is emitted by the burner, the principle of operation is aimed at preserving and releasing heat to an external resource. Roughly speaking, this is a mechanism for heating and storing the heat released by combustion.

Circular pump

Designed for uniform heat transfer. To make it more clear, in conventional heating systems the temperature in the room is higher near the heat source. That is, in the room farthest from the boiler it should be colder than in those adjacent to it. This pump drives heat to the farthest areas so that when it returns, it takes less time to heat up and restart through the pipes.

For your information! The system is designed in such a way that heat goes through the cycle with the least amount of time. This allows you to heat the house faster.

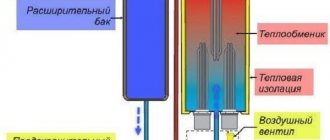

Expansion tank

When heated, the water begins to expand in the heating system and expansion tanks are installed to compensate for the excess pressure. All boilers without exception have them, but they may differ in shape and size (depending on the power of the boiler).

The expansion tank consists of 3 parts:

- space for heating system water;

- membrane;

- space pumped with nitrogen.

During operation of the heating system, the tank neutralizes changes in pressure due to the membrane, so the pressure remains unchanged during operation of the boiler.

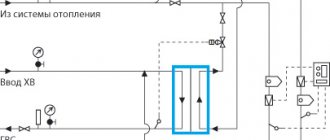

DHW system

The main difference between double-circuit boilers is the hot water supply system (DHW). It allows you to get hot water almost instantly. For this purpose, the boiler has a secondary DHW circuit, which consists of a plate heat exchanger, a water flow sensor and a three-way valve. The main sensor that controls the process of starting the secondary circuit is the flow sensor. When the tap opens, it sends a command to the control board, and it, in turn, to the three-way valve, which shuts off the water supply to the heating system and directs it to the hot water plate heat exchanger. As a result, hot water, which is heated in the main heat exchanger, begins to circulate through a “small” circle inside the boiler using a pump, passing through the DHW heat exchanger and heating the water in it.

Bypass

It connects the forward and return pipelines of the main circuit. An adjustable bypass valve is installed on the bypass, which opens when critical pressure occurs, and part of the water flows from the direct pipeline to the return one. The valve ensures that there are no hydraulic shocks when the pump is turned on and limits the maximum speed of water circulation in the heating system.

Review of manufacturers and prices

In the era of technological development, there are a large number of companies engaged in the production of household appliances. The heating market is a large segment in which many brands are represented. Based on consumer reviews, a list of the most popular manufacturers of gas devices was compiled.

Protherm

The Czech brand has been producing various boiler equipment for a long time. The company produces heating devices that are safe to use and can heat water in record time. Each model provides many protective functions, thanks to which the boiler does not overheat, its heat exchanger does not freeze, and so on. If an emergency occurs, the automation turns off the pump.

The boilers are suitable for both residential and commercial premises. Several lines of equipment are available, which makes the choice easier.

The most popular are turbocharged units. On their body there is an LCD display where performance indicators are displayed. Servicing the boiler is not difficult, since all the necessary components are available on the market.

The cost of Czech equipment starts from 25,700 rubles.

Baxi

This is an Italian company whose products have gained popularity among Russian users. The peculiarity of the manufactured gas heat generators is their high efficiency and complete automation of operation. They are able to ignite on their own, taking into account the characteristics of the room, not to mention the possibility of control via the Internet.

Advantages:

- There is a self-diagnosis mode that helps identify the problem;

- frost protection;

- electronic modulation;

- automation that responds to climate change.

Baxi offers users easy-to-use and relatively affordable boilers that perform well in Russian conditions. The price of equipment starts from 68,300 rubles.

Buderus

In a wide range of devices from the German company Buderus, each buyer will definitely select the equipment that interests him. Gas equipment is notable for the fact that it can be “switched” from liquid fuel to solid fuel. Thanks to this versatility, Buderus heating devices are in demand all over the world. Floor and wall mounted devices are characterized by reliability and durability.

Advantages:

- easy operation;

- reliable structural elements;

- high-quality protective systems;

- efficiency;

- you can connect additional devices.

Buderus boilers are made from high-quality modern materials. Suitable for installation in any room.

You can buy German heating equipment starting from 73,750 rubles.

