Characteristics of extruded polystyrene foam

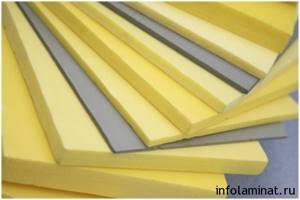

Extruded polystyrene foam for laminate has been in demand on the market for a long time. It consists of closed cells and has a uniform structure. It is obtained by mixing polystyrene granules at high temperature and under pressure with a mixture of light freons and carbon dioxide, or by adding another foaming agent.

Expanded polystyrene acquires high thermal insulation and strength characteristics thanks to the method used in production, the homogeneity of the composition and the cellular structure of the material. Extruded polystyrene foam is resistant not only to water, but also to various chemicals (propane, ammonia, alcohol and alcohol-based dyes, bleach, saline solutions, etc.).

Extruded polystyrene foam is not subject to rotting, and there is practically no water absorption. Water fills only the side open “honeycombs”, since the cells of the substance are sealed. This substrate is completely safe for humans. The use of such a substrate will allow you to obtain a warm floor, and will also have a positive effect on the service life of the laminate.

Characteristic

The material is distinguished by its safety and meets environmental requirements. It is made in several types. It all depends on the performance characteristics and thickness. Expanded polystyrene boards can have milled grooves to create a tight connection.

Extruded polystyrene foam has a low water absorption coefficient. It can be used as a substrate for laminate flooring on the first floor of a building, regardless of the depth of the aquifer.

The thickness of the sheet does not exceed three millimeters. This size is mainly used for rooms where the floors must differ in their heat-insulating properties. Typically, sheets are produced packed in packs of 20 pieces.

For all its positive properties, extruded insulation also has several negative qualities:

- high price;

- not very high depreciation rate;

- there is no microventilation.

For a minimum difference in floor levels, you can install any version of polystyrene foam sheets. Thanks to the groove system, the material adheres more tightly to the floor surface and excellent air flow is maintained.

In homes, polystyrene foam boards of the “PSB-S-35” type have become the most popular. If the floors experience increased pressure, PSB-S-50 will be more reliable.

PSB-S-35 series

When choosing a brand of heat insulator, you need to take into account its service life. It is designed for 15 years. After the end of the guaranteed period, the structure may change and deformation of the material may appear.

Expanded polystyrene is a type of polystyrene foam. It has a smooth surface and microporous structure. The material is obtained by foaming polyethylene granules in special extruders.

To obtain a cellular structure and minimal weight, water vapor and some types of volatile petroleum products are supplied to the pressure zone. The lightness of the material does not affect its strength; it remains very high, and the thermal insulation performance is higher than that of other similar materials.

PSB-S-50 series

This polystyrene foam substrate has a large number of positive characteristics:

- does not allow moisture to pass through;

- mold does not appear on the surface;

- fungus never forms;

- does not cause an allergic reaction;

- high strength;

- does not lose stability under high pressure.

The production of such sheets for laminate coating is carried out using special equipment. The result is an excellent material that does not react to accidental snags. It functions as an excellent heat insulator and protector against moisture.

This insulation for laminate is produced in the form of separate sections, with dimensions 1000x500x20. The sections are joined together with a special foil-coated multilayer polymer fabric. The result is an original design that has a moisture-resistant base with well-sealed joints.

Such packs are not unpacked when sold. Therefore, the color scheme can have a variety of shades. However, this does not in any way affect the strength properties of the material.

Advantages and disadvantages

Compared to other materials, extruded polystyrene foam is characterized by relatively high quality and reasonable price. The advantages include the high strength of the material and durability, which allows you to preserve the beauty and integrity of the floor for a long time. Expanded polystyrene provides good thermal insulation due to its porous surface. This material, due to its structural features, ensures good air circulation and at the same time it does not allow moisture and condensation to pass through. Extruded polystyrene foam is able to smooth out small irregularities. It can also be used in unheated rooms at low temperatures. It also provides excellent sound insulation, absorbing up to 70% of sound.

The disadvantages of this material include low leveling ability. So, if the height of the unevenness is higher than 1 cm, then the laminate will lose its relief, and this can also contribute to the presence of squeaking when walking. Another drawback is the large packaging of the material, as a result of which it is necessary to buy material with a remainder, overpaying for extra sheets.

Flaws

The main disadvantage of the insulation was the inability to hide existing unevenness with its help. If their size exceeds one centimeter, a laminate floor with such a substrate will quickly lose its relief and begin to creak when walking.

Another disadvantage is the packaging of the material. It is not sold in parts; you have to purchase extra material, which certainly leads to financial losses.

Packaging of polystyrene foam material

Laying rules

In order to place extruded polystyrene foam under the laminate , no additional fastening materials or special skills are required.

The main rule is that the seams of the substrate and the laminate do not match. To do this, polystyrene foam is laid at an angle of 45 degrees. Sheets with a thickness of 3 mm of various colors and manufacturers are used as a substrate. First of all, the surface should be leveled and free of dirt. Next, the sheets of expanded polystyrene are laid tightly next to each other in a checkerboard pattern.

It has long been noticed that people pay much less attention to secondary things than to the main ones. This also applies to installing laminate flooring in an apartment: it takes a long time to select a lamella strip and, almost without hesitation, buy a backing for it. Considering that foam polystyrene substrates are among the leaders in popularity, let’s consider how justified this is.

Penoplex warm floor base

There are many floor insulation technologies. This includes expanded clay, mineral wool, and, of course, penoplex. The latter is one of the best modern heat insulators, although, it should be noted, not the cheapest. To insulate the floor, a 20-30 mm slab is sufficient (on the first floors it can be increased to 50 mm), while the thickness of mineral wool, for example, is recommended to be twice as thick.

