Insulation from the inside with mineral wool is similar to sabotage in order to cause maximum damage to the structure and people. Standards require that experts recommend thermal insulation only on the outside of the building.

But insulation from the inside is an extreme necessary measure, and it must be carried out according to certain rules. Can this be done using mineral wool with special measures to protect structures?

Let's decide in order - how to properly insulate, how mineral wool should be used, what common mistakes and opinions exist in this regard.

Lack of insulation from the inside - freezing

When insulated from the inside, not only with mineral wool, but also with any heat insulator, the wall is protected from heat, so its temperature decreases.

Moreover, with a sufficiently large amount of insulation, the wall can freeze through. Freezing a structure is always bad, because for any material there is a finite number of freezing cycles before its destruction. It’s even worse if the wall freezes while wet. In this case it will be so.

Humidification, dew formation

The dew point - the temperature at which dew falls from the air - will be located directly on the wall. More precisely, condensation may begin to fall in the insulation, but the cold surface of the wall will also condense water on itself.

And there will be a lot of water, it will also flow onto the wall from the insulation, especially if you use mineral wool.

A wet wall will grow excellent “greasy” mold and large colonies of putrefactive microorganisms. All this will be located indoors, spreading from the wet collapsing wall along the ceiling, floors... Residents will need means of rescue. Finally, when insulating from the inside, the heat insulation and finishing will take up part of the usable space. The usable area of the room will decrease by about a square meter. It's a lot.

The above disadvantages can be circumvented and leveled out (except for eating up the usable area). But only if mineral wool is not used for internal insulation.

Mineral wool is moisturized and accumulates water

Mineral wool is not suitable for insulation from the inside, even in forced situations, due to its properties. This insulation perfectly allows water vapor to pass through itself and can accumulate water inside, becoming simply wet.

It is clear that when insulating from the inside, the insulation will become wet due to the dew point in it and the lack of ventilation. The consequences are known. The material consists of tiny fibers of basalt or other minerals. It is also made from blast furnace slag and silicates (glass wool), these samples are cheaper. To bind the fibers together, phenol-formaldehyde resins are used, the same as in the production of chipboard.

Mineral wool owes its good thermal insulation to the air trapped between many interwoven fibers. If the air is replaced by water, at least partially, then the required thermal insulation qualities will disappear.

Damp wood and harmful fungi

It is no secret that wood is very quickly attacked by mold fungi if it is always wet. The tree ceases to be strong enough after just a few months. If you start the process and ignore it for a couple of years, the fungus will spread and the material will turn into dust. The most important condition for mold development is optimal amounts of moisture. Therefore, in order to keep the floor of your home in optimal condition for a long time, it must be protected from high humidity.

The absolute humidity of freshly felled coniferous trees is about 90%, of a log house before installation - from 25 to 35%. As for a wooden floor, its absolute humidity under normal conditions throughout the year remains at 10-20% - everything is connected with the current time of year. It is worth saying that the fungus begins its activity when the humidity rises to 22%, and this is only a couple of percent more than the maximum natural state of the tree. By the way, this environment is also optimal for the wood-boring beetle to take a fancy to the log.

With constant high humidity, the wood will lose strength, mold and mildew will begin to appear.

Note! Under no circumstances should the wood be over-wetted as this will cause the structure to decay.

If there is too much water in the tree, it will begin to rot.

Why is vapor insulation necessary?

As we said earlier, wood is a rather specific material for construction: it is excellent for air permeability, but likes to absorb water, and for this reason it swells. Ignoring this fact, you may encounter the following troubles:

- the floor will become crooked or “bulge”;

- finishing materials or coatings will be damaged;

- You can find mold in the corners, which will make the house smell disgusting;

- when water freezes during winter frosts, it expands, causing cracks and small crevices in the wood to become larger - this causes rapid wear of materials (if we are talking about open spaces);

- After a few years, the floor will no longer function correctly, and you will have to install it again - this is costly both financially and in terms of effort.

Moisture frozen in winter expands, and this can lead to damage to building materials.

All of these problems can be avoided if you make a high-quality vapor barrier for the floor.

Floor construction

Floor coverings in wooden houses can be completely different - it all depends on the financial capabilities and preferences of the home owner. But this is only the last stage of a lot of work with the floor - before this, several layers of different materials must be laid, which will ensure the durability of the structure.