"Rostovgazoapparat"

This enterprise, located in the city of Rostov-on-Don, traces its history back to the 19th century. Gas installations of this brand were installed in many apartments back in Soviet times. Now that the heating equipment market is constantly improving, there is fierce competition, forcing engineers to develop unique products.

The domestic brand introduced a floor-standing gas boiler to the market called Siberia. The power of the units varies from 11 to 35 kW, which is enough to heat not only a private house, but also non-residential premises with an area of up to 350 m2.

All produced models are distinguished by safety, reliability and attractive appearance. They perform well in Russian operating conditions, that is, they can operate at low gas pressure.

The cost of floor-standing boilers from a domestic manufacturer is from 21,190 rubles.

Navien

The South Korean brand produces high-quality double-circuit devices that are used for heating and hot water systems. Within one minute they are capable of preparing up to 34 liters of hot water.

Peculiarities:

- adapted to Russian heating systems;

- can operate at low pressure;

- built-in surge protection;

- equipped with an antifreeze system;

- Smoke removal is carried out using a powerful fan.

It is very convenient to use this equipment, as it is equipped with an informative LCD display and a remote control. Navien equipment has received an international quality certificate due to its reliability and high technical characteristics. There is a built-in auto-diagnostic system, which, in case of critical performance indicators, automatically turns off the equipment and displays an error code on the screen.

The cost of equipment starts from 34,700 rubles.

"Signal"

The city of production of gas equipment of this brand is Engels. The range includes models with one or two circuits, with thermal power from 6.4 to 40 kW. The heat exchangers are made of steel, there are all the necessary sensors and an automatic control system. According to user reviews, the products are easy to use and last at least 20 years.

Difficulties can arise only at the installation stage, since connector standards differ. Otherwise, this is high-quality and durable equipment with an optimal price-quality ratio. The maximum heated area is 350 m2. The price of the equipment is from 6657 rubles.

"Conord"

These are heating devices of a domestic manufacturer; the company’s plant is located in the city of Rostov-on-Don. The boiler fireboxes are made of high-quality steel with a thickness of 3 mm. The outer part of the housing is treated with fire-resistant powder coating, which extends the service life of the equipment. As the manufacturer assures, floor-standing models last at least 15 years. The efficiency of the units is 90%.

Product power parameters vary from 8 to 30 kW. There is a built-in expansion tank with a capacity of 8.5 liters. A distinctive feature of the Conord models is that they can operate at a gas pressure of 0.6 kPa (the average in systems is 1.3 kPa). Devices are available with both steel and cast iron heat exchangers.

The price of boilers starts from 14,420 rubles.

"Danko"

The Ukrainian brand of household appliances presents floor-standing gas installations, which can be non-volatile or powered from the network. They have different design features and execution. Automatic protection systems made in Poland or America make the devices safe and reliable. The advantage of Danko gas boilers is the presence of a micro-tile burner, thanks to which the equipment is suitable for heating any premises.

Additionally, the boiler design includes draft and air regulators necessary to increase efficiency, which reaches 92%. Models are available with programmers, which is required for more economical fuel consumption. As a rule, such boilers are used in private households, hotels and country houses.

The main circuit is assembled with a copper coil, so the user immediately receives hot water as soon as he opens the tap.

Cost - from 19,174 rubles.

Characteristics of a double-circuit gas boiler

When choosing a double-circuit boiler, you should pay attention not only to the materials, but also to the stated characteristics:

- Power. The larger the area of the heated house and the greater its heat loss, the more powerful the boiler will be required. For a house of 100 square meters in temperate latitudes, you will need a boiler with a capacity of 12 kW.

- Efficiency. Improved heat exchangers and burners of double-circuit boilers, the presence of “smart” automation and control programs make it possible to bring the efficiency closer to a fantastic 98%.

- View of the combustion chamber. There are boilers with open and closed combustion chambers.

When the combustion chamber is closed, the air supply and combustion products are emitted by a special coaxial flue exhaust. An open combustion chamber uses indoor air, and the exhaust goes into a stationary chimney with natural draft. For boilers with an open combustion chamber, a chimney and a separate boiler room are required. With a closed combustion chamber, they can be installed near any external wall, but they are more expensive.

- Availability of an additional condensation system . The temperature of the exhaust gases of a conventional boiler is about 150 degrees , and that of a condensing boiler is only 40 . The temperature difference is used to heat the house.

