Construction of a wall with a ventilated air gap

Dry insulation is the key to 100% protection against heat loss. Due to natural diffusion, moisture vapor moves from the walls of the house, which normally evaporates from the surface. And if the house is insulated and the thermal insulation is covered with dense materials, the movement of flows is disrupted. As a result, the thermal insulation may become wet and lose its insulating properties. How to make sure that evaporated moisture leaves the insulation freely, let’s figure it out together!

What are gaps and why are they needed?

By gaps we mean the distances between the walls, which promote ventilation and prevent the accumulation of condensation inside the structure. In such gaps you can place thermal insulation material for insulation. With this method of bricklaying, the outer wall of the house consists of three layers:

- Basic structure.

- Insulation.

- Facing.

It is used to increase the thermal insulation of a home and to save energy resources. Thermal insulation material inside the structure protects the load-bearing wall from freezing. In addition, it itself is reliably protected from damage. And the existing air gap between the insulation layer and the facing masonry promotes ventilation and evaporation of excess moisture.

Saving heat supply energy in the construction aspect

To understand the need, methods and types of thermal insulation of walls, you should first identify:

- Proposed type and mode of residence;

- Heating method and operating mode of heating devices.

Occasional living

If living in a frame house is planned only in the summer, that is, the house is built as a country house, then thermal insulation is carried out from the inside. In this way, heating devices will be used more efficiently and less costly in winter to compensate for the heat loss of the building in a short time.

Internal thermal insulation is also provided during intermittent and irregular operation of heating equipment.

Permanent residence

Continuous operation of the heating system is necessary when living in a house permanently. In this case, external thermal insulation of the walls should be preferred. Then they will begin to accumulate heat, which will prevent large fluctuations in room temperatures.

Properties and characteristics of foam plastic

The foam consists of 98% air, the rest is thin-walled polystyrene foam balls. The list of positive properties of polystyrene foam is extensive; it is extremely difficult to find analogues of the material based on the sum of its positive properties:

- Easily processed by hand using a knife or saw;

- Attached in any available way;

- Sticks to any material;

- Resistant to aggressive solutions;

- Inert to building materials of mineral origin;

- Application in insulation eliminates the need for a vapor barrier;

- Does not add loads to the foundation of the frame structure;

- Has excellent sound insulation properties;

- Significantly reduces insulation costs compared to other insulation materials;

- Allows you to reduce the total amount of energy consumed and reduce the amount of equipment for heating your home;

- Allows reduction in wall thickness.

Penoizol

Despite the complexity of the process of mixing the liquid components of the insulator, foam insulation between walls is a fairly popular method of insulation. It's all about cost. Polystyrene foam is cheaper than polyurethane foam, practically not inferior to it in terms of its technical characteristics. However, when practicing independently, such equipment requires certain skills and knowledge.

It is necessary to know how much it is necessary to increase or decrease the performance of the compressor unit when working on different sections of the walls. In addition, the components are mixed in certain proportions, which also need to be known. At the same time, experience in performing such operations is also important - filling voids requires care and experience, since if the process is not carried out correctly, you can not only create a poor-quality layer, but also destroy fragile structures. If you do not have experience in such operations, it is better to pay attention to other methods of insulation.

Foam plastic: the most common material for insulation

In order to avoid problems with thermal insulation during operation, the material is selected and calculated according to the intended application. PSBS 25 and PSBS 35 foam plastic is installed in the walls for insulation. The numbers indicate the density of the insulation in kg/m3. The letter abbreviation stands for:

- P – foam;

- C – suspension;

- B – non-sedimentary;

- C – self-extinguishing.

Polystyrene foam, or expanded polystyrene, has a number of advantages over other insulation materials, but its environmental friendliness is always questioned.

There are many discussions and opinions on this topic, which can and should be listened to, but safe foam plastic has been developed and is conquering the market under the brand “METTEMPLAST”®.

Top – foil thermal insulation

Stenophone type B NPE-LP 1m 4mm

The insulator, made of non-crosslinked polyethylene foam and a foil layer, is produced in rolls. The width of the canvas is 1 m, thickness – 4 mm.

Specifications:

- density – 35 kg/m;

- thermal conductivity coefficient – 0.04 – 0.038 W/(m*k);

- degree of flammability – G2 – G4;

- vapor permeability coefficient – 0.001 mg (m*h*Pa);

- Max. operating t° – 100°С;

- min. operating t° – minus 60°С;

- Application options - for interior work, for floors and walls, under laminate, for roofing structures, floors.

