Insulation problem

Thus, each person releases on average about 100 grams of water vapor per hour when breathing, which is 2400 grams per day.

In addition, steam is generated as a result of everyday activities - washing, drying clothes, cooking, taking water procedures (about 3000 grams in total). In total, per day of living in a house, a family of 3 releases more than 10 liters of water into the air. If this moisture is not removed outside the house, it can condense on building structures and roofing. Moisture saturation also harms the building’s insulation, reduces its efficiency, increasing thermal conductivity.

Moisture that is not removed from building structures in a timely manner promotes the proliferation of mold fungi and putrefactive bacteria, house dust mites and other pests. Gradually, the walls are destroyed, mold spores are released into the air of the interior space, and the atmosphere in the rooms becomes harmful to health.

How to protect your home from excess moisture?

There are several ways to protect your home from the harmful effects of water vapor. Firstly, ensuring good ventilation, in which moist indoor air will be constantly released into the street, and fresh, drier air will begin to replace it.

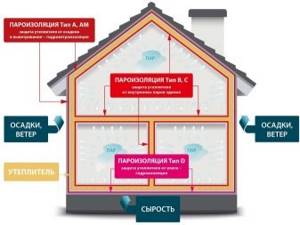

Secondly, the use of water- and vapor-tight barriers that do not allow moisture to pass through, but allow it to slowly evaporate.

With this method of protection, water does not get into the insulation and onto the walls, and the resulting condensate evaporates directly from the protective coating.

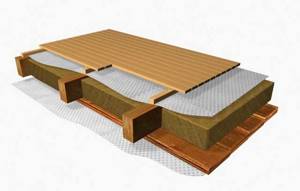

What is the difference between hydro- and vapor barrier

Vapor barrier is a thin film that is installed inside the floor pie. However, quite often it is confused with waterproofing, but these are completely different materials. So, the waterproofing layer is designed to prevent moisture from entering the room from the outside. If water does reach the insulation, its characteristics will deteriorate significantly - it will no longer retain heat. This will be especially felt in winter, when the water inside the insulating layer turns into ice crystals. The floor will become colder, and in general it will no longer be so comfortable to be in the room. To prevent this from happening, it is necessary to lay a layer of waterproofing. In general, it does not allow precipitation or groundwater to pass through itself and is laid outside the floor pie.

Waterproofing the floor on the ground

The vapor barrier is installed inside the floor pie. And it will protect the materials included in the structure of the base, no longer from moisture from the outside, but from condensation coming from inside the room, which is formed due to breathing, cooking and other processes accompanied by the release of steam and moisture.

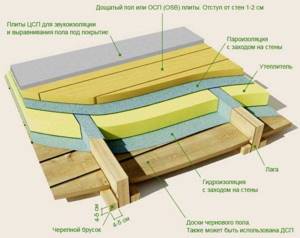

Scheme of floor arrangement on beams

The main difference between these two types of materials is their structure. Waterproofing coatings do not allow moisture to pass through, but are quite capable of allowing evaporation to pass through. But vapor barriers retain both moisture and steam, thereby protecting the insulation. Thus, the vapor barrier does not have a membrane structure as such.

Vapor barrier laid on the floor

Izospan for flooring in a wooden house

The membrane material Izospan will help to protect floor elements in the house made of wood. It has a special structure that will help protect any wooden structures from exposure to steam and moisture.

Types of material

Izospan in general is a special material, which is a membrane that reliably protects various structures from the effects of external environmental factors - wind, steam, precipitation, moisture, including condensation. Thanks to it, the tree will be reliably protected from the premature onset of rotting processes.

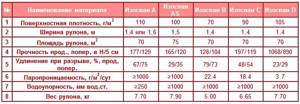

Table of material characteristics Izospan

Technical characteristics of Izospan:

- it is not afraid of exposure to ultraviolet rays and copes well with their reflection;

- durable, copes well with some type of mechanical loads, even if it is exposed regularly;

- has an antioxidant layer;

- moisture-resistant material that retains the ability to resist moisture throughout the entire period of use;

- not afraid of exposure to positive or negative temperatures;

- can be used in any type of structure.

Vapor barrier film Izospan V

On a note! Certain types of Izospan have not only vapor barrier properties. They can act as a heat-retaining material - usually this Izospan has a foil layer.

Izospan is not a completely waterproof material. On the contrary, it helps the steam escape, due to which condensation does not accumulate on the material or wooden surfaces covered by it.

Izospan B - sample

Types of Izospan

There are several types of Izospan, which are marked with letters. Each type is designed for its field of application and has its own special functions and characteristics.

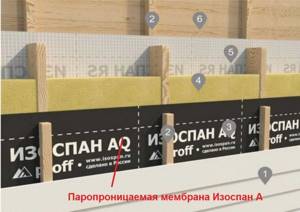

Izospan A

Such membranes allow, on the one hand, the release of steam so that moisture does not accumulate in the thermal insulation, and on the other hand, Izospan allows the insulation to be ventilated. And moisture from the outside, which causes condensation to form, and wind cannot get inside the structure at all. The opposite side of the membrane is waterproof.

The best way to extend the life of thermal insulation is to install an Izospan membrane, which, thanks to its waterproofing properties, will protect the insulation from moisture and wind. Regardless of the quality of the insulation itself, when exposed to the atmosphere, it will quickly lose its properties.

Installation of Izospan A must take into account three basic rules:

- The angle of the roof can exceed 35 degrees.

- Installation of the membrane must take place in calm and dry weather.

- An air gap is required, created by control slats installed on the rafters.

Due to the fact that Izospan A works on the principle of a check valve, the membrane must be installed outside on top of the insulation. The smooth side should face outward. The membrane is laid in wide strips overlapping the next layer.

