A common and even advertised home siding option includes insulation. Thus, heat loss is prevented, wall protection is improved, and additional sound insulation is provided, which is a mandatory element when using steel slats. However, there are a number of cases when the building does not need insulation. How to properly cover a house with siding without insulation is not such a simple question.

Installation process

The issue of vapor permeability

The building wall in SNiP is described as a multi-layer enclosing structure. Interior decoration - wallpaper, for example, plaster, the wall - monolithic, with voids, double, and exterior decoration - this is the simplest version of its construction. If thermal insulation is assumed, the design becomes much more complex.

Obviously, the ratio of different materials in such a “pie” cannot be random and is subject to a certain pattern. It sounds like this: the ability of a material to remove steam should increase from layer to layer from the inside out.

Why is this necessary? In a residential building, a constant source of steam formation is not only a gas stove or water in a sink, but also people, animals and plants. Steam released through breathing or during washing and cooking is removed using a ventilation system or simply through an open window, but also through the walls of the building. If this does not happen, moisture accumulates in the room, and condensation falls on surfaces - walls, furniture, clothing.

- This case is best illustrated by a bathroom in a multi-story building, where there is almost never good ventilation. After taking a bath or even a shower, the entire room from the ceiling to the handles on the washing machine becomes wet. Why? The bathroom is finished with tiles or tiles; this material is completely vapor permeable, and therefore moisture is not removed at all. The dew point is condensation, located inside the living space on the walls.

- Option two is thermal insulation inside. A solution that builders try their best to avoid. Compared to a brick wall, the vapor permeability of insulation is much higher, therefore, in the design - finishing / insulation / wall, the most vapor-permeable element is mineral wool or polystyrene foam. Condensation falls in the thermal insulation area and quickly destroys the material, which makes waterproofing necessary.

- If insulation is carried out from the outside, then the “pie” looks like this: wall/insulation/cladding, and, again, the dew point falls on the thermal insulation layer, since the cladding absorbs moisture much less. To prevent this from happening, the insulation is protected with hydro- and vapor barrier. Then the dew point ends up in the air gap between the wall and the insulation, for which purpose a substantial ventilation gap is left here during installation.

Installation of siding without insulation

- But if the walls of the building themselves have high thermal insulation characteristics - a brick wall of sufficient thickness, for example, then there is no need to additionally insulate them, but they do need to be protected from wind and rain. Do you need waterproofing and wind protection for siding without insulation?

The design looks much simpler: wall/cladding. However, the vapor permeability of the wall is higher than that of both metal and vinyl finishes, that is, the rule for increasing vapor permeability occurs and the dew point ends up in the area between the wall and the finish.

To avoid moisture accumulation, a ventilation gap is left between the finish and the wall. Therefore, installation of finishing without thermal insulation is quite possible, but without sheathing - not. If there is an air layer, then condensation accumulates on the inner surface of the finish, which is insensitive to water; if not, then directly on the wall, which leads to its destruction.

- Is waterproofing required here? It is not needed, since during sheathing its task is to protect the insulating layer, which in this case is not used.

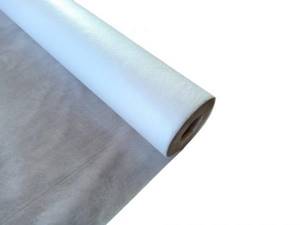

- Do you need a vapor barrier for siding without insulation? Vapor barrier or wind protection is a vapor-permeable membrane that allows steam to pass in both directions, but water only in one direction, away from the heat-insulating layer. Again, if it is not there, then there is nothing to protect. Siding technology without insulation

Installation without heat and vapor barrier is much simpler.

- The surface of the facade is cleaned. Old finishing, if any, must be removed. If you plan to cover a wooden house with siding without insulation, then before work you should caulk the cracks between the beams or logs - this procedure will significantly reduce heat loss.

- A sheathing is fixed to the surface - made of a galvanized metal profile or a wooden beam treated with an antiseptic. The thickness of the timber should not be less than 50 mm, despite installation without thermal insulation.

- The pitch between the frame elements, as well as the direction - vertical or horizontal, are determined by the type of siding - lamellas, panels, and installation method.

- The material is fixed to the sheathing using the usual method: first, the starting strip is fixed, then the corner elements and near-windows, and the connecting profiles are fixed, if necessary.