Bulk materials for insulation

The construction of Finnish houses, by analogy with modern frame houses, was very common in the vast Russian expanses in the post-war years of the last century. They were designed for insulation with bulk materials - slag, peat, baked clay, and their mixtures with local, historically used insulation materials.

Frame buildings were erected quickly, technology made it possible to use unskilled labor, and construction costs were affordable. Mass housing was built similarly in other countries of Europe and America.

Today, the construction of frame houses is extremely popular all over the world; it has preserved the idea: a house should be built quickly and inexpensively.

But with the development of technologies for the production of building materials, bulk materials gradually disappeared from the list of insulation materials. There is only one reason - the low technological efficiency of the process of filling insulation into the wall frame. There is a suspicion that the use of inexpensive materials is simply unprofitable for manufacturers of various modern, chemical-rich insulation materials. The issue is controversial, but a return to bulk fillers for frames is being observed.

The main reason for the rejection of expanded clay and other loose insulation materials is considered to be their significant compaction during operation with the subsequent loss of insulating properties. Natural compaction does occur and cannot be avoided. But technologically the problem can be solved simply and very inexpensively - as compaction progresses, it is necessary to add an additional top layer of material to replace the settled one.

To do this, during construction it is planned to install technological holes in the upper part of the walls, sometimes under window openings. The process is simple, inexpensive, and does not take much time to complete. The lifespan of fill-in insulation like expanded clay is very long, and the price is low. Various films, construction cardboard and other inexpensive materials can be used as insulating layers in the frame.

The nuances of brick lining

It is preferable to carry out brick lining 3-4 years after construction. During this time it will dry out and shrink.

This insulation option requires compliance with a number of conditions:

- A solid foundation. Concrete or metal structures are used for the frame. If the base is fragile, you should create a separate base for the brickwork 25-30 cm wide.

- Creating a layer. There should be a small distance (5-6 cm) between the masonry layer and the wall of the house for ventilation. Ventilation prevents the accumulation of moisture and mold.

- Connection installations. The wall and masonry must be fastened. You can use nails; the gaps are additionally insulated with expanded clay.

- Strengthening openings. It is recommended to install concrete lintels over doors and windows. They are highly durable and compatible with brick.

- Strict adherence to a straight line. The brickwork must be vertical, otherwise, due to the presence of an air gap with the house, it will collapse.

Brick consumption is about 50-55 pcs. per 1 sq. m with a seam width of 13 mm. It is better to dilute the solution based on sand and cement in a ratio of 4: 1.

Insulating a house with bricks.

Gap in brickwork

Brick has a high level of water absorption. Therefore, when facing a house with brickwork, ventilation gaps are made to ventilate excess moisture. The thermal insulation properties of brick walls are not high enough, and in order to create comfortable living conditions, insulation is a prerequisite for the construction of houses from this building material. When using the method of three-layer masonry of load-bearing structures with internal insulation, gaps are also left for ventilation.

Work technology

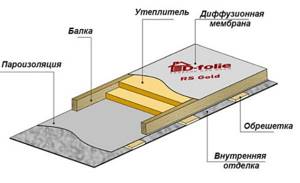

The most effective will be the insulation of the interfloor ceiling if it is carried out during the construction process. It is in this case that all the subtleties can be taken into account and all available materials can be used.

If the interfloor ceiling is not yet ready, but only consists of a set of wooden beams laid on load-bearing walls, it is necessary to install a vapor barrier layer on the lower surface, and then hem the ceiling of the lower floor. As a result, if you look at the ceiling from the upper floor, it will look like several long boxes formed by the beams and ceiling covering.

It is in these boxes that you need to put the insulation. After the material is laid in the space between the beams, it must be covered with a second layer of vapor barrier. Sheets or panels must be overlapped and glued together. Logs are installed immediately along the top layer of vapor barrier, on which the floor boards of the upper floor will subsequently be laid.

If you are insulating a finished interfloor floor, as often happens during major renovations of residential buildings, the insulation will have to be installed on the underside of the floor. To do this, a frame is installed on the side of the ceiling of the lower floor or basement using wooden bars or metal profiles. Insulation is secured between the frame elements using special fasteners. Next, a lower layer of vapor barrier and a ceiling covering are mounted along the frame, close to the insulation.