Volatile and independent models

It is also worth making a choice in favor of a non-volatile or electricity-dependent boiler. In the first case, even a power outage will not affect your heating system. But such floor-standing boilers are not equipped with powerful automation. You will have to do all the adjustments manually, and this is sometimes difficult and unsafe.

If your equipment is equipped with powerful and reliable automation, then servicing it will be easy. But in this case, your house must be connected to a reliable source of electricity, because if there is no current, the boiler will turn off, which means the house may get colder.

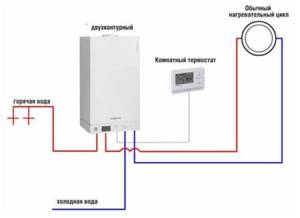

The principle of operation of a double-circuit gas boiler

Now we will begin to analyze the principle of operation of a gas double-circuit boiler. We have found out the purpose of individual components and modules, now this knowledge will help us understand how all this equipment works. We will consider the principle of operation in two modes:

- In heating mode;

- In hot water generation mode.

In heating mode, the boiler provides your home with heat.

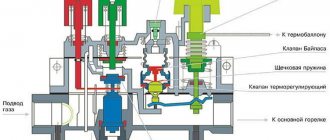

Let us immediately note the fact that operation in two modes at once is impossible - for this purpose, double-circuit boilers are equipped with a three-way valve that directs part of the coolant to the DHW circuit. Let's look at the principle of operation when heating, and then find out how the equipment works in hot water supply mode.

In heating mode, a double-circuit boiler operates in the same way as a regular flow-through heater. When first turned on, the burner works for quite a long time, raising the temperature in the heating circuit to the set point. As soon as the required temperature is reached, the gas supply will be turned off. If an air temperature sensor is installed in the house, the automation will take its readings into account.

The operation of the gas burner in double-circuit boilers can also be affected by weather-dependent automation that controls the temperature of the outside air.

The heat from the operating burner heats the coolant, which is driven through the heating system in forced mode. The three-way valve is positioned to ensure normal water flow through the main heat exchanger. Combustion products are removed in two ways - independently or using a special fan located in the upper part of the double-circuit boiler. The DHW system is in a switched off state.

Operation in hot water mode

As for the hot water supply circuit, it starts the moment we turn the handle of the water tap. The resulting water flow triggers the three-way valve, which turns off the heating system. At the same time, the gas burner is ignited (if it was turned off at that time). After a few seconds, hot water starts flowing from the tap.

When switching to hot water supply mode, the heating circuit is completely turned off.

Let's look at the principle of operation of the DHW circuit. As we have already said, turning it on turns off the heating operation - only one thing can work here, either the hot water supply or the heating system. A three-way valve controls all this. It directs part of the hot coolant to the secondary heat exchanger - note that there is no flame on the secondary. Under the influence of the coolant, the heat exchanger begins to heat the water flowing through it.

Rating of the best models

The most popular in the Russian Federation are:

ATON Atmo 10ЕВМ

A distinctive feature of the device is its complete energy independence. The coolant circulates naturally, without the use of a circulation pump. The installation power is 10 kW, and the heating temperature of running water in the DHW circuit reaches 45 0C. The unit has compact overall dimensions (765x385x390), economically consumes gas (1.3 m3/h) and has an original design. The average cost is 17,700 rubles.

Lemax premium – 10

The thermal power of a double-circuit boiler is 10 kW with an average fuel consumption of 0.6 m3/h. The unit is equipped with an Italian micro-flare burner Polidoro, which provides optimal gas combustion mode and precision flame modulation. In addition, there is an auto-ignition mode, protection against overheating of the coolant and blowing out. The manufacturer provides a 3-year warranty, and the average service life, without replacing the main elements, is 15 years. The average cost is 16,600 rubles.

KITURAMI STSG 13 GAS

With a power of 15.1 kW, the device can effectively heat an area of up to 150 m2 and heat running water in the DHW circuit to 80 0C, and the heating system coolant to 85 0C. The installation control is fully automated, with the possibility of remote control and programming. The gas boiler is equipped with a closed combustion chamber, which avoids additional costs for installing a vertical chimney. The average cost is 41,500 rubles.

BUDERUS LOGANO G125-32 WS

The main advantage of the model under consideration is its efficiency of 96%. Another feature of the installation is the possibility of conversion to diesel fuel. A combined mechanical-electronic control system ensures coordinated operation of all modules of the unit and safe operation. The boiler power is 32 kW, which is quite enough to effectively heat 320 m2 and provide hot water supply. The design of the unit provides the possibility of connecting additional modules. The average cost of installation is 52,000 rubles.