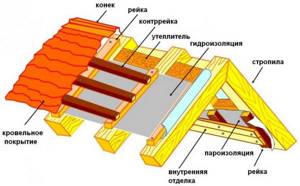

Roof vapor barrier

Vapor barrier is carried out starting from the bottom. Installation of Izospan A has an important condition: the material must not come into contact with the thermal insulation. Otherwise, the waterproofing properties of the film will be seriously reduced.

An example is a canvas tent, which during rain will leak in the place where a person runs his finger inside. To prevent such a situation, Izospan A is laid using double lathing.

When installing Izospan, it is necessary to ensure that various swellings and sagging do not occur, which will become a source of unpleasant sound in gusty winds. Fastening the canvas is possible using a thin strip.

Izospan B

This type of Izospan roofing waterproofing is necessary to protect against internal vapors. Type B consists of two layers: with a smooth structure and with a fleecy structure. The first is used for better connection with the insulation, and the second is used to absorb accumulating condensate.

Type B film insulation is used to insulate walls, roofs, and ceilings inside a building. It is considered a universal means of protection against condensation.

Due to the peculiar structure of Izospan B, it is laid with the fleecy side down; it is also necessary to maintain a gap to collect condensate and weather it. The membranes must be overlapped with an overlap of more than 10 centimeters.

Izospan C

This type of insulation consists of two layers identical to Izospan B: the first has a smooth surface, and the second has a fleecy surface. Izospan C is used to prevent the accumulation of condensation by absorbing moisture particles indoors. The area of application is identical to type B membranes.

Izospan S performs the following functions:

- Roof protection.

- Insulation of moisture and steam.

- Protection of wooden and concrete elements from the effects of water.

But Izospan S is distinguished by its increased membrane density. For this reason, the cost of the canvas is approximately 50% higher than type B.

Izospan D

Durable material that is completely waterproof. The canvas is one-sided: it is a laminated coating. Thanks to its distinctive feature, Izospan D has a wide range of applications in all types of structures.

Izospan D is used as a barrier that prevents under-roof condensation from collecting. The material resists atmospheric influences well. Often used on construction sites for temporary roofing. Mounted when installing concrete blocks that must be in contact with the ground.

The Izospan D membrane is capable of coping with the most complex tasks:

- Waterproofing floors in contact with the ground.

- Insulation of basement floors.

- Creation of a temporary roof.

The membrane can easily withstand moderate mechanical loads, so a large snow load will not damage the material. Type D is the most durable and reliable option. But along with this, the price of the film also increases.

New developments - energy-saving materials

There are modern Izospan films produced under the FB, FD, FS and FX types, which, thanks to their unique abilities, can reflect up to 90% of infrared radiation. Insulation is a sure way to protect the roof from steam, moisture and wind, which also allows you to save on energy costs for heating your home.

Izospan types FD and FS are developed on the basis of polypropylene double film. FX is made from polyethylene foam, and FB is made from kraft paper. All of these types have a common element - a metalized side used as a reflective screen, which can often be found when creating a warm home. This use of reflective surfaces can be found:

- in baths, saunas;

- as a lining for insulated floors;

- when installing floors;

- when covering walls (behind radiators or radiators).

We recommend: Infrared underfloor heating for laminate

You can also find other types of membranes that are created for certain areas of construction: AM, AS, DM.

Carrying out work on laying a vapor barrier membrane

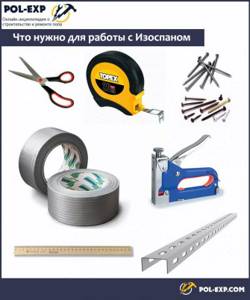

In addition to the vapor barrier film, the following materials will be needed to install a vapor barrier:

- double-sided adhesive tape for fixing the film;

- insulation, usually mineral wool is used for wooden floors;

- wooden slats for mounting the counter-lattice on top of the film;

- self-tapping screws for fastening the slats.

To perform the work you will also need tools:

- screwdriver for flooring and installation of sheathing;

- construction stapler for securing film.

https://www.youtube.com/watch?v=ANw2Utp2I6w

Before laying a vapor barrier on the floor, all wooden structural elements (joists, boards, bars) must be treated with antiseptic agents that will protect the wood from rotting.

If a vapor barrier is laid on an existing floor, you must first remove the finished floor boards and also remove all layers of previously made heat and vapor barrier. Then they remove debris, dirt and dust, carry out an antiseptic treatment of the wooden parts of the subfloor and install them in place.

Laying insulation

Advantages and disadvantages

Advantages of the material:

- strength;

- reliability;

- comes with fire retardant additives;

- multifunctionality;

- environmental Safety;

- ease of installation;

- vapor permeability;

- resistance to high temperatures (suitable for use even in bathrooms and saunas).

Thanks to its structure, Izospan prevents condensation from penetrating into walls and insulation, protecting their structure from the formation of fungus and mold. Many positive reviews ensured the popularity of the material for many years. Izospan A is a film membrane impermeable to air and moisture. Its use reduces the number of drafts, prevents moisture from entering and helps improve the quality of the indoor atmosphere. Additional use of a primer is not required before installing the membrane on most building surfaces.

Isopane A is an innovative material that contains components that make it possible to use it on surfaces with elevated temperatures. This is important in the construction of roofs of baths and saunas. Unique properties make it possible to extend the construction season and ensure year-round construction of buildings in areas with cold climates.

The product can withstand up to 12 months of direct UV exposure while maintaining the integrity required for long-term construction projects. The material is lighter weight than competitive products. This property is indispensable when it is necessary to reduce the load on the structure. Long sections of canvas can be installed, which will increase the speed of work on site. The vapor barrier is installed horizontally or vertically, always with intersecting panels by 5 centimeters.