As a rule, the floor consists of the following elements:

- subfloor - consists of wooden logs and boards. Sometimes sand and concrete screed are used;

- waterproofing layer - it is necessary to prevent moisture from entering from below, that is, it protects all subsequent layers. The waterproofing film is placed between the subfloor joists and secured so that there is no tension. If necessary, the sheets are joined, but always with an overlap of about 20-30 cm. Such a film can be secured using a special adhesive tape, a stapler, or nails;

A layer of waterproofing must also be laid, which will protect the structure from moisture from below. - thermal insulation - it is usually placed between the subfloor joists. For thermal insulation, stone, mineral wool, and sometimes basalt wool are used. It is mounted in such a way that there are no gaps left. If the subfloor was made of sufficient quality and is durable, you can use bulk insulation (like expanded clay);

- vapor barrier. This layer is necessary to protect the inside of the floor cake. It prevents the penetration of steam that accumulates indoors.

- finishing layer. Here we are talking specifically about floor coverings - these can be ceramic tiles, parquet, laminate, natural boards, etc.

The floor covering should be laid only after a layer of vapor barrier

It is important that the sequence must be strictly the same as we described earlier. If you swap at least two layers, you may encounter moisture accumulation under the floor covering, which will lead to rotting of the floor in a wooden house. It won't last very long and you'll have to do a lot of work first. This is why vapor barrier is so important.

At the same time, we note that some craftsmen prefer to lay several layers of vapor barrier: the first - on the subfloor boards (instead of waterproofing), the second - after thermal insulation.

By the way! Typically, vapor barrier materials are sold in rolls, which are twisted so that they are laid with the correct side to the insulation. If you miss this moment, the vapor barrier simply will not “work” as it should.

It is important that the vapor barrier material is laid on the floor with the correct side, otherwise it will not “work” properly

Insulating the house from the inside: installing thermal insulation for the ceiling without condensation

The purpose of constructing a ceiling is to create an insulating pie that would be maximally protected from the effects of condensation moisture. In order for the ceiling to always remain dry, when installing insulation, it is necessary to solve a triune technical problem to protect the ceilings and remove moist air:

- Protect the insulation from saturation with vapors from below. For this purpose, vapor-proof films are usually used.

- Provide mechanisms for extracting condensate formed in the insulating layer itself. This goal is achieved by arranging ventilated gaps between the insulation and the overlying floor boards or sheathing.

- Provide a way to drain water from the lower surface of the vapor barrier film - so that drops from the film do not flow down, but dry out. This problem is also solved using an air gap.

There are two most important technological measures to get rid of moisture in the ceiling of a private house:

- Minimization of condensation due to uniform heating of the entire ceiling surface. This measure is aimed at creating the most homogeneous interfloor pie: it helps to overcome two dangers.

The first danger is wide gaps in thermal insulation and vapor barriers. Occurs between panels of insulation, between panels, in the corners of rooms;

The second danger is cold bridges - places where frosty air penetrates most intensively into the room. Conductors are metal dowels, anchors and other heat-conducting objects driven into slabs or beams.

Main recommendations for installing floor vapor barrier in a wooden house

What is important to consider?

- Do not skimp on vapor barrier material - how long the floor will last depends on this layer. If you do something wrong, mold and mildew will quickly form, and the wood will turn into dust.

- All overlaps and gaps must be glued - this is the only way to ensure high-quality vapor barrier.

- There must be a ventilation gap between the vapor barrier and the floor covering, which can be ensured by laying a counter-lattice.

It is worth leaving a gap between the vapor barrier and the floor covering, which is formed after installing the counter-lattice - Using a vapor barrier material with an aluminum layer will help retain heat in the room.

- It is worth using materials only from well-known, trusted manufacturers.

Important! Even if the vapor barrier was done correctly, using only high-quality materials, it will not work properly without properly equipped ventilation in a wooden house, which is necessary to remove moisture. Without this, living in the house is unlikely to be comfortable, and the microclimate will not be correct.

Ceiling insulation: features of choice

Building a wooden house is the fastest way to get your own home. If the owner has the intention of living there not only during the warm season, but all year round, then he needs to take its decoration seriously. In the Russian climate, insulation is important when building a residential building.

The more the owner of a private house is faced with the problem of high heating costs, the faster he comes to the conclusion that the room needs to be further insulated. Thermal insulation of the ceiling space is extremely important in this matter. This is due to the movement of air around the room.

If the ceiling is not insulated, there is no heat reflector, then most of the warm air will escape through it.

According to physical laws, heated air will always be at the top. Therefore, if energy-saving packages are installed, walls are insulated, good doors are installed, but the ceiling is not insulated, all efforts will be in vain.