Ventilated façade cladding

Almost any materials can be used as cladding on a ventilated facade; the only limitation can be the low load-bearing capacity of the base. In this case, only lightweight materials are acceptable. Ventsads are usually lined with:

- siding - vinyl, acrylic, metal, fiber cement, base panels from the listed groups;

- slabs - mainly OSB and DSP with decorative elements for half-timbering or with further cladding with flexible facade tiles or flexible bricks;

- tiles - often concrete, with integrated fasteners for fixing to the subsystem;

- porcelain stoneware - for the subsystem and clasps;

- wood - lining, planken, thermowood, edged and unedged boards, imitation timber, etc.

Advantages and disadvantages

Before you start insulating your home, you need to weigh the pros and cons. Of course, many are interested in what benefits will come from this method of insulation. These include:

- fast speed of insulation, even if a large surface is processed;

- foam is not subject to biological influences, mold or mildew is unlikely to appear on the wall;

- low-flammability material: it can only melt at temperatures above 80 degrees;

- there is no need to first attach the frame to the facade - this saves effort, time, and money;

- a monolithic surface is obtained without seams into which cold air could penetrate;

- When insulating pipes or other metal elements, a sufficiently dense layer is created, through which moisture will not seep through and corrosion will not appear.

But, like any other insulation method, it has its drawbacks. You should know about them in a timely manner:

- should not be exposed to direct rays;

- inability to interact frequently with water;

- cost of material: to insulate large areas you will need to buy or rent special equipment;

- insufficient level of vapor permeability, artificial ventilation will have to be installed inside;

- You cannot perform the application procedure without a tarpaulin suit, a respiratory mask with goggles and gloves. Of course, all this is unlikely to be found at home, and this is also an extra waste of money.

People have long begun to insulate their homes with foam, but the ideal means of insulation has not yet been invented.

Of course, the effectiveness of this method cannot be disputed. The main thing is to buy high quality materials. If you have equipment for installation, the process will not take much physical effort and time. After applying the foam composition and after it has completely dried, craftsmen advise treating the surface of the facade with a special coating, which can be purchased at any hardware store. This is required first of all to protect human health, and only then - to protect the insulation itself.

What are the methods for facing aerated concrete blocks with bricks?

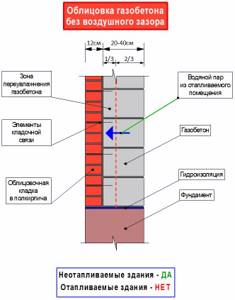

A gas block wall can be covered in several ways. This refers to the distance between the brick and the aerated concrete block, as well as the presence of insulation, if there is a gap between the wall and the cladding. Let's look at each of them in detail.

Dense masonry without gaps and ventilation

The danger of rapid destruction appears when it is planned to use a heated room. That is, the difference in temperatures inside and outside the house will significantly reduce the service life of such a building. When the room is heated from the inside, water vapor will begin to move out through the porous aerated concrete. If there is no gap or insulation, they will accumulate between the gas block and the brick, destroying both materials. In this case, condensate accumulates unevenly, which accelerates the process of decay and deformation of the structure of the gas block. The most cost-effective option would be to use external insulation in the form of mineral wool or wet plaster finishing. A similar finishing of aerated concrete with bricks (without a gap) is applied only to unheated buildings.

Bricklaying at a distance from aerated blocks without ventilation

The rules SP 23-101-2004 (Design of thermal protection of buildings) contain a regulation on the principle of the arrangement of layers between the wall and the cladding surface, which states that the closer to the outer layer of the wall, the lower the vapor permeability of the material should be. In accordance with paragraph 8.8, layers with greater thermal conductivity and vapor permeability should be located closer to the outer surface of the wall. British experts, after conducting a series of studies, explained that it is necessary to arrange the layers so that the vapor conductivity to the outer layer increases with a difference of at least 5 times from the inner wall. If this cladding method is chosen, then according to the rules of paragraph 8.13, the thickness of the non-ventilated gap must be at least 4 cm, while the layers are recommended to be separated by blind diaphragms made of non-combustible material into zones of 3 m.

