A heated towel rail performs not only its main function - drying towels and small wardrobe items. Thanks to this device, the bathroom is always warm and comfortable, which is especially important during the non-heating period. Connecting a heated towel rail to a hot water riser is not the easiest task. It can be performed in several ways, which we will consider below.

About the advantages of side heated towel rails from MStal

The choice of connection diagram depends solely on the characteristics of a particular bathroom. The ideal option is to prepare a separate outlet for a heated towel rail with a bottom connection.

The second main rule for long, uninterrupted operation of a heated towel rail with ANY layout, including a side one, is to MINIMIZE the number of fittings and connections!

That is, an ideal lateral connection - directly to the riser without adapters!

To provide this opportunity it offers:

- Bends with external thread or union nut

for reliable connection and direct connection of the heated towel rail to existing riser pipes without additional fittings. - The ability to select the diameter of the bends themselves

for connection to the same riser pipes without adapters - 1" or ¾". - Possibility of manufacturing according to individual projects, taking into account the dimensions of

the heated towel rail itself up to mm,

placement of outlets

on it (any height, any side), structures with complex elements (in particular, heated towel rails with two shelves).

We will produce a side version of almost any

heated towel rail from those presented in the assortment, and if what you need is not in the assortment, we will make it

to order

according to an individual drawing. In general, we will do everything so that you can hang a new one in the place of the old one WITHOUT UNSCHEDULED REPAIRS. - THE MAIN DIFFERENCE OF OUR TOWEL RIDERS is

the presence of

a narrower insert

in the heated towel rail manifold closest to the riser to normalize the circulation of coolant inside the product at any pressure and with any supply (for more information about its necessity, see the technical section below).

Preparation of tools and materials

Installation of drying requires certain tools and materials. For example, installation on polypropylene pipes requires valves, special brackets, pipes, a soldering iron, and a device for cutting such pipes. The standard set of heated towel rails consists of:

- silicone-based gaskets;

- brackets;

- transition corners;

- crane "Maevsky".

It is recommended to mount the device from only one metal to prevent corrosion in the future.

A little more detail for those interested

Firstly.

Selecting

an external thread

or

union nut on the bends

will allow you to accurately reproduce the current connection of the riser and not carry out ANY additional work on routing pipes and installing new fittings. Manufacturing is even possible in different versions for each individual outlet.

Possible options:

- When you have a pipe with a nut sticking out, you will need a male threaded outlet for the connection:

- When you have a threaded pipe, you need a bend with a nut.

- When it is necessary to raise or lower the heated towel rail relative to the terminals (for example, the upper or lower boundary coincides with the level of the heated towel rail), a connection through an angle is used.

Secondly.

The production of

bends

is carried out

according to the required diameters (

1" or ¾") - for direct connection directly to the riser pipes WITHOUT ADAPTERS.

Fewer transitions means fewer connections. Fewer connections means less risk of leaks and air pockets, and, of course, cost savings

! Each outlet can have its own diameter.

Third.

Manufacturing

according to individual projects, taking into account the connection sides, the location of the outlets and the dimensions of the heated towel rail itself.

The main task of such projects is the ability to connect any new heated towel rail in place of the old one, regardless of what shape it was before. Even after a standard coil, you can install a ladder directly on the same riser pipes! Minimum required connections and the simplest and FAST connection possible.

The distance for the terminals can be not only the standard 320\500\600 mm, but any (at least 666 or 999 mm). If you need to raise the heated towel rail above the outlets or lower it to the floor, the connection point can be shifted both up and down the product.

In MStal heated towel rails it is possible to manufacture a heated towel rail with any connection side - including REAR SIDE

, which is necessary in apartments with “special” risers located, for example, through a wall in another room, or the entrance and return lines are in different rooms.

You can choose your own direction for EACH individual bend, for example, one back, one sideways!