- The advantages of penoplex for floor insulation are as follows:

Excellent moisture insulation properties Good thermal insulation Mechanical strength Durability Easy installation

Before installing the laminate on Penoplex, you need to lay the insulation itself. This is quite easy to do. It all depends on what kind of leveling screed it will be - cement or made of sheet material (plywood, OSB, GVL). For one you will need as smooth a rough surface as possible, for the other you will have to lay down wooden logs as a base for the coating.

Under a cement screed on penoplex, on which the laminate will then be laid, it is better to choose slabs with grooves at the ends for tighter joints. If the system requires the presence of wooden logs, then the heat insulator can be taken without a curved edge.

Installation of penoplex under laminate with concrete screed

- Prepare penoplex laminate with screed as follows:

Insulation is laid on the leveled base. It is covered with waterproofing on top to prevent liquid from the screed from getting into the joints. After this, it is filled with sand-cement screed. If necessary, the surface is leveled with a self-leveling device - it must be perfectly flat if the laminate is to be laid on polystyrene foam. Next, the substrate and finishing coating are installed in accordance with the technical requirements.

If you want to install a heated floor system under the laminate on penoplex, the screed is installed using the technology provided for heated floors. It is better to stay on a water heated floor. Electric systems typically heat up faster than water systems, and extreme temperature fluctuations are not desirable for our finish. Laying laminate flooring on penoplex and an electric heated floor system will be justified only if there are thermostats that provide a smooth increase and decrease in temperature.

Installation of penoplex under laminate with dry screed

Dry floor screed, which does not require long concrete work, can also be used. In this case, it is attached to wooden logs. First, insulation is laid between the joists. In principle, it can be anything. Afterwards the screed is installed. They use plywood (it is better that in this case the heat insulator lies flush with the joists and provides additional support surface), gypsum fiber boards (GVL) and other materials suitable for dry screed

It is necessary that the surface level be accurately adjusted - this is important for subsequent laying of the laminate on polystyrene foam and dry screed. The last step will be laying the substrate and actually installing the laminate.

Types and characteristics of polystyrene foam substrate

Polystyrene belongs to a group of synthetic polymers collectively called foam. Obtained by polymerization of styrene. The output is translucent granules, from which finished products are obtained by injection molding (pressed polystyrene) or extrusion at +190-230 degrees Celsius (expanded polystyrene).

Polystyrene granules.

The production of the substrate occurs by extruding polystyrene granules mixed with foaming reagents (volatile petroleum products and water vapor), under enormous pressure and high temperature. The result is polystyrene foam with a low density (30-40 kg/m2), moisture absorption of 0.08%, thermal conductivity of 0.035 W/(MxK) and a high level of noise absorption (up to 22 dB).

The substrate for the polystyrene foam laminate is available in the form of slabs (individual sheets or accordion) or rolls.

- width - 50.0-60.0 cm;

- length - 100.0-120.0 cm;

- thickness - 2, 3, 5 mm.

Sheet backing made of polystyrene foam.

Sold in packs of 10 or 20 sheets. Sellers do not open the packaging, so you won’t be able to buy one or two sheets. Roll material is produced 15 m long, 110 cm wide, 2 mm thick.

The backing made of extruded polystyrene foam under the laminate can also be foil-coated, when the foam and foil are glued together. Available in sheets. Possesses:

- noise absorption - up to 23 dB;

- dynamic strength (impact) - 0.035 W/m2;

- bending strength - 0.25 MPa;

- thermal conductivity - 0.035 W/(MxK);

- compressive strength - 0.16 MPa.

Specifications

| Common parameters | |

| Material: | Polystyrene |

| Thickness: | 3 mm |

| Length: | 105 mm |

| Width: | 50 mm |

| Thickness: | 3 mm |

| Material: | Expanded polystyrene |

| Release form: | Sheet |

| Number of sheets per package: | 10 pieces |

| Quantity per package: | 5.25 sq.m |

| Operating temperature from: | -40 degrees Celsius |

| Operating temperature up to: | 40 degrees Celsius |

| Water absorption: | 1 % |

| Soundproofing: | 20 dB |

| Base leveling: | 2 mm |

| Weight: | 630 g |

| Height: | 3.0 cm |

| Width: | 50.0 cm |

| Depth: | 105.0 cm |

| Additional Information | |

| Country of Origin: | Russia |

Delivery of online orders

Goods ordered in the OBI online store are delivered throughout Volgograd and the Volgograd region within 50 km from the city limits. Delivery costs are automatically calculated when placing an online order, based on the weight of the product and delivery area.

Minimum order amount for free delivery:

We will deliver your order free of charge if the delivery address is located in the first delivery zone for online orders, and also:

- > 3,000.00 ₽ – for orders weighing up to 5.0 kg

- > 6,000.00 ₽ – for orders weighing up to 30.0 kg

The courier service delivers small-sized orders (weighing up to 30 kg) to the buyer’s door, large-sized ones to the entrance (gate, gate) of the house. Delivery includes free unloading of goods from the vehicle and their transfer within 10 m.

Delivery date and time

Next day delivery is available if you place your order before 6:00 pm. You will be given the choice of one of two 7-hour delivery slots:

- – from 10:00 to 16:00

- – from 15:00 to 22:00

If you want to reduce the waiting period, you can choose one of the 3-hour delivery intervals for an additional fee:

- – from 10:00 to 13:00 +250.00 ₽.

- – from 13:00 to 16:00 +200.00 ₽.

- – from 16:00 to 19:00 +200.00 ₽.

- – from 19:00 to 22:00 +250.00 ₽.

Rescheduling the date and changing the delivery time interval is possible no later than 24 hours before the previously agreed date and time.