- Then the panel is inserted into the groove of the starting strip and fixed to the sheathing. The fastening is not rigid; a film under the siding without insulation is not needed.

The photo shows one of the working moments.

Hand on heart, it is better not to insulate houses made of solid wood at all. High-quality massive logs and beams, being preserved in their natural form, provide an optimal microclimate in the house. Wood, unlike most other wall materials, “breathes”, this is one of its main advantages. However, if the wooden walls are not thick enough, or if the house has stood for many years and the logs need protection from external influences, external insulation and cladding are justified measures that help reduce heating costs and extend the life of deteriorating wood. The most practical material for the exterior cladding of a wooden house is vinyl siding. It is inexpensive, has a service life of half a century or more, is easy to install, and can be repaired without problems. A house covered with siding looks neat. We'll tell you what proper insulation of a wooden house under siding should be like.

To improve thermal insulation without worsening the microclimate or harming the structure, you need to understand the specifics of the construction and operation of a wooden house. Let's start with theory: a little about woodworking and a little bit of construction physics.

Features of installation of vapor barrier films

If you create protection with a vapor barrier film, then when purchasing, carefully read what the coating is intended for. Vapor barrier is often confused with waterproofing. In our case, the film should not allow steam to pass through. Waterproofing films are permeable to steam. They create a barrier only for water. This option is not suitable for us, since if steam penetrates into the insulation, then there is no point in creating a vapor barrier at all.

You also need to pay attention to which side to lay the vapor barrier. The manufacturer indicates this in the instructions, but if you did not find instructions, then the principle of laying out the roll is as follows: lay it on the log with the side that is adjacent to the roll as it rolls out, i.e. external.

Among the waterproofing films, there is one type that can also be installed as a vapor barrier. They are called anti-condensation films. One side of such films is smooth, and the other is fleecy due to the cellulose layer. Look carefully at which side to attach the vapor barrier: the smooth side is fixed to the log, and the fleecy side will face the insulation. Why is this so? The smooth side creates protection for steam. But no film can give a 100% guarantee that steam will not leak inside, because even the manufacturer does not provide this guarantee. Moisture that gets onto the inside of the anti-condensation coating does not flow down, but gets entangled in the cellulose fibers, and then comes out with the air flow through the ventilation gap. This property is very beneficial for insulation, which will not absorb moisture flowing from below and will remain dry.

Vapor barrier device outside the house

Wood moisture and harmful fungi

We all know how quickly wood that is constantly in a damp state is affected by mold fungi. The loss of strength of the material occurs in a matter of months, and in a year or two a log, in the thickness of which favorable conditions have been created for the life of fungi, can turn into dust. The main condition for mold growth is a sufficient amount of moisture. Accordingly, in order to preserve a wooden house for many years, its walls and other structures must be protected from waterlogging. The absolute humidity (the ratio of the mass of water to the weight of absolutely dry wood) of a freshly cut coniferous forest reaches 90%, of a log house before installation - 25-35%, of a wooden house, which has stood for a year under normal conditions - 10-20%, depending on the season. At the same time, fungal infection of wood begins to develop at a moisture level of 22%, which is only slightly higher than the natural state of the log house. By the way, these same conditions are suitable for wood-boring beetles to settle in logs.

It is important to know: under no circumstances should wood be allowed to become over-moistened - the main cause of its destruction.

Over-watering wood causes it to rot.

Where does moisture get into wood?

There is an opinion that moisture enters the walls of a wooden house from the outside with slanting rain, fog and snow. Precipitation actually moistens the walls. But wet weather does not last so long; the sun and especially the wind help to quickly remove excess moisture. An attentive reader will tell you: the average annual air humidity outside is 78% (data for the Moscow region), and in the house it fluctuates between 40-70% - which means there is more moisture outside and it should penetrate from outside to inside.

But actually it is not. The fact is that climatologists operate with relative humidity, this is the ratio of the proportion of water vapor to the maximum possible, taking into account the temperature. And the colder the air, the less moisture it can contain. To understand the real moisture content in the air, absolute humidity values are used in building physics. In the summer, when the temperature outside and inside the house is approximately the same, the humidity is similar. But in winter and in the off-season the picture is completely different. For example, at an outside temperature of -20 ºС and a relative humidity of 80%, the absolute value will be 0.6 g/m3, and inside the house at 20 ºС and a relative humidity of 60%, the absolute value will be 10.4 g/m3. Accordingly, the actual moisture content in the air inside the house is 17 times higher. It is not surprising that wood, like a pump, absorbs moisture from the inside and releases it to the outside through micropores and joints between logs filled with flax, moss, jute or other “breathable” inter-crown insulation.

