The most important stage in finishing any room is insulating the floors. Many people underestimate the amount of heat loss through the floor, but properly selected insulation can save up to 30% of energy on heating. Particularly large savings are achieved when using a heated floor system, which simply needs to be insulated from below so that it does not heat the floors or the ground.

Floor insulation thickness

Choosing the type of insulation that is best suited for your room is only half the battle. It is important that the insulation layer is of sufficient thickness, because even the best insulation will not provide sufficient thermal insulation if it is laid in too thin a layer. On the other hand, an excessively thick layer of insulation reduces the height of the ceilings in the room and is an unjustified waste of money.

Thermal conductivity of some insulation materials

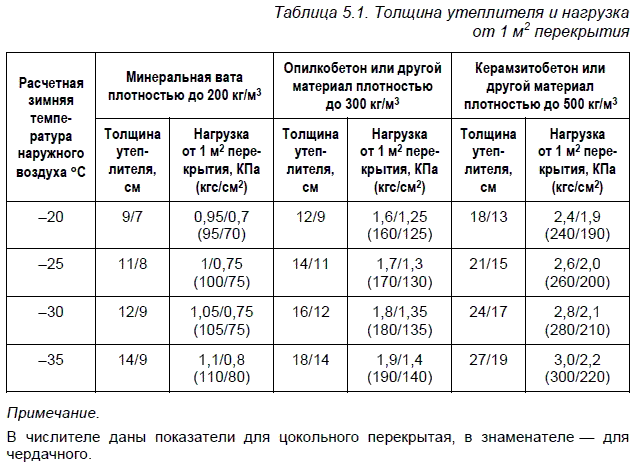

It is important to understand that the required thickness of insulation depends on the climatic conditions in your area. It is obvious that when using the same insulation in houses of the same type in Sochi and Norilsk, completely different layer thicknesses will be required. Therefore, you need to take into account that all the recommendations in the article are given for the typical climate of central Russia, where the temperature in winter rarely drops below -25 degrees. If you live in a milder or more severe climate, then the recommendations need to be adjusted up or down.

Let's consider the main types of thermal insulation and the required layer thickness when used in various types of floors.

Calculation of insulation thickness for underfloor heating systems

Styrofoam

Usually this word refers to foamed polystyrene and extruded polystyrene (penoplex). In terms of chemical composition and thermal insulation properties, these materials are practically the same, however, penoplex has much greater bending strength and resistance to crumbling than traditional polystyrene foam. For this reason, recently most consumers are abandoning foamed polystyrene (foam) in favor of extruded polystyrene (penoplex).

Styrofoam

The advantage of this type of thermal insulation is its low price, ease of installation and moisture resistance. The disadvantages include the flammability of this material, and when polystyrene burns, a large amount of toxic substances is released.

Polystyrene slabs are produced in thicknesses from 5 mm to 50 mm; a special chamfer is made on the edges of the slabs so that during installation, gaps and, consequently, “cold paths” do not appear at the joints.

Expanded polystyrene

If a layer thickness of more than 50 mm is required, then two or even three layers of polystyrene are laid, with each new layer being laid offset relative to the previous one so that the joints of the slabs of the upper row fall on the centers of the slabs of the lower one.

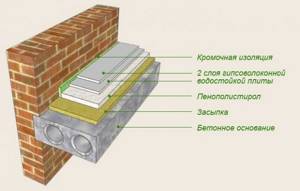

Screed diagram with foam plastic

When insulating a floor located directly above the ground, the foam layer must be at least 300 mm for a house with a wooden floor, and 200 mm for a house with self-leveling concrete floors. You should lay at least 4 layers of the thickest foam panels, offset from each other.

If there is a cold basement under the floor, then the foam layer can be reduced by 50mm.

To insulate floors between floors of a private house, 150 mm of foam is sufficient for wooden floors and 100 mm for concrete floors.