You can learn more about the operating conditions of the courier service in the section Delivery of online orders.

Advantages and disadvantages

Like any building material, the substrate for polystyrene laminate (more precisely, expanded polystyrene) has its advantages and disadvantages in comparison with similar materials. The advantages include:

- the ability to maintain elasticity due to the high strength of the molecular bonds of the material during compression, as a result of which the floor covering retains its integrity and beauty for a long time;

- long service life, coinciding with the service life of the laminate;

- absence of deformation during prolonged exposure to heavy objects (under the legs of furniture, the polystyrene backing is able to restore its dimensions over a long period of time);

- high thermal insulation properties - the porous structure conducts heat poorly;

- good level of noise absorption - up to 70% or 22 dB;

- retains its properties in a wide temperature range - from -50 to +75 degrees Celsius, which allows polystyrene material to be laid under laminate or linoleum in unheated rooms (dachas);

- the ability to ensure air circulation on the concrete surface of the screed or waterproofing material (ribbed underside), as a result of which condensation does not form under the laminate;

- environmentally friendly - safe for the environment (does not rot);

- quality corresponds to price;

- the ability of the cellular structure to prevent the formation of condensation, and when it occurs, to absorb moisture, which makes it possible not to waterproof the floor screed;

- accuracy of sheet dimensions in length and width, which simplifies the installation process;

- light weight and compact packaging, allowing the polystyrene foam pad to be transported in passenger cars.

There are also disadvantages, but very few:

- low leveling ability - with a thickness of 3 mm, it is not able to eliminate the impact of irregularities of more than 1 mm on the flooring, as a result of which creaking quickly appears;

- has a temporary drawdown that will go away in 4-5 weeks;

- not sold in sheets, but only in packages, as a result of which quite often a large balance arises - a loss of the family budget;

- low resistance to aggressive environments (easily dissolves in gasoline, acetone, chloroform, etc.), with the exception of ammonia, alkalis, alcohol, propane;

- highly flammable due to the high content of carbon (92%) and hydrogen (8%) in the composition;

- in packages, sheet material is constantly curved;

- fragility of the substrate under strong bending.

Testing polystyrene foam for flammability.

Insulating the floor before laying the laminate

Laying laminate flooring, from selection to installation. How to choose the right laminate - basic criteria

How to choose insulation for laminate flooring

Those who want their stay in their own home to be comfortable often wonder what kind of floor insulation to choose for laminate flooring. Floor insulation is not the least important when arranging a home, especially if the family has small children who like to play on the floor covering, or if they like to walk around the house exclusively barefoot. How to choose the right insulation and how to install it correctly. This will be discussed later in the article.

Choosing material for insulation under laminate

When choosing a material for floor insulation, it is necessary to take into account how cold it is in the house in winter, the characteristics of each room, their purpose, as well as the type of laminate used. Floor coverings, and therefore insulation in a house, apartment, loggia or balcony and other rooms can vary significantly.

"Warm floor"

The presented system is often installed in children's rooms, in the bathroom, toilet, and kitchen. It consists of durable pipes that are resistant to various influences, through which water heated to a certain temperature continuously circulates. This method of floor insulation is very effective, but at the same time labor- and financially expensive. In addition, if such a system breaks down, the floor covering must be dismantled. Infrared or film “warm floor” is easier to install and operate. It fits easily under the laminate and can be transferred to another surface if necessary.

Styrofoam

Unlike the previous option, polystyrene foam does not require connection to an electrical network and the use of additional communications. Polystyrene foam is a time-tested insulation material for laminate flooring. It has excellent heat and sound insulation properties, is durable and reliable. It is often used during the installation of a floating screed, filling the material with a layer of concrete mortar before laying the floor covering. Polystyrene foam can be used both in ordinary rooms and in rooms with high humidity and on balconies.

Expanded clay

Expanded clay is one of the cheapest insulation materials. To insulate the surface, it can be used either during the installation of a dry screed or added directly to the concrete solution. Thanks to its porous structure, expanded clay allows you to create a warm surface even in the coldest weather. It is worth noting that good thermal insulation qualities are achieved when laying the material about 10 centimeters in height, which can slightly reduce the space of the room.

Polystyrene concrete

Unlike expanded clay, to insulate the surface with polystyrene concrete, it is enough to make a layer of material of only 5 centimeters. This will provide not only high-quality heat, but also excellent sound insulation of the floor. The insulated surface turns out to be quite flat, so you can safely lay out not only laminate flooring, but also ceramic tiles and even make self-leveling floors.

Glass wool and mineral wool

The presented insulation materials are very widely used, as they are inexpensive. They are produced either in rolls or in the form of slabs. They can be laid under a wooden floor covering, but they must be well insulated so that insulation particles cannot get out, because they can pose some danger to humans. The main advantage of materials is vapor permeability, but at the same time they are capable of excessively absorbing moisture, as a result of which they lose their properties.

Cork

Cork has many advantages, including lightness, safety, naturalness, moisture resistance, ease of installation, durability and many others. Not surprisingly, it is quite expensive. Cork can be used as insulation under laminate, or can be used as an independent floor covering. In the latter case, the material is additionally coated with varnish.

Ecowool

Ecowool is a crumbly material that is used to insulate even those places where it is very difficult to get to. To insulate the surface, pour it with your own hands or using a special device with a layer of about 16-18 centimeters. At the same time, it will show excellent heat and sound insulation characteristics, and will also be absolutely safe for health. Ecowool is also not at all afraid of moisture, so it can be safely used in rooms with high humidity.

Polyethylene or polystyrene?

There is an interesting confusion in life: due to the fact that foamed polystyrene and polyethylene are classified as foam plastic, professional builders often confuse them. However, these are completely different materials, with different characteristics and, naturally, prices.