Vapor insulation materials

At the moment, the industry presents a fairly large range of materials for vapor insulation. Almost all of them are artificial polymers, since fibers of natural origin are characterized by excellent water absorption and transmission in two directions.

An important criterion for the quality of such products is the impossibility of steam passage. This is defined as the amount of water in grams that can pass through a square meter in a day: grams per square meter. Good permeability should not exceed 15-20 grams per square meter.

You can create a vapor barrier using various materials

If you look at the pros and cons of materials, then you need to analyze the material from the angle of the following qualities:

- service time;

- mechanical strength;

- the ability to pass air and at the same time hold water.

When choosing a material, you need to take into account strength, ability to pass air and retain water

Most of these materials are characterized by an insufficiently high ability to provide access to air, as a result of which a greenhouse effect occurs in housing. People should systematically ventilate the house, even if the winter weather outside is cold.

Let's consider a comparative table of materials, which describes the advantages and disadvantages, as well as the degree of budget.

| Material | Characteristic |

| The cheapest option that provides heat insulation. You can buy it in rolls. It has very low strength and a short service life. Therefore, it is better to take a model reinforced with fiberglass mesh. This allows you to strengthen the material, as a result of which it “lives” longer. This film protects well from steam, but it does not allow air to pass in either direction. Therefore, condensation may accumulate on the material; water from the natural drying of the wood remains. The effect of this isolation is doubtful. |

| This material costs a little more. As for insulation from steam, the performance is similar to the first material, however, the metal surface allows you to accumulate heat, drying the condensate. |

| This material is completely moisture- and vapor-proof. It differs from the others in that it insulates heat. The metal side of the film is placed towards the home, allowing it to effectively reflect heat. Based on the thickness, the thermal insulation properties of the material are considered. |

| A quality option. The idea is that the membrane allows steam to pass in one direction. In other words, moisture will come out of the floor, but new moisture will not appear. The price of the material is rather high, and it is also not always suitable for vapor insulation of walls on the street side. |

| Another membrane material. In addition to flooring, it is used to insulate walls from the outside, as well as for roofs and ceilings of buildings. This is a one-way material that does not allow steam to pass in the opposite direction at all. There are several varieties - we will talk about them a little later. The film is of high quality and can withstand gusts of wind without any problems. Installs very easily. The best option in our case. |

If you puncture small holes in polyethylene or propylene film, you will not get enough air. The floor must receive air directly from the entire surface. In addition, warm air will enter such holes along with the water that has evaporated there. Therefore, this material makes no sense.

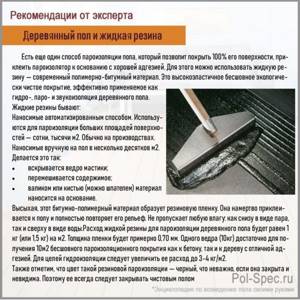

Wooden floor and liquid rubber

Types of membranes for vapor insulation

If we look from the point of view of consumer properties, it is advisable to divide the materials for the insulation we are considering into membranes and others. The reason is that the membrane is a new generation material, it is not similar to the usual polymers of artificial origin.

Main advantages:

- they allow water to pass through in volumes of no more than 10 grams per square meter per day, so they are very often used in rooms with high humidity (for example, a bathhouse);

- since the structure of the material is porous, it perfectly holds condensation, preventing it from getting into the insulation material;

Vapor barrier membranes can be used when arranging a bathhouse - the material copes with temperature changes from minus 40 to plus 80;

- since the structure is reinforced, the fibers can cope with work without wearing out for ten years or more;

- the porous structure provides excellent gas exchange between the home and the environment;

- Some of the membranes are reinforced with foil, which reflects heat coming from the room, so they help the insulation material maintain the internal temperature of the house in winter.

Based on their functions, membranes can be divided into:

- anti-condensation – preventing water from penetrating;

- foil - in addition to insulating steam, they leave heat.

Membranes can be anti-condensation or foil

If you look at market prices, the cost of membranes is quite high compared to other materials. Let's look at the price tag for a 75 square meter roll.

| Brand | Cost in rubles |

| "Tyvek Soft" | 5200 |

| "Delta Vent N" | 8900 |

| "Delta Maxx" | 12100 |

| "EUROTOP T150" | 8000 |

The cost of membrane vapor barrier is quite high, but its properties justify the price

To a large extent, the production of membrane material is carried out in Germany. The high cost will pay off if the owner plans to thoroughly decorate his house. If you do the math, constantly replacing the insulating material and laying out a new vapor insulator will cost more than choosing high-quality materials.

