PENOPLEX product line

INTRODUCES NEW PRODUCTS TO THE THERMAL INSULATION MATERIALS MARKET:

PENOPLEX PITCHED ROOF - focused primarily on use for insulation of pitched roofs of any type. The slabs are produced in an extended length of 2400 mm and have a special tongue-and-groove edge, which ensures absolute thermal uniformity.

PENOPLEX GEO is an analogue of the material PENOPLEX FOUNDATION and is aimed primarily at use in industrial and civil construction, in particular in loaded structures, foundations, floors, with a protective layer (for example, cement-sand screed), stylobate, as well as in structures with low requirements for fire resistance, has increased compressive strength.

PENOPLEX FACADE is an analogue of the material PENOPLEX WALL. Focused primarily on the use of insulating external and internal enclosing structures (for example: walls, partitions, facade systems); Unlike the PENOPLEX WALL material, it has a milled surface, which improves the adhesion of plaster and adhesive compositions to the surface of the slab and reduces the time required for plastering work.

PENOPLEX BASE – is primarily intended for use in industrial and civil construction; it is a universal material for use in any structures (floors, walls, roofs) where special load requirements are not imposed.

Penoplex insulation

In the warm season, few owners think about the fact that it should be warm and cozy in winter. Insulation of a house or apartment outside and inside is most important. Because it is not only warm, but also helps to enhance sound insulation and save money.

Insulating walls with penoplex is the most common method for creating a cozy room.

This material has many positive aspects, but negative aspects are not excluded. Easy and quick installation, practically free of debris and dust - in a short time you can save money on payments and heat in the house.

Penoplex for walls

To create coziness and comfort in your home, it is necessary to choose only high-quality materials during the renovation process. This rule directly concerns the thermal insulation of the room.

|

Penoplex for walls is foamed polystyrene, which is made using the extrusion method from general purpose polystyrene. Penoplex boards are an effective thermal insulation material that is successfully used in almost all industries. The structure of this material indicates its high strength and excellent technical characteristics. Plates produced with the addition of fire retardants have a certain resistance to combustion, zero water absorption and low thermal conductivity. By its chemical nature, the material is an inert, environmentally friendly material, not at all susceptible to rotting. This material can be used in any weather conditions without any protective equipment. Penoplex for walls works great, cuts well and attaches well to the wall. The technical characteristics of the material remain unchanged at sufficiently low and high temperatures.

Basic properties of penoplex

1. Low level of thermal conductivity. 2. Complete absence of water absorption. 3. Low level of vapor permeability. 4. High level of compressive strength. 5. Not subject to combustion. 6. Non-biodegradable. 7. Environmentally friendly material. 8. Easy to install. 9. Durability of use. 10. Low chemical activity.

Most building mixtures cannot dissolve the base of this material. There are only a small number of mixtures that can react with this material.

Objectives of the material

Penoplex wall insulation will help save up to 45% of heat, which is an excellent way to save energy. In order for the effect to be long-lasting, it is necessary to use a material that is resistant to deformation, because repair and restoration work is impossible in this case. The main task of penoplex is reliable thermal insulation of walls, which is rightfully considered the most profitable and reliable. The stepped edge shape can provide a fairly tight lock when joining. Beginners do not know at all how to insulate walls with penoplex . This process is quite simple. The slabs are securely attached flush and tightly to the load-bearing wall.

Insulation of walls from the inside

Insulation of walls with penoplex from the inside is carried out in cases where this process cannot be carried out from the outside. This happens when the building is of some cultural value or when insulation is carried out in the basements.

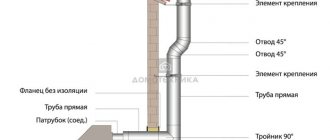

Penoplex insulation technology

1. The preparatory stage of wall insulation includes high-quality cleaning of the working surface of the wall. To do this, all remnants of old materials or various salt deposits are removed. If fungal deposits form, they must be treated with special antifungal materials. 2. Inspect the wall using a plumb line in order to eliminate all chips and irregularities. 3. Installation begins with the installation of the base profile. It serves to reliably protect the bottom slabs of penoplex from the influence of external factors and various rodents. 4. The cutting of slabs must be carried out strictly with the required surface dimensions, discarding window and door openings. 5. Preparation of adhesive for slabs. It is recommended to glue the slabs with a special glue “Teplokley”, which is quite reliable and has an affordable price. 6. Gluing of penoplex boards is carried out with a tight fit of the material to the wall. 7. Final fastening with dowels. This is necessary in order to make the insulation process completely reliable.