Foamed polyethylene can be cross-linked (abbreviated PPE) and non-cross-linked (NPE). Both types of material (Izolon, Stenofon, Porilex) have the lowest price among substrates (15-28 rub./m2). But this does not mean that they are of equally low quality.

Non-crosslinked polyethylene foam (NPE) does not have a cross-linking network at the molecular level, which leads to rupture of the material under significant loads. In cross-linked polyethylene (XPE), the hydrogen atom is replaced by a carbon atom during the manufacturing process, resulting in the formation of molecular bonds in all directions (hence cross-linked). This polyethylene significantly exceeds NPE in all indicators:

- density - 30% higher;

- strength - 40-50% higher;

- long service life - almost 2 times longer;

- high level of sound insulation (NPE has practically none);

- thermal conductivity - 20% lower.

However, cross-linked polyethylene foam is still slightly inferior in quality to the polystyrene substrate, which is reflected in the price. For expanded polystyrene it is in the range of 35-50 rubles/m2.

Conclusion: based on prices and quality characteristics, PPE is the best foam backing for linoleum. For budget renovations, it is better to lay expanded polystyrene under laminate or parquet.

Methods for laying laminate

Laminate laying technology provides two methods:

- adhesive;

- glueless or locking.

The first method has recently been used very rarely due to its disadvantages. When using the adhesive method, the planks are fixed using the tongue-and-groove method using special glue. However, over time, the glue loses its adhesive properties and cracks form in the laminate. In addition, if it becomes necessary to replace a separate strip, this cannot be done without completely destroying the entire structure.

Laying laminate flooring using a glueless method

Therefore, today more modern and reliable methods are used for laying laminate flooring - glueless systems (“locking” and “prefabricated”). When using them, installation time is reduced, assembly quality is improved (strong connections are formed), the formation of gaps is eliminated and repairs are made easier. A laminate flooring installed in this way can be used immediately without waiting for the adhesive to dry.

Popular manufacturers and prices

When planning to buy foam polystyrene for the substrate, you should keep in mind a few points:

- no laminate or parquet manufacturer recommends polystyrene foam underlay for their products and, therefore, does not provide a guarantee for the floor covering;

- the foamed polystyrene substrate successfully performs all the functions of the damper layer;

- For many buyers, a low price is a priority over a warranty on flooring.

Production of polystyrene foam substrate.

Linings for extruded polystyrene laminate are produced in Russia, Poland and China (such products are not sold in other countries of Europe and America - natural materials are a priority there) for the population of the countries of the former Soviet Union.

The most popular brands are:

- The company VTM IsoPolin (Isopolin) (Poland) produces products in the form of rolls and sheets with a thickness of 2, 3 and 5 mm. Roll dimensions 20 m x 1.1 m x 2 mm, slab dimensions - 100 cm x 50 cm. Thickness may vary. It fits not only under laminate, but also under wooden floors. In terms of its technical characteristics, the XPS substrate occupies a middle position between cork and NPE. High quality is accompanied by an appropriate price - from 55 rubles / m 2;

- “Izoshum” (Russia and the Republic of Belarus) is considered the best in terms of price and quality ratio. Available in a thickness of 3 mm and an area of 0.5 m2. Pack contains 20 sheets. The price starts from 25 rubles/m2;

- “Solid” (Russia, Aramil, Sverdlovsk region) - produced in the form of single sheets and accordions with a thickness of 2 to 5 mm. The package contains 5.25 m2 of simple substrate and 52.5 m2 of accordion. Prices start from 55 rubles/m2;

- Aberhof - a German company produces a 5 mm thick underlay for floor screed with a height error of up to 3.5 mm. The package contains 5.25 m2 (10 sheets). For 1 m2 you will have to pay, oddly enough, only 25-30 rubles. The disadvantages include rapid shrinkage. However, among this type of substrate, with high leveling ability (3.5 mm), it is the undisputed leader.

Types of substrates

Expanded polystyrene is used to make several types of materials that can be used as a substrate for laminate flooring. They differ in thickness and performance characteristics. Expanded polystyrene boards are often equipped with milled end grooves, ensuring a tight fit of the elements to each other.

Structure of sheet substrate

Note! Due to the low coefficient of water absorption, a substrate made of extruded polystyrene foam can be safely used in rooms on the first floor, without focusing on the depth of groundwater.

To ensure thermal insulation of a laminate flooring, it is enough to use a three-millimeter underlay. It is produced in the form of sheets of 20 pieces per package. A convenient backing is folded into an accordion. A minimum number of joints are formed between such sheets due to the fact that when unfolded, the material is laid along the entire length of the room.

Nowadays, in light of the popularity of caring for one’s health and attention to the environmental situation in the apartment, coniferous underlay for laminate flooring is especially popular. Read more about its properties in a special article.

Polystyrene sheets for flooring

As noted earlier, polystyrene foam backing can be rolled or in the form of sheets. The second variety is available in the form of separate plates or an accordion. They differ only in the installation method.

The accordion-type underlay allows you to lay the material faster

When laying sheets with an accordion, be careful not to damage the joint of the sheets. If this happens, the gap is sealed with ordinary tape. Also, using tape, the individual sheets are fastened together so that they do not fly apart. The advantage of an accordion is that its installation is much faster.

With a sheet length of 1000 - 1200 mm and a width of 500 - 600 mm, the thickness of the product can vary from 2 to 5 mm. There are several types of sheet substrates.

"Solid" 2 mm thick

This variety can be used in a heated floor system. The density of the “Solid” sheet substrate with a thickness of 2 mm is 40 kg/m³. To prevent the substrate from being an obstacle to the heat flow coming from the coolant, it is perforated.

