Engineering systems

This article is provided for informational purposes

. As is known, modern insulation materials used in

the production of sandwich panels need protection from moisture.

Firstly, water increases the thermal conductivity properties of any insulation, and with sufficient water content it can form so-called cold bridges. And, secondly, moving from one state of aggregation to another during temperature fluctuations, it can mechanically damage the structure of the insulation. All manufacturers of sandwich panels go to all sorts of tricks to prevent moisture from getting inside them during operation, and to ensure that it is removed from there. But insulation manufacturers are also looking for ways to increase the hydrophobic properties of their materials. Let's consider the most popular insulation materials used in the production of three-layer structures, from the point of view of their hydrophobic properties, and ways to improve them.

Expanded polystyrene

Today, the use of polystyrene foam as insulation is the most common method of thermal insulation of premises. And expanded polystyrene itself is often called simply polystyrene foam. However, these are not identical concepts. Expanded polystyrene has a higher density, it is less prone to absorbing moisture and is a more effective insulation material.

Expanded polystyrene is produced by foaming polystyrene. For foaming, vapors of low-boiling liquids are used. The result is granules, which are then heated to increase their size by 30 times. After this, sintering and formation of the finished product are carried out.

Styrofoam brands

Expanded polystyrene is produced in a number of brands. They differ in material density. The most common brands used as insulation are PSB-S. Depending on the density, polystyrene foam grades PSB-S 15, 25, 35 and 50 are distinguished.

Thus, polystyrene foam PSB-S 15 has the lowest density of the listed grades and, accordingly, the highest thermal conductivity - 0.037 W/(m×K). It is least suitable for insulating structures.

More widely used as insulation is the PSB-S 25 brand, which has a thermal conductivity of 0.035 W/(m×K). It is this brand that dominates in housing construction.

Brand PSB-S 35 with a thermal conductivity of 0.033 W/(m×K) is mainly used when using permanent formwork. She also participates in the technological process of producing sandwich panels.

The best insulation is polystyrene foam PSB-S 35, the thermal conductivity of which is only 0.04 W/(m×K). It is used in the construction of heated soils and refrigerated warehouses, as well as in the construction of roads.

Advantages of expanded polystyrene

Expanded polystyrene has a unique combination of properties for insulation - low thermal conductivity at the same time as low density. Because of this, it is very convenient to use both directly during construction and for subsequent insulation as part of a major overhaul.

Quite decent frost resistance allows the use of polystyrene foam even at -50ᴼC. At the same time, its properties do not deteriorate in any way. In addition, the material is resistant to aggressive environments. Expanded polystyrene is characterized by biological resistance - it is not susceptible to the influence of moss, microorganisms and fungi, and is the least attractive to rodents, mainly if it is an obstacle in their path.

Test results, by creating a strong temperature difference, showed that the expected durability of the material ranges from 60 to 80 years, which is a completely acceptable indicator.

Disadvantages of expanded polystyrene

In addition to the advantages, polystyrene foam also has a number of disadvantages. Thus, despite its biological inertness, colonies of fungi or mosses can form in its pores. In addition, the material is moisture and vapor permeable, although the permeability value is low and varies greatly depending on the brand.

Expanded polystyrene is a flammable material, and during combustion it releases toxic substances. However, without an external source of energy, it quickly goes out.

The final choice of insulation is up to you, we hope our article about the types was useful to you. We will be grateful if you share the article “Types of insulation” with your friends on social networks.

Application of hydrophobized mineral wool

The slabs have a thickness of 3-10 cm. Also, if you need hydrophobized mineral wool, pay attention to the information indicated in the code.

For thermal insulation of three-layer foundation or basement walls, the material may be less rigid. The point here is that in this case the hydrophobic basalt insulation is protected by a layer of the wall. Hydrophobic basalt insulation can also be used to insulate floors on the ground. It is best, in this case, to use mineral wool with increased resistance to moisture. As a rule, in floors on the ground, thermal insulation material is laid over concrete. Here it would be appropriate to use plates with increased rigidity. A 15-centimeter layer of insulation will become a serious obstacle to the cold.

Transverse joints between slabs should not merge into a single line. A construction film is laid on top of the mineral wool. And already on it they make a concrete screed, sometimes reinforced with reinforcing mesh. Any floor covering can be laid on the prepared base.