It is important to know: most of the year, with the exception of the warm period, water vapor penetrates the wood from inside the house and tends to escape outside, the greater the quantity, the colder it is outside and the warmer it is in the house.

How steam is formed and transported

Saturation of warm air with steam occurs:

- from the breath of people and pets;

- in the process of plant life;

- during cooking, washing, ironing, etc.

The heating season in our latitudes lasts more than six months. The air temperature inside the room at this time is significantly higher than outside. Warm air is able to absorb more moisture than cold air, so the absolute saturation of air with water vapor is higher than atmospheric. Steam pressure is created, which tends to escape outside, where its concentration is lower. In addition, there is a process of convection, or the movement of warm air upward into a cold area, since warm air has less density. As a result of these processes, moisture is transferred from the living space to the area where the insulation and supporting structures are located.

Ventilation – vapor barrier – wind protection

We found out that a prerequisite for maintaining a log house and a healthy microclimate in it is that the insulation of the walls of a wooden house under the siding should not prevent the free escape of water vapor to the outside.

Modern designs in wooden (and not only) house building involve the widespread use of vapor barrier and windproof films. The first ones are absolutely sealed and do not allow air or steam to pass through. The latter repel water droplets, but do not prevent the penetration of water vapor. In frame houses, the inside of the wall is covered with a vapor barrier, thereby preventing the penetration of moisture from the premises into the insulation and wooden structures. From the outside, the walls are “wrapped” with wind insulation: it counteracts the blowing of the insulation, prevents drops of water from the outside from getting inside (condensation can form on the inner surface of the siding), while water vapor freely escapes outside. Since the insulation is covered with finishing material (in our case it is siding), there must be a ventilation gap between the insulation and the finishing so that excess moisture can leave the wall structure.

It is important to know: the ventilation gap is a mandatory element of the insulation design for siding and other cladding materials.

Many shabashniks, Internet sources, managers of construction companies and even professional builders claim that the same should be done when insulating a house made of solid wood. That is, the first layer, along the logs, is a vapor barrier, then insulation, on top of which is wind protection, the design is completed by a ventilation gap and finishing material, siding in our case. This does not take into account that moisture rushing out will encounter the vapor barrier, the humidity in the area adjacent to the vapor barrier will increase, and condensation will form when the dew point occurs. Conditions will be created for the germination of fungal spores, and from the inside we will not notice the beginning of wood destruction for a long time.

The windproof film (diffusion membrane) has many micro-holes, due to which steam passes through, while at the same time drops of water roll off the material

What do errors in terms lead to?

Manufacturers' marketers are interested in increasing sales of vapor barrier films and waterproof vapor-permeable membranes. They advertise their properties in every possible way, coming up with various names. Thus, the complex word vapor-waterproofing was created, which led to confusion of the characteristics of two completely different materials used to solve opposing problems.

Due to this, building owners can allow the installation of vapor barriers on both sides of the wall structure, when moisture cannot escape from the building elements and will create increased dampness and their destruction.

An even worse situation with moisture occurs when the location of the vapor barrier, which was installed outside the wall, is confused with the vapor-permeable membrane installed inside the room.

Then all the moisture from the room is directed into the wall, and its exit is blocked. As a result, mold, fungi, and dirt form.

The installation of protective film coverings must not be interchanged. They perform different, opposing functions.

The eternal question: what to do?

We support the point of view of those specialists in building physics and technologists working in the field of wooden house construction that a vapor barrier is not needed when insulating a wooden house. The only case when placing a vapor barrier between the load-bearing wall and the insulation can be justified is when the house (dacha) is used seasonally, is rarely heated in winter, or the rooms are kept at a minimum temperature and are well ventilated. With this operating mode, the difference in temperature and, accordingly, absolute humidity outside and inside is low. For a house where people live permanently, there are internal sources of moisture (people’s breath, steam from kitchen pots and showers, moisture from watering house plants), vapor barrier is more likely to do harm than good. It is not always possible to do without film, especially if the logs are uneven and the insulation is too soft or even filled in. In this case, as a limiting material between the wall and the insulation structure, wind insulation (with the highest vapor transmission value), building cardboard, kraft paper, and even spunbond that has served its purpose in the garden bed can be laid under the siding.

