Home / Installation, repair, maintenance / Insulation / How to insulate a corrugated roof from the inside

Corrugated sheeting has become a modern substitute for outdated slate. In many respects, this is a more advanced material, which has only one significant drawback - it is completely unable to retain heat. Therefore, a roof made from it will require the construction of an additional insulating structure. In this article we will try to figure out how to insulate a corrugated roof from the inside, since it will not be possible to do this from the outside without completely disassembling it.

The need for roof insulation

It is unlikely that anyone will insulate the attic roof. The cold attic in private houses of old traditional construction serves as a storage place for things that have served their time.

A complex insulated roofing assembly can be constructed by a person who, with the help of an attic, intends to significantly increase the volume of a residential location. That is, he creates additional living space under the roof of his house.

Its construction will require different technological content. The traditional roofing assembly has been thoroughly modernized, introducing into its structure new elements necessary for the construction and long-term functioning of the insulating layer.

The modern attic usually serves as the main sleeping area for family members. The premises are equipped with all types of plumbing and sewer systems:

- showers;

- toilets;

- natural and forced air ventilation;

- electricity.

All this requires a certain positive temperature for its normal functioning.

An insulated roof covered with corrugated sheets, metal tiles, painted reeds and other roofing materials can create a favorable operating conditions.

What thermal insulation materials are needed to insulate a corrugated roof?

Private housing construction has received an exclusive direction for the manufacture of insulated attic roofs. From the various methods of installing a warm roof covering, the best option has been identified, which has become the dominant element today.

Integrated into the warm layer:

- lining or dry plaster;

- a thin layer of vapor barrier is placed on the internal finishing material;

- the space between the rafters is filled with insulation;

- then they are completely covered with a hydrobarrier (roofing felt, a special synthetic film);

- they are sewn over the top with lathing in increments of 1-4 cm. To organize the ventilation space, counter-lattice is installed in increments of 40-50 centimeters.

Corrugated sheeting is attached to the sheathing. With a pitch of 35 centimeters, there is a guarantee that the wind will not “lift” the profiled sheets.

Important

- Use environmentally friendly thermal insulation materials.

- With low thermal conductivity.

- Does not form unpleasant odors

What to prepare before starting work

Insulation installation work

A classic of the genre - marking corrugated sheets using twine and chalk

Electric scissors – will provide high productivity

Basic requirements for materials when installing a warm roof made of corrugated sheets

When insulating a roof, you should use materials with the following characteristics that have acceptable performance:

- by thermal conductivity;

- by hygroscopicity;

- by vapor permeability;

- by elasticity;

- by compressive strength;

- by elasticity.

The installation of a warm roof requires high-quality materials. It refers to

- vapor barriers

- hydrobarrier

- insulation

- corrugated sheets.

A warm roof includes auxiliary materials: for steam removal, waterproofing devices.

Today, construction trade enterprises will offer the developer a wide range of goods, both domestic and imported. Usually these are polyethylene films with the necessary performance characteristics. Inexpensive but functional.

Steam-hydro-windproofing materials

Many people still use roofing felt as a water barrier. Cardboard impregnated with bitumen cannot be a suitable location for harmful bacteria and fungal colonies that can turn wooden components and elements of the roofing system into dust.

As for insulation, all kinds of materials of organic and chemical origin are used:

- mineral wool

- stone wool

- bulk materials subject to packaging

- penoplex

- Styrofoam

- other

Thermal insulation materials

Installation

Depending on the selected material, the installation technology will be different. However, expanded polystyrene boards are laid between the rafters or simply glued to the surface of the ceiling with glue, which does not cause difficulties and does not require detailed explanation. Polyurethane foam is sprayed by specialists using special sprayers and you don’t have to do anything yourself at all.

