Types of waterproofing from the inside

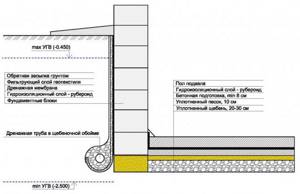

For a cellar, vertical waterproofing is the most popular method of protecting the basement from moisture, and a special composition is applied to the walls. But experts advise making a drainage system and removing water from the structure by creating horizontal waterproofing. You can watch a video on this topic. The material is also selected depending on the location of groundwater. After all, when they are close, the humidity will be higher.

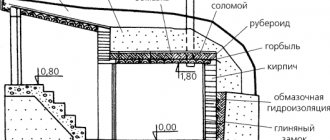

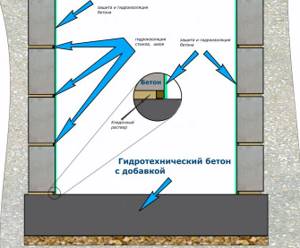

Isolation scheme depending on the location of groundwater

- Apply the first layer on top of the structures so that the insulation covers the waterproofing of the floor from above by 15 cm;

- The second layer should be located approximately 30 cm above the blind area itself. If the ceiling is located below the second layer, then it is necessary to apply a third layer under the structure.

The cheapest and easiest way of vertical waterproofing is to apply special insulating paint to the surface of the walls. The advantage of this insulation is the complete filling of the seams.

Attention: But with a damp surface, bitumen emulsion should be applied to newly made seams or wet plaster, it is best to first use a liquid composition in the form of a primer and then apply a thicker layer, and then apply about three more protective layers. The best option would be to use bitumen solutions.

Types of waterproofing

Waterproofing basements and cellars can be done with many materials. But before you make a choice, you need to decide on the type of waterproofing. There are three types that you can see in the photo:

| Anti-pressure waterproofing |

|

| Non-pressure waterproofing | Non-pressure waterproofing can protect against various natural precipitation and floods. For this protection, polymer-bitumen mastics are used. |

| Anti-capillary waterproofing | Anti-capillary waterproofing of basement walls can protect against water that penetrates through the capillaries of the floor. This protection option is the same as anti-pressure waterproofing, but injection waterproofing of all floor capillaries is added. |

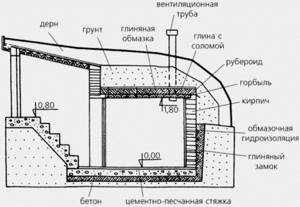

Waterproofing scheme

Please note: In all suitable basements, general work to obtain a waterproof layer will also include replacing the floors, provided that the structure is rotten.

- In addition, additional measures need to be taken if moisture appears as condensation, for example, from heating pipes. In this case, the waterproofing of the room will begin with the application of a waterproof layer for other ways of moisture, which includes insulation, as well as repair of heating pipes.

When and why do you need basement waterproofing?

The floor and walls of the basement are destroyed under the influence of moisture, concrete cracks due to dampness, metal fittings rust, and mold and mildew spread. If urgent measures are not taken, it will not only be impossible to store anything in the basement, but the structure may completely collapse.

Waterproofing the basement from the outside is the main thing, it protects walls and ceilings from the effects of groundwater, does not allow moisture to get inside the basement or cellar, is usually done during the construction stage, and is maintained during the operation of the building.

Internal basement waterproofing protects the floor, walls, and sometimes the ceiling from the inside from moisture. It is a means of additional protection. The combination of internal and external waterproofing allows the basement to remain dry, safe and useful for the owners.

Protecting the basement from groundwater in a private house is usually done on your own. At the same time, you need to know exactly how to carry it out correctly and what materials to use in order to provide maximum protection not only for the basement, but also for the cellar, because excess moisture and mold instantly affect the products stored in it, and can not only leave the family without a harvest, but also cause serious illness.

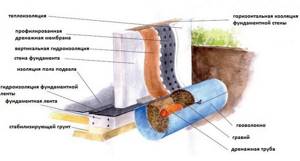

When carrying out insulation work, a distinction is made between vertical and horizontal types of waterproofing installation. Horizontal, protects the base of the foundation. Placed on a special bed of sand and gravel. Does not allow melt and groundwater to penetrate into the room from below. When installed correctly, it forms an airtight base and extends 15-20 cm onto the perimeter walls.

The vertical method of protecting a room involves applying any type of protective coating to the walls of the building. The combination of vertical and horizontal waterproofing can completely protect the basement from exposure to dampness.