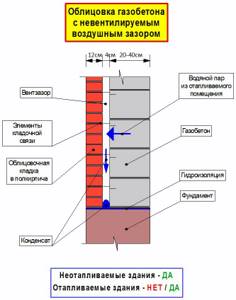

Finishing aerated concrete with bricks with ventilated space

This cladding method is the most rational in terms of the technical characteristics of materials and the durability of the structure. However, the construction of such a structure must be carried out according to certain rules (SP 23-101-2004 clause 8.14).

Let's consider how to line a house made of aerated concrete with bricks with a ventilated gap between the masonry according to all the rules. The air space must have a thickness of at least 6cm, but not exceed 15cm. In this case, the aerated concrete wall itself serves as thermal insulation . If the building has more than three floors, then perforated partitions are placed in the gaps (once per 3 floors) to cut off the air flow. The brickwork must have through ventilation holes, the total area of which is determined according to the principle: for 20 sq.m of area there are 75 sq.cm of holes . In this case, the holes located at the bottom are made with a slight slope outward to drain condensate from the wall cavity.

In the event that it is planned to insulate an aerated concrete wall in addition to the air gap, then thermal insulation materials with a density of at least 80-90 kg/m 3 are used for this purpose. The side of the insulation in contact with the air layer must have an air-protective film on the surface (Izospan A, AS, Megaizol SD and others) or another air-protective shell (fiberglass, fiberglass mesh, basalt wool). It is not recommended to use ecowool and glass wool as insulation, as these materials are too soft and not dense enough. It is also not allowed to use polystyrene foam and EPS due to their flammability and vapor barrier characteristics. When walls made of aerated concrete are faced with bricks with additional insulation on aerated blocks, soft, loose, flammable materials are not used. The vapor conductivity of these materials must be quite high to avoid the formation of condensation.

Let's sum it up

So, what conclusions can be drawn about the methods of facing aerated concrete walls with bricks? For convenience, we summarize the features of each cladding method in a table:

| Characteristics | Cladding without gap | Cladding with gap without ventilation | Cladding with ventilated gap |

| Brickwork | + | + | + |

| Protection of aerated concrete walls from external influences | + | + | + |

| Thermal insulation | Insignificant increase | Increase (resistance of brickwork), decrease (moisture content of aerated concrete wall increases) | No increase (ventilation of space between walls) |

| Service life, building destruction | The service life is reduced by 60%. | Reduction due to humidity and condensation. | No reduction or increase due to the absence of condensation and controlled air circulation. |

| Construction costs | Costs for foundations, expansion (up to 15 cm), bricks, mortar, and flexible connections increase. | Costs for foundations, expansion (up to 19 cm), bricks, mortar, and flexible connections increase. | Costs for foundations, expansion (up to 21 cm), bricks, mortar, and flexible connections increase. |

| Cost-effectiveness and feasibility | Economically unprofitable due to reduced thermal insulation and service life. | No particular benefit in most cases. It is advisable only in an even, temperate climate that does not require heating the building from the inside. | It is not economically profitable, but it is advisable if brick cladding is required on the outside of heated buildings. |

Thus, by covering an aerated concrete wall with bricks, it will not be possible to save significantly on materials, and it will also not be possible to increase thermal insulation. The only positive aspects are a respectable appearance and an increase in service life, but this is achieved subject to the correct organization of construction processes, the use of materials and technologies recommended by SP 23-101-2004.

Video: how to properly line a wall made of aerated concrete with bricks

Insulation foam rating

The market offers a wide range of insulation foam from various manufacturers. This makes her choice somewhat difficult.

To avoid mistakes using low-quality substances, you should pay attention to products from well-known manufacturers:

- Polynor. Popular sprayed insulation based on polyurethane foam. Very easy to use and has good vapor permeability . With its help you can create a high-quality and durable thermal insulation layer. The cost of a cylinder is within 450 rubles.

- Sipur. The material is lightweight, which allows it to be used for facade insulation. It easily withstands extreme temperatures. The cost of one cylinder is about 430 rubles.

- Teplis is a polyurethane insulation material that is widely used for thermal insulation of apartments, industrial buildings, balconies, loggias and other structures. Made from polymer materials. It has high heat and sound insulation properties. The cost of one cylinder (1000 ml) is approximately 650 rubles.

- Ecotermix. Modern popular sprayed insulation. Widely used for thermal insulation of various structures. To facilitate the application process, they began to produce it in the form of cylinders. Depending on the thickness of the layer, the cost of insulating 1 m2 will range from 470 to 1300 rubles.