Below we show the most “popular” methods of lateral connection:

- Lateral connection through corners:

An example of our design of a heated towel rail with side connections through the corners can be found here.

- Lateral connection with external thread:

An example of our design of a side heated towel rail with external thread can be found here.

- Lateral connection with union nut:

An example of our design of a side heated towel rail with a union nut can be found here.

- Rear side connection:

An example of our design of a heated towel rail with a rear side connection can be found here.

Fourthly.

When ordering according to an individual project, not only the size of the new heated towel rail can be absolutely any, but also its shape.

The catalog presents the most popular options, but if you don’t find the heated towel rail you want, MStal will make it according to your drawing

.

Due to all the technical advantages mentioned above (tapered inserts, minimizing transitions and fittings), complex structures

can be made with side connections , which will also well maintain proper coolant circulation over the entire surface and will not remain cold at the most inopportune moment.

By the way, you can find a review of this heated towel rail here.

Fifthly (almost the most important).

In heated towel rails

with a side connection, the presence of a narrower insert

in the manifold rack on the riser side is necessary to normalize the coolant circulation inside the product when:

- Any problems with pressure,

- Bottom water supply,

- The height of the heated towel rail is more than 800 mm,

- The presence of a hot shelf in the design, etc.

It will help distribute hot water evenly throughout all pipes and ensure 100% heating

(compared to similar products from other manufacturers, in which, in these situations, one side always remains cold).

In addition, such an insert will protect your heated towel rail from “rupturing” in the event of an emergency problem in the public water supply system.

Typical mistakes of independent craftsmen

When, with a side or bottom connection, the lower outlet is located above the extreme point of the PS, a stagnation zone is formed between the bottom of the device and the connection point of the lower outlet.

This is a consequence of the fact that the cooled liquid, having dropped down, cannot get back into the riser due to the pressure on it from a column of hot water with a lower specific gravity. As long as the permissible height difference between the bottom outlet and the bottom of the heated towel rail is not exceeded, the device works, and after that the circulation in it stops.

Circulation will also stop if there is a bend formed by the upper pipe. The only way to make such a scheme work is to insert a Mayevsky tap to periodically bleed off the accumulated air. Sometimes a loop is made in the upper pipe, laying it behind the ceiling trim, and the lower pipe is walled into the floor.

Air will accumulate at the top, and the cooled water in the unit will be blocked in the lower loop located in the floor. The movement of the coolant will stop completely.

In order to release the air formed when the coolant boils or brought into the heating system during its filling, air vents are installed (+)

Summary about side heated towel rails "MStal"

By installing a heated towel rail "MStal" with a side connection, you:

- Minimize the risks of uneven heating of the heated towel rail to 0;

- Minimize the number of connections that risk causing leakage;

- Make it easier to replace an old heated towel rail with a new one;

- Reduce the amount of work required for connection without disturbing recent repairs;

- Save your budget on additional pipe routing;

- You can finally get exactly that heated towel rail that you have long dreamed of, but did not find on sale.

That is, any heated towel rail with a side connection from MStal is a reliable and durable device that will not cause inconvenience either during installation or during operation.

But, if the connection has even more non-standard nuances and in an individual “section” requires a little more experience and professionalism - to prevent leaks and damage to the heated towel rail in the future, it is worth paying attention to the features of the connection with the bypass, presenting it as the main part of the riser or using it for creating additional closing pipes.

And now information for self-taught plumbers - the theoretical part about the correct LATERAL connection of a heated towel rail. If you are not a self-taught plumber, you don’t have to read further; you have already learned everything about the benefits of heated towel rails.

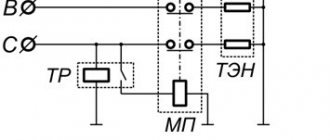

Algorithm for creating an electrical model

The creation of a model powered by electricity is based on the design of a water device. Therefore, the work begins with its acquisition. In addition you will need:

- electric heating element for the device (power not less than 110 W), with an external threaded connection of ½ inch, with a temperature controller;

- plugs (external thread ½ inch) – 2 pieces;

- Mayevsky tap (external thread ½ inch) – 1 piece;

- for sealing tow joints.