Soft fibreboard (fibreboard)

The natural type of insulation is obtained from wood waste. The shavings and sawdust are crushed to dust, and astringent and antifungal components are added. A homogeneous mass is obtained, which is then dried and slabs are produced.

There are also solid fiberboards, which in the Western style are called MDF, which in English sounds like medium density fiberboard. Solid boards are not insulation and are more classified as finishing materials, such as plywood, OSB, chipboard, etc.

This type of insulation is quite durable, can withstand high loads, has good heat-shielding properties, but is afraid of moisture. Hence its application follows. Typically, soft fiberboard is used to insulate walls and floors.

This type of insulation has been used for several decades, but recently soft fiberboard has been used less and less. It has been replaced by more modern insulation materials with higher performance.

Waterproofing solution

Waterproofing can be carried out at all stages of construction. The choice of materials depends on the type of structure and its purpose.

To protect the foundation, EPPS is used in combination with bitumen mastic, roofing felt, and sprayed waterproofing. To protect the house from dampness, horizontal wall insulation is used, capillaries are blocked with liquid and impregnated with paint.

To waterproof ceilings in rooms with high humidity, coating and penetrating compounds, powders, and paints are used. Insulating the ceilings additionally provides sound insulation.

Choosing moisture-resistant material

Waterproof insulation is the least susceptible to moisture. Hygroscopic insulation deteriorates when in contact with condensation, so foam sheets are used for external insulation work.

Moisture-resistant polystyrene foam material practically does not absorb water. Its installation can be carried out in a humid environment with additional vapor barrier. When installing mineral wool fiber boards, two-sided sealing is required.

Foil and traditional insulation with a reflective coating are used for installation in the interior of premises. Added to the positive properties of this type of insulation are vapor barrier, the ability to reflect infrared rays, and additional strengthening of mineral wool slabs, polystyrene foam and expanded polystyrene.

Fibrolite

Fiberboard slabs are made by drying and pressing wood chips. The binder can be Portland cement or magnesium salts.

The hydrophobic insulation is covered with a protective layer that is resistant to mold, mildew, and insects. It is used in rooms with high humidity. To increase the service life of fiberboard, additional waterproofing is required.

Mineral wool

Another material for insulating walls and other elements, which has recently come to the fore, is mineral wool. To insulate a frame house, an option in the form of pressed slabs .

It is convenient to transport, install and cut with a simple knife. In addition, mineral wool has a number of other advantages . Namely:

- has a low thermal conductivity, which makes it one of the best insulation materials;

- is lightweight, which greatly facilitates and speeds up the installation of the heat-insulating layer;

- has a long service life;

- is not afraid of fire and does not emit toxic gases.

The main disadvantage of mineral wool is considered to be its fear of moisture . Even slight wetting of the thermal insulation layer will lead to a significant loss of efficiency. Therefore, during installation you will have to spend additional money on a layer of vapor barrier film and waterproofing material.

An additional protective layer is necessary for one more reason. Mineral wool, or rather, its smallest particles, getting into a person’s lungs, can cause harm to health. If you do not install a layer of film on walls and other areas, this can cause great harm in the future.

If you follow all the recommendations, mineral wool will be the ideal insulation for a frame house. In addition, the price of such material is not so high.

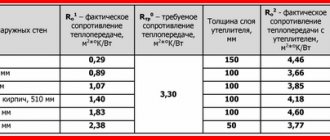

Let's look at the differences in key characteristics

Next, we will analyze in detail the differences in the main characteristics. First of all, let's consider thermal conductivity (the ability of a material to transmit heat through itself). The lower this indicator, the more effective the insulation. This is a key characteristic for this category. The thermal conductivity of glass wool ranges from 0.045-0.055 W/m*K. For mineral wool this indicator is better: 0.041.- 0.44 W/m*K. The indicator of basalt wool is lower, which means it is more effective than its counterpart. However, the difference between them is very small.

Now let's look at other, no less significant indicators:

- Soundproofing. In this component, glass wool has no equal - it is the most effective of all thermal insulation materials. When using it, there is no need to lay a noise-absorbing substrate.

- Safety. There are small pieces of glass inside the glass wool, which can cause cuts. Moreover, when cutting it, tiny fibers begin to float in the air, which, if they enter the lungs, can cause serious harm. Working with basalt wool is completely safe, so it wins in this component.