- Heatlok Soy. Two-component sprayed insulation having different densities. It is made from soy extract, vegetable oil, and plastic production waste. The material is securely attached to any structure, which improves its load-bearing capacity. The thermal conductivity of polyurethane foam is at a high level. The cost of insulation using such a substance will be about 400-1100 rubles. for 1 m2.

Ventilation and drainage boxes

Ventilation and drainage boxes are used in the façade ventilation system. They come in two types: ventilation and drainage element for a 10 mm seam and ventilation and drainage element for a 10 mm seam

The facade ventilation system is quite simple to create and consists of only two elements: an air gap 10 cm wide with a distance between the heat-insulating layer and the façade layer of 4 cm and ventilation holes - vertical seams between the bricks that are not filled with mortar, into which the ventilated elements of the facade are mounted.

Before starting the construction of the first row of masonry, it is necessary to lay a waterproofing layer (an apron made of bitumen mass), along which condensate will flow freely through the ventilation holes to the outside. Similarly, waterproofing should be laid over each opening of the building.

Ventilation holes are located in the first and last rows of brickwork. If the wall height is more than six meters, another row of ventilation holes is additionally located in the middle of the wall. At the same time, the distance from the corners of walls and openings to the first ventilation hole should not be less than 25 centimeters.

Horizontally, the holes are placed at a distance of 1 meter from each other (every 4 bricks). At the same distance, ventilation holes are located under and above the openings, but at least two holes for each opening. Vertically, the holes are placed directly above each other, and in no case in a checkerboard pattern.

Correct placement and installation of fans is a guarantee of their effective use, which means long-term preservation of the reliability, strength and ideal appearance of your facade.

Location of ventilation boxes

Advantages of ventilation boxes:

- The inner surface of the facade is dried, which ensures its durability.

- Salt stains do not appear on the ventilated façade and mold does not form.

- The insulation is drying out. Only dry insulation meets all thermal insulation requirements.

- According to studies conducted in Germany, the thermal resistance of a wall with a ventilated air gap is 6% higher than a similar wall without an air gap.

Benefits of wood

Floors are horizontal structural elements of buildings and structures that divide them into floors or separate them from technical rooms (attic or basement). Depending on what material the building is constructed from, the floors can be monolithic, prefabricated reinforced concrete or wood.

For the construction of a private house, floors on wooden beams are most suitable, since their weight is less than that of structures made from other materials, and constructing them with your own hands is cheaper and easier.

Wooden interfloor ceilings can be installed in houses made of any material, with the exception of monolithic reinforced concrete. They are erected simultaneously with the construction of the walls, as the latter are built to the height of the next floor. In frame wooden buildings, floors can be made simultaneously with the construction of the frame of the entire building, even before it is insulated and covered.

Perlite chips have excellent performance qualities. It has been performing its functions for many years, maintaining its original condition without losing its visual appeal.

Perlite has high physical and technical properties, which is why it is so in demand; it is the best among thermal insulation materials.

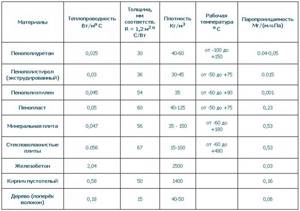

Requirements for insulation

All modern insulation systems are based on the axiom that the best heat insulator is an air layer. Thermal insulators are usually called materials with a thermal conductivity lower than that of wood, while the lower its density, the higher the thermal insulation performance.

For a frame house, the basic requirements for insulation can be formulated as follows:

- It must have long-term dimensional stability, that is, not sag over time;

- Have a minimum density, or in other words, be as saturated with air as possible;

- Have a low thermal conductivity;

- Be moisture resistant;

- Have good fire safety and environmental friendliness of the composition.

How to use foam insulation

When using foam in cylinders for insulation, certain rules are followed. First of all, you should seriously think about safety precautions. To do this you need:

- Purchase a special suit in which the work is carried out. This is especially true for large-scale thermal insulation when special equipment is used. If we are talking about insulating a small section of the structure, then you can get by with old clothes.

- During the spraying process, use safety glasses, gloves and respirators. This will protect the respiratory organs, skin and eyes from toxic substances that are part of the insulation.

- You need to purchase a special solvent in advance, which removes even the hardened composition.