In addition, you should take into account the level of groundwater, the fact that it can change over time, the amount of precipitation in the place of residence and other conditions that can affect the level of humidity in the basement. Depending on the amount of water there are:

- Anti-pressure waterproofing. It is used when, under the pressure of groundwater or melt water, the insulating coating is tightly pressed against the outer surface of the room. Refers to the types of external insulation, used in the absence of a drainage system around the building and the risk of flooding. In this case, there must be a serious, sealed barrier in the way of water.

- Non-pressure waterproofing. It is produced to protect the room during seasonal flooding during the flood period, to prevent an increase in humidity in the basement from the effects of precipitation. It can be done both outside and inside the basement.

- Anti-capillary waterproofing. This method prevents the penetration of moisture through capillaries and microcracks into the building material from which the building is constructed, because even the most durable building material is destroyed under the influence of dampness.

They try to protect not only basements, subfloors and cellars from exposure to moisture; waterproofing should also be done in the garage, since vehicles suffer from dampness.

Selecting the material

Waterproofing cellars is done by a certain group of materials; their selection is the most important stage of preparation, because high-quality protection, as well as the cost of all repairs, depend on this. The best way to protect from the inside in terms of price/effectiveness ratio is to cover the basement walls with slate in two layers, and at the same time glue them together with bitumen lubricant. By doing the work yourself, everything can be done efficiently and quickly.

Attention: It is worth noting that the cost of the material should not be considered a determining parameter; it is important to obtain a protective water-repellent layer, and also to choose the resistance of the waterproofing to various mechanical damages.

- Waterproofing building material in rolls is considered a traditional, lightweight and cheap method of protection, which creates a multi-layered carpet;

- Waterproofing in liquid form perfectly protects the surface of the room from moisture in seams and microcracks;

- Bentonite clay;

- Metal in sheets;

- Binding compounds;

- Penetrating waterproofing is used to seal cracks.

Attention: When choosing a material, you need to take into account its purpose: if it is necessary to protect building reinforcement, you need to use anti-corrosion materials, to seal seams and joints, use a sealing material, and anti-filtration materials will prevent moisture from approaching.

If we take into account the composition of the material, it can be divided into several types:

- Floor waterproofing by plastering, painting and pasting. In these cases, polymer compounds (plastic, plastic) are used;

- Mineral materials are the most popular type of protection, based on clay, binders or cement;

- Asphalt-containing waterproofing based on petroleum bitumen is considered a simple method of protection, given all modern bitumen-polymer mixtures;

- Metal sheets made from stainless steel, brass, copper and aluminum.

Now let's see for which room and what material is better to choose:

- The advantages of cement-based mastics are that they are the usual waterproofing of a room from the inside and in order to carry it out, you need to follow the instructions.

- To create a strong water barrier, it is necessary to use cement-based solutions that can expand during hardening.

- If you need to get a surface that is resistant to deformation, then it is best to use bitumen mastics, which create a strong and elastic membrane on top.

- If, during the construction of a basement, wall insulation is used using slab insulation, then polymer films will be an excellent option for waterproofing.

If the wall is brick

The popular plastering waterproofing of premises with various modified solutions is considered the best option for protecting brick walls. Modifying solutions are polymers, additives, liquid glass that can increase the waterproof properties of cement-sand mortar.

Attention: This technology is the simplest and cheapest work that you can do yourself, so this method is still popular among all other modern methods.

All work is performed in the following order:

- First, the surface is cleaned of the previous coating. This is a pretty important point. It will guarantee the quality of the connection. If this is not done correctly, then there can be no question of durability;

- After this we prime the surface. This action will guarantee us a quality connection. Let the surface dry completely;

- After this we plaster the surface. For this, a solution based on sand and cement is used.

If you follow the order of all actions, you will get a dense and stable layer that can perfectly protect the basement from moisture. When the basement walls are made of concrete or natural stone, the best option for waterproofing the room is to treat the walls with special resins that have a bitumen base.

Attention: To protect the walls you need to apply only 2 layers of resins or use polymers: polyurethane, methyl methacrylate or polypropylene.

- But the best finished product for reinforced concrete or concrete structures is considered to be waterproofing the room with Penetron. This material penetrates well and its main characteristic is the greatest protection efficiency.

- A well-known protection option that has now become popular is coating waterproofing with liquid rubber. It can also be used on wet surfaces.

- In the basement, you can use a one-time application of liquid rubber, which is used for both external and internal work.

Methods for protecting floors with waterproofing

Waterproofing the floor in the cellar is done in several ways and there is no universal option for protecting the floor. All methods are based on the material of construction, and, of course, on everyone’s preferences.

The most modern method for concrete floors in reinforced concrete structures is waterproofing using sheet or roll materials, which is considered a simple and cheap method of protection.