BaxiSlim 2.230

An electronic self-diagnosis system and a whole range of protective systems ensure a long service life of the unit. The rated power of the floor-standing boiler is 22.1 kW, the device can be connected to a heated floor system. Three circulation pumps provide intensive circulation of the coolant, and the productivity of the DHW circuit can reach up to 12.5 l/min. This performance fully satisfies the needs of 3-5 people. The device is intended for heating residential and industrial premises with an area of up to 220 m2 and providing hot water supply. Installation cost 112,500 rubles.

When choosing a boiler for heating a private home, you should not neglect the reviews of the owners of such equipment, who have assessed its advantages and disadvantages in practice.

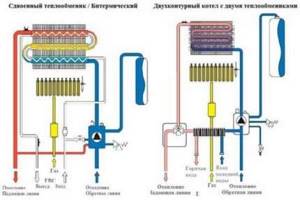

Scheme of operation of a double-circuit boiler

The presence of a hot water supply system slightly complicates the operation of a double-circuit gas boiler. The coolant heated by the burner, moving through the heat exchanger, ensures heating of the plate heat exchanger through which water from the water supply flows.

Design diagram of a double-circuit gas boiler with bithermal and two conventional heat exchangers. In the first option there is no need to use two heat exchangers

Simultaneous use of a dual-circuit model in heating and hot water supply mode is impossible. When the hot water tap is activated, the three-way thermostatic valve stops the circulation of coolant through the heating lines. The boiler switches to the mode of moving water along a circuit with a plate heat exchanger, which heats water for domestic needs.

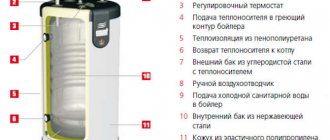

If there is a significant consumption of hot water, the operation of the heating-oriented boiler may be paralyzed for a long time. The problem can be solved in two ways - to provide for the installation of a more powerful heating device or to include an indirect heating boiler in the arrangement.

If the hot water system is actively used, it is possible to install a double-circuit boiler with a built-in boiler. In this case, fuel consumption increases slightly due to the fact that during the pause between operating cycles of the heating system, the burner energy is used to maintain the water temperature in the additional gas water heater.

A certain supply of hot water in the built-in boiler allows you to use the DHW system without turning off the heating circuit. As a result, both systems operate alternately, without overheating the liquid and extending the life of the heat exchanger.

A boiler with a built-in standard boiler not only provides a sufficient reserve volume of hot water, but also helps to avoid long-term shutdowns of the heating circuit

The built-in standard boiler allows you to get hot water at the desired temperature at any time, the supply of which is provided automatically. While a flow-through DHW system takes several minutes to heat the water to the required temperature.

Recommendations for selection

Compared to wall-mounted units, floor-mounted units are characterized by greater power and therefore fit perfectly into the heating system of a large country house. But in order for equipment to effectively use working resources, you need to choose it correctly, taking into account key characteristics.

Criterias of choice

When purchasing heating equipment, a number of other features are taken into account that significantly affect its operation.

Experts advise considering the following points:

- Rated power. This parameter is a priority. To do this, the square footage of the room is calculated.

- Other performance characteristics. We are talking about fuel consumption and pressure indicators in communications.

- Work resource. Judging by the ratings, in which both wall-mounted and floor-standing models from various manufacturers took part, a longer service life is observed in domestic models. This is explained by the fact that foreign units are designed for operating conditions different from Russian ones.

- Efficiency. This characteristic is reflected in efficiency, where the optimal indicator will be from 85 to 92%.

- Manufacturer country. If we take into account the ratings data, the most popular are products created in Germany, followed by Italy and Sweden.

What to choose - flow or storage

The flow-through type immediately prepares hot water, while the storage type does this for a certain time in a special large-volume tank.

The first type of thermal equipment is also called a column. Water is heated using a direct-flow system. The heat from the heating heat exchanger is transferred to the water tube, causing the water to heat up instantly, immediately after opening the tap. Combustion products in such installations are removed through the chimney. Ignition can be either manual or automatic.