Electric heated towel rails are most often found in the form of a “ladder” model.

- More often, the left rack is chosen, with plugs screwed in at the top and bottom;

- then on the right side, below, an electric heating element is inserted into the rack;

- the structure is filled with water through the upper open hole;

- after the water has occupied all the free space inside, the hole is closed with a Mayevsky tap;

- By inserting the plug into the socket, the work performed is monitored.

The last step in working with an electrical device is to mount it on the wall.

About the important nuances of lateral connection and bypass

Briefly about what “ bypass”

».

With the course of historical progress, heated towel rails today have two outlets directed to the riser. The bypass is located between these taps. It is the closing section of the connection. Bypass diameter = riser diameter, or exactly 1 step less.

Why bypass is necessary:

- It will allow you to maintain the rate of circulation of hot water throughout the riser. It will also evenly distribute its temperature at any time and at any point in the system.

- The bypass will “separate” the heated towel rail from the general flow, allowing heat to be retained for other products connected to the system (relevant for the water supply system of apartment buildings).

- Using a bypass, you can manipulate ONE heated towel rail without affecting the operation of others. For example, adjusting its temperature.

Attention! If you want to be able to adjust the temperature of the heated towel rail, its design must have an additional valve. DO NOT adjust the temperature with a ball valve. More precisely, you won’t succeed!

But still, even with a bypass, you can encounter problems such as non-standardized diameter and inconsistency in the materials of the closing pipe, the height of the bends, the distance between the bends, etc. We'll talk about them later.

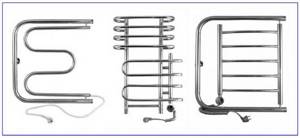

Types of heated towel rails

The retail chain sells a wide range of bathroom dryers (their standard diameter is 32 mm), which can be classified into the following groups:

According to the method of heating the working surface:

Mermen. The most common type of heated towel rails installed in all apartments of multi-storey buildings. They are usually connected to a separate hot water supply pipe running through all floors.

The coil can be installed in the pipeline gap in series or parallel to it through a bypass and shut-off ball valves. In individual houses, the dryer is connected to a common vertical riser with hot water.

Electrical. These are completely autonomous devices in the form of a coil or ladder, inside of which there is a tubular electric heater (TEH) and oil is filled.

The heater can be mounted on the wall anywhere (bathroom, kitchen, loggia); some models have a floor-mounted design. To heat the coolant, the device consumes an average of 60 watts of electricity. An important advantage of electric dryers is the ability to regulate the heating temperature using an external thermostat.

Combined. A type of heated towel rails that is not so common in the retail chain. The device has two separate, unconnected circuits. One of them is connected to the hot water supply, and the second, with the coolant oil, is connected to the electrical network.

Combined appliances are convenient because they can be efficiently connected to the heating circuit. When the heating system is operating, the room will be heated by hot water passing through the coil, and when the heating is turned off, by an oil radiator powered from the electrical network.

Rice. 2 Electric dryers

Based on the material used, the following types are distinguished:

Steel. These are budget types, for the production of which a metal pipe galvanized on both sides is used. Typically, dryers of this type are produced in a simple U-shaped or M-shaped form.

The coil has a gray, not very aesthetic appearance, but it can always be painted in a color suitable for the user.

Made of stainless steel. The vast majority of bathtub dryers are made from stainless steel. To give it a shiny, aesthetic appearance, the surface is usually chrome-plated.

Stainless steel can withstand temperatures up to 450 °C, has high corrosion resistance and strength, and a long service life. The disadvantages include much lower thermal conductivity than non-ferrous metals, as well as susceptibility to corrosion when used in the production of low-quality cheap alloys.