Roll waterproofing

The work is performed in the following sequence:

- First, we completely clean the plane;

- After this, a layer of primer is applied. In this option, it is better to give preference to deep penetration liquid. It will provide high-quality adhesion to surfaces;

- After this comes the laying of roll bitumen materials or sheet polymers, for example, roofing felt, roofing felt.

- Next, create several layers of materials for waterproofing, and then gluing the layers with a special composition: hot bitumen (for bitumen floors) or primer (for polymer floors).

To reliably protect the floor, it is enough to apply many layers, which will consist of three layers of the necessary material. But pasted waterproofing is not the only protection, so you can choose other methods:

- Cast waterproofing of the room (hot, cold or asphalt-polymer). It is made using mastic or special solutions, which represent a continuous waterproofing layer. A distinctive feature of this material is the filling of the composition, which is carried out between the floor and the fence;

- Impregnating waterproofing when binder mixtures are used. This is the most optimal method of protection if linoleum or wooden flooring is installed after waterproofing.

Attention: When choosing materials for adhesive waterproofing, it is best to choose advanced bitumen mastics, for example, pure polymers, bitumen-rubber or bitumen-polymer.

As a result of this, the surface of the basement will last a long time, it will not crack and remain elastic, and will not lose its waterproofing properties.

Important: when choosing a waterproofing method, you need to well insulate those places where the connection to the wall occurs, and also apply the selected material continuously and the layer should be 30 cm above the floor, or better yet, more.

Waterproofing a cellar with your own hands is not that difficult. It is important to correctly determine the material here. The price is not so important here, but the quality of the work is important. And then waterproofing the cellar will reliably protect your room and products.

Victor Martovich

He worked as a foreman, head of the construction and installation site. Organization of work and supervision of the quality of construction and installation works of construction sites on the territory of the Balakovo NPP, maintaining and submitting as-built documentation (magazines, acts, documents), purchasing materials, equipment (performing the duties of a supply engineer, quality engineer). Management of construction teams (registration, training in labor protection and industrial safety). Victor completed training courses under the program “Major repairs of buildings and structures. Organization of work and construction control.”, 2015 Balakovo Institute of Professional Retraining and Advanced Training, Occupational Safety and Health Specialist, 2012 Pugachevsky Irrigation College, construction technician, 2000 prof. school, accountant, 1996

Source

Methods for installing waterproofing in the basement

There are several types of basement waterproofing:

- non-pressure - will protect the basement from rainwater entering it and will help in case of floods;

- anti-pressure - used if the basement is constantly flooded with groundwater;

- anti-capillary - will not allow drops of water to seep through cracks and joints, as well as through building materials.

There are several ways to waterproof a basement.

Methods for waterproofing a floor in the basement of a house can also be divided into:

- pasted or rolled;

- painting;

- impregnating or penetrating;

- cast;

- injection;

- membrane

Pasted waterproofing is used if the humidity in the basement is low and the groundwater threshold is low. Roofing material, waterproofing material, foil-proofing material or roofing felt are usually used as adhesive waterproofing material. Polymer sheet materials can also be used. They form a kind of multi-layer carpet, with all layers glued together. The material is glued onto a pre-primed layer of mortar until the final screed is poured.

Bitumen roll waterproofing

Painted waterproofing is quite simple; it is used on the floor, walls, and ceiling of the basement. Excellent for well poured concrete floors. Previously, this was carried out using bitumen-based mastics, but, as practice has shown, this is not the best option. Bitumen mastics quickly lose their waterproofing properties as they crack. It is much better to use mixed polymer-bitumen or bitumen-rubber substances.

Application of coating waterproofing

Impregnation waterproofing is usually carried out before the floors and walls of the basement are covered with tiles or covered with other materials used for finishing. Impregnations are mixtures containing bitumen or polymer varnishes. The method is based on the fact that the substance with which the surface is treated penetrates through the smallest pores and cracks to a depth of 60 cm and crystallizes inside them due to the chemical reaction of the so-called penetrates - special reagents. This gives rise to another name for the waterproofing method – penetration. Reagents can be aluminum oxide, alkali metal carbonates, and silica. This type of waterproofing is applied very simply, and serves faithfully for a long time.

Liquid glass for floors

Injection waterproofing is a subtype of penetrating waterproofing. But it is performed with a flowing gel, which is simply injected into cracks and holes. The gel can be made on the basis of microcement, acrylate, polyurethane or epoxy resin. This type of waterproofing allows you to treat hard-to-reach places without special material costs, however, the technique is quite complex and is usually performed by a specialist.

Injection waterproofing

Cast waterproofing is the most reliable option that will protect the basement from the penetration of any moisture. In this case, all surfaces are filled with special mastics or solutions. Thus, a reliable, durable and thick layer of waterproofing is formed. By the way, the cast form of moisture protection can be cold, hot, or asphalt-polymer.