The use of penoplex for walls

The most active use of penoplex is its active use in insulating various types of premises, both mansions, apartments, and basement-type buildings. There are varieties of this material that are used for various wall surfaces, roofs and interior work. Also on sale is penoplex for foundations, swimming pools and saunas, balconies and more. Penoplex 45 is actively used for thermal insulation of heating mains and railway tracks, since this material can perfectly withstand the weight of an entire aircraft. This material can be used to insulate almost all existing surfaces.

Due to its high-tech properties and ease of installation, penoplex is very popular among buyers, and its sales are increasing every day. Grateful customer reviews indicate that the use of this material is indeed the best option in the process of wall insulation, quite environmentally friendly and durable.

In cases where it is impossible to purchase the required material, the best option would be to consult with professionals who have many years of experience working with similar materials. The team of the online store is quite highly qualified personnel who are always ready to provide information support on the selection of building materials necessary for carrying out repair and construction work.

Advantages and disadvantages

Expanded polystyrene is used to insulate buildings inside and outside. Installation is carried out inside when it is not possible to carry out work outside, as well as partial insulation - a balcony wall, one wall facing the north side. It has advantages for which it is often used.

- The material is light and easy to work with.

- Low thermal conductivity. Under various conditions (high humidity), the thermal conductivity indicator is maintained.

- Practically does not absorb water.

- Strength – withstands compressive loads.

- Service life is 50 years.

- Soundproof.

- Temperature range from -100 0C to +75 0C.

Penoplex does not rot and is not “sharpened” by rodents.

Disadvantages include poor adhesion. Therefore, before applying the adhesive solution, the back side of the polystyrene foam is cleaned.

The second disadvantage is that when burning it emits acrid smoke.

Despite the identified drawback, the material is used for insulating walls indoors, in buildings with high humidity, and outdoors.

Table of technical characteristics of standard types of PENOPLEX

| Name | Test method | Dimension | Slab type | |||

| Penoplex | ||||||

| comfort | WITH | TO | F | |||

| Density | GOST 17177-94 | kg/m3 | 25,0-30,5 | 25,0-30,5 | 28,0 — 37,0 | 28,0 — 37,0 |

| Compressive strength at 10% linear deformation, not less | GOST 17177-94 | MPa | 0,20 | 0,20 | 0,25 | 0,27 |

| Water absorption in 24 hours, no more | GOST 17177-94 | % By volume | 0,4 | 0,4 | 0,4 | 0,4 |

| Flammability group | Federal Law 123 | group | G4 | G3 | G3 | G4 |

| Coeff. λ at (25±5) °С | GOST 7076-94 | W/(m.°C) | 0,030 | 0,030 | 0,030 | 0,030 |

| λ A | SP 23-101-2004 | W/(m.°C) | 0,031 | 0,031 | 0,031 | 0,031 |

| λ B | 0,032 | 0,032 | 0,032 | 0,032 | ||

| Coeff. vapor permeability | GOST 25898-83 | mg/(m.h.Pa) | 0,018 | 0,018 | 0,018 | 0,018 |

| Standard sizes TU 5767-001-56925804-2007 | width | mm | 600 | 600 | 600 | 600 |

| length | 1200 | 1200 | 1200 | 1200 | ||

| Thickness (compressive strength) | 30(0,15); 40; 50; 60; 80; 100 | 20(0,18); 30(0,2); 40; 50; 60; 80;100 | ||||

| Durability | Test report No. 132-1 dated October 29, 2001, NIISF | more than 50 years | ||||

| Operating temperature range | THAT | °C | -50…+75 | |||

Peculiarities

Due to its advantages, penoplex insulates houses inside and outside. Feature of the material: does not rot, waterproof, has a long warranty period. Soundproofing can be considered an important point. Therefore, by insulating the walls, the house will become warm, quiet, which will bring coziness and comfort.