- Moisture resistance. Glass wool absorbs moisture, as a result of which its technical characteristics begin to deteriorate significantly. Therefore, it is not recommended to use it when insulating rooms such as bathrooms, kitchens and toilets. Mineral wool is excellent at resisting moisture.

- Fire resistance. Both of these materials are classified as flammable.

Important! Mineral wool can smolder for several hours, while glass wool undergoes active combustion.

- Strength. Mineral wool is soft and not too elastic. Its “brother”, which is made on the basis of glass fibers, on the contrary, is very durable and resistant to physical stress.

- Temperature resistance. The maximum operating temperature of glass wool is +450 degrees, and its counterpart is +700. However, it is worth noting that when used under normal conditions, these indicators have no meaning.

Advantages and disadvantages

Stone wool does not absorb moisture, unlike mineral wool.

The advantages of basalt insulation are manifested in almost everything, with the exception of price. Therefore, the question of whether basalt insulation is harmful can be answered with confidence - no. Even despite the fact that such dangerous components as phenol and formaldehyde are used for production. Hearing this, some may jump to conclusions that are not supported by facts. These two substances are bound in the structure of the material and cannot leave it in any way; this is absolutely impossible. If price is important, then there is the option of insulating the house with the most economical material - sawdust.

What is good about stone wool in terms of ecology:

- it is made of stone, that is, a natural material;

- this is not dusty insulation;

- withstands heating up to 1100 degrees without releasing harmful substances;

- complete chemical inertness;

- does not cause irritation to the epidermis upon direct contact.

From all sides the material is extremely positive, therefore it is useless to look for shortcomings in basalt insulation. Of course, if you wish, you can pull them by the ears, but this is no longer constructive.

Glass wool

One of the most common types of insulation nowadays is glass wool. This is insulation produced, as the name suggests, from glass production waste. Glass wool consists of long and wide glass fibers, the length of which can reach up to five centimeters.

Advantages of glass wool

It is quite actively used due to the fact that it has a number of undeniable advantages, among which it is important to note, for example: - High elasticity. During transportation, glass wool is compressed up to 4 times, and when transportation is completed, it is straightened out without any problems. — Very high resistance to vibration. - Extremely high moisture resistance - such an excellent material almost never gets wet! - Exceptional non-toxicity and purity - No less good sound insulation and thermal insulation. — Complete fire safety. Glass wool generally does not ignite at all! — Glass wool does not rot or mold. - Glass wool is not at all edible for mice, rats and any other rodents who like to feast on building materials. This is especially important for those who live on the ground floor of a high-rise building or arrange their summer cottage with glass wool.

Disadvantages of glass wool

But it would be unfair not to note certain disadvantages of the glass wool material: - Short service life when compared with insulation materials consisting of other materials; - Low level of thermal performance for products consisting of glass wool (again, compared to other insulation materials); — Some types of glass wool contain formaldehyde; — When working with glass wool, special, enhanced precautions must be taken to avoid problems. The fact is that glass microfibers, when they come into contact with mucous membranes and skin, can cause persistent severe itching, redness, and burning. These microfibers will be extremely difficult to wash off, because they get into microcracks and pores of human skin. In addition, when small particles of glass enter the respiratory tract, serious health problems often arise, often irreversible. An unambiguous conclusion follows from the last drawback - if you still decide to use such an ambiguous type of insulation, then you will need devices that can ensure safe work with glass wool. A respirator or special one is good. gloves, professional glasses. You should definitely dress with the expectation that your special suit will be thrown out because... it will be more than permeated with fine glass dust and fiberglass.

Basalt insulation

Basalt insulation takes a leading position when a homeowner makes a list of thermal insulation materials for insulating his home. To reduce heat losses and improve the microclimate in country houses or cottages, today it is customary to insulate building envelopes, floors, and roofs. To insulate a house efficiently and reliably, you can use materials based on superfine basalt fiber.

Depending on the application and desired technical characteristics, stone wool production processes vary slightly. But the main raw material is basalt crushed stone. Basalt insulation is made from its melt in melting furnaces.

When choosing insulation for your home, you should pay attention to mineral wool. The most popular type of such insulation is basalt-based insulation. Stone basalt wool is made from molten rocks (dolomite, basalt and others). Fiber from natural stone is of higher quality than from glass or blast furnace slag.