As a counterargument to the lack of vapor barrier, supporters of its placement say that insulation unprotected from steam penetration will become moist and its thermal characteristics will deteriorate. Alas, they are right. But the ventilation gap facilitates the removal of moisture, and a relatively small (5-15%) drop in heat-insulating properties is a forced sacrifice in the struggle for the durability of the building.

It is important to know: a vapor barrier is not needed when insulating a wooden house in which people live all year round.

This cannot be done if the house is inhabited year-round! Walls “wrapped” in glassine will become waterlogged and become defenseless against damage by mold fungi

Frame material and “correct” insulation

For the frame, only smooth wooden blocks, preferably antiseptic, should be used. The steel profiles that “sofa” craftsmen recommend using freeze, and condensation appears on them, which does not benefit either the insulation or the walls.

The cross-section of the bars must correspond to the thickness of the insulation; for mineral wool this is, as a rule, 5 cm. Accordingly, the bars are 5x5 or 4x5 cm. The recommended ventilation gap is 4-5 cm, therefore, for a counter batten that provides the required distance between the insulation and the siding, you can use the same material.

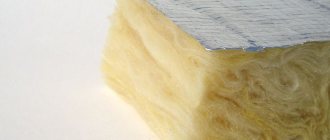

The insulation must be vapor permeable and lightweight. The most affordable are semi-rigid mineral wool mats; soft rolls should not be used, as they will shrink in the wall over time. Ideal for a wooden house, environmentally friendly, very durable, but alas, expensive material - linen and hemp mats. You can put cellulose wool and wool waste between the wall and the windbreak. Let us repeat, the main thing for insulation is vapor permeability. Mineral wool can be placed in two layers (10 cm) or one (5 cm). What the total insulation layer should be is decided based on climatic conditions and the thickness of the existing walls.

Linen mats have much longer fibers than mineral wool, so they hold their shape better and longer

It is important to know: polystyrene foam, polyethylene foam, sprayed polyurethane foam and other non-breathable materials are absolutely not suitable for insulating a wooden house.

Work production technology

The technology for insulating a wooden house under siding is quite simple; any “handed” man can perform such work.

- The distance between the bars should not exceed 60 cm; it is better that it is equal to the width of the insulation; for mineral wool it is 50 cm.

- We recommend mounting the first level of bars vertically. The second, if the insulation is laid in two layers, is horizontal. The counter-batten to which the siding will be directly attached is vertical.

Frame for insulating a log house with mineral wool in two layers.

- It is convenient to attach the bars to uneven walls using perforated plasterboard hangers. The traditional method will be labor-intensive, but preferable from the point of view of heating engineering: adjust the distance from the wall by placing wooden pegs. Screws will hold the frame in place better than nails.

Options for framing and insulation for siding.

- If the mineral wool mats are too soft, we recommend installing one or two horizontal jumpers in each vertical section, this will reduce the subsidence of the material.

- Having sewn the frame and filling the gaps between its elements with insulation, they attach the wind protection, and on top of it - the counter batten.

The frame is filled with insulation, the next stage is wind protection

- The final work is covering the wooden house with siding.

The “correct” design of wall insulation under siding with a double layer of mineral wool.

Free air flow must be ensured in the ventilated gap. To do this, gaps are left in the outer cladding at the bottom and top of the wall (covered with a mesh to prevent mice and insects) or grates are inserted into the siding panels.

It is important to know: ventilation holes must be located in the lower and upper parts of the wall cladding.

Not everyone has the capabilities and necessary skills to perform such work. If you don’t have confidence in your abilities, it’s better to entrust the insulation of your own home and covering it with siding to experienced craftsmen.

Video: wooden house - how to sheathe it and how to insulate it

(

votes, average:

4.96 out of 5)

Quite often you can feel a sharp cold snap indoors. Most often this happens when there is a strong gusty wind outside the window. This is especially typical for the autumn period. To avoid unpleasant sensations, you should choose the right insulating material.

A sharp gusty wind can cause cold temperatures indoors. Not all building materials can hold back a strong flow of cold air. Most often, such unpleasant situations occur in the autumn or spring. To combat such an unpleasant situation, there is a windproof film. Very often such insulation is neglected, but it is not always worth doing.

Siding used as a finishing material inside or outside a building unconditionally requires additional thermal insulation. However, whether special wind protection is needed for such material is worth finding out exactly, since its installation is associated with additional costs.