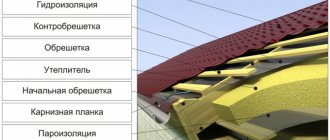

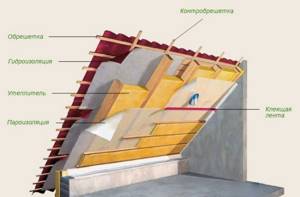

You will only have to figure out the technology for laying mineral wool. This is not difficult - the main thing is to follow the order of laying the different layers of the structure. If you count from above, from the plane of the corrugated sheet, then the order will be as follows:

- Waterproofing layer

- Insulating layer

- Vapor barrier film

- Exterior finishing (if necessary)

The rest is simple - choose the form of insulation that is most suitable. It can be a roll or slabs. The parts are cut to size with a special knife and attached either with glue or with special dowels spaced between the rafters. The insulation cannot be compressed, therefore, you need to adjust its size as accurately as possible. After laying the heat insulator, the surface is covered with a decorative coating if necessary.

Corrugated sheeting with insulation on pitched roofs

Private housing construction rarely has flat roofs. Most of the objects are of pitched type. And here it is necessary to strictly observe the measure.

A pitched roof with an optimal slope of 20% will be effective.

From the bottom, fixed to the counter-lattice of the corrugated sheet, there is waterproofing, in the descending direction - insulation, then vapor barrier and internal finishing lining.

The entire layer is necessary not only to retain heat in the attic. It dampens street noise.

If it were not for this layer, it would be impossible to sit in the attic during a summer rainstorm.

Roof installation. Roofing pie

Reference! Builders and heating engineers estimate that 20 percent of the heat from a house escapes through the roof.

It turns out that people use valuable fuel, especially natural gas, to heat the air. Help industry create the greenhouse effect. Heat escapes through objects that have attics. They are not insulated and are used ineffectively.

People have become thoughtful and today it is clear that there is an active offensive against the irrational consumption of home heat. Successfully. A significant amount of thermal energy can be conserved in attic buildings. Occurs thanks to a roofing cake consisting of various materials. To confirm these words, consider what it consists of:

- The roofing pie is formed from several dissimilar materials with different technological characteristics.

- The most important layer is corrugated sheeting, which creates conditions for the formation of the best performance characteristics of the roofing pie. It prevents it from getting wet during rain, snow, melt water, and so on.

- To help him, there is a hydrobarrier - a kind of gasket between a warm cake and metal profile sheets.

- Next, the insulation is located in the roofing system. Its task is to prevent thermal energy from entering the atmosphere and to prevent cold air from entering the attic space.

- The last layer, the vapor barrier, regulates the removal of vapors from the attic space. Even lower comes the finishing material, which creates a creative interior in the attic.

We make sure that each element of the roofing pie performs its specialized function. And the more rationally the layers are selected, the better the roofing cake will work.

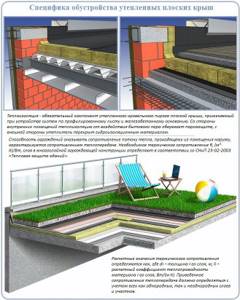

Installation of warm roofing from corrugated sheets on flat roofs

The technology for installing warm roofs on flat roofs has not gone far. It existed before, but with the advent of innovative materials, it did not become worse, but better.

Corrugated sheeting is used in large quantities in the construction of flat roofs for offices, private houses, buildings of small and medium-sized enterprises, and warehouses.

Flat roofs are:

- traditional;

- inversion.

Their structure includes bases that experience force loads. It can be

- reinforced concrete floor slabs

- corrugated sheet

- or another basis.

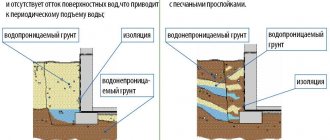

If the floor is reinforced concrete, then first a thin cement screed is made, insulation is placed on top, and then a waterproofing layer is applied. The final coating is roofing felt, poured with heated bitumen mastic.

This is a traditional method with a limited number of layers. If there is no lump insulation, then a layer of expanded clay is used.

In recent years, they have begun to use it as a material, a vapor layer.

They began to integrate into a warm pie

- fiberglass

- geotextiles

- other materials.

Moreover, bulk insulation began to be used as a material that forms roof slopes.

In the middle they make the layer thicker, reducing it towards the eaves.

Inversion structures are installed on already completed roofs. Gardens are laid out on them and terraces are arranged.