If you are insulating floors in an apartment building, then for all floors except the first it is enough to lay one layer of foam plastic 50 mm thick. On the ground floor the thickness can be increased to 80-100 mm.

| Index | Polyspen | Polyspen Standard | Polyspen 45 | Control method |

| Density, kg/m3 | 30-38 | 30-38 | 38,1-45 | 5.6 each |

| Bending strength, MPa, not less | 0,4 | 0,4 | 0,4 | 5.8 each |

| Water absorption in 24 hours, % by volume, no more | 0,4 | 0,4 | 0,4 | 5.9 each |

| Thermal conductivity at 25+-5 degrees Celsius, W/m * °C, no more | 0,028 | 0,028 | 0,030 | at 5.10 |

| Toxicity, Hcl 50, g/m3 | T2 moderately hazardous | T2 moderately hazardous | T2 moderately hazardous | at 5.11 |

| Flammability group | G-3 normal-flammable | G-4 highly flammable | G-4 highly flammable | at 5.12 |

| Flammability group | B-2 moderately flammable | B-3 flammable | B-3 flammable | at 5.13 |

| Smoke coefficient | High smoke generating ability | High smoke generating ability | High smoke generating ability | at 5.14 |

| Compressive strength at 10% linear deformation, MPa, not less | 0,2 | 0,2 | 0,3 | 5.7 each |

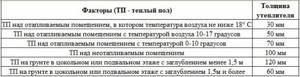

Calculated thicknesses of Penoplex thermal insulation

Using a vapor barrier for external insulation

Placing a vapor barrier on the outside of the wall is a more serious mistake, especially if the walls inside the room are not protected by this same vapor barrier.

The timber absorbs moisture from the air well, and if it is waterproofed on one side, expect trouble.

The correct version of the “pie” for external insulation looks like this:

— interior decoration (9); — vapor barrier (8); — wooden wall (6); — insulation (4); — waterproofing (3); — ventilation gap (2); — external finishing (1).

Penoizol

This is a liquid version of polystyrene foam, which has the same pros and cons as the solid version. Its advantage is that it can be poured into hard-to-reach places and, after hardening, forms a monolithic coating without seams.

Penoizol

The disadvantages include the fact that you need to think about the method of supplying penoizol for pouring; on high floors this can be a problem. In most cases, penoizol is used during the construction of private houses; when insulating floors in apartment buildings, it is more convenient to use polystyrene foam and penoplex.

The required thickness of the penoizol layer is the same as that of solid foam.

Glass wool and mineral wool

An example of floor insulation with mineral wool

Perhaps this is one of the most budget-friendly options for thermal insulation. In addition to its low price, cotton wool does not burn at all and has good vapor permeability, so it is excellent for insulating wooden floors. This is where the advantages of this material end. The disadvantages include the fact that cotton wool tends to accumulate moisture and this causes rotting and mold growth, the second disadvantage is that over time the wool crumbles if the thermal insulation layer under the floor is not sealed tightly enough, as a result, particles of fibers can pass through the finishing coating become airborne and cause respiratory irritation. Also, wool has very low strength, easily breaks and deforms, which makes it impossible to use it under a concrete screed.

For floor insulation on the ground, rigid mineral wool slabs are recommended

Despite its disadvantages, mineral wool is widely used as insulation, usually in wooden floors.

Most manufacturers produce glass wool and mineral wool in rolls or sheets with a thickness of 50 to 200 mm. Sheets can be laid in several layers with offset joints for better thermal insulation.

Insulation thickness

To use mineral wool on the first floors located above the ground, very good waterproofing is required. Cotton wool instantly absorbs moisture, after which it loses its thermal insulation properties. For this reason, it is better to use foam plastic for thermal insulation of the first floors. If for some reason it is still necessary to use mineral wool, then its layer should be at least 400 mm.

Multilayer laying of insulation

If there is a basement under the floor of the first floor, then a layer of mineral wool 300 mm thick is sufficient.