House finished with siding

As practice shows, most often siding panels are often used as exterior finishing material in the reconstruction of old buildings. Often, old buildings made of timber, wood, and brick are sheathed in this way. This method of reconstruction allows you to revive the building, giving it a modern, stylish look.

It’s worth noting right away that siding panels do not have thermal insulation properties, which is why we can say with confidence that you will have to work hard to create high-quality insulation.

Final Recommendations

Let's summarize the use of film materials for the home craftsman:

- In cold climates, the vapor barrier membrane is placed exclusively from the inside of the room, regardless of the type of building structure - wall or roof.

- In order for the vapor barrier to work effectively, it must be made as airtight as possible, using a construction type of tape with a butyl rubber base of glue, which effectively glues the film for the entire period of operation.

- An ordinary polyethylene film 200 microns thick works optimally as a vapor barrier. It is a good alternative to advertised “brand” models.

- The installation location for vapor-permeable superdiffusion membranes is the outside of the building.

- Before installing the membrane, it is necessary to clarify the distance of its location from the surface to be protected: close or at a distance. You can find out this in the instructions that manufacturers put in a roll of film and post on their website, and it is better to double-check the seller’s recommendations.

- The quality of vapor-permeable membranes is higher from well-known manufacturers from Europe and America.

To better understand the topic of vapor barrier and the role of vapor-permeable membranes that create waterproofing, we recommend watching a video by the owner of ASC Group.

Now it’s convenient for you to share the article with your friends on social networks and ask any questions you have in the comments.

Wind protection for siding – panels

During restoration work, it is safe to say that wind protection under the siding is necessary. Its presence will help protect the quality properties of the thermal insulation layer.

If the insulating layer fully performs its functions, then the following indicators are immediately visible:

- while maintaining the quality properties of the insulation, there is no need to constantly heat the premises in the building;

- the atmosphere inside the room cools down more slowly, which makes it much easier to maintain a certain temperature inside the room;

- if you have a high-quality insulating layer, you will protect the walls from possible freezing at low temperatures;

- among other things, remarkable sound insulation properties are revealed.

Mineral wool is most often used as insulation for external walls. This insulation has remarkable properties, but its use requires high-quality waterproofing. Since open penetration of moisture has a detrimental effect on the properties of any insulation.

Wind protection scheme for siding panels

Very often, the waterproofing film includes a windproof layer, which eliminates the need to purchase additional material. However, not every waterproofing material has these properties.

When windproofing, it is very important that individual pieces of material are sewn overlapping, and the joints are properly taped using a special tape.

Windproof film has a limited history of use. We can say that this is a new material that was specially developed for new facade materials with high ventilation rates. It’s worth saying right away that in this case, you cannot do without special wind protection, otherwise, with strong gusts of cold wind, the temperature in the room will quickly drop.

Types of windproof film

Currently, there is a great abundance of insulating materials. This nuance does not bypass wind protection, which is available on the modern market in several types, namely:

- Diffuse membranes. Using this material, not only waterproofing is performed, but also reliable protection of the insulation from wind loads. In this case, the material consists of several layers. For better results, it is recommended to use three or four-layer films. It is also worth noting that this material is also used to provide vapor barrier for siding. Diffuse membranes are considered the most popular insulation material today.

- Windproof film. Many companies are engaged in the production of such products. This material is designed to withstand strong wind currents, providing a reliable barrier to cold air. Such a film is characterized by resistance to heavy loads, which is why films with increased density are used as wind protection.

Wind bar

When cladding external walls using siding panels, it is important to pay attention to wind strips. This element allows you to contain loads from sudden gusts of wind. When using these elements, the facade siding wears out significantly less. This material allows you to significantly redistribute the load.

The use of a wind strip will not only significantly extend the service life of the cladding, but will also give a completed look to the façade of the building. It is worth noting that, as in many other cases, the installation of such elements is carried out with precise calculations and in strict sequence. Otherwise, the use of wind bars will not give the desired result.

Types of vapor barrier materials

You can find many different materials on the market designed for this purpose. To understand which one is better to choose, it is worth studying the main types on sale.

The vapor barrier membrane for walls includes polypropylene as the main material, with fiberglass mesh, which increases reliability. It also has a coating of cellulose-viscose fabric, it can be covered on both sides, or only on one; this fabric provides vapor and moisture insulation. Rough matter creates a barrier that prevents moisture from penetrating the wall and insulating element. This moisture then simply evaporates during natural ventilation.