Made of brass. Brass with chrome, silver, gold or other plating is used in the production of expensive brands of heated towel rails. Its main advantages are excellent thermal conductivity, four times superior to conventional steel, as well as high corrosion resistance.

Bronze, copper. Dryers made from these materials are practically not found on the market; they are mainly used for the manufacture of exclusive models. Bronze and copper coils have the best thermal conductivity of all metals and favorably emphasize the design styles of retro, classic, and Italian interiors.

Rice. 3 Combined electric water dryers

Related article:

How to connect a heated towel rail to a heating and water supply system . It may be interesting to read an article on our website that describes in more detail how to connect a heated towel rail to the heating system.

Depending on the design of the heating pipeline, dryers are made in the form of:

Serpentines. These are S-shaped single-link and multi-link, U-shaped and M-shaped heated towel rails. Products of simple shapes have fairly low heat transfer and are typical for budget models. All these devices are designed for lateral connection to a water riser.

Combined type. These are models of more complex shapes, combining, for example, U-shaped and M-shaped, U and C-shaped contours. Many types of combined products include coils of a more complex design.

Ladders. The ladder dryer consists of two large-diameter vertical pipes with a number of smaller horizontal jumpers. The number of fragments in a heated towel rail-ladder can be as large as desired; in some cases, instead of straight horizontal jumpers, curved S and U-shaped ones are used.

Most ladder heated towel rails are equipped with an air vent and a plug in the upper part, which can be swapped.

The disadvantages of ladders include the possibility of accumulation of mud deposits in the lower part of vertically located pipes. To combat this phenomenon, some dryers are equipped with plugs that unscrew from the bottom.

In addition to the most common dryer options listed above, in the retail chain you can find more complex and original in terms of design models of various shapes and colors.

Also, some exclusive devices have rotating stands that are connected to the main structure using gland sealing units.

Rice. 4 Dryers of complex shapes

Connection conditions for stable operation

Focusing on the side connection of the heated towel rail, we note that the bypass is also taken into account here. He can be:

- Untapered / Tapered;

- Undisplaced / Displaced.

Or imagine combinations of options.

If the bypass is not biased or narrowed

That is, the bends are welded directly to the riser, the diameter and direction of which do not change. The bypass here is directly part of the riser

, therefore, manipulations with it must be done EXTREMELY thoughtfully.

The functionality of such a scheme is often questioned by plumbers, who say that the water in the riser will simply pass by, bypassing the heated towel rail.

We are forced to please or disappoint (plumbers who claim otherwise). Operation of the device under such connection conditions is POSSIBLE

due to the gravity pump underlying the design of the heated towel rail.

And in the case of heated towel rails - due to the presence of a special solder-narrower

, which we wrote about above.

When the coolant cools down, it goes down, pushing the hot one up. Logically speaking, if the incoming flow is at the top, then cold water will be pushed straight into the riser, and the heated towel rail will always remain hot. Physics, friends.

For connection with NOT narrowed and NOT biased bypass IMPORTANT:

- Placement of the supply riser - it should be ABOVE the connection point with the heated towel rail.

- Placement of the return riser is similar to the supply riser, but BELOW the connection point.

- The angle of inclination of connection pipes is from 3 mm and above.

- The connection pipe must be selected exactly in size, excluding sagging or bending - air can accumulate in the “humps”, which will interfere with the normal circulation of water in the system. If the pipe is too long, you need to fix it in several places for additional support.

- The diameter of the connection pipes is at least 3/4″ (25mm).

- The supply circuits must be covered with thermal insulation to reduce heat loss and extend the uninterrupted operation of the heated towel rail.

IT IS FORBIDDEN! Install shut-off valves on the bypass! This will negatively affect the operation of the entire DHW riser and your relationship with your neighbors!