Overlapping installation avoids drafts. The membrane is compatible with various building materials such as gypsum, plywood, OSB, cement board, concrete, CMU, sealant. You can save on heat consumption, which allows you to install and use heating equipment in smaller rooms. Energy costs can be reduced by as much as 40%. The risk of mold and mildew also decreases.

Among the main disadvantages it is worth highlighting:

- poor moisture resistance;

- small area of application.

If too much water accumulates on the surface of the film, the moisture will begin to roll inward. You should not use a single-layer film for roofing. In this case, a multilayer membrane is best suited. The manufacturer's instructions indicate that Izospan A can be used in roof construction, but it is desirable that the slope does not exceed 35 degrees. You should not purchase material if you plan to have a metal roof covering.

Benefits of isospan

The material is used to protect the insulation of industrial or residential buildings; the height does not matter. Can be used to protect different types of insulation from moisture, such as mineral wool, polystyrene, polyurethane foam.

Advantages of the material:

- Strength.

- Reliability. After installation, the insulation is guaranteed to be dry.

- Versatility. Protects any insulation.

- Environmental Safety. The film does not emit any chemicals.

- Easy to install.

- Resistance to elevated temperatures. Suitable for use in baths and saunas.

Due to its structure, Izospan prevents condensation from entering the walls and insulation, protecting the structure from the formation of fungus and mold.

Technical characteristics and scope of use

If you have already decided to use infrared heated floors for heating, the technical characteristics given below will help you accurately calculate the amount of material needed and future heating costs:

- Width – from 0.5 to 1 m;

- Roll length – 50 m;

- Sheet thickness – from 0.23 to 0.47 mm;

- Power consumption per m2 of film is 25-35 W/h;

- The temperature on the film surface is 33°C.

It should be remembered that if infrared thermal film is used as the main heat source, it must cover at least 70% of the floor surface. This type of heating is not recommended in areas with harsh climates. In these regions, infrared heating can only be used as additional or emergency heating.

Everything you need to connect a heated floor - this is what the classic delivery kit looks like

Thermal film can be cut only in specially marked places; take this into account when calculating the required amount of material. As a rule, the distance from one place of a possible cut to another is about 25 cm. In order not to buy too much, check the details with the seller.

In addition, infrared heating can be used not only in the house, but also in most outbuildings where central heating is difficult to supply. This could be a garage, greenhouse or animal shed. In severe frosts, the use of thermal film will help prevent freezing of the pipeline or icing of the porch.

- The material is waterproof;

- Elasticity is beyond praise; it is not difficult to get around the most difficult areas and bends;

- Resistance to ultraviolet radiation;

- Resistance to negative atmospheric phenomena;

- Does not emit harmful substances. Safe for human health. Does not harm the environment.

- Withstands temperature changes in the range from – 60 °C to 80 °C

- Fireproof elements added in production determine the fire hazard group G4, which is confirmed by relevant certificates.

Izospan has various applications, taking into account the field of construction use. Isospan, a type of insulation unique in its structure, has individual technical characteristics and its own labeling.

Manufacturers classify their products by letter indices A, B, C, D, F, R. The combination of letter indices adds numerous variety, applications and installation of isospan. Each new designation assumes its own isospan application. This fact must be taken into account when building your home.

roof vapor barrier isospan

Application area

- Manufacturers offer a wide range of materials. All types of Izospan differ in density, as a result of which they can be either laid on the floor of a frame house or used in a roof structure.

- Izospan is one of the most popular types of insulation due to its price and unique properties. It is suitable for walls, ceilings, basement floors, attics and lofts. Hydrophobic fabric is widely used as a waterproofing layer on ground floors, cement screeds in wet areas and as a wind barrier. Vapor barrier is one of the main advantages of the material.

- The moisture-proof membrane can be used in the construction of a heated floor. The windproof function has significantly expanded the range of application of the material. Depending on the operating conditions, it may be necessary to create a ventilation gap of 40–50 mm, due to which moisture is evaporated. A special feature of the fabric is its ability to reflect thermal radiation.

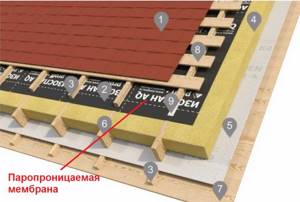

- The rolled material is not afraid of water, is durable and easy to install, and is easy to use in the attic. Widely used as a roofing vapor barrier for pitched roofs and partitions. At the preliminary stage of roof construction, the plates are installed between the rafters. The second layer of film overlaps the top one by 15–20 cm without tension.

The Izospan operating instructions indicate the basic requirements for the use of the material.

- It is advisable to avoid the strips adhering to the edge of the ridge.

- A ventilation gap (50 mm) must be created, which provides an air flow that promotes the weathering of moisture.

- All connections are treated with sealing tape.

Izospan marked AF is distinguished by the presence of ignition protection, so it is used in flammable areas. The presence of the letters AM means a three-layer film construction that can protect the building structure from any external influence.

On sale you can find material marked AQ. It is this film that has maximum insulation properties.

Which side to lay the vapor barrier

When installing a vapor barrier, it is necessary to strictly adhere to the technology, otherwise the system will not function effectively. And here one of the important points is which side the vapor barrier sheet will be laid in relation to the insulation.

Not all manufacturers indicate this on the film or indicate this in the instructions, so you should adhere to the basic rules for installing vapor barriers:

- The smooth side of the double-sided film is always placed on the insulation, and the rough side is on the outside. The fleecy surface absorbs and retains steam and moisture well inside, preventing it from passing to the heat insulator.

- Single-sided laminated polypropylene film is also laid with the smooth side inward and the woven side outward.

- Films with foil coating are placed with the aluminum side facing the room.

- When rolling out any rolled vapor barrier, the outer part is inside the roll, and the inner part is on top.