Cast waterproofing

Membrane waterproofing is the use of special membrane materials about 2 mm thick to protect the basement from water. This type refers to roll types of waterproofing. These materials also have thermal insulation properties and often already have an adhesive layer, which means they may not require the application of glue. The membranes are very light and do not place additional load on the foundation.

Membrane waterproofing

Table. Types of membrane materials.

| View | Description |

| PVC membrane | They are made on the basis of plasticized PVC, they are a two-layer film, the top layer of which is made of plasticizers. The membrane is fire resistant and at the same time insulates water well, is very elastic, and can be installed at low temperatures. To obtain a seamless coating, the edges of two membrane cuts are joined using a special apparatus. |

| EPDM membranes | The material is also called synthetic rubber. It can easily withstand low air temperatures and ground movement. Durable. |

| TPO membranes | Manufactured on the basis of thermoplastic polyophenes. This material has two layers - rubber-polypropylene and reinforced with synthetic fiber. The material combines the waterproofing properties of rubber and the high strength of reinforcing mesh. It is not cheap, so it is rarely used. |

pvc membrane

Consequences of improper waterproofing

Groundwater that comes close to the soil during floods, heavy rains or snowmelt causes damage to buildings in low-lying areas. When leaking, the structure experiences a number of risks:

- the basement is filled with damp air, which reduces the quality of preservation of vegetables and preservation, and corrosion of metal parts occurs;

- mold and mildew form, wooden elements rot, toxic substances are released;

- the strength of the structure is compromised, and a large number of cracks and local sources of destruction lead to the destruction of the building.

The water that appears in the cellar affects the surfaces of the walls and floors in two ways. Pressure occurs when soil moisture rises above the floor, and non-pressure occurs when water is at the bottom of the covering. To maintain the strength of a private house with a basement, it is necessary to waterproof it.

What is important not to forget when waterproofing your basement?

To summarize, here are the basic principles for organizing basement waterproofing from the inside:

In addition, internal waterproofing will not replace external waterproofing, drainage and blind areas. This is a temporary measure, so it is necessary to correct the situation as soon as possible. Otherwise, you will have to repeat the procedure of insulating the basement from the inside regularly. And this is an extra waste of time, effort and money.

The video explains what to do if the basement is heavily flooded and how to waterproof it in this case:

We are planning work to eliminate leaks

To get rid of water in the cellar, you should protect the interior and exterior of the building. You need to start with planning:

- the process of processing joints of walls and floors, walls and ceilings;

- applying working seams to concrete or formwork;

- isolation of communication systems;

- eliminating cracks and fractures that appeared as a result of shrinkage.

After checking the condition of the room, you need to decide on the material to insulate it.

Ditch, seal, waterproof

Our user with the nickname ALEXUS_81 has constant water in the basement because “a goblin brigade of monolithic workers poured screed onto the floor without any waterproofing or reinforcement.” Because the floor is unprotected, he doesn't see the point in digging out the basement and applying waterproofing to uneven surfaces. All the water has already been pumped out by the pump, but where it comes from is not visible, so the plan to combat basement flooding is as follows:

- To groove and seal all joints between concrete walls and floors;

- Treat all basement walls and floors with penetrating insulation so that there is no more “capillary action.”

ALEXUS_81FORUMHOUSE Member

If all the cracks are caulked and the capillary movement of water is stopped, then there should be no water flow into the basement. Although one unsealed hole may be enough for flooding.

This is what the underground garage of our user with the nickname Magma looked like before the basement was waterproofed:

Water penetrated into the basement through the capillaries of the concrete and through the junction of the floor and the wall. We had to make grooves to dump water into a drainage well with a pump. Water began to flow quite actively from the opened seams, the pump worked in continuous mode. To stop the water, we first had to make hydraulic seals, and then seal the grooves with joint compound. At the last stage, the concrete surface was treated with a penetrating compound.

This is the result that we managed to obtain.

Regulatory requirements for waterproofing

The process of insulating underground premises, including basements, is regulated by SNiP 2.03.11-85:

- thoroughly priming the area and gluing strips of waterproofing 2 cm thick to the corners;

- mandatory surface preparation - cracks are sealed, concrete sagging is cut down, rust is removed, dirt is cleaned;

- checking the humidity of concrete surfaces before processing them - it should be equal to 4%.

The document also indicates: the main types of materials, how the technology of events is correctly implemented.

Coating insulation

Internal and external waterproofing can be done using bitumen mastics. This technology is characterized by high adhesion. Thanks to this, the basement foundation will be reliably protected from moisture penetration. Before applying coating waterproofing, the following actions must be taken:

- The wall surface is thoroughly cleaned of all kinds of contaminants. This includes dust, grease and other contaminants.