Can I replace it with foam?

Craftsmen recommend using extradiated polystyrene foam for insulation, because it has a denser structure. Due to this, cold air does not penetrate into the room. Compared to polystyrene foam, it does not collapse quickly.

Another feature of polystyrene foam insulation is its installation technology. You must do the work correctly, consistently, following the advice of the masters. Otherwise, cold air and extraneous sounds will penetrate into the room, and the insulation will be of no use.

Penoplex is mounted on different surfaces:

- wooden base;

- brickwork (the material is not destroyed by the released alkali);

- concrete wall;

- aerated concrete, foam block.

Installation is carried out with your own hands only after reading the step-by-step instructions and nuances.

Outside

From the outside, most often, the façade of private housing construction is insulated with penoplex. This keeps the house warm and there are no damp walls or traces of mold in the house. After all, when insulating walls, the dew point shifts only from the inside. Dampness and mold appear. The house becomes uncomfortable. In addition, due to constant dampness, the structure itself is destroyed.

Installation of penoplex from the outside is carried out using two methods:

- On glue. The use of certain brands of glue preserves the durability and functionality of the insulation. For strength, the slabs are fixed with umbrella dowels.

- “Ventilated facade” - creating a sheathing from metal profiles or wooden slats. Insulation is placed in the resulting cells, and the facing material is mounted on the sheathing itself.

When decorating the façade of a building with polystyrene foam, it is possible to create modern decor and originality. Penoplex is covered with mosaic, decorative plaster, and other materials are used that create originality and difference from other houses.

Inside

If it is not possible to insulate the walls outside (the top floors of apartment buildings) or it is necessary to insulate the balcony, then penoplex is used indoors. There are both disadvantages and advantages here:

- If the insulation is installed incorrectly, condensation will appear, which will lead to negative consequences. Where the material touches the wall, mold will appear.

- When installing the material, the usable area of the room is reduced.

Positive sides:

- All insulation work can be done with your own hands, without the involvement of a team of craftsmen.

- Properly fixed penoplex will keep the room warm and quiet.

- The material levels the walls.

- It is often laid under plasterboard structures.

To install expanded polystyrene indoors, you do not need to make lathing, unless plasterboard cladding is provided.

For insulation, choose insulation with tongue-and-groove edges. This allows for end-to-end installation. PPS 25-RG-B slabs are mainly used.

Penoplex Wall

The main task of thermal insulation of a building is the insulation of the street walls of the building. If the walls are poorly insulated, then depending on the type of construction, the building can lose up to 45% of heat. That's why you should give preference to high-quality insulation. The term “quality” means resistance to deformation, environmentally friendly and moisture resistance with maximum thermal protection ability.

Features of application

By using Penoplex, you can significantly save on paying for electricity or on other types of fuel, since it retains heat well in the house and thereby saves money.

Penoplex wall has an optimal adhesion effect to other types of finishing materials. Such heat-insulating boards have increased resistance to deformation and are moisture resistant. They can be widely used not only as insulation for facade panels, but also for decorative lining.

Application area

Penoplex walls are also used for well laying. In this case, the thickness of the walls will decrease several times, in contrast to the construction of a wall built of brick. The most optimal way to protect a building from cold bridges is to insulate the walls on the outside of the building. Internal thermal insulation of walls is necessary if you need to quickly heat the room, or if it is not possible to make thermal insulation on the street side.

Using a Penoplex wall in construction, you can bring to life even the most daring and unusual design ideas for the facade of a private house.

Penoplex wall, designed for thermal insulation of walls in a private house, has the following advantages:

- Low thermal conductivity coefficient. It is only 0.032, accordingly, it has consistently high thermal insulation properties;

- Moisture resistance;

- Resistant to temperature changes. Thanks to these qualities, the material can be installed in any weather;

- Low vapor permeability;

- Lightweight slabs for the best thermal conductivity coefficient;

- Easy to install;

- An L-shaped edge located on each side of the slab, allowing the slabs to be tightly joined together like a construction set;

- Biostability;

- — Durability;

- - Environmentally friendly.