Which side to lay

It is necessary to lay the vapor barrier material from the side of the room on top of the insulation with the side that is specifically intended for this purpose by the design of a particular type of insulating material.

- Polyethylene film. Polyethylene film is a vapor barrier material that provides complete insulation from water vapor contained in the air, and is one of the cheapest and simplest vapor barriers. It has only one layer, with the same characteristics of the sides, which allows you to lay it however you like.

- Steam condensate film. The vapor-condensate film is created using a two-layer technology with an inner smooth layer and an outer rough layer, along which drops do not flow down, forming puddles and, lingering on its unevenness, evaporate. It spreads with its smooth inner side on the insulation material, and its rough side faces the inside of the room.

- Diffusion membranes. Diffuse membranes belong to insulators with limited vapor permeability and consist of a polymer-based film and non-woven polypropylene. Unlike conventional film, they allow a certain amount of water vapor to pass through them, which does not harm the insulation, as it evaporates very quickly. Such an insulator is fixed according to the same principle as its steam-condensate counterpart, that is, the smooth side is on the insulation, and the rough side is out.

- Energy-saving vapor barrier materials. Energy-saving vapor barrier materials are installed with a foil covering inside the room, because it has the property of reflecting heat back into the room in the form of infrared radiation. This type of insulation is represented by films with a heat-reflecting coating. The energy-saving effect in them occurs due to the presence of an outer metallized layer that is resistant to elevated temperatures and reflects a significant proportion of energy in the form of radiation in the infrared range.

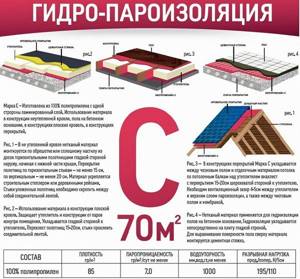

Types of materials

Based on the location of the material in a particular part of the home, they are classified:

- types A and AM – protects the insulating material from the influence of the external environment;

- types B and C – protection of the insulating material from the action of internal moisture;

- type D – protection of the floor from moisture coming from the soil.

There are several types of vapor barrier materials

Type A

Materials of this type are used for walls and roofs. Type A materials are rarely used for flooring.

For the membrane to work correctly, so that it allows water to pass through from the inside and does not allow it to pass through from the outside, it is necessary to carefully place the layers. The marked side must be placed in the direction of the street.

Type A vapor barrier materials can be used for walls and roofs - they are rarely used for floors

Type AM

This type is mounted in the same way as the previous one; it is also more suitable for walls and roofs. However, it has a rather complex and multi-layered structure:

- layers of spunbond (1-2);

- diffuse film.

Due to the film, steam escapes from the inside, but liquid from the outside does not enter inside. A distinctive feature of the type is that it does not need to provide a ventilation gap. Therefore, it is placed close to the insulating surface.

Spunbond is a method of producing a waterproof polymer film and a direct product of this production. In this situation, the fiber is made from artificial threads, which are stitched together under the influence of chemicals, heat or water jets.

Materials of type AM are similar to type A, but differ in their multilayer structure

Type B

This insulation is required to protect the floor of a wooden house from water from the inside. It is also used for walls. By the way, type B materials are often used for vapor barrier between floors.

Multilayer materials protect well from the wind, while foil materials keep heat inside, since they reflect it over the entire surface.

Type B materials are most suitable for internal floor vapor barrier

Type C

This is a very durable membrane that includes 2 layers. It is necessary for the same thing that the B-type is for. It is advisable to use for additional heat in rooms without heating that are associated with housing:

- attic;

- basement;

- base;

- veranda or porch.

Type C vapor barrier materials can be used for rooms without heating, but they are also perfect for floors in a wooden residential building

Type D

These materials are made from polypropylene. For reinforcement, an additional lamination layer is used. Therefore, it can be used for floor insulation - in other words, when there is a possibility of a large mechanical load from furniture, movement and wind.

vapor barrier for floor

Why is it necessary to do a vapor barrier when insulating with polystyrene foam?

Since the air humidity inside the building is higher than outside, steam moves from an area where there is more of it (high pressure) to an area where there is less of it (low pressure). When it passes through a wall or insulation, along its path it can hit the dew point (the point at which the temperature of the wall corresponds to the value at which steam begins to condense, approximately 13-17 ° C).

When condensation occurs a short distance from the outer surface, this is normal. But when the dew point moves inside the structure, the wall freezes, and moisture gradually permeates the structure until it reaches the inner surface. This way the wall gets wet.

To avoid this, you must:

- move the dew point outward of the wall. This can be achieved by insulating the walls from the outside, in which case a vapor barrier will not be needed;

- to prevent moisture from penetrating inside the structure when the dew point is closer to the inner surface, a vapor barrier is installed.