- If there are sharp protrusions, they must be rounded. Major flaws should also be eliminated.

- If there are cracks between the blocks, then everything should be covered with special compounds.

- If there are sinkholes or widened cracks in the wall, then cement mortar will be required.

- To increase the quality of adhesion of the mastic to the surface, the wall should be treated with a special primer.

- Next, you should apply bitumen varnish under the mastic. It must be based on a binder material.

- Now mix all the components and apply the first layer of bitumen mastic to the wall.

Advice! To achieve the best result, it is recommended to treat the wall with two or three layers.

Basic options for protecting the basement from dampness

Check the intensity of moisture penetration inside and whether there is water in the room. Depending on the moisture level, the following waterproofing coating options will be relevant:

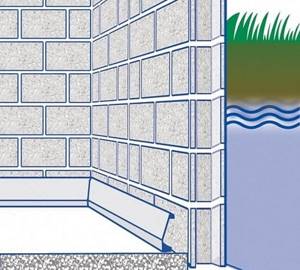

- anti-pressure is indicated when groundwater approaches the foundation at 10 m, and the foundation itself is not isolated from the outside and there is no drainage connected to it. The technique is based on pressing rubber or rolled material against the wall, but is effective at the initial stage of construction;

- You can get rid of the destruction of the damp base using the anti-capillary method. It is necessary to lay waterproof fabrics inside the basement;

- a non-pressure type of insulation, made as protection against temporary flooding, will prevent water from standing in the room. Bitumen is used as the material.

Each method of insulating the foundation and basement requires the correct choice of material.

Causes of dampness

To know how to effectively deal with dampness, you need to know the reasons for its occurrence. In some cases, the waterproofing is done, but there is dampness in the basement. The reason may be that the existing waterproofing was not installed correctly and because of this, the foundation began to leak moisture. Among other things, waterproofing can be installed correctly, but years later it does not fulfill its main purpose. This may be caused by groundwater rising in your area and eroding the existing protection.

The cause may also be an incorrectly manufactured or damaged blind area. As a result, water flowing from the roof seeps into the foundation. Of course, fixing such a problem can be very problematic, or rather, it will require a lot of labor. Below we will talk about how this kind of work is done.

There is another reason for the formation of dampness in the basement - condensation. It is formed due to temperature differences. For example, the heating system in the basement is designed incorrectly. Warm air flows interact with less warm ones and because of this, condensation forms on the basement walls. In this case, the ideal solution would be to waterproof the basement from the outside.

Types of waterproofing compounds

How to get rid of water that is destroying your basement? Start by studying the soil and foundation features. Before purchasing waterproofing compounds, determine the approximate depth of groundwater, the increase in soil during frost, the type of soil in your place of residence, and the purpose of the building. Modern manufacturers offer several types of compositions to prevent moisture in the cellar. Let's look at the most popular ones.

Use of bitumen resin

Waterproofing a cellar with bitumen is a budget option for eliminating a damp environment. The material consists of small bars that are applied to the surface in liquid form:

- bitumen resin and machine oil are placed in a large container in proportions of 3:1.

- the reservoir is heated and the mixture is brought to a liquid state.

- apply the mass onto a previously leveled surface with repaired cracks using a brush or roller.

- work from the bottom of the surface at a distance of no more than 20 cm from the soil.

- The optimal thickness for a cellar is 5 cm, i.e. 3 coats will be required.

The composition must be maintained in heating mode for ease of application. The bitumen shell blocks the appearance of moisture and protects the foundation from destruction for 5 years.

Roll types of materials

Roll materials are used with liquid formulations or separately. Owners of private houses and summer cottages can purchase roofing felt, TechnoNIKOL, Technoelast, Stekloizol, Rubitex and Gidrostekloizol. An inexpensive but high-quality option for independent use is roofing felt. To properly protect your basement from destruction, work like this:

- fix the material on a flat surface and apply bitumen mastic to it, heat the canvas with a burner and place it overlapping on the plane.

- the second option is fastening with liquid mastic. Coat the foundation with the heated mixture, and lay the rolled material on top of it. Coat the roofing material with bitumen and place another layer on top.

The combination of mastic and base material promotes good penetration into the concrete foundation and reliable waterproofing.

Advantages of liquid rubber

If water accumulates regularly in the cellar, use liquid rubber. The compositions adhere perfectly to surfaces, are protected from fire and form a continuous coating. Experts advise working with single-component rubber, choosing from two types of compounds:

- mixture for application in one layer. They dry within 2 hours after application, but can harden quickly in an open container;

- compositions that are applied in one layer. Sets within 24 hours.