Basalt insulation is made from rock melts. This explains its long service life. In addition, basalt wool is a more reliable and effective thermal insulation material, in contrast to insulation made from glass wool or slag wool. If you have seen the preparation of cotton candy, you can imagine the process of turning basalt rock into insulation.

Basalt insulation pros and cons

Products based on basalt wool have a fibrous structure. Numerous stone fibers are randomly intertwined with each other, so there are air pores between them. In the absence of moisture inside the insulation, its thermal insulation characteristics are very high. This is due to the fact that air convection does not occur within the material and, therefore, there is no heat transfer.

There are no chemically active substances or toxic components in stone wool. Good basalt insulation has a very high resistance to mold and mildew.

Basalt fiber can withstand high temperatures, does not burn, and does not change its properties in chemically aggressive environments. Mineral wool is easy to install yourself; it also does not emit toxic substances and is therefore absolutely harmless. This insulation is excellent for insulating floors, roofs, ventilated facades, walls, and for the “wet facade” system.

A special advantage of basalt thermal insulation is its fire resistance. Stone fiber can withstand prolonged exposure to fire and does not melt or smoke. Rigid stone wool slabs retain their shape at high temperatures, helping to slow the spread of fire through a building.

Thermal insulation boards made of basalt insulation are vapor permeable. This is an important advantage of mineral wool insulation over polystyrene foam and polyurethane foam. Thanks to its vapor-permeable structure, mineral wool releases excess moisture from the building, thereby preventing the accumulation of condensation on building structures. Wooden walls do not rot, and metal and concrete structures do not corrode due to the absence of dampness.

Basalt insulation cons

The disadvantage of mineral wool products is that when water gets into the insulation, its thermal conductivity increases significantly, which is why the thermal insulation performance decreases. To prevent moisture condensation in stone wool, manufacturers impregnate it with water repellents, which prevent water droplets from adhering to the threads.

The disadvantages of stone wool include the fact that it contains binding resins, due to which the fibers are held in place. Thanks to resins, stone wool retains its shape, however, with a large amount of such substances, the environmental friendliness of the material deteriorates. Binding components enter the atmosphere and pollute the air in the house.

If thermal insulation materials made from stone wool are installed correctly, these two disadvantages can be easily eliminated. The insulation is located inside the structures, covered with vapor and waterproofing, windproof membranes, as well as finishing materials. Therefore, the negative impact of stone wool on the environment is practically zero.

Moreover, manufacturers strive to use modern formaldehyde resins that do not contain harmful components. Good basalt insulation from a well-known manufacturer, such as TechnoNIKOL or Batiz, is not at all dangerous to human health.

Certified basalt insulation can be used in areas of increased responsibility. The harmfulness of basalt wool is too exaggerated and only poses a health hazard to irresponsible installers who neglect basic protective equipment - gloves and respirators. The material generates dust only during installation of the structure.

Area where basalt insulation is used

Areas of application of stone wool are thermal insulation of external walls, partitions between rooms, floors, interfloor ceilings, and various building structures. This method of insulation is very simple to implement and allows you to create a durable layer of thermal insulation. Basalt insulation has become especially widespread in construction in the insulation of frame houses.

Based on the technical characteristics, we can conclude that basalt insulation can be used in almost any area of construction and production. It can be especially recommended for the facades of buildings with high fire safety requirements. Indeed, is it possible to set fire to a stone?

Compromise, but reality

Universal insulation is always a compromise, because each structural element of the house has its own specific requirements for thermal insulation. But now there are already materials obtained by thermal bonding (polyester insulation), which are at the same time environmentally friendly, resistant to moisture, heat-efficient, unattractive to all types of pests and, with such an extensive list of useful properties, have a very reasonable cost.

On FORUMHOUSE you can read an article that examines in detail the pros and cons of natural insulation and find out what consequences improper vapor barrier leads to. We choose insulation for thermal insulation of the interfloor ceiling in a wooden house. Join the discussion on how to choose insulation for different elements of the house. Watch a video about the insulation system invented by a member of our portal.

Subscribe to our Telegram channelExclusive posts every week

What is basalt wool

It has already been mentioned that basalt insulation belongs to the group of mineral materials. Its distinctive feature is the production raw materials used. To obtain the fibers of the future heat insulator, rock materials are used. Therefore, basalt wool is often called stone wool.