Based on the name of storage devices, it becomes clear that they first accumulate cold water and then heat it. The main element is a capacious tank, the capacity of which may vary depending on the model. On average, 50 liters of household water is enough for one person per day. The advantage of storage devices is that they automatically maintain the set water temperature.

How to calculate power

The power characteristics of modern units can vary from 7 to 100 kW. To determine the main indicator - power, many features are taken into account, since this is a complex and responsible task that directly affects the operation of the heating system.

You need to consider the following:

- What size is the heated room? It is convenient to use a tape measure for measurements.

- Insulation of housing and possible heat losses. For example, if the house is new, with high-quality thermal insulation, heated floors, and energy-saving windows, then the equipment is selected “end-to-end”. If after the calculations you get a figure of 60 kW, you don’t need to add anything to it. When the room is old, with insufficient thermal insulation, it is better to take a higher value.

- "In reserve." There are users who believe that if you take a unit with more power than necessary, then there is nothing wrong with it. However, this may not lead to the best consequences, at a minimum - an increase in payment bills and rapid wear and tear of equipment. It is allowed to add no more than 20% to the received calculations.

- Climatic features of the region. The house can be located both in the north, where winters are harsh, and in the south, where it is relatively warm.

A full power calculation is a labor-intensive and complex procedure that is recommended to be entrusted to specialists. In addition to the above points, the calculation formula takes into account several more parameters. If you want to see an approximate figure, then there is a unified formula - to heat 10 m2 you need 1 kW of power.

Types of gas boilers with two circuits

The operating features of gas equipment are largely determined by the design version of the heating device. Modern boilers are available in two form factors - floor-mounted and wall-mounted.

When choosing a design option, you need to focus on the size of the heated area and the activity of using the hot water system. You need to understand that wall-mounted boilers are more compact, but at the same time they have much less power.

The double-circuit wall-mounted gas boiler has a compact size and modern design, but is only effective when heating small areas with moderate hot water consumption

The choice of a wall-mounted double-circuit boiler may be justified if the heated area does not exceed 200 sq.m, and the total productivity of the hot water system does not exceed 14 l/min.

The small size of a wall-mounted boiler, although it seems like an advantage, actually hides many disadvantages. Compactness is achieved through the use of thinner heat exchanger tubes. In addition to the fact that they have a shorter service life, there is a possibility of clogging.

In floor-standing installations, more massive and reliable cast iron heat exchangers are used. This not only increases the reliability of the heating device, but also extends its service life.

Materials for the manufacture of the heat exchanger

Currently, this structural element is made from three materials: copper, steel and cast iron. Each of them has its own operational characteristics.

Steel

The most common option is installed in models of domestic manufacturers. This is due to the availability of the material and the ease of its processing. The material has good ductility, and equipment with a steel heat exchanger has a relatively low cost. The property of plasticity plays an important role, since the surface of the element during operation is exposed to thermal influences, which can cause cracks to form.

Steel heat exchangers have one significant drawback - susceptibility to corrosion. In addition, they are quite heavy and bulky, so the boiler will require more energy to heat them.

Copper

It is a compact, corrosion-resistant, lightweight and small-volume element. Despite its small size, due to the peculiarities of the material, it transfers more heat than steel and cast iron options.

In the first versions of the equipment, the copper heat exchanger was quickly destroyed, since there was a large thermal impact per unit of mass of the copper device. In modern units, this feature of the material is taken into account, so the burner power is gradually reduced, depending on the degree of heating of the coolant. In terms of durability, a copper heat exchanger can be compared to a cast iron one.

Cast iron

Heat exchangers made from this material are durable and resistant to corrosion. In turn, they impose serious operational requirements. For example, due to the accumulation of deposits, the heat exchanger may begin to heat up unevenly, which will significantly reduce its service life.

At the moment, this type of heat exchanger is not so common, which is explained by their high cost, heavy weight, bulkiness and high inertia.

Advantages and disadvantages of dual-circuit devices

The advantages of a double-circuit heating unit are as follows:

- Economical fuel consumption. The direction for comparison is to use a double-circuit boiler or a single-circuit boiler with indirect heating.

- Compact sizes. The overwhelming majority of double-circuit boilers are wall-mounted heating devices. They are easy to place both in utility rooms and in small kitchens.

- Versatility. There is no need to buy additional equipment and resolve issues with its compatibility with the boiler.

In one unit, a flow-through water heater, a heating device and a circulation pump have already been successfully combined into a single automated system.