- If the two sides of the film are different colors, the outer surface will be the one that is darker.

- Conventional polyethylene films have two identical surfaces, so they can be laid on either side.

We invite you to familiarize yourself with Bath hats - cool, for a gift, how to make a felted felt hat with your own hands, sewn patterns

The waterproofing layer involves not only the insulation itself, but also intermediate materials that form the frame and thermal insulation.

Laying such structures involves performing several preparatory operations:

- First of all, you should inspect the old base for damage. If the floor is made of wood, it is important to remove rot and sagging boards. But waterproofing is best done on a concrete slab, especially if the surface is on the ground floor. The floors between floors must be checked for strength and quality.

- If the surface is ready for decorative finishing, then the base should be treated with special strengthening solutions. For wood, impregnations are used that increase resistance to burning and rotting. Floors without screed are treated with strengthening primers.

- When the surface is ready, the subfloor should be formed. In some cases, it is built directly on the ground. But this approach will not allow the wood to last long. Therefore, it is better to use concrete screeds as rough foundations, on which logs for finished wooden structures are laid.

Arranging a protective “pie” consists of the following sequential actions:

- The procedure begins with waterproofing the subfloor. To do this, the film is rolled out over the entire surface, placing it between the lags. It is important to fasten it in such a way that there is no tension. If the width of the sheet is not enough, it is joined to another, forming an overlap of at least 20 cm. When everything is fine, the material is attached to the base using adhesive tape, staples or special nails.

- Insulation is installed on top of the film. Its fastening is carried out differently depending on the selected substance. If wooden logs are used, then mineral wool is inserted between them. It should fit tightly between them without forming gaps.

- At this stage, a vapor barrier membrane is spread on top of the insulation. It is also joined using an overlap. All joints are glued with tape to prevent moisture from penetrating through them.

The procedure ends with the installation of the decorative floor. As you can see, installing a water vapor barrier is not very complicated.

To learn how to install roll waterproofing, watch the video.

carried out at the stage of its insulation

In some cases, when installing a floor, along with thermal insulation material, not one, but two layers of vapor barrier are laid at once. The first layer is placed between the insulation and the subfloor. This protects the material from vapors that rise from the ground. Note that this method is used quite rarely.

- PVC film;

- special membrane.

Installation subtleties

Before using Izospan film, it is necessary to check the insulation of the gaps between the insulation blocks, and if any deficiencies are found, correct them. Seal the contact points of the membrane with structural elements, for example, with windows. For vapor barrier of walls, Izospan A is used on the outside of the building, and Izospan B on the inside. During the construction of walls, Izospan A is laid in layers on their surface. The work is carried out from the bottom up. Fixation is done using a stapler. In this case, it is necessary to prevent sagging of the canvas, otherwise, with a strong wind load on the facade, unnecessary noise (flapping) may appear.

During roof installation, the material is cut directly into the rafters above the insulation. Laying is done horizontally. Start from the bottom of the roof. Fastening is done using nails (sometimes self-tapping screws). It is recommended (but not necessary) to leave a space of about 5 cm between the bottom side of Izospan and the insulation, and between the membrane and the roof there is a gap, the width of which is usually equal to the size of the rails.

As noted above, the placement of Izospan begins from the bottom row with horizontal stripes. The overlap must be at least 10 cm. The places where the film adheres to the surface must be glued together with mounting tape. This method is suitable for wood cladding.

It is very important to lay the material with the right side facing the insulation. Before installation, you must carefully read the instructions for use of the canvas. For external insulation of roofs and facades of buildings, it is necessary to use Izospan AND, AM, AS brands, which provide the necessary protection.

Different variations of Izospan A also have different material densities. For model A it is 110 g/m², for AM it is 90 g/m². The AS model has an indicator of 115 g/m², and the highest density is AQ proff - 120 g/m². To create a high-quality hydro- and vapor barrier, experts recommend using an additional Izospan V vapor barrier.

The installation diagram depends on the purpose of the structure. If it is a sloping roof without insulation, then the main structure is installed, then a vapor barrier layer, and then a wooden flooring.

In the attic, first the floors are laid, then the vapor barrier, then the insulation and slats, and lastly the beam. When using a membrane on a concrete floor, at the first stage a base is created, then a screed is created, a film is laid on it and then only the finishing is done. If you want to achieve good results, you must strictly follow the manufacturer’s recommendations, observe the subtleties of using the Izopane material and be sure to take into account the characteristics of the surface on top of which the film layer will be laid.

We recommend: Infrared heated floors for laminate

For fastening to wooden sheathing or rafters, use a stapler and adhesive tape Izospan KL or SL. Izospan DM brand is mainly intended for installation under metal roofing. To ensure the proper level of vapor barrier, Izospan RS, C, DM brands are used. For the installation of heated floors, thermal insulation of walls and roofs, it becomes necessary to simultaneously provide hydro- and vapor barriers to prevent heat loss. In these cases, Izospan FD, FS, FX are used.

The use of a membrane is a mandatory requirement for installing insulation in a roof structure. Thanks to it, you can protect mineral wool from steam and condensation. If polyurethane foam is used, then there is no need to use Izospan.

As waterproofing, it is recommended to use a diffusion-type membrane, which allows steam to pass through without blocking it and prevents moisture in the room. It is necessary that ventilation holes of at least 50 mm remain between the thermal insulation layer and the waterproofing material. The ultimate goal is to remove excess moisture.

For any structure, vapor barrier plays an important role. Izospan offers a modern and simple solution to this issue. Moreover, it ensures safety for the insulation, roofing and walls. The use of the material allows you to significantly insulate the room, although waterproofing is greatly underestimated by the modern consumer.

Izospan products are represented by a wide range of products, each of which will find application for a specific type of work. It is possible to lay the film not only in the roof structure, but also as an insulating material when organizing the base, including crushed stone, sand and soil.