Important! Do not neglect safety precautions, as your health depends on it.

Spray insulation is used according to the manufacturer's recommendations. Often instructions for use of the composition are applied to the container or packaging.

Features of thermal engineering calculations of the external walls of a building by analyzing the insulation used

It is important to determine which insulation is best to use, as well as the required level of strength, durability, fire resistance, etc. parameters for building a house. Cold air that exists outside the house and warm air inside can, if the insulation and its thickness are chosen incorrectly, create condensation on the walls, this is especially true in basements where humidity is high. Such a side layer should be selected taking into account thermal conductivity.

An example will be given to help you understand the principle of calculations more easily. In the house, calculations are being made for a corner residential type room, in which there is 1 window measuring 8.12. The building was built in the Moscow region. The thickness of the walls is 200mm, the size of the area according to external criteria is 3000x3000.

It is necessary to find out the required power to warm one square meter of area. The answer will be Qsp = 70 W, if a thinner insulating material is installed, then more power will be required: 100 mm – Qsp = 103 W.

Such a side layer should be selected taking into account thermal conductivity.

Insulation of wooden floors

As a rule, the ceiling located under a cold roof is insulated from the attic side. To do this, the first step is to hem the ceilings from below so that mineral wool or expanded clay can be safely laid between the beams. The filing will serve as a support for it, which means it must be designed for the appropriate load. This is especially true for expanded clay or clay with sawdust, whose weight is quite significant.

The second important stage is laying a vapor barrier layer. It is well known that mineral wool absorbs moisture well, so do-it-yourself attic insulation should include a protective layer of film and an air gap for ventilation. Due to this, water vapor from living quarters will not get inside the insulation, and those that condense on the vapor barrier will erode through the air gap. The general layout of the thermal insulation layer on the ceiling under the roof is shown in the figure:

The film sheets should be laid with an overlap of at least 10 cm on each other, after which the joint is carefully taped with construction tape. The organization of the air opening is carried out by installing an internal sheathing of bars up to 50 mm wide, to which the finishing coating of the ceilings is nailed. On the roof side, the insulation is covered with a diffusion membrane, which protects from wind and water droplets, but allows steam to pass through.

How to do thermal engineering calculations of house walls

Carrying out these calculations should help to find out whether the structures have the same requirements for thermal protection. Determines the quality of the created microclimatic conditions in the room. Is the heating system able to achieve the required level of thermal comfort?

To achieve optimal conditions, a balancing temperature regime must be created between the internal enclosing structures and the room. If it is not recreated, then all the heat will go into these zones and will not reach the main living area.

The temperature indicators inside the building should not be significantly affected by changes in heat flows. This level is called heat resistance.

As a result of the calculations, the best options are obtained for the dimensions of the wall covered in thickness, and the minimum and maximum values are calculated. As a result of observing these results, the room will not freeze or overheat for many years.

To achieve optimal conditions, a balancing temperature regime must be created between the internal enclosing structures and the room.

Basic parameters required to perform calculations

Heat transfer is calculated taking into account a number of parameters, without which it will not be possible to obtain the correct numbers. What they will be like is determined by the characteristics described below:

- The purpose of the structure and its appearance;

- Vertical orientations of structural fences according to the cardinal direction;

- Geographical location of the planned house;

- The size of the structure, how many floors there will be, total area;

- Types of windows and doors that will be installed, as well as their sizes;

- Type of heating and its technical features;

- How many people will permanently reside in this building;

- What type of material are the vertical and horizontal structures that serve as fencing made of?

- View of the ceiling of the last floor;

- Availability or absence of hot water supply;

- What type of equipment will ventilate the house.

Heat transfer is calculated taking into account a number of parameters, without which it will not be possible to obtain the correct numbers.

Complex insulation of a bathhouse with insulation and foil

Just like any other reflective insulation, sauna insulation with foil is installed indoors. In this case, the shiny side should face the middle. This type of thermal insulation for use in a bathhouse has many advantages:

- reflects IR rays, of which there are a huge number in the steam room;

- does not allow moisture and steam to pass through, although it does allow moisture and steam to pass through at the joints;

- does not enter into any chemical reactions.