Obviously, along with the advantages, there are also disadvantages:

- Impossibility of simultaneous operation of the heating and DHW circuit. In this regard, significant consumption of hot water can cause a decrease in the temperature in the house.

- Power limitations of wall-mounted models. Compact wall-mounted boilers, due to the minimum size of the burner, are not able to provide the required temperature conditions at maximum pressure. A similar disadvantage is observed when water intake points are located remotely.

- Sensitivity to water quality. The secondary plate heat exchanger is demanding on the quality of the water consumed. The presence of impurities causes the use of means to reduce its hardness and clean the coolant.

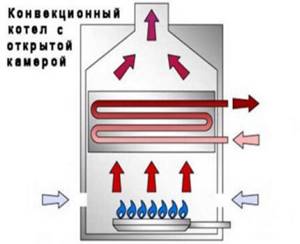

Convection or condensation boiler?

Let’s try to figure out what you need to know about the characteristics of such equipment, its design and operational features.

Convection gas floor boilers use heat to heat the coolant, obtained from the energy that is released during gas combustion. In this case, a large amount of heat, along with steam and flue gases, escapes into the atmosphere.

The operating efficiency of convection gas boilers is expressed in terms of efficiency and often does not exceed 85-90%

Although convection boilers are not considered the most efficient, from an economic point of view, their existence on the heating equipment market justifies a number of advantages. These include simple design, reasonable cost, compact size, easy installation and repair.

Condensing boilers are considered the most economical and efficient - they are 20% more efficient than convection heating devices. Higher efficiency is obtained thanks to an additional heat exchanger, which also uses steam energy (+)

One of the disadvantages of condensing boilers is their relatively high cost. The last factor, however, quickly pays off, since there is a noticeable reduction in gas consumption. The second is the difficulty of disposing of condensate, which cannot be easily drained into a septic tank so as not to destroy the bacteria that process the wastewater.

The operating principle of a condensing double-circuit boiler allows you to reduce gas consumption and obtain much more energy with equal fuel consumption (+)

Boiler with instantaneous heater

A plate heat exchanger is used for operation. Operating principle: conducting two ducts perpendicular to each other, between metal plates. The ducts do not connect.

The plates have a large area, increase heat transfer, and allow you to obtain hot water in a constant supply mode.

With a small size, the device heats water only up to 50 degrees. When water leaves the main heat exchanger, it enters the secondary one.

The downside is unstable heating. Depends on the speed of water flow. The device must be cleaned of lime.

Storage boiler

A boiler is a container with a snake-shaped pipe inside through which hot water flows. Compared to a traditional heat exchanger, the liquid is static and constantly receives heat energy.

When water is wasted, the volume is constantly replenished. The temperature of the water from the tap is more even, an order of magnitude higher, compared to plate heat exchangers.

Storage boiler

Operating rules

During operation of an open-type gas boiler, it is necessary to ensure a sufficient air supply in order to ensure complete combustion of gas.

Otherwise, the efficiency of the unit will be low, and the volume of unburned gas will be large, with possible release into the room. In closed fireboxes, it is also important to monitor the sufficiency of air and the functionality of the blower fan.

Basic rules for the safe operation of a heating boiler operating on gas fuel if there is a gas smell:

- immediately turn off the gas valve to the burner device;

- open windows for ventilation;

- in closed-type boilers, forced ventilation is turned on in the chimney system of the gas boiler;

- do not use electrical switches and matches;

- immediately turn off the open flame;

- report an emergency to the gas service.

Autonomous heating is gaining popularity; for many homeowners it has become as necessary in the cold season as an air conditioning system in the summer - an affordable level of comfort in residential premises that ensures normal life activities.

The main function in this is performed by modern boiler installations - technologically advanced, innovative units capable of solving multi-level thermal problems.

Use of coolants in boilers

If irregular residence or frequent and long-term departures are planned at a dacha or in a private house, and draining and purging liquid from the system is not considered an acceptable option, then it is necessary to prevent it from freezing.

This can be done by adding antifreeze to the coolant - substances that do not freeze to a certain negative temperature, and in the case of even lower temperatures do not harden, but turn into a gel-like substance without increasing in volume.

In most cases, it is not recommended to use antifreeze in double-circuit floor-standing boilers running on gas (these standards are less stringent for single-circuit boilers). The instructions clearly state that the coolant in the heating system must be water.