Some types do not allow moisture to pass through at all, so they can only be installed in rooms with forced ventilation. For heated floors, you cannot find a better film as a reflective lining.

Each product is packaged in a specially designed sleeve made of polyethylene. The kit contains an information sheet and instructions for use.

Features of correct installation of Izospan A to insulation

Izospan A is laid with the front side facing the street, as it does not allow moisture to pass through

Which side to place Izospan to the insulation depends on its type. Group A materials work on the principle of a check valve: they release air and steam, but do not let anything in. To protect the heat insulator, such a membrane is laid with its “front” side facing the street.

The sides of the membrane must not be mixed up. The front one is smooth, water-repellent, facing “outside”, the rough inner one is turned towards the insulation. The material is sold in rolls. It is cut into wide strips and overlapped by 15 cm.

When laying Izospan, a gap is left between it and the thermal insulation. If they take the AS or AD brand, there is no gap.

During installation, the film must be stretched. Otherwise, when there are gusts of wind, it will hit the surface and be damaged.

Laying Izospan B

The rough side is directed towards the interior lining of the room - it should absorb moisture and steam

The smooth side of the film does not allow water to pass through, while the rough side absorbs condensation and evaporates it back. Izospan B is placed on the inside of the insulation or roofing pie. The smooth surface of the membrane faces the insulation, the rough surface faces the room. A ventilation gap is left between the vapor barrier and the finish.

Lay the film in wide strips, overlapping by 10 cm.

Laying Izospan C

Its operating principle is the same as the previous vapor barrier: smooth surface to the insulation, rough surface to the finish.

Izospan A: instructions for use

Group of materials Izospan A - vapor-conducting windproof membranes that do not conduct liquid water. The exception is Izospan A base. This membrane is only wind protection. It does not interfere with the passage of steam and water. Used in the ceiling above a ventilated facade, stuffed from the underground side. Protects mineral wool from blowing and does not interfere with the removal of moisture from the insulation.

| Name | Maximum elongation in transverse/longitudinal direction N/50 mm | Withstands steam density, g/m2*24 h | Withstands water pressure, mm.water.st. | Withstands ultraviolet radiation (without protective coatings) for at least months |

| Izospan AQ proff | 330/220 | 1000 | 1200 | 12 |

| Izospan AQ 150 proff | 270/160 | 880 | 1200 | 12 |

| Izospan AS 130 | 240/130 | 880 | 1200 | 3-4 |

| Izospan AS | 190/110 | 880 | 1200 | 3-4 |

| Izospan AM | 160/100 | 880 | 1200 | 3-4 |

| Izospan A | 190/140 | 2000 | 300 | 3-4 |

| Izospan A base | 170/100 | 1700 | — | 3-4 |

| Izospan AF+ (NG) | 1400/1000 | 800 | 900 | — |

| Izospan A with OZD (RP-1) | 190/140 | 1800 | 300 | 3-4 |

To understand where and how best to use Izospan A, look at the characteristics. Once again: the film is not blown (retains heat), removes steam, and does not allow water to pass through. These properties are needed in the following constructions.

Rules for laying and installing windproof, vapor-permeable membranes

Vapor barrier materials are laid on vertical, inclined and horizontal surfaces. Despite the fact that the designs are different, the installation rules are no different. Here's what to remember:

The basic rule of installation is to make overlaps and carefully glue them

- On pitched roofs and walls, work begins from below. On horizontal roofs - from one of the walls.

- The second layer of material is laid overlapping. That is, one panel overlaps another by no less than:

- 10 cm on walls;

- 15 cm on roofs;

- 15-20 cm in overlaps.

- Vertical joints (if any) have the same dimensions.

- All connections of the canvases are glued using double-sided adhesive tapes.

- The connection to the walls and rafter system is also glued. To adjoin the rafter system, it is recommended to use self-adhesive sealing tape Izospan. For joints - KL, for adjoining the structure KL+.

The task of vapor-permeable waterproofing and windproofing is to allow steam to pass through, but not to allow moisture to enter in a liquid state. Therefore, the strength of the joints is important.

On a pitched roof, on top of insulation

The vapor barrier is laid on top of mineral wool and covered with any roofing material. Let's see how everything works. Here it is necessary that the steam that gets into the insulation from the attic is removed. At the same time, condensation and possible leaks did not enter the insulation. So you need to remove steam and not let water through. This is what Izospan A does.

Application of Izospan A in an insulated pitched roof

The membranes are turned with the logo facing towards you. It is better to lay it not under tension, but with sagging. In this case, condensation, which cannot be avoided on the roof, will flow into the center, and then into the gutter of the drainage system. This way it will dry out faster even in damp times, moisture will be retained less, and there is less chance of it getting into the insulation.

On top of the vapor barrier, slats are placed along the rafters, and then across the sheathing for installation of the roofing material. With this device and the presence of ventilation holes in the roof, the vapor barrier will be blown and dried.

In frame walls on the street side

Typically, indoor humidity is higher than outdoors. And no matter how much we protect the walls, steam leaks into them. These are the laws of physics. And since he hit the wall, he needs to be taken out. So the task here is the same - to let off steam. This can only be done from the street side. So Izospan A in frame walls is also placed on the street side. Here you can use all types of Izospan A, except for the “base”.

Izospan A - instructions for use in a frame wall

When using Izospan A “in its pure form”, it does not matter which side it is laid on. We unfold all other modifications - AS, AQ, AM - so that the logo is facing out.