Before the start of the event, the concrete base is cleaned of dust and primed. It is recommended to apply liquid rubber with a brush or spatula.

How to make internal anti-pressure waterproofing

Waterproofing the outside of the basement is done during the construction of the house. Since the water pressure presses the waterproofing to the base, it is made from roll coatings, bitumen mastics or cement materials.

And for internal waterproofing, it is important that the waterproofing material has excellent adhesion to the brick or concrete of the supporting structure.

Anti-pressure waterproofing from the inside of the basement is installed in already constructed buildings when water has treacherously filled the premises being used. Usually in such areas there is a high pressure of groundwater, there is no drainage system, and a solid and durable barrier is needed that will not allow water to enter the basement.

It is preferable to make a new one or restore the destroyed external anti-pressure waterproofing, but if this is not possible, do the internal one.

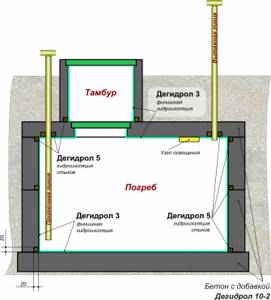

This method of waterproofing the inside of basements in private houses began to be used when new generation plaster solutions appeared, which quickly set and firmly adhere to the surface. The structure of such a water barrier consists of several layers - they are shown in diagrams published in 1996 by the Central Research Institute of Industrial Buildings in a document entitled “Recommendations for the design of waterproofing of underground parts of buildings and structures.”

Here's how this kind of waterproofing is done: a layer of hydrophobic cement solution is laid on a primed concrete wall. When it dries, it is primed again and three layers of cold bitumen mastic are applied, and a cement-sand mixture of grade M-75 is applied to it.

The next step is to install the reinforced floor screed, lay the reinforcing mesh and make formwork for the concrete slab.

In areas where the groundwater level fluctuates at around 15-50 cm, waterproofing is done according to a simpler scheme, without erecting reinforced concrete walls, with a slight slope to the pit.

1 - wall, 2 - crushed stone cushion with a thickness of at least 10 cm, 3 - concrete grade M-100, 4 - hydrophobic cement mortar grade M-150, 5 - bitumen mastic, 6 - TsPS grade M-75, 7 - TsPS M -100, 8 - thickening of cement-sand mortar, 9 - duplicating layer of bitumen mastic 3 mm thick, 10 - concrete of the original structure, 11 - foundation slab, 12 - formwork for pouring a concrete slab, 13 steel pins of round section, 14 - height UGV.

An automatic pump is installed in the pit, which pumps water into the drainage system or sewer system.

It is quite difficult to make the correct anti-pressure waterproofing in the basement with your own hands. You can master this technology, but you need to be prepared for its high cost: that a square meter of a basement will be more expensive than a square meter of living space. As the moderator of our portal with the nickname al185 says, success is only possible if

- The right project.

- Proper supervision that understands where to look.

Here's how and with what he recommends doing it:

al185MODERATOR FORUMHOUSE

- Footing - a layer of low-quality concrete 5-10 cm without reinforcement.

- Level the walls for pasting with grout or plaster.

- Pasting bitumen GI in two layers inextricably on the concrete base and on the walls.

- Floor screed 5-10cm M150-200, reinforcement #4x100-150mm on stands 20-30mm.

- Pressing masonry to the walls, half a brick.

- If insulation is necessary, use 10 cm PSBS-35 under the brick/screed, protect from bitumen GI with polyethylene film.

We arrange vertical waterproofing

The cellar in the house can be protected from water that appears after rain or melting snow, using the vertical technique of applying an insulating coating. Before starting work, it is appropriate to prepare the surface and surrounding area. To do this, the walls, floor and ceiling are cleaned, and a drainage system is created. Do-it-yourself waterproofing of the cellar is carried out in several versions.

Possibilities of the injection method

What should you do when water gets into the basement under your house or garage? Use a progressive but expensive injection technique. The work is carried out by creating a curtain of filter elements and installing a special membrane to protect against moisture. Injection waterproofing technique has a number of advantages:

- finishing materials and cladding from the base of the building are not removed;

- the underground room remains protected for several years thanks to the quality of acrylate gels and polymer resins.

One of the disadvantages of the technique is the strict sequence of work technology, which is difficult for inexperienced craftsmen to achieve.

Coating type of insulation

You can protect the cellar from the inside from groundwater, as well as perform external manipulations, using cement-polymer compositions. The waterproofing material with a flexible and rigid structure is vapor permeable and adheres well to the surface. The affordability of the composition, plasticity and ease of DIY work make coating a priority for home construction. Foundation waterproofing is carried out using fiberglass, brushes, rollers, spatulas and liquid mastic. To ensure the quality of the coating, proceed in stages:

- Clean the surface of the walls from dirt, round corners, and seal protrusions and crevices. Smooth porous areas with cement mixture;

- Operate on a minimally damp surface, which can be checked using polyethylene film. Place the sheet over a shaded area and inspect for fumes after 24 hours.