When insulating wooden floors between floors of a private house, the layer of wool should be at least 200 mm, and in wooden floors of apartment buildings a thickness of 100 mm is sufficient.

| Name | Advantages | Minuses | Thermal conductivity |

| Sawdust | Cheap, environmentally friendly material, lightweight | Flammability, susceptibility to rotting | 0.090-0.180 W/mK |

| Expanded clay | Eco-friendly, durable material, not subject to rotting, non-flammable | Heavy weight, fragility | 0.148 W/mK |

| Styrofoam | Does not rot, is waterproof, lightweight and easy to install | Low vapor permeability, cannot withstand high temperatures, releases toxins when melted | 0.035-0.047 W/mK |

| Mineral wool | Low thermal conductivity, easy to install, environmentally friendly, fireproof | When moistened, it shrinks and loses its insulating properties. | 0.039 W/mK |

Anti-draft measures

In order to completely protect your home from cold and drafts, in addition to thermal insulation, it is recommended to install anti-draft equipment. It is represented by flexible strip seals for thresholds, brush seals for floors, flexible arch material, and door threshold kits.

The first type is the simplest. It is a flexible plastic or rubber strip that adheres to the floor covering and slides along it, covering the gap. Most basic models consist of a rigid plastic or aluminum profile that is screwed to the door.

Brush seals are brushes with nylon bristles. They also have a metal or aluminum profile. The equipment option is suitable for uneven floors and textured floor finishes. It can be installed on both swing and sliding doors.

The arch seal design consists of a vinyl insert in an aluminum profile that is pressed against the bottom end of the door. This type of equipment is perfect for wooden floors, as it is attached with screws or nails, which is not easy to do on a concrete base.

Door kits combine an aluminum drain strip and weather strip with a tubular anti-draft seal made of rubber or plastic. The first part is attached to the door with screws, and the second to the threshold.

Whatever option of anti-draft equipment you choose, they all operate on the same principle and perform the task of enhancing thermal insulation.

Ecowool

Ecowool

This material is very similar in characteristics to mineral wool, but is made from cellulose fibers, therefore it is absolutely safe for health. Just like mineral wool, ecowool is afraid of water and is easily deformed. Therefore, in most cases it is used to insulate wooden floors between floors.

Ecowool insulation

The big advantage of ecowool is that it is installed by spraying under pressure from a special pipe. Thus, the insulation can be “blown out” under the already assembled floor; for this you only need to make several small technological holes.

Spraying ecowool

The required thickness of the ecowool layer corresponds to the thickness of the mineral wool layer, all other things being equal.

Characteristics of basalt and ecowool

How to insulate a concrete floor in a house

If you are wondering how to insulate the floor in an old wooden house where the floor is made of concrete, check out the step-by-step instructions:

- Create a multi-layer base that will provide reliable protection for the insulation. In no case do not abandon the waterproofing layer, since concrete allows moisture to pass through well, and it will gradually transfer to the layer formed for thermal insulation.

- Make a sheathing consisting of metal or wooden slats. Lay the resulting frame (this step is required when implementing the classic version of floor insulation from below using mineral wool).

- Having cut the insulation into strips of the required size, install it into the cells by surprise.

- Next, proceed to organizing work aimed at protecting the heat-insulating layer from fumes.

- Place a counter-lattice and plywood or other material of the same type on top of the vapor barrier film (without the use of lathing, the work process goes faster, but later difficulties arise associated with installing the sheathing).

Sawdust floor insulation technology

Consider an economical option using sawdust. The work is carried out before the flooring is laid.

Before insulation, treat the sawdust with a special antiseptic and dry thoroughly.

By doing this you can protect the material from mold and rodents.

When the insulation is ready for use, use a shovel to evenly distribute slaked lime into it. To determine the required amount of this material, focus on the amount of sawdust (you will need 1/10 of the insulation taken).

At the next stage, be sure to add gypsum, it will add strength to the thermal insulation material. Maintain a ratio of 17:2:1 (sawdust: lime: gypsum). After adding water, prepare a moderately cool solution.

Fill the cells gradually, placing the solution in small portions.

Insulation of floors with mineral wool

Make sure the boards to be treated are dry. If not, dry them thoroughly first.

Create a layer of waterproofing, then lay mineral wool, having previously cut it into pieces of the required size. Use thin stainless steel wire and staples as fasteners. The wire can be replaced with plastic mesh. The thermal insulation layer will protect against steam using a special membrane.