Simple Sheet Underlay Options

Note! Since the leveling ability of a material with such a thickness is minimal, and the laminate must be laid on a flat base, it is necessary to carefully consider the preparatory stage.

When installing the coolant (pipes with water or electric cable) into the screed, during the operation of the heated floor, make sure that its temperature does not exceed 28 degrees. When creating a vapor barrier layer, the substrate may not have perforations.

If you are installing an infrared heated floor, when the heating elements are laid directly on the substrate, you should choose a material without perforation to avoid heat loss.

The cost of this type of polystyrene foam substrate starts from 60 rubles/m². The package contains material to cover a surface area of 8.4 m².

It is recommended to purchase “Solid” polystyrene foam substrate with a thickness of 2 mm for electric or water heated floors.

How to make a heated floor correctly? This process will largely depend on what type of system has been chosen for installation. Installation is not as complicated as it seems, but it is quite a troublesome task. Read more about how to install heated floors in a special article.

"Solid" 3 mm thick

The 3 mm thick substrate is more comfortable to use and has a better leveling effect. The ribbed surface on the back side of the sheet promotes shrinkage of the material under load.

The accordion-shaped type of polystyrene foam backing is 10 meters long and designed for an area of 10.5 m². Its average density is 45 kg/m³. There is no ribbing on the back side. Compared to foam substrates, which are also often used when laying laminate flooring, this option has greater density and durability.

Accordion type substrate parameters

As previously noted, accordion-shaped material is laid faster than sheet counterparts. The cost of the material starts from 55 rubles per m² and exceeds the price of a foam roll analogue.

"Aberhof" 5 mm

Aberhof 5mm sheet substrate is sold in 10 sheets per package, designed for a surface area of 5.25 m². The size of one sheet is 1050 x 500 x 5 mm. This variety is characterized by higher sound and heat insulation properties (higher than the three-millimeter one by about 2%). The sheet density is 35 kg/m³. The advantage of the material is its high leveling ability (3.5 mm).

Aberhof underlay

When using such a substrate on an uneven floor, it must be taken into account that it shrinks over time. However, this type of underlay is best suited for laying laminate and parquet flooring where the substrate is uneven.

Advantages and disadvantages

Extruded sheet polystyrene foam substrate has the following positive properties:

- High density and long service life when compared with a foamed counterpart.

- Relatively low cost, which starts from 20 rubles per 1 m².

- The material does not rot or mold.

- Available in a convenient format and packaging, which facilitates the process of transportation and installation.

Laminate installation process

Disadvantages include:

- Flammability of the material.

- The package may contain defective sheets of curved shape.

- Due to their fragility, sheets must be laid carefully.

- You need a perfectly flat and clean base without small pebbles that could disrupt the integrity of the sheet.

- The need to use a vapor barrier film.

Table 3. Average cost of material

| Options | Average cost (as of August 2021), rubles | |

| Arbiton Secura Extra Aquastop 3mm/6 m²/pack | Thickness: 0.3 cm Width: 118 cm Packaged: 6 m² | 720 (pack) |

| Bonkeel Smart 3mm/9.45m² | Thickness: 0.3 cm Width: 105 cm Packaged: 9.45 m² | 579 (pack) |

| Solid perforated for heated floors 1050x500x1.8mm (sheet, polystyrene) | Thickness: 0.18 mm Width: 50 cm Length: 105 cm Packaged: 8.4 m² | 45 (sq.m.) |

| "Teplon" sheet | Thickness: 0.3 cm Width: 50 cm Length: 100 cm Package: 10 pcs | 520 (pack) |

| Welliger 3 mm (expanded polystyrene) | Thickness: 0.3 cm Width: 100 cm Length: 100 cm Package: 10 m² | 150 (sq.m.) |

| Solid sheet | Thickness: 0.3 cm Width: 50 cm Length: 100 cm Package: 10 pcs | 300 (pack) |

What to consider when laying underlay under laminate

You will find detailed step-by-step instructions for laying laminate flooring in the article . ” We talk about the nuances, choosing a substrate and its types, the installation process and how to cut holes.

The joints between the sheets must be taped with moisture-resistant tape.

Prices for laminate substrates

underlay for laminate

Video - How to choose a substrate for laminate

Laying nuances

In principle, there are no significant differences in laying polystyrene foam underlays compared to other types of underlays for laminate flooring. An exception is the location of the polystyrene foam material in relation to the laminate:

- the rolled underlay is positioned perpendicular to the floor covering;

- The slabs are laid at an angle of 45 degrees relative to the parquet or laminate.

Laying the substrate.

The rest is the same procedure:

- Before work begins, the substrate is brought into the room and unpacked so that the material takes on geometric dimensions suitable for the temperature and humidity of the room where it will be installed;

- Some of the slabs are cut diagonally from one corner to the other and laid near the walls;

- A strip is laid out lengthwise for the installation of several strips of laminate. It's better to play it safe here - this is one of the few types of substrate on which you can walk. But it’s better not to take risks, especially since there are no problems with this scheme of work;

- The joints are glued together with masking tape or construction tape;

- Laminate is installed;

- The next strip of substrate is laid out, etc.

There are some nuances when laying rolled material. The problem here is the constant curling of the cut backing sheet. Attempts to straighten it often lead to it crumbling and then breaking. The solution to the difficulties that arise is simple - cut the sheets to size, unfold, put something heavy on the ends and leave for a couple of days. During this time, internal tension will weaken and the problem will disappear.

Which manufacturer should you choose?

As noted above, there are many different models of polystyrene foam substrates on the modern market. At the same time, the most popular and sought-after brands are: Polish companies VTM and Arbiton, Russian Izoshum. These are high-quality products that cannot be called cheap, but their characteristics and technical indicators allow them to be used together with laminates of different types and different classes of use.

