Installing the regulator: the need to use the device

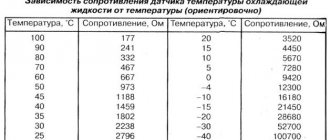

The temperature sensor is a guarantee of uninterrupted operation of the heated floor without overheating and early failure. Despite the fact that a water heated floor can work without a sensor (if there is no equipment in the project being laid), installation of the equipment will allow you to change the heating level, which, you see, is quite useful during certain seasonal weather changes. In addition, systems with liquid coolants, where the device regulates the operation of a three-way valve and/or circulation pump, are able to heat up to the desired temperature without depending on the temperature conditions of the coolant.

Purpose of a thermostatic valve and its scope

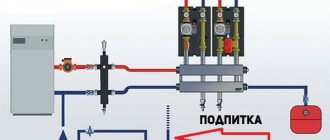

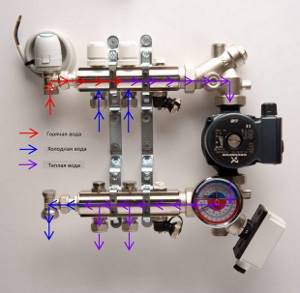

The thermostatic mixing valve is used in underfloor heating with circulating water inside.

The heating temperature of the coolant for conventional batteries is much higher than that required for water floors. Overheating of the concrete screed will worsen the microclimate and lead to damage to the floor finishing material. A thermostatic mixing valve for underfloor heating will help solve this problem. Using it, you can create an independent circuit with the desired temperature, or power a heated floor from central heating.

The thermostatic valve allows you to solve the following problems:

- Change the direction of the water flow and add cold to the hot in the required proportions;

- Receive a liquid output at a constant temperature.

A mixing tap is not needed if:

- all circuits have the same coolant temperature;

- the heat source is capable of providing the required degree of heating of the coolant at the outlet.

Types and types of sensors

Remote electric sensor for adjusting floor temperature

All sensors and regulators can be divided into two types:

- The mechanical device has an operating principle based on the property of changing volume depending on temperature readings.

- Electronic, installed remote sensor in the form of a thermistor. It is supplemented by a separate control unit containing an electronic circuit, operating order and indication elements.

Devices are also divided by type:

- a device operating in economy mode, which allows you to reduce the level of floor heating in the room when there are no people;

- sensors with a timer, which have a program for turning on/off the heating system;

- intelligent sensors with a built-in operating algorithm and control of other factors: humidity conditions, temperature fluctuations outside the room, presence/absence of people in the room, etc.;

- limiters are thermal devices that turn off the heating of the coolant when a predetermined temperature is reached.

Advice! In simple heating systems, the presence of highly intelligent sensors is less justified than connecting a conventional electronic regulator. Numerous functions of the devices will not be in demand, for example, in warm water floors.

Thermostats for water heated floors differ in the type of monitored environment:

- floor temperature control;

- control of the degree of air heating.

As a rule, sensors for determining air temperature are located in the thermostat housing. This provides additional convenience, since no unnecessary installation problems are foreseen; on the other hand, the installation of the thermostat must meet a number of conditions:

- absence of nearby sources of heat/cold;

- There is no threat of direct sunlight or draft blowing.

Important! The installation location of the device is selected taking into account the accuracy of the temperature display, so it is best to place the equipment at a height of at least 1-1.5 m from the floor.

The water floor system can be supplemented with a remote temperature sensor. Representing a small-format device attached to the end of a long cable, the measuring device is mounted in the floor with a distance of 0.5 meters from the wall. The placement is shown at a distance equidistant from the nearest coolant pipes. The second end of the structure is connected to a temperature sensor and attached to the terminals according to the diagram.

Where are the most expensive new buildings in the Moscow region?

Advice! This type of device must be installed during pipe laying before pouring the concrete mixture. It happens that such devices fail, so it would be useful to provide for the possibility of replacement by laying a corrugated hose.

Which is better, manual or automatic?

Today the market offers a large selection of such devices from various manufacturers. Note that the first underfloor heating systems were equipped with mechanical thermostats. However, this method of setting the desired temperature of the heated floor was inconvenient, as it required constant human control. There are still such models on sale, and it is worth saying that during this time their sales have not decreased much.

We recommend: Kitchen apron made of MDF panels: advantages and disadvantages

After some time, mechanical thermostats were replaced by electronic thermostats, which allow you to control heated floors automatically. With their advent, people no longer needed to constantly monitor the floor heating temperature. It’s just that their price is slightly higher than the first ones, but not so much as to deprive yourself of the pleasure of being free from constant temperature control.

If your budget does not allow you to purchase an expensive automatic controller, then you can install a mechanical device, even if it does not have a large number of functions, but the ease of installation and control can also be considered a big plus, and if you add the low cost, then such a thermostat will be suitable solution for a heated floor system on a limited budget.