Floor insulation with penofol

Install the insulation so that its reflective side is directed downwards, that is, towards the warm space.

Attach the insulation to the joists, maintaining a small gap between it and the rough surface. Secure the material with slats, filling them in a perpendicular direction, or with construction staples.

Insulation of basement floors

If the house has a basement, the process of increasing the thermal insulation properties of coatings should begin with this room, since heat loss is the highest in it.

If you want to know how to insulate a floor without opening it, consider this procedure:

- prepare small-thick wooden slats and securely attach a film that provides a vapor barrier to the ceiling lining. Make sure that the overlap is 10 cm;

- When filling wooden blocks, keep gaps between them that correspond to the size of the slabs with which you plan to insulate;

- place insulation boards into the cells, secure them securely with slats or wire mesh;

- Attach boards on top of the insulating layer.

The process of insulating the floor is quite simple and can be done independently. The choice of material remains with the consumer. Consider all the options presented and choose the one that suits your case best.

Cork material

The main advantage of natural cork insulation is the extremely high sound insulation of the coating. The high price of the material is compensated by the fact that you simultaneously solve the problem of heat and sound insulation. In addition, cork insulation almost does not burn, is not afraid of moisture, is resistant to rotting and is extremely durable, which allows it to be used as insulation under self-leveling floors.

Cork insulation

Due to its rather beautiful texture, cork insulation is sometimes left even as a finishing coating. In this case, the top layer is covered with a special varnish, which protects it and at the same time emphasizes the design.

Cork insulation is available in rolls and sheets with thicknesses from 3 mm to 200 mm. Sheets of maximum thickness allow you to insulate floors above the ground in just one layer, but at the same time they are very expensive. The cost per square meter of thick cork insulation can reach up to 5,000 rubles. For this reason, cork insulation on the first floors of buildings is rarely used.

Cork thermocork insulation

The thickness of cork insulation on the ground floor of a private house with concrete floors should be at least 100 mm; in floors between floors with concrete floors, a layer of 50 mm is sufficient; if the floors are wooden, then the layer should be increased to 70 mm. In an apartment building, cork insulation is laid in a layer of 10 mm to 30 mm; this is quite enough for effective thermal insulation and complete sound insulation from neighbors below.

Video - Cork insulation

A variety of methods for insulating floors using joists

One of the simplest methods, which is effective and economical, is insulation over wooden joists. The technique of arranging floors in this way is most suitable for the first floors of buildings, basements, and basements. Typically, the temperature regime in such rooms leads to very cold floors. A comfortable indoor environment can be achieved through the use of techniques and materials. Wood will naturally create conditions for increasing the heat capacity of the floor without the use of additional materials.

Options for laying floors on wooden logs may vary. One of the most reliable is their installation or insertion into a log house in the form of a T-shape on the foundation. The step size should be about 1 meter.

Wooden shields are attached from below. To enhance the effect of wear resistance, a cranial beam is used, which is nailed to the logs from the sides. It is advisable to take care to impregnate the materials with an antibacterial and antifungal mixture. Due to the increased humidity under the floors, bacteria multiply quickly, and the materials may begin to rot and fungus will appear.

Insulation for hydro- and vapor barriers is laid on top of each other slightly overlapping and both cotton wool for construction and polyethylene film are suitable. In some cases, brick columns are installed, while insulation is laid between them and a vapor barrier is applied on top.

Protecting the base with film

One approach is to arrange the floors according to the “double” principle. This type of flooring is very easy to make with your own hands, as a minimum of materials is required. The first layer is rough, when the raw board is nailed to the beam. They must be properly fitted and verified, since the absence of cracks will effectively retain heat. The second layer – the finishing version – is mounted on top of such a coating. This can also be finishing, decorative materials that have a high level of insulating properties. Such coverings are glued with glue in separate strips, not forgetting the joints.

Polystyrene concrete

This is a relatively new material for insulation; it combines the strength of concrete and the lightness of polystyrene. The material has excellent heat and sound insulation properties and at the same time is a durable screed. It is ideal for thermal insulation of large rooms, since it is very easy to pour and level; a team of experienced craftsmen can pour up to 500 m2 of polystyrene concrete per day.