The production technology involves obtaining a liquid rock melt in a furnace at 1400-1500°C, from which fiber is drawn. Binding components are used to bind the resulting fibers into a homogeneous array. Correct selection of the binder base helps to significantly improve the characteristics of stone wool. After forming the structure, setting the direction of the layers and obtaining the required density, the finished material is cut to a standard size and packaged. Forms of release: mats, soft rolls, hard slabs.

Cheat sheet. To help consumers

The requirements named by the expert are universal and important for the thermal insulation of all structural elements of the house. But for the insulation of each structure there are also special requirements. We have collected them in a cheat sheet.

Design

Requirements for insulation

Dimensional stability, elasticity (the material does not cake over time, the area and insulation layer remain uniform throughout the entire period of operation). Low weight. Easy cutting and installation. Environmentally friendly, especially when it comes to internal insulation.

Resistance to deformation, including temperature changes; sound absorption, moisture resistance

Sound and noise insulation properties, low density (low weight), moisture resistance

Resistance to temperature changes, porosity, clear geometry, effective protection against the formation of temperature bridges (“cold bridges”).

On the one hand, the consumer needs high thermal efficiency and noise absorption, non-flammability and resistance to moisture, and on the other hand, safety, lightness, and ease of installation. Cost also plays a significant role in the choice. But in order, for example, to achieve non-flammable properties in a material, it is necessary to introduce additional chemicals - fire retardants, which to some extent cannot be completely safe.

"Isover"

Insulation for baths "Isover". Along with conventional insulation, it also produces a special insulation for baths and saunas - IsoverSauna. Made from mineral wool containing polymerized fiber. One side of the wool is equipped with a foil coating, which is why the material is called foil insulation.

Is it possible to use Isover insulation in a bathhouse?

If we talk about the above product, then this option is a completely acceptable solution for insulating a bathhouse. The foil layer gives the isover vapor barrier properties. The material itself is characterized as suitable for rooms with high humidity. Such qualities fully comply with the requirements determined by the characteristics of the bathhouse.

As for using a regular (non-foil) isover, in this case you will have to lay a layer of foil on top of the material yourself.

Arbolit

Also among the popular materials used for thermal insulation in construction and renovation is wood concrete. The word arbolit means, translated from Greek: arbo - wood, litos - stone. This is a type of cellular, super-light concrete, which contains wood chip filler and a binding material (cement or, less commonly, gypsum).

Wood concrete is divided into grades from 5 to 50 according to categories depending on composition and strength. In terms of density, wood concrete can be thermal insulating (the highest density in dried form is 400-500 kg/m3) and structural (the highest density in dried form is from 490 kg/m3 to 860 kg/m3).

Main technical characteristics of wood concrete:

- density, average from 490 to 860 kg/m3

- strength 0.5-3.5 MPa in compression and 0.7-1.0 MPa in bending

- thermal conductivity 0.07-0.18 W/(m K)

- elasticity (modulus) 250-2300 MPa

- resistance to low temperatures 25-50 cycles

- water absorption 40-85%

- additive 0.35-0.55%

- biological immunity of the fifth group

- heat resistance to fire 0.70-1.6 hours

- sound absorption (119-1999 Hz) 0.20-0.59

From the characteristics of wood concrete it is clear that it ideally combines the main qualities of insulation: low thermal conductivity and high air permeability, which makes it indispensable for thermal insulation. At the same time, wood concrete is also used as a material for the construction of buildings.

Advantages of wood concrete:

1. with properties close to wood, wood concrete does not burn 2. this material, when compared with materials made of wood and their analogues, is less dependent on biological factors, such as fungus, rot and other microbiological factors 3. low cost in comparison with other insulation materials similar in quality characteristics 4. easy to process, nails can be driven into wood concrete, screws can be screwed in, cut into various shapes 5. it is an environmentally friendly material, it does not contain chemical additives hazardous to health 6. has high sound insulation 7. air permeability of wood concrete makes the atmosphere in the building healthy and comfortable 8. During sudden temperature changes, due to its high heat capacity, it accumulates heat. In hot weather, the room is cool, in cold weather it is warm 9. Wood concrete weighs little, which reduces the load on the foundation and reduces the cost of construction 10. Under extreme loads, wood concrete is compressed and does not collapse.