And one moment. When the coolant is supplied from the bottom in the riser, no narrowing between the outlets should be allowed in this connection. Because of them, additional pressure drops may form in the riser, which will disrupt circulation and prevent the cold coolant from fully escaping, which means the heated towel rail risks remaining cold.

If the heated towel rail is installed correctly, it will heat evenly on all sides to the optimal temperature. And if there is no water in the system, it will not require additional drainage procedures, which is most convenient, for example, if the hot water was turned off when the owner was on a long business trip.

All other bypass options are used for one single purpose - to increase the coefficient of coolant flow into the system!

If the bypass is not biased, but narrowed

Option (for some unknown reason!!!) is the most common. Here, the bypass is also part of the riser, but between the branches its diameter becomes smaller (for example, a 1″ riser - a 3/4″ bypass).

According to many “experts”, the bypass when connecting a heated towel rail between the outlets must be narrowed. And only in this case can the stable operation of the product be ensured.

No no and one more time no! In the case of a bottom supply, such a connection, on the contrary, will be the main reason for a cold heated towel rail! Therefore, we consider only the top feed

!

The advantages of such a connection include:

- Great job!

- No need to drain water;

- Possibility to remove the heated towel rail from the riser at least 10 meters.

- With this scheme, the KTZ is 0.4.

The lower outlet with a narrowed bypass must be lower than the device or at least equal to it!

If the bypass is offset and/or narrowed

With this connection, part of the riser moves closer to the heated towel rail. In this case, the bypass diameter itself can be reduced by 1 step. A simply biased bypass has a coefficient of 0.33 - 0.4, and a biased one with a narrowing - 0.48 - 0.52.

In this case, a lateral connection is only possible if the coolant is supplied to the system from above. When hot water is supplied from below, the heated towel rail CANNOT function!

And among the important nuances of such a connection:

- No need to drain water.

- Any distance from the riser is possible.

- A slope of the connecting pipes is required - from 3 mm.

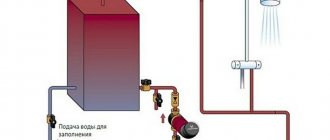

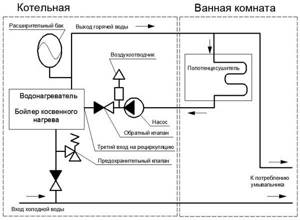

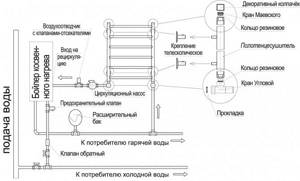

Connection to the boiler

Connecting a heated towel rail to a boiler is considered an exceptional option. The scheme is used only in cases where the implementation of other methods is impossible. For example, in the absence of hot water supply in a private house heated by a single-circuit boiler. The supply of cold water to the boiler and the supply of hot water to the “towel box” is carried out through flexible hoses. They are connected to the device using a stainless steel or bronze coupling. The temperature of the water, and therefore the heated towel rail, is set using the water heater thermostat.

The disadvantage of this scheme is the inconsistent heating of the dryer. The hot water circuit is connected through the device and the flow directed to the mixer first passes through the “towel box”. This means that the jumpers and racks will only be warm during selection - when the hot water tap is turned on. To avoid airing the system, a Mayevsky valve must be installed - accumulated air is periodically released through it.

How to understand that the problem is in the connection

Incorrect connection of the side heated towel rail is the most common problem with its malfunction. Although the side scheme is optimal for most bathrooms, and MStal, as best they could, made it easier for installation, you can still do a lot of things with it.

So, typical connection errors are:

- The lowest point of the product is below the return outlet

! In this case, the heated towel rail will only heat up to a certain point - until it is filled to the bottom outlet. After this, the circulation of the coolant in the upper part becomes simply impossible - the hot water will not be able to overcome. In addition, dirt from the riser will accumulate in the pipe, which will deform the heated towel rail from the inside even with the most “durable” manufacturing material. - The upper outlet pipe has an arched or protruding shape

. Air will definitely accumulate in such a pipe. Operation is impossible if there is no drain valve for air removal or a Mayevsky tap at the highest point.