Technical characteristics of Penoplex Wall

| Name | Test method | Dimension | Slab indicator |

| Density | GOST 17177-94 | kg/m³ | 25,0-32,0 |

| Compressive strength at 10% linear deformation, not less | GOST 17177-94 | MPa (kgf/cm2; t/m2) | 0,20 |

| Ultimate strength during static bending, not less | GOST 17177-94 | MPa | 0,25 |

| Water absorption in 24 hours, no more | GOST 17177-94 | % by volume | 0,4 |

| Water absorption in 28 days | % by volume | 0,5 | |

| Fire resistance category | F3-123 | group | G3 |

| Thermal conductivity coefficient at (25±5) °C | GOST 7076-94 | W/(m×°K) | 0,030 |

| Calculated thermal conductivity coefficient under operating conditions “A” | SP 23-101-2004 | W/(m×°K) | 0,031 |

| Calculated thermal conductivity coefficient under operating conditions “B” | SP 23-101-2004 | W/(m×°K) | 0,032 |

| Sound insulation of partition (GKL-PENOPLEX® 50 mm-GKL), Rw | GOST 27296-87 | 41 | |

| Standard sizes | Width | mm | 600 |

| Length | mm | 1200 | |

| Thickness | mm | 20; 30; 40; 50; 60; 80; 100 | |

| Operating temperature range | THAT | °C | -50 … +75 |

*TU 5767-015-56925804-2011

Kinds

There are different types of penoplex on the construction market. The name indicates where the material is used.

- "Roof". Waterproof appearance, density 28-33 kg/m3. This type is used to insulate a flat roof. They also insulate attics. Due to the lightness of the material, the structure does not bear additional load.

- "Wall". Used for external and internal insulation of buildings. Density 25-32 kg/m3. It is also used for insulation and soundproofing of partitions.

- "Foundation". 29-35 kg/m3. A special feature of this brand is its water resistance. They are used to insulate the foundations of houses and basements. They carry out thermal insulation of septic tanks that have a recess.

- "Comfort". 25-35 kg/m3. Insulation of balconies, loggias, walls inside the apartment. They install the material in baths and saunas.

- "The basis". The technical characteristics are the same as those of the Comfort brand, but it is more rigid and can withstand greater loads. A type of penoplex is used to insulate various load-bearing surfaces (floor insulation). It is also used in industrial construction.

- "GEO". Alternative to "Foundation". Used in industrial and civil construction work. Floor and foundation cladding.

- "Pitched roof". The thickness of the material is 10-15 cm. It is used for insulation of single-pitched roofs.

- "Facade". Thickness 2-10 cm. They are used to insulate building facades. It has a milled surface for better adhesion to the base.

- "Penoplex-45". 35-47 kg/m3. Used as a protective layer against low temperatures for various types of road surfaces (garden paths). And also for roofing.

The insulation material is also divided according to markings. Each of them denotes a specific density.

Table of technical characteristics of types PENOPLEX 45C, 45, 75

| Name | Method tests | Dimension | Type of boards PENOPLEX® | ||

| 45C | 45 | 475 | |||

| Density | GOST 17177-94 | kg/m3 | 35,0-40,0 | 40,1 — 47,0 | 40,1 — 53,0 |

| Compressive strength at 10% linear deformation, not less | GOST 17177-94 | MPa | 0,41 | 0,50 | 0,75 |

| Water absorption in 24 hours, no more | GOST 17177-94 | % By volume | 0,4 | 0,2 | 0,2 |

| Flammability group | SNiP 21-01-97* | group | G4 | G4 | G4 |

| Coeff. λ at (25±5) °С | GOST 7076-94 | W/(m.°C) | 0,030 | 0,030 | 0,033 |

| λ A | SP 23-101-2004, NIISF report from 03/22/2005 | W/(m.°C) | 0,031 | 0,031 | — |

| λ B | 0,032 | 0,032 | — | ||

| Coeff. vapor permeability | GOST 25898-83 | mg/(m.h.Pa) | 0,015 | 0,015 | — |

| Standard sizes TU 5767-001-56925804-2007 | width | mm | 600 | 600 | 600 |

| length | 2400 | 2400 | 2400 | ||

| Thickness (compressive strength) | 40; 50; 60; | 80; 100 | |||

| Durability | Test report No. 132-1 dated October 29, 2001, NIISF | more than 50 years | |||

| Operating temperature range | THAT | °C | -50…+75 | ||

Penoplex 20 mm

Penoplex 30 mm

Penoplex 40 mm

Penoplex 50 mm

Penoplex 80 mm

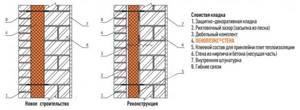

Wall “pie”