Disadvantages of wood concrete:

1. the main disadvantage is the very high requirements for manufacturing quality; if the production technology is violated, the material loses its thermal insulation properties 2. due to high water absorption, wood concrete cannot be used at high humidity without additional finishing treatment 3. aggressive gases destroy wood concrete 4. rodents easily penetrate into the material is made of wood concrete, which requires additional processing especially in garden plots.

Although wood concrete is a unique material that can be used both for thermal insulation and load-bearing in the construction of buildings, when using it, one must weigh the pros and cons. And if you choose wood concrete for thermal insulation, pay special attention to the quality of the purchased material.

Methods of internal thermal insulation of walls

The choice of installation technology depends on the shape of the insulation. There are two possible mounting methods: on the frame or the adhesive method.

Insulation on the frame

This technology is suitable for the following materials:

- Styrofoam;

- basalt insulation and mineral wool;

- wood fiber.

Thanks to the structure of the frame, the thermal insulation material is protected from mechanical influences. In addition, the method allows you to achieve tightness of the placement of slab insulation.

- Clean the wall from dirt and loose plaster.

- Build a frame from beams or aluminum profiles.

- Secure the racks with dowels or self-tapping screws. The fixation step of the vertical elements is selected according to the width of the insulation. When using mineral wool, the cell is reduced by 2 cm from the overall size of the insulator.

- the wooden frame elements with antifungal impregnation .

- Place insulation in the spaces between the posts. Seal the seams with polyurethane foam.

- Finish the walls.

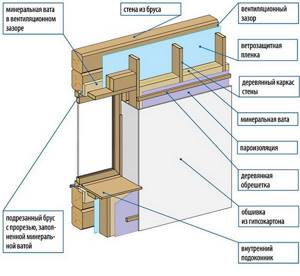

Methods of insulation with mineral insulation

There are several methods of insulation. One of them is to fasten the material to the wall, as well as finishing it with plaster. In this case, the thickness of the insulation should not exceed 15 cm. The slabs are mounted in horizontal rows.

The material for their fastening is special glue and dowels. There should be no gaps between the slabs, and their surface should be perfectly flat. This method can be used to insulate frame walls.

The second method is to attach a frame (steel, wood or PVC) to the external walls and lay insulation between its elements, followed by covering the facade (for example, siding). Insulation, at least 12 cm thick, is inserted between the frame elements. Secure it with dowels. And between the sheathing and the insulation, a gap of 2-3 cm is left. In this case, elastic mineral wool is used in the form of:

As for thermal insulation in three-layer walls, in this case the insulation is attached to the load-bearing wall. From the outside it is closed by a boundary wall. The mineral wool is held on the wall by anchors that connect both the enclosing and load-bearing walls.

TechnoNikol: insulation with impeccable quality!

If in your house with the onset of cold weather it is only a little warmer than outside, this can only mean one thing: you did not take care of high-quality insulation in time. You can, of course, wrap yourself in a hundred clothes, but it’s easier to perform proper thermal insulation and not worry about heat leaks for at least 50 years. Meet TechnoNIKOL insulation, the price of which fully corresponds to its excellent quality!

TechnoNIKOL Corporation is the winner of the DIY Advice Russia TOP 2013 rating, nomination – “Thermal Insulation Materials”.

5 reasons to buy TechnoNikol basalt insulation

Molten mountain gabbro-basalt rocks are the ideal raw material for creating amazing insulation. Let's find out why TechnoNikol stone wool is at the peak of popularity among thermal insulation.

Basalt insulation TechnoNikol

- Fire safety. If you care about the safety of your own home, this is an ideal option! The material begins to melt only at a temperature of +1000°C and above, and up to this limit its positive qualities remain unchanged.

- Versatility. Using TechnoNikol insulation, the price of which will not hurt your wallet, you can insulate apartment and interior partitions, pipelines, walls, roofing, floors and various curved surfaces.

- Vapor permeability. TechnoNikol basalt wool is able to regulate the microclimate in the room, maintaining an optimal level of humidity and removing excess moisture from the house.

- Good sound insulation. Stone wool is not only excellent thermal insulation. The material provides reliable protection from extraneous noise.

- Excellent thermal insulation. The thermal conductivity coefficient of TechnoNikol basalt insulation is only 0.035-0.039 W/m K. Thanks to it, you will get excellent insulation results.