To prevent moisture from entering the thermal insulation layer, the foil insulation for the bathhouse at the joints is glued with special aluminum tape. The task is to create a continuous screen so that heat cannot escape outside the room, similar to the principle of a thermos. It is also worth noting that only foil thermal insulation for a bath made of mineral or stone wool is laid in the steam room. For other sauna rooms, where temperatures are not so critical, foam plastic is also suitable.

In order for heating a house with diesel fuel to be used as the main method of heating a home, you need to acquire a fuel and lubricants warehouse where you will store diesel fuel reserves. Sellers have a minimum order for delivery, usually starting from 500 liters.

You can read about what types of garage heating equipment are available in this article.

Installation methods

In order for the insulation to lie tightly in its cells, the distance between the guides should be 3 cm less than the width of the roll.

The thickness of foil insulation for the floor, walls and ceiling must be at least 50 mm. It is advisable to use the same material for complex insulation, but it will not be a mistake if you insulate the ceiling with foil insulation using thicker rolls or mats. The fact is that the main amount of heat comes out through the ceiling, so it should be insulated especially carefully.

It must be remembered that mineral wool is prone to absorbing moisture, and when it gets wet, it loses its insulating qualities. At the same time, it does not release moisture well, and in the cold season, when the temperature outside drops below zero, the moisture in the wool layer even crystallizes, that is, turns into ice.

What kind of foam can I use?

You can create a heat-saving layer using several types of spray foam insulation. Each of them differs in its technical operational characteristics, but the choice, as a rule, is made on the basis of one’s financial capabilities and equipment. Available in stock. To understand which option is right for you, you need to know the differences between different types of foam:

- Penoizol is offered in stores in the form of slabs or liquid composition. In terms of technique, this will be one of the most difficult methods. To obtain the finished composition, you will have to mix in certain proportions a special liquid foam, a hardener or polymer resin and a device for mixing the components.

- Polyurethane foam in cylinders. The simplest option from a technical point of view. You just need to buy a lot of cylinders and that’s it. No special equipment is needed.

- Liquid polyurethane foam. The optimal option in terms of costs and quality of insulation. Polyurethane foam is formed by mixing two liquid components in a special mixer connected to a compressor.

Important: any of the compositions involves the creation of complete insulation - the walls will become vapor-tight. Therefore, in order to avoid the appearance of fungus and mold, it is necessary to take care of good air exchange and provide high-quality ventilation in the house.

You should choose the material based on the ability to rent or even buy the equipment necessary for the work. Installations for mixing and spraying liquid components are quite expensive, but they can be rented, significantly reducing the cost of insulation compared to the case. When insulation is carried out by a team of specialists. Using foam canisters over a large area will be unreasonably expensive. Such compositions are more suitable for insulating small sections of the wall where insulation is required.

Which variety to choose

In many ways, the choice will depend on the specific situation and what area needs to be treated. Using an example, we can consider the most common cases when a house needs foam insulation:

- If you need to seal cracks or eliminate any other defects on the surface, then polyurethane is suitable. But such material should not be exposed to sunlight.

- If you need to fill a large volume, then penoizol is suitable. But an ordinary cylinder will not be enough; you will need to purchase a special device with high pressure. You don’t have to buy it at all - you can rent it or borrow it from friends, because no one will use it often.

- If you need to seal small cracks and carry out thermal insulation in small areas, you can buy a cylinder with regular polyurethane foam. It does not support combustion, after hardening it is particularly hard, and it has an ecological composition.

- If defects are found on the outside of the wall, then you need to apply a composition based on polyurethane. It is applied directly using a special cylinder or apparatus.

It is worth remembering that foam insulation creates errors inside the layer that need to be eliminated. To do this, you will need a long hose to push the material inside. If it is necessary to fill air gaps inside the insulation, then holes are made in the wall with something sharp.

Additional findings and recommendations

The laying of communications and hidden engineering systems must be carried out before installation of the decorative facing layer. Electrical wires are installed in cable channels. They can be flexible or rigid, made from various materials. The main task of the wiring channels is to protect the building from fire in the event of a short circuit.

When installing inside the walls of the water supply system, there should be no inaccessible detachable pipe connections. The slightest leak, not detected in time, can lead to destruction of the insulating layer.

Insulating the walls of a country frame house with irregular residence with polystyrene foam and other materials is possible from the inside. In other cases, preference should be given to external insulation. This is due to the fact that the dew point during internal insulation is transferred inside the frame, which causes gradual destruction of the insulating layer.