Wall insulation with penoplex is carried out in different ways. One of the most common is the “wet facade”. This method includes mixtures and formulations that are prepared using water. They also use reinforcing mesh and primer. The result is a multi-layer insulated wall that does not allow cold air to pass through, without shifting the dew point.

Each layer applied in a certain sequence is important:

- The adhesive composition is prepared on the basis of water and a dry mixture. Penoplex is mounted on it.

- Penoplex slabs insulate and soundproof the building from the outside.

- Fiberglass reinforcing mesh is a strong connecting element. It promotes better bonding with the surface and also prevents cracks.

- Primer. Neutralizes, protects, promotes better adhesion.

- The facing material is a decorative element. It also protects the insulation from external factors.

The insulation boards are mounted tightly to each other. The glue must be completely dry before applying the next layer of cake.

How to calculate the required thickness so that the walls are not cold

To calculate the thickness of the thermal insulation material, you need to know the material from which the walls are made, their thickness, and provide the characteristics of the finishing coating.

You need to calculate the thermal resistance. Data on SNiP are presented in the table by region of Russia. It must be taken into account that the thermal resistance of each layer of the cake is different. All indicators of words are summed to obtain one figure.

The thermal conductivity coefficient is calculated using the formula: P=R/K, where R is the thickness of one layer of the cake, K is the thermal conductivity.

Phased work

To insulate walls, methods are used that differ in the installation method and location of insulation. For outdoor work there is:

- "wet facade";

- "curtain façade"

For insulation inside, the following methods are applicable:

- on glue;

- creation of sheathing.

Each method involves a step-by-step process of work, the violation of which will lead to the appearance of dampness.

Surface Requirements

Before you insulate a wall with penoplex, you need to prepare it. Basically, insulation goes on sale with a smooth surface. The adhesive mixture does not stick to the back side, there is no adhesion. To do this, you need to treat the back side of the insulation:

- pass in one direction with a needle roller;

- wipe the surface with sandpaper - roughness will appear;

- pass with a router (if available).

By doing one of the above actions, the back side will become rough, this helps the adhesive mixture stick and adhere better to the wall.

Preparing the walls

To install penoplex, you need to prepare the surface, which means:

- Level it - remove excess mortar, protruding pins, dust, cobwebs.

- Peeling plaster and old whitewash are removed from the walls of a private house.

- If there are traces of dampness or blooms, you need to dry the wall, then apply an antiseptic composition (the usual treatment with diluted bleach will do).

- Apply primer 2 times. The second layer is applied only after the first has completely dried.

Wooden walls should not show signs of rot. If such are found, then you need to replace this part.

Is vapor barrier necessary?

Depending on the location where the thermal insulation material is used, a vapor barrier is used.

- Outside . This should be done in rare cases. If the house is located in a damp area, in a lowland, near water pits. A vapor barrier is also installed outside when insulating a bathhouse or sauna. Basically, vapor barrier is not carried out. Penoplex provides the necessary protection (water-repellent property).

- Inside. A vapor barrier layer is a mandatory layer if the outside walls are not insulated. There is a shift in the dew point in the design. Condensation will leak into the room from above the insulation. This will lead to constant dampness, destruction of the wall, and the appearance of fungi.

The material from which the walls are made also plays a role. For concrete and brick structures, a vapor barrier layer is required, but for wooden walls it is optional.

Lathing

To create a frame base, wooden slats of 50x50 mm are required. In this case, the width of the slats should be equal to the width of the slab. First, fix the bottom rail horizontally with self-tapping screws.

Vertical slats are mounted from it with a step equal to the size of the slab. The insulation should fit tightly between the slats. Next, attach a second horizontal rail for the second row of penoplex. So to the top. In some cases, metal profiles are used instead of wooden beams.