When insulating walls with mineral wool and for ventilated facades

With external insulation of walls, in ventilated facades, the situation is almost the same as with the frame. Some moisture is seeping into the wall from the room. Then it penetrates into the insulation. Since wet mineral wool is a poor insulator, care must be taken to ensure that this steam is quickly removed. At the same time, it is necessary to protect the cotton wool from getting wet and retain heat as much as possible. That is, the problem is solved by the same vapor-permeable membranes of the Izospan A group.

Application of Izospan A for external wall insulation and in the system of ventilated facades

Any vapor barrier for use in the case of external wall insulation, except Izospan A with OZD, AF+ and base. The installation rule is the same - turn it with the logo facing you. For use in ventilated facade systems, Izospan AF+ is recommended. If a metal structure is used, its strength will ensure that the vapor barrier will not break. If the ventilated facade is covered with wooden blocks, Izospan AM, AS and AQ in any of the options may well be suitable.

Ceiling over a ventilated subfloor

The floor insulated with mineral wool over a ventilated base has its own characteristics. First and most important, for the scheme to work, the subfloor must be ventilated. This means that there must be vents in the foundation. And they must be open even in winter, otherwise you will have wet insulation and cold in the house.

How does this pie work? From the side of the house, moisture and steam seep into the insulation. If you simply line the insulation with mesh or slats, the wind blowing underground will do an excellent job of removing moisture. But at the same time, it will carry away heat and gradually remove mineral wool particles, reducing its thickness. To get rid of heat and insulation from escaping, Izospan A base vapor barrier is used. It allows steam and moisture to pass freely in both directions, but does not allow wind to pass through.

Izospan A: instructions for use in the ceiling above a ventilated subfloor

The following objection may arise. Moisture from the soil will evaporate and enter the insulation. Under certain conditions, it condenses on the membrane, causing the insulation to become wet. Maybe it’s better to use a vapor barrier with waterproofing properties? No. This won't work. If the membrane does not conduct moisture, then the moisture that condenses or gets into the insulation will remain there. Because it will not heat up enough to evaporate and be released as steam. In a couple of years you will have bags of water hanging from the ceiling and completely wet and unusable insulation.

And in order to reduce the evaporation of moisture from the soil, a dense film is placed in the underground, a layer of sand (any kind, but without clay and dust) is poured on it in a layer of 5-10 cm. The film retains most of the moisture, and the sand works as an adsorbent, absorbing fallen condensate. It (the sand) is also dried by the passing wind.

Interfloor and attic floors

In ceilings, steam enters from below and must be discharged from above. Therefore, a vapor barrier is placed at the bottom to protect against moisture, and a vapor-permeable wind barrier is placed at the top. In this case, it also additionally protects against the penetration of mineral wool particles into the room. You need to put Izospan in the same way - the logo should be facing you.

Izospan A for flooring - in interfloor and attic floors

In the interfloor ceiling, to reduce the cost, vapor-permeable Izospan can be replaced with non-woven material (any type of geotextile). Its main function here is to protect against the penetration of small mineral wool particles into the air. But you can do this only if the flooring is sheet material in two layers, with the seams spaced apart. Otherwise, moisture may seep in and then simply the non-woven material will not protect the insulation from getting wet.

In the attic floor, such a replacement is not considered at all - here it is also necessary to protect the heat from weathering. So wind protection is necessary here.

Also note that the vapor barrier is attached to the beams with counterbattens. And the flooring is already laid on them. Counter rails are needed to create a ventilation gap, which is a prerequisite for moisture evaporation. It is important.

Izospan D

High-strength, completely moisture-proof waterproofing material. Polypropylene sheet with one-sided laminated polypropylene coating. The versatility of the moisture-vapor-proof material implies widespread use in construction technologies for the construction of any type of structure.

Izospan D successfully withstands moderately strong mechanical loads, is resistant to tearing, withstands strong gusts of wind, and in winter copes with heavy snow loads. In comparison with other similar films, Izospan D has gained fame as the most durable and reliable option.

Izospan D Area of application

In any type of roof, as a barrier preventing the formation of under-roof condensation. Widely used in the installation of hydro- and vapor barriers during the construction of buildings and structures. Protection of wooden structures. The material largely resists negative atmospheric phenomena.

Izospan D is often used on construction sites as a temporary roof covering and installation of a protective wall in objects under construction. Such a roof or wall can last up to four months. Type D is especially popular when constructing concrete floors that require a waterproofing layer to protect against earth moisture.

Application

- In non-insulated roofs as protection for wooden structures;

- As protection against roof condensation;

- Protection from negative atmospheric phenomena;

- In the arrangement of basement floors;

- Installation of concrete floors.

If there is a task to preserve the internal parts of the home from the influence of vapors generated as a result of life activities, and to extend the service life of the insulation, then the correct solution would be to use the vapor barrier option with the letter designation “D”

Recently, more and more owners of country houses understand the importance of the role played by vapor barrier materials, the ever-growing demand is a strong confirmation of this

Izospan D is spread directly on the rafters directly onto the insulated surface of the pitched roof. In this case, the layers of material are the same and you don’t have to worry about which side to lay Izospan to the insulation. Installation is carried out horizontally, overlapping, the rolls are cut into sheets of the required size quite easily.

Work is carried out from the lower element of the roof and gradually proceeds towards the top. During installation, the joints are glued together with SL tape, similar to double-sided tape. An adhesive surface on both sides connects two vapor-waterproofing sheets. The laid isospan is secured to the rafters with wooden slats or staples from a construction stapler.

To summarize our review, it remains to add that the manufacturer produces 14 types of similar roll insulation. We have considered only four main types. The buyer, guided by the characteristics of different types, always has the opportunity to buy isospan specifically for his needs. In addition, the manufacturer does not stand still and is constantly expanding the range of products, for example, there is a film option with fire retardant additives.

From our review it is clear that working with the material does not require complex special skills and can be done by almost any man. Ease of use and low installation costs make this building material have a wide range of uses. The vapor barrier material will completely take over the functions that will ensure the reliability and long service life of your home and industrial thermal insulation.