Due to its multi-layer nature, the membrane “breathes”. By stopping moisture, the material allows a small amount of air to pass inside, which prevents the formation of greenhouses, the surface will “breathe” and can last for many years.

There are several types of film protection. The first polyethylene films are distinguished by the fact that they are reinforced with fabric or reinforcing mesh. What makes the product more reliable. They also have their own subspecies:

- Perforated, in which there are mini-holes that make them vapor permeable. But they do not perform this function well enough to obtain the necessary effect in the frame pie; they make a gap;

- Non-perforated, they are mounted using tapes created to fasten the canvases.

The downside is the tightness and fragility.

Polypropylene film materials have been used for a long time. The main positive properties are strength and resistance to UV rays. There is an anti-condensation layer that does a really good job of absorbing moisture.

The coating vapor barrier for walls is mastic, it is easy to work with. They are a solution; before use, it is stirred and applied to the surface to be treated; it is suitable for working with smooth surfaces; it can be used to process joints and seams. After drying, the coating becomes vapor permeable.

Liquid rubber

Liquid rubber is becoming popular today; it is a bitumen-polymer mixture based on water. It is very easy to work with and spreads easily on the surface. The coating appears after complete drying and takes on the appearance of rubber, which monolithically covers the surface.

This creates a vapor and wind insulation for the walls, as well as a sound insulation layer.

The types of this product can be distinguished:

- A composition that can only be applied using an automated method.

- Composition for manual application.

Other possible options

It is also necessary to mention this type of product, such as films laminated with aluminum foil, which also do an excellent job of vapor and waterproofing, but they can only be used in bathhouses and swimming pools.

Wind protection and its properties for siding panels

As practice shows, this type of building insulation, such as wind protection, is extremely necessary to create comfortable and cozy conditions inside the building. Very often, it is precisely because of sudden gusts of strong wind that it is impossible to stay in living quarters without warm clothes.

As for siding panels, many people mistakenly believe that air flows do not penetrate through them. This opinion is wrong. As practice shows, air flows pass everywhere. Because of this, simple siding cladding will not be enough, and you will need to install high-quality wind protection.

Windproof film attached to the facade of the house

Wind protection is a kind of membrane that acts as a barrier against harsh cold currents. This membrane is designed to restrain external air flows, but it allows air from inside. In case of installation, the main thing is not to make a mistake and install the film the other way around. Otherwise, it will be impossible to achieve comfortable conditions inside residential premises.

High-quality wind insulation must have the following properties:

- Protection of the structure from possible moisture penetration.

- The windproof layer completely covers the entire surface of the walls, while closing any possible gaps in the insulation.

- The surface of such a material should facilitate the removal of moisture, while preventing moisture from entering.

And ventilation of external walls

We must take care of the ventilation of the interior space simply because theory differs from practice and we are not able to make a 100 percent reliable vapor barrier.

Now let's return to the problem at hand.

If the underside of the exterior trim in a built house becomes wet, this means that the vapor barrier is made very poorly, the ventilation is not done at all, and this also means. that the wall is not insulated enough. It is this last statement that I would like to particularly comment on.

I am the humid air

Let's say I warm room air. I have steam. Somehow I got inside the frame wall and started moving towards the cold. Why am I moving from warm to cold? These are the laws of physics. Density difference and all that…. So I move myself and reach the insulation layer. I need to overcome it. Overcoming the insulation, I notice that the temperature around me is decreasing and for this reason I am losing my steam. It is deposited on the wool fibers right in its thickness. It is clear that as I lose moisture I become drier. But I still move on. Somewhere in the middle of the layer of cotton wool the temperature exceeded zero. In this case, I have already lost a lot of steam and left it behind right in the cotton wool, on its fibers. And when I had not yet left the cotton wool, but had already come somewhere very close to its outer edge, I felt that there was almost no steam left in me. And so I come out of the cotton wool and hit my forehead directly into a serious obstacle in the form of some terrible film or OSB sheets. Here I feel like a sperm in a condom (sorry for the hooligan example), and I start hitting against this film. BUT THERE IS PRACTICALLY NO STEAM LEFT IN ME, and on this film or OSB boards I leave some last and completely microscopic molecules of frost, which can only be seen under a microscope.