The range of TechnoNikol stone wool insulation products includes a truly innovative solution - double-density slabs, which the company first released in 2008.

5 incredible advantages of extruded polystyrene foam TechnoNikol

Extruded polystyrene foam is an insulation material that consists of tiny air granules measuring 1-5 mm, which are firmly bonded to each other. This helps the material to be an excellent thermal insulator. Right now we will tell you about 5 advantages of this TechnoNikol insulation, which became the reason for its enormous popularity.

- Environmentally friendly. The material is guaranteed not to contain substances harmful to human health and the environment. This is proven by the fact that it is used for packaging products.

- Moisture resistance. Extruded polystyrene foam does not absorb moisture - its moisture absorption coefficient of the total volume is no more than 0.2%. This way you can save on waterproofing.

- Excellent sound insulation. 90% of the material is air, which is not only excellent thermal insulation, but also excellent protection from extraneous noise.

- Stability of characteristics. During operation, this TechnoNikol insulation does not shrink or swell when exposed to moisture. Its surface remains consistently hard and smooth, therefore providing good thermal insulation throughout the entire period of operation.

- Easy to process and install. Extruded polystyrene foam is easily cut using a heated knife: it is not difficult to give it the required dimensions, and the process of working with the material is extremely simple due to its light weight.

The material is resistant to various biological and chemical influences and can be safely used in any climate. Its thermal insulation coefficient is 0.031-0.032 W/m·K - this figure is even better than that of stone wool!

Where will using TechnoNikol insulation be economically beneficial?

Insulation of walls with stone wool

TechnoNikol stone wool, the price of which on our company’s website will help you save, is often used as insulation for ventilated and plaster facades. It is indispensable for thermal insulation of walls and pitched roofs. Rigid basalt thermal insulation, which does not shrink under load, was developed specifically for insulating flat inversion roofs and other loaded structures such as floors.

TechnoNikol extruded polystyrene foam, the price of which we have specially reduced for you, has a wide range of uses. Insulation of the foundation, floors and facade are not all the options for its application. The material is actively used for thermal insulation of roads and other engineering structures.

Do you want to buy high-quality insulation? Choose TechnoNIKOL - our price will definitely make you happy!

Is internal vapor barrier necessary?

The need for internal vapor barrier is undeniable. Almost the whole point of internal insulation is to create an airtight boundary between steam-saturated air and the wall.

Moreover, if the insulation itself is a good vapor barrier (like EPS or EPS), then the presence of a separate layer of rolled vapor barrier is not necessary, especially if there is effective supply and exhaust ventilation.

However, to insure against possible microscopic cracks, gaps or other cavities in the insulation, as well as to cut off adjacent walls, an additional vapor barrier layer is often installed.

If a looser material that allows steam to pass through is used as insulation, then a complete vapor barrier is required. Attempts to do without it will negate the whole idea of insulating the wall - it will get wet, condensation will saturate the insulation, causing it to stop retaining heat and turn into a moisture accumulator. At this time, the wall material will get wet, freeze and, as a result, actively collapse.

Internal insulation is significantly less effective than the external method, and is used only as an additional measure. As an independent measure, this technique is questionable and requires an understanding of the dynamics of the processes occurring in the wall cake at different temperatures and at different times of the year.

The effect of such a technique often requires a lot of experimentation and change, which in practice means constant repair. Therefore, you should act very carefully and carefully to try to achieve the desired result on the first try.

Foam glass

It is produced from quartz sand, broken glass and foaming agent in special installations, after which a porous material is obtained with high thermal protection and is quite durable.

An excellent material that is not afraid of water and fire, can be easily processed with a regular hacksaw, has high frost resistance, and can withstand high pressure.

We suggest you read: You can go to the bathhouse after a cold

As you can see, foam glass has a lot of advantages, but it is not widely used, most likely due to the lack of information about this insulation and, of course, due to the high price.

Available in the form of granules and blocks.

Application area

Roof. Since this material is absolutely not afraid of water and tolerates high loads well, it is often used as insulation for flat roofs.

Foam glass should not be used for pitched roofs, as it is heavy compared to other insulation materials, which leads to an increase in load on the rafter system.