Before installation, wooden beams are treated with antiseptic agents (linseed oil).

Glue attachment methods

There are various materials for gluing foam boards.

- Mastic for gluing extruded polystyrene foam boards. The use of a bitumen-polymer composition is an economical way to fix insulation to the wall. Mastic is used in buildings with high humidity.

- Adhesive dry mixtures. These materials are based on cement. The solution must be made according to the instructions on the package. Apply the solution with a notched trowel over the entire surface of the slab and fix it on the wall. For strength, additional fixation with dowels is required.

- Adhesive foam. It has good adhesion. The work is carried out quickly and without debris or dust. The foam is applied from a gun to the slabs and fixed to the wall.

- "Liquid Nails". Used when insulating a small area.

After selecting and applying the glue, the foam boards must be additionally secured with mushroom-shaped dowels.

Types, characteristics, properties

Penoplex is available in several categories:

- Comfort. For insulation of walls, balconies, loggias.

- Foundation.

- Pitched roof.

- Wall.

Types and purpose of Penoplex insulation

As you can see, the manufacturer clearly delineates the areas of application of the material. With the general technology, they differ in density. The densest ones are for the foundation and floor, since they must withstand considerable loads for a long time. The manufacturer claims that the service life of Penoplex Foundation is up to 50 years.

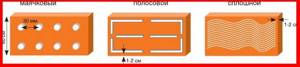

Design differences

Some of the types of Penoplex have structural differences:

- Penoplex Wall slabs have a rough surface; stripes are applied to the surface of the slab using a router. All this improves adhesion to the wall and/or finishing materials.

- Penoplex Comfort is distinguished by an L-shaped edge, which during installation guarantees the absence of through seams.

- Penoplex Roofing has a U-shaped edge, which increases the reliability of the connection.

Can be distinguished by external signs

This is what concerns external differences. Next, consider the technical characteristics

First, let's pay attention to what is common to all types, then to what distinguishes them

General characteristics

Since the production technology of all types of Penoplex is similar, they have many of the same characteristics:

- Water absorption is very low: when immersed in water for a day, no more than 0.4% of the volume;

- when immersed for 28 days, 0.5% of the volume.

As you can see, according to temperature indicators, any type of Penoplex can be used in any part of the country - from the south to the north. Moreover, if you leave it to “winter” unprotected, nothing will happen to the material. This is not the merit of Penoplex, but a general property of extruded polystyrene foam.

What distinguishes different types

The manufacturer divided the types of Penoplex into areas of use. Their properties are optimal for a specific application. For example, the increased density of EPS required for a screed will not be needed when installing it on a plinth. Taking into account the fact that the price differs significantly, it makes no sense to use the “Foundation” brand for other purposes. But the difference in locks, with other characteristics being equal, can be neglected. This is about ease of installation.

Although this is also important

| Parameter | Comfort | Foundation | Roof | Wall |

| Density | from 20 kg/m3 | 27-35 kg/m3 | 26-34 kg/m3 | from 20 kg/m3 |

| Elastic modulus | 15 MPa | 17 MPa | 17 MPa | 15 MPa |

| Thickness | 20, 30, 40, 50, 100 mm | 50, 100 mm | 100 mm | 50 mm |

| Static bending strength | 0.25 MPa | 0.4 MPa | 0.4 MPa | 0.25 MPa |

As can be seen from the table, Penoplex for foundations and roofs is denser, stronger, and better able to withstand bending loads. Designed for walls and the “Comfort” brand are less durable, since their area of application does not require resistance to mechanical stress.

Life time

Unopened penoplex and subject to all storage and transportation requirements can be stored for an unlimited time.

After proper installation, the insulation has a warranty period of 50 years. If the building is damp (a bathhouse, the house is located in a lowland, in an area with constant moisture), then the shelf life of the installed insulation is 40 years.

Penoplex is a heat-insulating material used to insulate walls, ceilings, roofs and foundations. It has many advantages and virtually no disadvantages. The material is divided into types and labeled. Therefore, choosing penoplex for insulation will not be difficult. Installation is carried out in several ways.

After all the work is completed, the room inside will be warm and cozy.