But it is worth noting that with additional valves and taps, the design automatically assumes the risk of leakage! We remind you that fewer fittings and connections mean less risk!

With MStal heated towel rails, you simply won’t recognize other mistakes, since all the nuances of the design itself and its required dimensions will be clarified by experienced consultants. But the installation process itself (if it is carried out by your plumber) will have to be checked once again.

Connecting a heated towel rail in a country house

The conditions of a private home are more favorable for installing a dryer. With an autonomous supply system, the water here is cleaner. You can buy imported PS that is afraid of sediment accumulation.

Usually in such a house a fairly large room is allocated for a bath, which expands the boundaries of the choice of unit in terms of size and shape. And connection work does not require permission from neighbors.

Regardless of where you are going to connect the heated towel rail - to the heating system or to the domestic hot water supply, you cannot do without inserting the device into the pipes

The connection diagram itself is similar to that used in an apartment building. It must be remembered that the device should be connected exclusively along the flow of water. For line lengths up to 50 cm, place the pipes horizontally; for larger lines, make a slope along the entire length.

Maintain the distance between the wall and the water pipe. If the pipeline diameter is 4-5 cm, choose a distance from 5 to 5.5 cm. When the diameter is less than 2.3 cm, this gap is reduced to 3.5 cm.

Considering the temperature deformations to which hot pipes are subject, it is impossible to fasten the PS to the supports by welding; the fastening must be free.

We answer questions

- Does the basement pump affect the heating of the heated towel rail?

Yes, but only for the first time when connecting - the heating rate and the overall temperature in the riser depend on it. The rest of the time, a correctly connected heated towel rail maintains a temperature slightly different from the riser if it itself is hot. That is, the main thing in the connection is the riser itself: if it’s hot, that means the heated towel rail should work perfectly! - Does the material of the supply pipes affect the quality of the connection

? It influences! Press stainless steel remains the most durable, polyethylene (cross-linked) is of lower quality, and reinforced polypropylene is the most short-lived. The choice is yours. - Which connection is sure not to leak

? One that is sealed and has no joints or connections. Do you understand, right?! There is always a risk.

Of course, we reflected in the article only a small part of the technical information on the lateral connection of heated towel rails. But, if you are choosing a product for a long and faithful service, the connection of which you do not want to worry about and blush in front of your neighbors, we recommend heated towel rails with side connections, which are maximally adapted to modern realities and the state of water supply systems!

Installation features: how to start a heated towel rail

Before installing a heated towel rail, you first need to select it. For apartments, it is recommended to choose devices from a domestic manufacturer that will comply with certain GOSTs, since imported ones may not be suitable for our installation. But for private homes, foreign brands are also quite suitable.

A water heated towel rail will only work during the heating season, and in the future it will simply serve as a designer decoration. If you want the device to function all year round, then you need to install a combined type of this device.

It is also impossible to allow the pipes of the device to be smaller in diameter than the main system. If this happens, then you need to select and install the necessary adapters. For main connections it is best to use “American” ones. They will allow, if necessary, to easily and without problems remove the entire device. It is also recommended to install ball valves and special jumpers for convenience.

Installation of a heated towel rail:

- First of all, the device needs to be assembled: to do this, it is necessary to install shut-off valves on the supply line, which have detachable connections;

- Attach the assembled device to the wall;

- Bring pipes from the main riser.

Having completed all these steps, you can begin the initial launch of this device (heated towel rail). To start the device we need a pre-installed Mayevsky tap, which is usually located at the top of the device. Having opened the tap, you need to gradually fill the entire device with water so that it does not become airy, that is, air jams should not form. In order for the launch to take place correctly, you need to have enormous professional skills, and not just turn off the water.