When choosing a substrate, you must take into account the recommendations of the laminate floor manufacturer in this regard. For example, some companies recommend laying a thin cork underlay, while others recommend using a standard coniferous option. This question must be clarified before purchasing and starting installation work.

Production technology for polystyrene foam laminate substrate

The insulation is made by mixing polystyrene granules with a special foaming agent. The entire process takes place under high pressure and high temperature. For mixing, a special machine is used - an extruder. The resulting material is characterized by a unique microstructure, which consists of many cells filled with air molecules. These cells are impenetrable, which means neither gas nor water can get into them.

The use of extruded polystyrene foam as a substrate for laminate is similar to the use of polystyrene foam, but our version is warmer and more durable, and also has much lower water absorption. Accordingly, it also costs more.

! Manufactured products have different properties. So, there is a warmer, more durable flooring, and one that is characterized by greater resistance to compression and a lower level of water absorption. Depending on the manufacturer, slabs/rolls can be green, pink or blue.

As you may have guessed, there are several forms of insulation available on the market. This can be either a rolled version or cut slabs. The second option is more versatile, since you can always buy thick sheets and simply cut them during use.

Such specialized layers are characterized by their own structure:

- The top layer is smooth, for contact with the lamellas;

- the bottom layer is ribbed, guaranteeing improved sound insulation and shock absorption properties.

Foamed polyethylene VS foamed polystyrene under laminate

Try not to confuse these two flooring options!

What is foamed polyethylene? This is the cheapest option for an intermediate layer between the lamellas and the rough base. It is not afraid of moisture, fungi and mold. It is characterized by excellent noise insulation and ease of installation. What's the downside? Low strength: polyethylene breaks under the influence of gravity. He's unreliable.

What is expanded polystyrene? This is a durable material that is also not afraid of moisture, fungi and mold, and is also characterized by excellent fillability, good heat and sound insulation properties. This is one of the most popular options.

If we compare these two types, the second has a higher noise absorption coefficient, but lower thermal conductivity than the first. This naturally affects its cost.

Expanded polystyrene price

The price of the substrate for polystyrene foam laminate is also different, depending on the quality characteristics, manufacturer and number of sheets in the package:

- Arbiton (2 mm) – 45 rubles per 1 m?;

- Arbiton (3 mm) – 60 rubles per 1 m?;

- Aberhof (2 mm) – 45 rubles per 1 m²;

- Aberhof (3 mm) – 50 rubles per 1 m²;

- DecorMatch (3 mm) – 50 rubles per 1 m?;

- Enke Krause (3 mm) – 70 rubles per 1 m?;

- Tuplex (3 mm) – 90 rubles per 1 m?.

Types of expanded polystyrene

Expanded polystyrene has several varieties depending on the method of its manufacture.

Table 1. Types of polystyrene foam

| Name | Description |

| Pressless | Expanded polystyrene labeled PSB (EPS) is used for wall insulation. Its variety marked PSB - C is less fire hazardous. |

| Extruded | Material marked EPS (XPS) has high compressive strength. |

| Press | Material marked PS-1, PS-4 has a high density. |

Extruded polystyrene foam laminate backing: pros and cons

The first thing I would like to note is that, of course, there are more advantages. The main ones include:

- High thermal insulation performance;

- lack of tendency to biodegrade;

- no deformation;

- no condensation under the laminate;

- fire resistance;

- resistance to significant loads;

- ability for air exchange;

- low water absorption coefficient;

- possibility of use at sub-zero temperatures;

- Possibility of use in unheated rooms;

- high compression performance;

- accuracy of geometric dimensions;

- no need to use fastening materials - bolts, nails, screws, glue.

There are only two possible disadvantages. This is a low leveling ability, as well as the possibility of a fairly large product residue.

In general, the substrate for polystyrene foam laminate differs very favorably from many other alternative options, since only it is characterized by a high degree of resistance to aggressive chemicals. Here we also need to separately note the ability to withstand really very large and long-term loads WITHOUT changing shape. Agree, this is the material that will last for a long period.

! Why is the precise geometry of the slabs so important? The fact is that precise dimensions allow all work to be completed in the shortest possible time. This is an excellent feature of such flooring, which is one of the main reasons why many people plan to buy extruded polystyrene foam for laminate flooring.

Nuances of floor insulation under laminate

All work with such material is quite simple. But it is necessary to take into account several nuances:

- The material is most suitable for insulating soil-based floors. It must be laid at the very beginning of construction on a site with an absolutely flat surface.

- When laying, be sure to leave special ventilation gaps along the walls.

- Before you start laying the laminate, you must first strengthen the substrate with lathing.

- If the floor surface will be covered with carpet, and the backing will be polystyrene foam boards, then you must first place chipboard or plywood boards on the floor.

- When installing insulating boards, you should strive to obtain a very tight connection.

Before laying the insulation, the floor screed is left alone for a couple of days until it completely sets. Only after this is the clean floor installed.

Polystyrene foam insulation backing

Iso-noise – modern polystyrene foam substrate

Iso-noise is a very durable and stable intermediate layer, which also guarantees a long service life of the laminated flooring. Why do many people choose this option over dozens of others? The point is not that this is a domestic product, but that it is affordable and quite effectively combines the functions of an excellent noise barrier and insulation.