And rivers flow within our walls! What kind of insulation is this if warm air comes out of it?

Installation of a windproof layer

When installing a windproof film, as in the case of a waterproofing layer, the film is overlapped. All joints that are formed must be glued using a special waterproofing tape. In this case, it is necessary to use just such a tape, this will protect the structure from the penetration of cold air.

When choosing a tape, do not forget that this material must have good vapor permeability. There should be no difficulty in purchasing such products, since such a building element is usually produced by the same manufacturer as the wind and waterproof film.

As for the overlap, to achieve the best performance, it is recommended to do it at least 15 centimeters.

The film material is sewn onto the finished frame, which makes an indentation of 2 - 3 centimeters from the insulation. This gap is necessary for ventilation.

As it becomes clear, without high-quality wind protection, it is almost impossible to achieve comfortable living conditions. Its use is necessary for almost any coating of external walls. This material is used for insulation only of private houses, since its use in multi-apartment buildings is difficult. As for cladding a building with siding panels, there is no way to do without the use of windproof film.

Wind protection under siding is an important stage in building a house. This will help in the future to avoid heat leakage and destruction of the thermal insulation layer on the outer façade of the wall. In what cases it is necessary to install wind protection under siding and what its main role is, we will look into this article.

How to deal with condensation?

It is unpleasant when condensation drips from the roof, so any owner of a building tries to get rid of such a problem as quickly as possible. Getting rid of condensation initially allows you to use high-quality building materials, competent installation of the roof and insulation according to the instructions. Otherwise, various problems described above may arise, the fight against which may require a lot of time, effort and money.

Steam is such an interesting substance that it seeps out almost everywhere. Therefore, the vapor barrier must be properly taped with a special tape at the joints of individual sheets and at the junction with building structures.

If the problem of moisture formation is not severe, you will not need to re-roof. It is enough to find one or several reasons why condensation may appear, get rid of them, and you will forget about this unpleasant problem forever. What might you need?

- Use of high-quality material for steam and thermal insulation, competent installation of materials. You should not skimp on insulation: a high-quality product is always quite expensive, but it guarantees warmth in the house and the absence of moisture under the roof. Condensation will not form because warm and cold air will not collide. A good layer of thermal insulation should be at least 20 cm.

- Check whether the waterproofing membrane is intact. Many builders install waterproofing in tension, causing it to crack. The material should lie freely. The film contracts as the temperature drops, so it can tear if it is stretched too much. If the insulation is torn, it will not need to be replaced entirely. You will need a small patch made of the same material, with which the hole needs to be overlapped. You can attach the material using construction tape.

- It is important to pay attention to how all the roof elements were assembled. That is why you need to monitor the installation process, even if it is done by professional workers. If you do the roofing yourself, adhere strictly to the technology.

Conclusion: if condensation has formed on the roof, what to do can be decided based on what caused it. It can and should be eliminated in any case. You shouldn’t delay it, since a major roof repair if condensation is constantly in the attic may be required very soon, and it will cost much more than a simple repair, as a result of which the condensation will leave you.

Why do you need wind protection for siding?

Installation of wind insulation is necessary to protect buildings subject to high wind loads. At the same time, maintaining heat in a building is only half the battle, because the most important thing is to protect the insulation under the siding from premature soaking and destruction. Thus, wind insulation is also a necessary layer of protection for walls from moisture and steam penetration.

Wind protection performs the following functions:

- Protection of walls and insulation from exposure to steam and moisture.

- Reducing the likelihood of fungi and mold appearing on the inner surface of the walls.

It is important to adhere to the main rules for installing wind and vapor protection. The vapor barrier is placed under the insulation, and the windproof membrane is placed on top of the insulation. On top, all materials are decorated with siding.

What materials to use for wind protection

The most popular and widespread materials are special windproof films or windproof membranes. They reliably protect the facade of the building both from strong winds and from soaking of the insulation.

Considering that the films must be installed with an overlap, the edge must be reliably isolated from the penetration of condensation, moisture and wind. To do this, it is recommended to use special films with adhesive tape, which ensures complete waterproofing of the seam.

Films are suitable for wind protection under siding.

Ondutis A100 Smart

or

A120 Smart

. They are mounted directly on the heat-insulating material, thereby reliably protecting it from destruction. In addition, Ondutis films come with special instructions for proper use. Installation does not require professional skills, abilities or knowledge. The films can be used to install windbreaks with your own hands.