Walls. It can be used as a backfill insulation when laying well walls in the same way as expanded clay. It is not recommended to use it to insulate the walls of houses built using frame technology, again due to the heavy weight of the material.

Foam glass is recommended for finishing the facades of brick houses. It sticks perfectly to the walls using ordinary tile adhesive, and the process is similar to ordinary bricklaying, after which the foam glass can be plastered and tiled, without the need for any additional measures.

In the next video you will find additional information about this type of insulation, and you will also see how to cover the wall of a brick house with foam glass blocks.

Floors. Excellent for insulating interfloor ceilings, basement and first floor floors. Due to its rigidity, foam glass can be used when constructing floors on the ground, the construction of which we wrote about in this article (link).

Foundation, basement, plinth, blind area. Foam glass can be used for thermal insulation of such structures, since it is absolutely non-hygroscopic and has sufficient density not to shrink under the load of the soil.

What insulation materials do not shrink?

EPS, XPS, PIR - these insulation materials are in a solid, fully polymerized state, have rigidity and do not shrink.

The problem of shrinkage is primarily characteristic of glass wool and light grades of basalt wool. The reason for this is the low density and hardness of the materials. The material can absorb a large amount of moisture and, when wet, loses its shape and volume. However, with proper installation of high-quality glass wool or basalt insulation with good water-repellent properties, the likelihood of shrinkage will be minimized.

The working principle of quick-drying materials

I know this sounds pretty boring, but to understand how quick-drying clothes work, I have to explain how the material they're made from works. Don't worry, it won't take long.

All clothing is made from fabric, which in turn is made from different types of fibers. Some fabrics are tight, others are loose. Some fabrics are thicker than others. The more fibers a garment has, and the thicker those fibers, the more surface area there is to absorb moisture. The more moisture the material absorbs, the longer it takes to dry. A thick cotton shirt is practically a big sponge with sleeves. A shirt made from a mixture of artificial materials practically does not absorb moisture due to the properties of polyester, and accordingly dries quickly. Clothes made from dense and thick fabrics tend to take longer to dry than thin ones. But thick fabric retains heat better than clothes made of thin and light fabric. Basically, more heat = slower drying time. However, modern fast-drying fabrics made from high-tech blends that retain heat without trapping moisture are increasingly beginning to challenge this rule.

How to install insulation under siding

You need to take care of truly high-quality external thermal insulation that has direct contact with the external environment, which must be non-flammable and hydrophobic.

The best insulation for siding

Typically, insulation for installation under siding is selected depending on the height of the house. Traditionally, basalt insulation is considered the best insulation intended for thermal insulation of house walls.

This is a non-flammable material that does not absorb moisture. It is produced in the form of slabs with dimensions of 100 by 50 cm, or 100 by 60 cm, with a thickness of 5 to 20 cm.

The density when laying under the siding should be selected from 35 to 90 kg/cub.m., and the greater the height of the structure requiring insulation, the higher the inherent density of the external thermal insulation should be.

The thickness of external thermal insulation should be selected depending on the climatic zone of residence, wall material and their thickness. For example, for the Urals, a wall thermal insulation thickness of 10 cm is recommended.

Installation of insulation

The insulation is mounted between the guides, the distance between which is selected based on the width of the insulation material slabs (50 or 60 cm).

After installing the insulation, it is necessary to install a wind and moisture-proof membrane designed to protect the wall insulation from exposure to dampness.

Currently, one of the best domestic materials of this kind is Izospan A, which protects the building structure and the insulation itself from the destructive influence of wind and moisture from the outside, ensuring the weathering of water vapor from the thickness of the insulation and preventing the penetration of condensation.

Installation of wind protection

Izospan under siding is laid strictly on the outer side of the material - insulation under the wall cladding from the outside.

The panels should be placed horizontally, starting from the bottom up, always turning the smooth side outward, overlapping, and the overlap at the vertical and horizontal joints should be at least 10 cm.

Moreover, it must be additionally secured to the frame using a construction stapler. On top of the covering, wooden counter-battens are attached to the frame, which carry the outer skin (in this case, siding).

Be sure to leave a ventilation gap of about five centimeters between the membrane and the outside sheathing - for the counter-rack thickness.

The lower membrane edge is designed to ensure proper drainage of the flowing liquid to the drainage drain of the building base.

Then siding panels and additional elements of the facade structure are mounted on the insulated house wall.