Among the advantages of Izoshum are:

- Thermal Insulation Properties: It is an excellent thermal insulation flooring. It is characterized by a low heat transfer coefficient. This intermediate layer can reach a thickness of 10 mm, while limiting thermal conductivity over a wide range of temperatures;

- sound absorption indicators: according to the results of recent studies, Isoshum dissipates about 50% of the noise reproduced in a room. It can also absorb about 20dB of different sounds;

- sound insulation characteristics: the use of sheets guarantees complete sound insulation, providing the necessary acoustic comfort, as well as the absorption of impact noise that occurs when walking on the flooring;

- environmental friendliness: using Isoshum, you don’t have to worry about your well-being and the health of your family and friends. This is an environmentally friendly material that eliminates the release of harmful substances;

- Compatibility with other surfaces: this high-quality substrate can be easily combined with a wide variety of coatings and surfaces, providing protection from small pests and chemical compounds.

Water floor under laminate

Another aesthetic, practical and functional option for arranging a heated floor would be a water floor. Experts say that it would be most appropriate to install it in private homes.

So, a water heated floor under a laminate is a system of special pipes under the finished floor covering, through which water of a certain temperature circulates. It is hot water that heats the laminate floor. It is worth noting that modern pipes for heated floors are made using the latest technologies and materials. Thus, metal-plastic and polyethylene ensure the safety of heated floors, preventing water leakage.

Laying a water floor requires taking into account a number of features. So, laminate - as already mentioned - is a material with insufficient thermal conductivity. It is obvious that when laying water floor pipes under wooden logs, a layer of hydro- and thermal insulation, laminate and, possibly, carpet, the heat transfer effect will be almost zero. That is why it is recommended to lay water pipes in a sand-cement screed.

This type of installation of heated floors under laminate is the most common and effective. This is due to the fact that the finished sand-cement screed prevents damage to laid pipes and acts as a continuous heating surface that evenly distributes heat.

As when laying infrared film heated floors, it is necessary to divide the floor area into sections and determine which of them will have a heated floor and which will not. At the next stage, the floor surface is leveled, a layer of the selected thermal insulation material is laid, and a reinforcing mesh is installed under the sand-cement screed.

Then the mounting strip is fastened and water pipes are laid. As a rule, pipes are fastened to an already laid reinforcement mesh using wire. Thus, the reinforcing mesh is a good marking for laying water pipes for a heated floor.

There are several ways to install warm water floors under laminate: parallel and spiral. With the parallel method, pipes are laid in the form of a snake - one after another.

Water-heated floor under laminate (parallel installation method)

The spiral method, accordingly, involves laying pipes in a spiral.

Water heated floor with a pipeline laid in a spiral

At the next stage, the finished structure is directly poured with cement to create a screed. After it has completely hardened, it is necessary to check the readiness of the heated floor system for operation. Thus, a water heated floor under a laminate - the reviews about it are the most positive - are subject to adjusting the temperature regime and checking all the hydraulics. If there are no malfunctions, then the heated floor can be considered ready for use.

The video will demonstrate another installation method for a room with heavy traffic:

Thus, there are quite a lot of options for installing a heated floor system, however, taking into account the operational features of the laminate, the best options are: infrared film and water floors. They will allow you to easily heat not only the finished floor covering itself, but also the air in the room where they will be installed.

Laying process

When laying laminate flooring with your own hands, do not forget about the backing. It cannot be laid under linoleum, but it must be laid under laminated boards. Here are some of the functions that the substrate performs:

- sound insulation;

- thermal insulation;

- leveling minor surface imperfections.

In addition, it helps preserve the flooring itself. You can't skimp on the substrate. Forget about cheap roll backing, which is usually sold by the meter. Over the course of several years of use, laminate boards will simply be destroyed, after which they themselves will become unusable.

Choose only high-quality substrate: cork, polystyrene foam, pine. Please note that it is not required to be fixed to the walls or floor. However, like the coating itself. You can only grab it at the joints with masking tape. And then, this is not necessary.

First, let's install the spacers, since the coating can be installed correctly only by maintaining the expansion gap. What it is? We have already said that as humidity and temperature change, wood can expand and contract. So, this is, roughly speaking, a gap between the wall and the floor covering, which is needed so that the material has somewhere to “grow”. Otherwise, the joints may acquire an Λ-shape, which is extremely undesirable.

Now we lay the underlay, after which we begin laying the laminate. Here is the algorithm to use when laying:

start at the corner farthest from the door. Take four boards. For those that will be laid against the wall (the first and third in a row), it is necessary to cut off the ridge with a sharp knife. But you don't need to touch the groove. When laying, it should always face the installer;

By the way, it is recommended to lay the boards perpendicular to the floorboards of the old floor;

- panels of adjacent rows must be offset. Therefore, measure this distance in advance. It must be at least 30 cm;

- snap the first and third panels into place. The latching method depends on the type of lock - Click or Lock;

- place the resulting floor fragment in its place;

- lay the second row in the same way as the first. Do not forget that the panels are shifted by at least 30 cm, and there must be a gap between the covering and the wall, which will subsequently be hidden by the baseboard;

- When laying the last row in the room, laminated boards must be cut to length according to precisely measured dimensions.

You can lay laminate flooring in any convenient way. You can join ready-made rows of boards or install them using the addition method, that is, one board at a time. If you are new to this business (and most likely you are), then you will probably find the second method more convenient.

After the last board is in place, you can remove the spacers and begin installing the baseboard. With its lower edge it should fit snugly to the floor, and its upper edge to the wall. Installation is carried out using dowels and self-tapping screws.

Of course, in those rooms where cleaning with soapy water will often be carried out, it is better to lay linoleum. Constant exposure to moisture can even lead to delamination of the board, and then there is practically nothing to “help” it.

In those places where the laminate meets another floor covering (tiles, carpet), use a padded threshold. It should be mounted, like the plinth, with self-tapping screws, which are most often sold as a set.