Warm flat roof pie

Advantages and disadvantages of profiled sheets

The metal roof looks very solid.

In this regard, many developers want to get such coverage for themselves. When purchasing thin sheets of metal, they may not even be aware of its weaknesses.

The disadvantages of corrugated sheets include:

- High thermal conductivity. No matter how cold the environment is, the surface of the metal will be even lower.

- In sunny weather, the material heats up to high temperatures, as a result of which it becomes simply unbearable to be in the attic.

- Low sound insulation. The same small thickness of the metal product becomes another disadvantage. When it rains, falling drops will create a loud noise that echoes throughout the attic space. In addition, you will always know exactly where the bird landed or the cone fell. For most people this is a serious drawback, but for some it has a calming effect.

- During operation, a large amount of condensation occurs, which can damage the thermal insulation material.

As you can see, there are plenty of disadvantages, but they are all covered by its advantages, even more than that.

- Some types of pronfastil can be purchased at a lower price than asbestos slate. Private developers are actively taking advantage of this and buying material, if not for a residential building, then for an outbuilding.

- Long service life. The material can last you up to 50 years without repair, the main thing is to take care of it. By this I mean frequent preventive inspections (at least 2 times a year) and surface painting. This way you will protect the material from corrosion, thereby extending the life of the entire building as a whole.

- Small mass. Thanks to this property, the material is easy to transport, load and unload, deliver to the roof and install.

- Easy to install. As a rule, corrugated sheets are purchased at a hardware store in such a length that they completely cover the length of your roof slope. Thus, very few seams are formed on the surface, which significantly affects the tightness.

- Due to additional stiffening ribs, the corrugated sheet can easily withstand prolonged loads.

- The sheathing can be laid using the discharge method, which saves on lumber.

There may be something missing in the two lists, but I have highlighted the main points.

Options for insulating a flat roof from the outside and inside

The variety of insulation options for such roofs is obvious. But they have one drawback. There is no rafter system. That is, the sinuses between the rafters. There are many options for insulating both outside and below. Choose the best insulation and hang it, for example, from a concrete floor using plastic dowels. Afterwards, the insulation is covered with a special cement mortar, painted or whitewashed.

Task number one: It is good to arrange the junction of the water removal and steam outlet. Work on the waterproofing device

Insulation of a flat roof

Mineral wool

The best would be an insulated roof made of corrugated sheets, where the heat-insulating lining will be mineral or basalt wool. This is the most popular insulation option, although installing wool will require more time and, in addition, you will need to purchase additional materials in the form of a vapor barrier and waterproofing film.

They are necessary in order to protect the fibers of the insulating material from moisture from the outside and protect it from excessively humid air coming from inside the room. The membrane will allow moisture to penetrate outside, but will not allow it to accumulate inside the insulating layer, and waterproofing will protect the heat-insulating layer from external influences such as precipitation.

How to make insulation with polyurethane foam

This is high-tech in the technology of insulating any structures of private houses. To create consistency, equipment has been created and sold that can be used to insulate both vertical and horizontal structures.

The blowing or pouring method is used. It is more productive to use a spraying method in which the following occurs:

- filling all gaps of any size;

- expanding in volume, creates a solid, durable coating.

Polyurethane foam is obtained by mixing polyol and polysacyanate, which are in a liquid state. Mixing occurs without access to oxygen during spraying. Apply the consistency to the structural elements with a pistol. As the material cools down, it increases in volume several times.

Important! Polyurethane foam is a universal insulation material. Used for insulation of walls, ceilings, floors, roofs

Expanded polystyrene

Despite the similarity of names, it is very different in characteristics from the previous type of insulation. Expanded polystyrene is sold in the form of slabs of different thicknesses, which can be attached to any plane using glue or special dowels with a wide head. Seams and joints between individual slabs are filled with polyurethane foam.

The disadvantages of this insulation include several points: it is flammable, capable of releasing caustic toxic fumes when melting and burning, and can also cause unpleasant olfactory sensations - a chemical smell accompanies this material almost throughout its entire service life. In addition, you will need to purchase a sufficient supply of polyurethane foam to seal the surface and fill the joints between the plates.