Options for fixing film for vapor insulation

You can record the material like this:

- using a stapler for construction;

- using special tape or adhesive tape.

Often these two options are combined. Most adhesive tapes are made from virtually the same components as vapor insulation. Reinforcement occurs using spunbond technology, since it is believed that the material will be under constant load.

Secure the vapor barrier material with a stapler or special adhesive tape

Let's look at the types of adhesives used for the types of membranes under consideration.

- Izospan KL tape is used to secure fabric classified as A-type. It is highly durable, copes with temperature changes, and is not afraid of exposure to water. Can perform its functions well for more than ten years. It is necessary to glue the fabric with an allowance of about 15-20 centimeters, no less.

- Izospan KL+ tape is characterized by high mechanical strength, since it consists of two layers of polymer with reinforcement. It is used for harsh winter conditions, as it is not afraid of temperatures down to minus 50. It is worth saying that the tape is universal, since it can be used for absolutely any type of membrane.

- Izospan ML Proff tape is an excellent choice if work will take place on complex surfaces, such as pipes, ceiling and wall curves, corner protrusions and communications. The tape perfectly secures the membranes and also serves as a good insulator against steam.

There are several types of adhesive tapes for different types of materials

adhesive tape Izospan

Installation of floor vapor barrier in a wooden house: step-by-step instructions

Step 1. If you are laying a vapor barrier under the finished floor, and not during the construction process, you need to remove the floor covering and remove all debris and dirt. The wooden elements of the subfloor are treated with special antiseptic agents - this is necessary to protect against mold and mildew.

Step 1. If you are doing a vapor barrier not during a major renovation, you will have to remove the floor covering

Step 2. The waterproofing is laid, a layer of thermal insulation is placed on top. If these layers are already laid on your floor, this step is therefore skipped.

roll waterproofing

Step 2. Before the vapor barrier, hydro- and then thermal insulation is laid

Step 3. Laying vapor barrier. It is very important to place it on the correct side (if you are using a special material and not just plastic wrap). You need to focus on the inscriptions on the material, its smoothness and roughness of the sides. The smooth side always fits against the insulation. When using metallized material, the metallized side must touch the insulation. Polypropylene, which has a one-sided lamination, is also laid with the smooth side down. And if you are using a three-layer film with a reinforcing mesh, you need to lay it so that the denser side touches the insulation.

Step 3. Lay a vapor barrier. The film, as mentioned earlier, must be laid correctly

How to fix it? As we said earlier, this can be done using special tapes and/or a construction stapler. Do not forget about overlaps of 20-30 cm. You need to try to fix the film as best as possible, in several places, but at the same time it should not be stretched - this can lead to damage.

Step 4. It is recommended to make a counter-lattice so that there is a gap between the vapor barrier and the finished floor. After this, you can lay the floor covering.

Step 4. The counter-lattice will allow you to leave a gap between the finished floor and the vapor barrier layer

Video example of the work

Insulation is a very important stage in the construction or renovation of a house, which determines whether you will be comfortable staying in it. Improper implementation of this “procedure” can lead to unpleasant consequences, for example, the release of condensation and increased humidity in the air. But this will not happen if you take care of the vapor barrier and lay it with the correct side to the insulation.

Where can I order materials and how much do they cost?

All necessary materials for insulation and insulation from steam can be purchased at construction stores. A very large assortment opens in hypermarkets that have a narrow focus.

Of course, they also sell materials in online stores. But this option will not allow you to immediately verify the quality of what you purchased. Therefore, it is better to make purchases in regular stores.

You can purchase the necessary materials both in construction stores and online.

So, installing a vapor barrier for the floor in wooden houses is most often necessary so that the building “lives” for a long time, and frequent repairs can be avoided.

What is mineral wool?

Rock melts (basalts, dolomites) are used as raw materials for production. Sometimes industrial slags are added. The molten mass is formed into fibers, which are then pressed into slabs or rolls.

The strength of the final products is determined by the degree of compression during pressing and the binders, which use phenol-formaldehyde or urea resins.

The greater the force applied at the molding stage and the higher the concentration of binders, the more dense and rigid the material is.

Density, depending on the release form, can fluctuate within a very significant range:

- Rolls – 20-50 kg/m3;

- Mats –50-80 kg/m3;

- Lightweight slabs – 80-120 kg/m3;

- Medium hardness slabs – 120-200 kg/m3;

- Rigid slabs – over 200 kg/m3.