- Apply a thick coat of primer primer. Cover the joints and seams with a second layer.

- After the primer has dried, apply liquid bitumen mastic using a roller or brush. Maintain parallelism and direction of movements, trying to evenly distribute the material along the wall.

- The cement mixture with polymer additives is applied to the moistened wall surface with a brush, spatula or roller.

Wait for the composition to dry, rub the surface.

Welded method of vertical waterproofing

It is advisable to treat an underground room from the inside with your own hands using rolled materials when the foundation is deeply buried. Pasting the inside of the building will protect the base from damage for a long time if you follow the construction algorithm:

- Purchase bitumen-polymer roll fabric or roofing felt. It is better to refuse fiberglass or fiberglass - in aggressive environments the foundation will leak again.

- Prepare the surface, prime it with primer.

- Using a special burner, melt the bottom layer of mastic.

- Glue the rolls from top to bottom, maintaining an overlap of 10 cm. It is most convenient to work with material 150-200 cm long.

- Pay attention to corners and transitions. Pre-reinforce them with a 30 cm long piece of base material.

- The number of layers of glued insulation depends on the location of the foundation. Shallow structures require a 2 mm thick membrane. At an average depth, the layer thickness increases by 4-8 mm.

It is recommended to install waterproofing for the cellar 30-50 cm above the soil and fix it with a metal strip.

Types of waterproofing

Waterproofing work is often underestimated, and this kind of neglect leads to disastrous results. The thing is that each brand of concrete has a certain shelf life, after which its inevitable destruction begins.

The impact of groundwater and precipitation, the pressure of the entire house and other operational characteristics make a significant negative contribution. Moisture insulation protects the material, prolonging its usefulness, and increases the reliability of the entire structure.

Even if the residents of the house do not feel the effect of insulation, then after several decades or earlier it will still become clear that the benefits of such work are definitely great.

Traditionally, penetrating, pasting, spraying or coating materials are used for waterproofing. As experts note, sprayed solutions have the maximum effect.

Penetrating mixture

Penetrating mixtures are optimal for those who provide budget protection for basements from moisture. High efficiency occurs due to the chemical reaction of impurities in the insulation solution with concrete and water.

The resulting crystals fill all cracks and penetrate 10-15 cm into the concrete and form a protective barrier. If there are large cracks, the use of the solution is impossible due to the loose structure of the material.

Waterproofing the basement from the inside with Penetron from groundwater

There are many different penetrating mixtures, depending on the types of material and the types of impurities in the solution. But in any case, the use of such mixtures requires abundant wetting of the surfaces with water, which allows the insulation to penetrate deeper.

Among the most famous manufacturers of such mixtures is Penetron.

The range of mixtures from this manufacturer includes paste and liquid mixtures, bonds, fillings, solutions and much more.

All solutions of this brand are capable of solving many construction problems - eliminating leaks at the capillary level, protecting reinforced concrete walls and brickwork from moisture, sealing all cracks and joints, seams.

These compounds will isolate the basement from water, increase resistance to low temperatures, and improve the wear resistance and quality of the concrete itself. The only tools you may need are a spatula and a brush.

There are materials alternative to Penetron - the Millennium mixture produced in Spain by Satecma has the same characteristics. The production of this material is established using Spanish technology on the territory of the Russian Federation, which allows reducing prices for transportation and production.

And, of course, the time-tested water repellent GKZh-11N, produced by many manufacturers.

It is capable of increasing frost resistance strength to 400 units, and raising the water repellency grade to W200, without losing the strength characteristics of the base.

At the moment, there are many different penetrating materials from well-known manufacturers on the construction market, and only a specialist can understand the subtle differences in characteristics between them.

Sequence of work for penetrating waterproofing

To perform high-quality waterproofing, it is necessary to carry out the following work:

- Pump out groundwater from the basement (if it is flooded) and around its walls, you can use a pump to speed it up;

- If there was water inside the basement, it must be thoroughly drained and ventilated;

- Inspect supporting structures for damage and eliminate existing ones;

- Wash walls, floors and ceilings from dust, seal large cracks;

- Moisten the surfaces with a spray bottle or a wet cloth;

- Prepare smooth surfaces for processing - use a metal brush to make the surfaces uneven and rough for better penetration of the insulation solution:

- Prepare the solution by mixing water with the insulation mixture in the indicated proportions;

- Apply insulation to concrete or cement;

- Repeat the layer if necessary, checking the re-application time on the packaging;

- Leave for about a month (each manufacturer has different terms) before finishing work begins.