Polystyrene concrete

Due to its low weight, polystyrene concrete does not place a large load on the floors, unlike traditional liquid screed. It does not require waterproofing or additional insulation. You can lay tiles or laminate on a thick backing directly on top of polystyrene concrete. To lay soft coverings such as carpet or linoleum, a thin layer of traditional screed, no more than 30 mm thick, is poured over the insulation.

Polystyrene concrete floors are being poured

For effective thermal insulation of the first floors of private houses, 300 mm of polystyrene concrete above the ground is sufficient; if there is a basement under the floor, then the layer can be reduced to 200 mm. 100 mm of insulation is usually poured into the floors between the floors of private houses; in apartment buildings, a layer of 50 mm is sufficient.

| General characteristics of polystyrene concrete | Values |

| Flammability group | G1 |

| Density | from 150 to 600 kg/m³ |

| Frost resistance | from F35 to F300 |

| Strength characteristics | from M2 to B2.5 |

| Coefficient of thermal conductivity | ranging from 0.055 to 0.145 W/m °C |

| Vapor permeability of polystyrene concrete | 0.05 mg/(m h Pa) |

Expanded clay

Expanded clay

Expanded clay is a popular thermal insulation material used in wooden floors and floors with dry screed based on gypsum fiber board. In the latter case, in addition to thermal insulation, it is also a leveling material.

Expanded clay is one of the cheapest materials for thermal insulation; it does not burn, is safe for health and is lightweight. At the same time, it easily absorbs water, which reduces its thermal insulation properties and significantly increases its weight. Therefore, the use of expanded clay requires reliable waterproofing. Another disadvantage of expanded clay is that when working with it, a large amount of dust rises into the air.

Expanded clay as thermal insulation

In terms of thermal insulation properties, expanded clay is inferior to most synthetic materials, so it requires backfilling with a thicker layer, which reduces the height of the ceilings in the room.

Using expanded clay for insulation. The photo shows expanded clay being poured with lean concrete

For effective thermal insulation of the first floors of buildings from the ground, the expanded clay layer must be at least 400 mm when using wooden floors and 300 mm when using concrete floors.

Between the floors of private houses, at least 200 mm of expanded clay should be poured into the floors for wooden floors and 150 mm for concrete floors. In apartment buildings, a layer of expanded clay of 50-80 mm is sufficient.

| Indicators | 10-20 mm | 5-10 mm | 0-5 mm |

| Bulk density, kg/m3 | 280-370 | 300-400 | 500-700 |

| Crushing strength, N/mm2 (MPa) | 1-1,8 | 1,2-2 | 3-4 |

| Grading, % | 4 | 8 | 0 |

| Frost resistance 20 cycles, gravel weight loss, % | 0,4-2 | 0,2-1,2 | not regulated |

| Percentage of crushed particles, % | 3-10 | 3-10 | No |

| Thermal conductivity, W/m*K | 0,0912 | 0,0912 | 0,1099 |

| Water absorption, mm | 250 | 250 | 290 |

| Specific effective activity of natural radionuclides, Bq/kg | 270 | 270 | 290 |

Important points of thermal insulation

- When purchasing insulation material, you need to check its quality. Don't be shy about asking for a certificate for verification. High-quality materials restore their shape after mechanical stress.

- The main criterion for choosing thermal insulation material for residential premises should be health safety, not cost. Remodeling a floor is a labor-intensive and time-consuming process.

- Waterproofing of insulation must be organized on both sides (internal and external).

- It is worth providing a compensation gap between the insulation and the finished floor.

- A metal mesh can be placed on the rough flooring to protect the floor from rodents.

- Between the rough and finished floors, you can organize a heating system using a special heating cable.

- The floor of a wooden house should be well ventilated.

- To increase thermal insulation, the foundation and basement are insulated.

We recommend: How to make floors in the house

A reliably furnished floor in a wooden house is a criterion for heat preservation. It is not difficult to insulate it yourself, the main thing is to choose the right material. The most popular method is the double floor system.