If the user, at his own peril and risk, fills the heating system with any other solution rather than prepared water, then problems arising due to this are not covered by warranty.

Some manufacturers indicate a specific brand of antifreeze that can be used to fill the heating system. For example, equipment manufacturer Viessmann Antifrogen brand coolant .

Others indicate that, as an exception, antifreeze can be used if its manufacturer guarantees that the product will not cause harm to the components and materials of the boiler, in particular the heat exchanger. It is necessary to take into account that for a certain model one coolant may be suitable and another may not be suitable at all.

Therefore, if it is important that antifreeze is used as a coolant in the heating system, you need to find out in advance, before purchasing, whether it is possible, and if so, what brand of coolant is allowed to be used for a specific brand and model of the boiler.

Advantages and disadvantages

The advantages of dual-circuit systems include the following:

- Fuel efficiency. Since the competitor of a double-circuit boiler is usually the “single-circuit boiler + BCS” combination, the consumption of natural gas will be higher in the second case.

- Compact sizes. If we consider that the lion's share of double-circuit boilers are used in wall-mounted versions, it turns out that such systems can be located not only in the utility rooms of private houses, but also in ordinary kitchens of small apartments, where they can take up no more space than a kitchen cabinet.

- Ready solution. In the case of a double-circuit boiler, there is no need to purchase additional equipment and think about its compatibility. A heater, instantaneous water heater and circulation pump are already combined in one device. And all this is automated!

However, there are no ideal boilers; there are also disadvantages:

- Impossibility of simultaneous operation of two circuits. When hot water is turned on, the heating system is blocked by a valve. Therefore, high consumption of hot water can lead to a drop in room temperature.

- Wall-mounted boilers, especially compact ones with a small burner, cannot always heat water to the required temperature while maintaining strong pressure. The temperature at different water intake points may differ - the further the tap is from the boiler, the colder the water will be when opened at all points simultaneously.

- The secondary plate circuit is quite sensitive to the quality of running water. This requires either regular cleaning with chemicals or installing a special softener for hard water.

The issue of cost is deliberately considered separately, since it is both a minus and a plus. The cost of any double-circuit boiler will always be higher than that of a single-circuit boiler. But if you compare it with a boiler to which an indirect heating boiler is connected, then a double-circuit boiler will be cheaper.

Power supply type: non-volatile or not

The principle of operation of a volatile boiler is as follows: the installed automation detects, using sensors, the activation of DHW equipment or a decrease in temperature in the heating circuit and turns on the heating.

The coolant, passing through the heat exchanger, is heated to the required temperature and supplied to the heating or hot water circuit using a circulation pump.

It is clear that a volatile device will consume electricity. To reduce its consumption, it is better to choose models with energy consumption class A++. But, in addition to energy consumption, it is also necessary to take into account the cost of repairs, replacement of spare parts, and automation.

For example, failure of electronic boards is a fairly common occurrence; repairs are expensive, and replacing a part with a new one will cost almost half the cost of the boiler itself.

Energy-dependent boilers are more technologically advanced, they maintain the temperature in a certain mode and save more gas.

But non-volatile models can be called the most adapted to conditions when the electricity is turned off, and energy fluctuations make you worry about the integrity of the automation.

Price

The market for double-circuit gas boilers is very vast, however, it also has its key players, whose products are well known and trusted.

The Ferroli trademark is widely used among Italian manufacturers. The Fortuna Pro model, which has average characteristics, costs in Russia from 23 to 30 thousand rubles, depending on the capacity and distributor in the region.

German Vaillant boilers are deservedly popular among consumers

German quality is promised by factories such as Vaillant and Viessman. The 24 kW Vaillant TurboFit model will cost 40–45 thousand rubles, the Viessman Vitopend is slightly cheaper - about 35 thousand rubles with the same power.

No less popular are the products of the Slovak company Protherm. The price for a 24-kilowatt Jaguar fluctuates around 30 thousand rubles.

The huge variety on the boiler equipment market forces you to carefully choose. After drawing up the project and determining the power parameters, proceed to selecting a model. Pay attention not to loud statements, but to the actual characteristics - heat exchanger material, circulation pump power, presence of forced draft from the combustion chamber. Electronic filling can only be verified by operation, so demand transparency of warranty obligations. Make a balanced choice and let your home be warm.