Thresholds with hidden fastenings look more aesthetically pleasing, where the heads of the screws are driven into a hidden groove, so they are not visible. The threshold without hidden fastening is fixed with self-tapping screws from above. Thanks to this, if necessary, it can be unscrewed and reused. But the profile with hidden fastening is not screwed, but driven into pre-prepared holes. If necessary, it can be dismantled with a pry bar, but it is not a fact that it will “survive” this procedure.

Now you know what it means to install laminate flooring on a wood base. In order for the flooring to serve you faithfully, you should not skimp on materials or try to invest in the shortest possible time. Be prepared that a good substrate and high-quality laminate will not be cheap. A stingy person, as everyone knows, pays twice, at least.

https://youtube.com/watch?v=aoHoHHzqbRY

Recommendations

When laying laminate flooring on a wooden floor, you should adhere to the following rules:

- The flooring joists should be at least 20–30 mm away from the walls. They should not be placed too close to wall surfaces.

- The subfloor and slats should be laid with a distance of 1–1.5 cm from the walls to form a compensation gap around the perimeter of the room. Then it will be covered with baseboards. And during installation, you can insert small wooden wedges there so that the gap does not close due to the displacement of the slats due to negligence.

- Laminated planks must be laid out offset to the previous row by approximately a third of their length. This will prevent the appearance of through transverse seams in the coating and weakening of the interlocking joints.

- The substrate is laid in one layer and in sheets end-to-end. There is no need to glue the resulting seams; this is not waterproofing.

- If the doors open into a room with laminate flooring, then there should be an appropriate gap between the lower edge of their leaves and the floor next to it. And the first row of laminated covering is best laid right from this place or from a corner nearby.

- If wood boards or gypsum fiber boards are laid to make a dry screed, then their thickness should be chosen in the region of 8–12 mm. It is not worth laying materials that are too thin; they are not designed to withstand the loads inherent in the floor.

There should not be any particular difficulties with installing laminate flooring on a wooden floor. All installation rules here are identical to those that apply in the case of concrete screed. You just need to fix and fasten the rough wooden base so that the individual floorboards and parquet boards do not sag later. They should remain stationary under the laminate.

It is recommended to cover joints with other floor coverings and in places under doors with special thresholds. Such products come in plastic and metal.

Laying laminate flooring on a wooden floor

How laminate is laid

The process of installing a laminate on a foam plastic must be carried out in accordance with the innovative process of other similar materials .

However, this material opens up auxiliary possibilities when you need to do work in a small space. For example, when the room is filled with furniture. There is no need to lay down the entire substrate at once. It will be possible to provide for the furniture arrangement and the mounting location of the insulation boards. This is often critical.

To work you will need:

- extruded polystyrene foam;

- boards Oriented strand boards.

These substrates are subsequently placed on the concrete surface. The outer covering will be attached to them. Extruded polystyrene foam usually has several options:

- extruded polystyrene;

- technoplex;

- TechnoNIKOL;

- styrex.

The perimeter of such panels is always the same (1200x600mm). The ends of the slabs have a one-sided chamfer prepared to obtain a tight connection. The sheets must lie on an ideal surface. There is absolutely no need for it to be completely smooth. The thickness of the panels is selected depending on the required power and the thermal insulation layer being laid.

At the beginning of laying the laminate with your own hands on extruded polystyrene foam, experts recommend perfectly gluing the joints of the substrate. To do this, use metal tape. As a result, the laminate will receive a complete vapor barrier, it will be well protected from the penetration of moisture that can enter through the floor coverings.

Expanded polystyrene slabs may not correspond to the square footage of the floor. They need to be cut with a sharp knife. In order for the floor insulation to be free of gaps, it is necessary to chamfer the edges of the slabs in order to obtain a tighter joining of the panels.

After installation work, the heat insulator under the laminate is covered on top with oriented strand boards. Reliability of extruded foam

so high that you can walk on them in boots with fairly hard soles. However, heavy furniture or a sharp object may leave a dent. To prevent this from happening, additional overlap is laid.

Laying extruded polystyrene under the screed

If you look very carefully at the performance of the polystyrene foam substrate, you can identify its similarity to cork material. He also:

- not subject to rotting;

- mold never appears on the surface;

- not subject to deformation.

Due to the very high compression ratio, the surface has quite impressive strength, which virtually never “squeezes through.”

You can find out how to choose a high-quality material for floor insulation under a laminate flooring from the video:

Important advantages

Compared to analogues, this material has a low price and important advantages. The service life of this heat insulator under a laminate floor is tens of years. Moreover, the floor remains intact, and its appearance retains its original attractiveness.

Thanks to the porous structure of the surface of the material laid under the laminate floor, excellent thermal insulation is provided. The unusual structure of the material ensures the necessary air circulation without allowing condensation and water to pass through.

Noise insulation

The cells of the material are filled with air. As a result, the thermal insulation material is transformed into an excellent sound insulator. It absorbs approximately 70% of sound waves.

Not a difficult installation process

Expanded polystyrene sheets can be installed without any problems. Each plate has specialized markings for installation. It is easy to calculate the step of laying the panels.

Slab laying

Moisture resistance

This polystyrene foam underlay makes an excellent insulator for laminate floors. The boards will stop absorbing moisture, they will not change or swell.

Resistance to aggressive environments

Foamed polystyrene does not react to the influence of chemistry; it is neutral to acids and alkalis. The artificial composition prevents the growth of bacteria.

Endurance

The physical characteristics of the material do not change even under very high loads. It is not affected by temperature fluctuations; it retains its own innovative characteristics.

Environmental friendliness

None of the substances included in the polystyrene foam material emit toxic substances as a result of operation.

The indicated properties of this foam material put it in first place among similar materials

. Remarkable thermal insulation properties and high efficiency brought it to the first place.