Penetrating waterproofing is applied, starting from corners and joints, and only then moving on to the flat surfaces of the floor, walls and ceilings. Can be used for application with a spatula. If you moisten the applied layer with water, the chemical processes are accelerated and the treatment can be repeated again.

Features of horizontal insulation

Waterproofing the cellar from the inside using a horizontal method is carried out at the initial stage of construction. It is impossible to equip it in a finished house. To ensure that there is no water on the ground floor, it is advisable to adhere to the following technology for performing tasks:

- The first level of protection is laying and compacting a cushion based on sand and gravel. It is placed under the base in the form of blocks or under a solid monolith.

- During the concrete screed, roofing material or PVC membranes are laid in the basement, which help protect the foundation from the inside from soil water or capillary rise of liquid.

- Rolled materials are laid on a surface treated with a primer. The sheets must have an overlap of 10-15 cm. When combining layers, the overlaps should be increased to 25-30 cm.

- The waterproofing coating is steamed with a gas burner - this improves the adhesion of the sheets.

The protruding ground part is processed according to a similar principle.

How to waterproof a basement from the inside with your own hands: step-by-step instructions

If there is a basement in the project of a house under construction, it is necessary to plan in advance the work on waterproofing the basement, otherwise later you will have to be content with only half measures - after all, the foundation will already be difficult to access for timely processing and the question will certainly arise: how to waterproof the basement from the inside with your own hands?

Let's start by watching the video: If water does appear in the basement of a new house, or the house was purchased with existing problems with waterproofing, then you will have to work hard and try to solve the problem of waterproofing the basement on your own. Basement waterproofing involves a set of operations to waterproof the floor and walls, as well as to prevent the movement of water from bottom to top through capillaries.

After all, a dry basement is not only a place for safe storage of conservation and unnecessary things, but also a guarantee of the longevity of the entire house.

Is drainage necessary?

Special communications installed in the yard are a reliable method to protect your cellar from water ingress. The drainage system enhances the effect of insulating materials. Drains are arranged in two ways - external and internal.

External drainage technology

The system involves the redirection of water flows from the basement and is installed at the stage of construction work. For an existing building, drainage is done as follows:

- A pit is dug with a width and depth of 40 cm;

- Wells are formed to the level of the sand layer at a distance of 2 m.

- A metal grating is laid over the dug holes.

- A plastic pipeline is being installed. The minimum diameter of pipes that are wrapped in geofabric is 40 cm.

- At the bottom of the pit, geotextiles are laid, and gravel with medium fractions is placed on it.

- The pipe is installed by extending the upper part beyond the lower part of the basement wall.

External drainage is covered with removed soil, carefully compacting each layer.

Creation of an internal drainage system

You can eliminate water standing in an underground basement using internal drains. The system is installed after the flooring has been laid:

- A trench is dug throughout the cellar, deepening it by 50 cm;

- Pour crushed stone into a 20 cm layer at the bottom of the pit and compact it.

- Lay a pipeline wrapped with geomaterial and fill it with material with fractions of no more than 20 mm.

The trench is filled with sand. It is advisable to install a drainage well at a low point in the basement. Water will flow there. If necessary, a sediment system for pumping water is installed in the containers.

What you need to know about self-waterproofing?

Independent installation of a waterproofing coating requires compliance with the basic rules:

- Materials are applied only to a dry surface;

- Seams, undried plaster layers or damp walls are painted with a liquid primer - a bitumen-based emulsion. The next layers will be made with thick compounds;

- When purchasing insulation products, consider their effect on reinforcing elements, joints and seams;

- For brick surfaces, it is worth using cement mortar reinforced with polymers or liquid glass;

- Floor surfaces are waterproofed with self-leveling polymers;

- For the walls, floors and ceiling to completely dry before work, 5 days are enough.

Follow the work technology and the requirements for the insulation procedure for the basement floor - this will reliably protect the structure from water in the cellar and destruction.

Source

Universal Cleaner

Moss and mold cleaner for walls, floors and roofs (concentrate)

Read more

In addition, it has the following advantages:

- works underwater;

- hardening time - from 1.5 to 5 minutes;

- has high adhesion to various materials;

- can be used for both external and internal work;

- it is environmentally friendly, which means it can be used without a doubt in private homes, in basements intended for storing food;

- vapor permeable;

- waterproof;

- frost-resistant;

- durable;

- economical;

- allows operation in the temperature range from +5°C to +30°C.

WaterPlug CEMMIX dry mix is easy to purchase in retail stores, for example, the Leroy Merlin chain or wholesale from the manufacturer.