Wood and humidity are incompatible things. Moisture has a negative impact on any wooden products. Even in small quantities, it gradually penetrates the structure of the tree and destroys it from the inside, activates the processes of decay, and due to increased humidity, mold and mildew appear on wooden products over time. When installing wooden floors in a house - especially if they are laid on the lower floor - you should take care of high-quality vapor barrier.

Membrane advantages

- rough base;

- wooden logs;

- thermal insulation layer;

- waterproofing;

- finishing floor;

- finishing coating.

You should not violate the technology for installing a wooden floor, because otherwise the structure will turn out to be unreliable. The entire pie should ideally rest on brick or concrete supports, with a small ventilated area between the soil and the wood floor. The vapor barrier should be installed immediately during the construction of the house; there is no need to postpone this stage “for later”.

Vapor barrier will reliably protect against moisture and condensation

Connecting tape (adhesive tape) Izospan FL

Laying Izospan B does not require any special skills or knowledge. Even a novice master can handle the material.

Step 1. The required amount of Izospan V material is purchased. It will be equal to the size of the floor area, to the value of which a certain amount of material required for the overlap is added. This is approximately 15-20% of the total area of Izospan V.

First you need to purchase suitable material

Step 2. A number of preparatory works are carried out in advance, as mentioned above. Next, insulation is laid between the joists.

Laying insulation between joists

Example of laying vapor barrier material

Step 4. To attach Izospan B, it is best to use a stapler. The material is targeted to the joists.

Fastening the material with a stapler

Step 5. The next piece of material is laid overlapping the previously laid and secured one. The overlap width is at least 15 cm.

The material is laid with an overlap

Step 6. Two Izospan B sheets in the overlap area are glued together using adhesive tape. This will allow you to achieve a certain tightness of the vapor barrier layer.

Adhesive tape is used to glue the canvases together

Step 7. It is recommended to additionally protect the lower part of the floor structure with a vapor and waterproofing layer of Izospan D material. It is also fastened using a construction stapler.

Izospan D

An example of using Izospan ML tape

The vapor barrier has been installed, now you can begin laying the final layer of the floor. As you can see, the installation of Izospan B is quite simple and does not require special skills, so you can carry it out yourself without calling specialists.

They need to be fastened differently. It is necessary to lay Izospan correctly: the film should be laid with a smooth surface against the thermal insulation, and the fibrous side of the roll remains outside. It will retain moisture generated from steam to prevent it from penetrating into the structure.

It is recommended to lay the vapor barrier with overlapping strips of 15-20 cm. The joints need to be firmly sealed. For this purpose, special adhesive tape with markings or Izospan tape are used. The area of contact between the sheets, counter slats, air gap and sheathing slats is sealed with a sealing strip. Its self-adhesive side is pressed simultaneously against Izospan and the adjacent surface.

Tape material is used in the area of joining niches, holes, windows, and in the construction of communications:

- water pipes;

- ventilation;

- sewerage

Izospan tape is also used in finishing joints with wooden and concrete structural elements. The installation scheme will largely depend on the element of the structure.

Vapor barrier is often used for external walls. If you need to cover the facade of a building, the strips are installed indoors, and the rough part of the roll will be adjacent to the thermal insulation.

Izospan is designed to protect insulating materials during the construction of industrial and residential buildings of any height.

It is able to protect polystyrene, mineral wool, and polyurethane foam from moisture.

Among the advantages are:

- reliability and strength;

- versatility and easy installation;

- environmental friendliness;

- resistance to elevated temperatures.

Vapor barrier with reflective layer Izospan F

The third group of materials is vapor barrier films with the effect of heat reflection. They differ in that the outer layer is a metallized film (lavsan or polypropylene). They can be used instead of similar materials (vapor barriers) in all of the above structures. If there is an air gap, the material is able to reflect thermal radiation back into the room.

We recommend: Carpet cleaning at home

Energy-efficient vapor barrier Izospan F is installed on the side of the room. When installing, turn the shiny side toward the room. The use of this group of materials can reduce heating costs by about 10%, but there is still debate about this: not everyone believes in it.

Metallized vapor barrier Izospan

The second area of application for Izospan F is the underlay for finishing floor coverings. Under laminate, parquet boards, and film heated floors, it is recommended to use Izospan FX. This is foamed polyethylene 2-5 mm thick with a metallized film glued. In addition to reflecting heat, it also acts as thermal insulation. Any other material of this group can be placed under all other coatings.

Using Izospan F in a heated floor system

When laying a heated floor system in a screed, the cake remains the same. Only a pipe or cable is added. But they need to be laid according to a certain pattern, so a metal mesh is also needed. Water heated floor pipes or an electric heating cable are tied to it.

Which Izospan to use under heated floors

In order not to heat the ceiling of the neighbors below, it is advisable to direct the heat as high as possible. To solve this problem, insulation is laid on the slab, and waterproofing with a heat-reflecting effect is placed on it. In this case, the material does not allow water to enter the slab and reduces heat loss during operation. For heated floors, it is recommended to use Izospan RF, FX, FD, FS.

Vapor barrier layout diagram

The main function of the vapor barrier film is to protect the wooden floor of the log house and insulation from the penetration of steam and condensation. In this regard, the vapor barrier must be located between the insulation layer and the finished floor.

As a rule, two layers of vapor barrier are laid, the second layer is placed between the heat insulator and the subfloor. The bottom layer prevents moisture from the soil from penetrating into the structure. Often, instead of a second layer of vapor barrier, a waterproofing film is laid.

A lower vapor barrier must be done when the subfloor is located in close proximity to the ground or is located above a damp basement.

Installation plan

Installation of Izospan B has features depending on which element of the structure needs to be protected.

For attics and attic floors

First you need to unroll the roll and cut the ribbons to size. To determine which size of panels is most convenient and economical for installation, it is necessary to measure and mark the walls and ceilings. Then you need to apply the first tape to the internal insulation of the attic or attic (from the ceiling side) with the smooth side and secure it.

The fastening method is chosen which is more convenient for the owner: it can be fastened with a construction stapler or on nails. The first tape in attics must be laid from below, parallel to the floor. For convenience, the tapes can be rolled into tubes with the desired side inward and unfolded as they are secured.

Next, you need to secure the following tapes in the same way, overlapping the previous one with an overlap of about 15 cm. Seal the joints with a special tape such as Izospan KL, KL+ and mount the lathing for cladding or finishing material on the coating. For ventilation and evaporation of possible condensation, the gap between Izospan B and the cladding should be 50 mm.

For interfloor ceilings

Installation proceeds as follows:

- Unroll the roll and cut the ribbons to size;

- secure the first tape with the rough side to the rough ceiling (floor) using a stapler or nails;

- fasten the remaining tapes parallel to the first, with an overlap of 150 mm;

- seal the joints for sealing with the appropriate tape of the Izospan family;

- install the sheathing and lay insulation.

Next, you will need to lay another layer of Izospan B with the smooth side facing the insulation, secure it to the sheathing and seal the joints.

On top of the insulation, it is necessary to provide a ventilation air gap (gap) of 50 mm using counter slats on which the finishing cladding can be installed.

For interior walls of the house, interior partitions

Installation is carried out similarly to the option with interfloor ceilings, with the tapes being laid starting from the bottom, parallel to the floor, also with a smooth surface facing the insulation.

To protect the structures of frame partitions and walls inside buildings, instead of type B, you can use Izospan with the designations C, DM, RS. Installation of these materials is carried out according to the same rules.

Required tools and materials

To work with Izospan B, you need to ensure that you have a certain number of tools:

- scissors - for cutting material;

- tape measure or ruler - for applying dimensions and measuring material;

- fastening elements - nails, self-tapping screws, both options are used with galvanization;

- adhesive tape used in construction - for gluing the joints of individual sections of material;

- stapler - will allow you to quickly attach Izospan V to the base (used only for wooden bases);

- slats, metal profiles - they can also be used to fasten the material, but the need for their use will depend only on the type of final finishing of the room.

What is needed to work with Izospan

Floor vapor barrier: instructions

Everyone knows that moisture is the enemy of wooden buildings. It has a significant, sometimes negative, effect on wood. You can avoid disastrous results only through high-quality vapor barrier.

Why Izospan

The advantages of using Izospan in comparison with other methods of vapor barrier are obvious:

- on the one hand, it insulates the wood from moisture;

- on the other hand, it in no way affects the flow of air, without which, of course, the wood will not last long.

Types of Izospan for the floor

This material has gained popularity among consumers as a non-alternative option for floor insulation. Which Izospan is right for you? It’s difficult to answer unequivocally, but let’s imagine the varieties that are most suitable for insulating the floor from moisture.

- Izospan AM is a universal product that can act as insulation for both roofs and walls, and for floors to protect insulation in unheated attics. Mounted with the white side to the insulation.

- Izospan AS is a three-layer membrane, durable, suitable for floors. It is used similarly to Izospan AM.

- Izospan B is a two-layer material that copes well with its function. The best option for vapor barrier of indoor floors.

Preparatory work before direct installation of Izospan

- You need to start with the fact that all the boards that make up the floor are treated with a special mixture, which does not allow them to rot, attract the attention of insects, etc.

- If the floor has already been rebuilt, then this action will need to be carried out by dismantling the floor.

- After dismantling, it is necessary to replace particularly worn materials, processing new ones according to the already announced scheme.

Laying vapor barrier

Even a non-specialist can carry out this procedure, guided by the presented sequence of actions.

When vapor barrier of interfloor ceilings, Izospan B is laid on top of the insulation, securing it with a stapler and sealing it by gluing the joints. Be sure to provide an overlap of 15–20 cm.

Note! It is worth mentioning which side Izospan should be laid if it is installed on the floor of an interfloor ceiling on top of insulation. Its rough side should be in contact with the insulation.

Preparation for installation of a water vapor barrier layer

Laying a vapor barrier involves carrying out a number of preparatory work. First you need to select materials for all layers of the so-called pie, and also decide which vapor barrier is best for the floor. This “pie” consists of the following stages (starting from the top):

- Decorative floor covering.

- Plank floor.

- Vapor barrier.

- Counterrail.

- Insulation (counter slats between boards).

- Waterproofing.

- Rough floor.

Preparation begins with the subfloor. All boards, joists and other wooden parts must be treated with a special antiseptic composition that prevents rotting, the appearance of fungus, and also protects against insect attacks.

If we are talking about repairing the floor, and not about constructing a new building, then the finished floor boards, floor covering and existing vapor barrier on the floor must first be dismantled. All debris must be removed and then the wooden structure must be treated with an antiseptic.

Recommendations and common mistakes

When laid on concrete, isospan acts as a vapor barrier, since almost any screed has good waterproofing characteristics. However, the manufacturer recommends following the accepted rules for installing the canvas.

Advice! In order not to completely get confused with the orientation of the material when laying the floor in a wooden house, lay the canvas with the printed logo facing up.

The biggest mistake is skimping on connecting tape. Instead, they try to lay the canvases with glue or stitch them with a stapler. This cannot be done, since in a wooden house the floor experiences significant loads, and even when poured into the screed, the edges will certainly separate.

Another mistake is the wrong choice of a suitable material; if in doubt, it is best to buy grades D or FD; the strength of the multilayer membrane is sufficient with a margin.