To understand which floor heating control is better, let's compare automatic and mechanical thermostats. To make it clearer, we present a comparison in the table according to several parameters:

| Comparison options | Mechanical thermostat | Automatic thermostat |

| Device price | From 3-4 thousand rubles | From 9 to 20 rubles |

| Work management | In manual mode | In automatic mode |

| Screen | Absent | Available |

| Thermal measuring device | Absent. Measuring the heating temperature of a heated floor occurs using tactile sensation | Available. The temperature sensor monitors the maintenance of the required parameters |

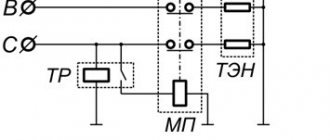

Connection diagram for a heated water floor thermostat

This design does not require the installation of the device, such as, for example, electric floors. In the case when the boiler is not powered by electricity, there will be no large financial costs with little optimization of heating operation.

There is an option for adjustment in the usual manual way, based on subjective preferences, but only if the floor is the only heating device and the boiler does not raise the temperature above +50 degrees. But if there are other heaters in the house (in the system): radiators, a hot water circuit, a thermostat for a water floor, installation is required.

The simplest connection diagram is to install a thermostatic head with a remote-type sensor on a two-way valve. In this case, the head filled with a heat-sensitive substance will instantly respond to any changes: when heated, the substance will expand, and when cooled, it will contract, thereby opening or closing the coolant supply.

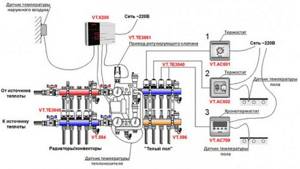

Advice! For a large house with several branches of the heating system, it is preferable to install several temperature sensors with servo drives.

Connection diagram for a thermostat for a water floor:

- the servo drive is mounted on the return comb of the manifold for a warm water floor;

- wires are pulled from the collector to the regulator device, equipped with an air temperature indicator;

- the distributor box for the drive and thermostat is located in the manifold cabinet at a level above the combs;

- the cable from the distribution box goes to the distribution panel.

What are water floor servos? These are devices without which it is not possible to regulate the temperature of the liquid water coolant. Representing small-format electrothermal devices that open/close the media supply, servos operate through a bellows - a cylinder filled with a substance that has the ability to change volume under the influence of temperature.

Today, manufacturers offer two types of servos: open and closed. Valve Position Difference:

- in open designs the valve is open until the heating/cooling signal appears (at which it closes),

- in closed - the valve is normally closed until a signal appears at which it opens.

The choice depends on the user’s preferences, however, experts recommend open-type servomotors due to the fact that even in the event of a breakdown, the water in the system will continue to function and the floors will not freeze.

Electric and water heated floors: scope, design diagrams and calculations

Important! When choosing servos with a 24V DC voltage supply, you will need to install an inverter.

Connecting the servo drive is not difficult. Depending on the type of thermostat, it is possible to connect:

- if there is a thermostat that controls a single floor heating circuit, installation is carried out with the appropriate wires;

- if the device is multi-zone type, the wires are connected to the corresponding terminals.

Thus, servo drives perform not only the role of passing/closing the coolant, but also a protective function. The closed position signals the end of pump operation, which will extend the life of all equipment - the pump will not run idle, which means the risk of system failure due to increased pressure will be minimized.

Important! In underfloor heating systems, the pumps of which are of the usual solid fuel type, turning off the pump is unacceptable: the boiler will not go out anyway, and stopping the functioning of the system (signaling) threatens to rupture the entire structure. Installing a bypass and bypass valve will avoid this situation.

Adjusting the heated floor temperature

The simplest adjustment option is with manual taps. A slightly more comfortable option is automatic thermostats with sensors and servos, but only with the additional installation of a restart valve and switching unit. In addition, there are other ways to regulate the heating of floor water systems:

- change in coolant flow;

- change in coolant temperature.

The second method is used especially often and involves the installation of a three-way valve, which is entrusted with the function of controlling the mixing unit. The relay output of the temperature sensor is connected to the solenoid of the electric shut-off device: at the slightest excess of the temperature of the value set in advance, the valve opens, causing the cooled water to mix with the incoming liquid, reducing the heat capacity.

Advice from professionals

In order for the water floor to work flawlessly and the installation of the thermostat to go perfectly, it is worth taking note of some installation subtleties:

- the presence of a normal cross-section of the thermostat cable is welcome;

- if the wiring in the house is old, it will be safer to install a separate line (when connecting a boiler powered by electricity);

- a regulator installed to control several water floor systems is not entirely convenient, since adjustment will only be available in the room where it is installed;

- You cannot use a single temperature sensor if the operating conditions in different rooms are different.

Connecting a thermostat to a water heated floor system yourself will not cause much trouble. It is enough to choose a device that meets all the requirements, carefully review the step-by-step work and enjoy the warmth and comfort of your own home.

How to choose a device

Thermostats have nuances that affect their operation. You need to know their features in order to get the desired functions and save money. First of all, you should pay attention to the strength of the plastic from which the case is made. What kind of internal elements can there be if the manufacturer has already saved on the product?

When choosing a device, you need to rely on:

- To heat a small room, it is enough to install a mechanical or electronic thermostat equipped with a sensor inside the system.

- The programmable type of the device is suitable if you need multi-zone control of circuits, also to save on electricity if residents are not in the house during the day.

- The thermostat must have a power in accordance with the maximum power rating of the elements for heating the floors. In this case, the power reserve should be up to 30 percent if the mains voltage suddenly drops.

- In wooden houses, thermostats with overhead boxes are used.

A wide range of devices allows you to choose practical and economical equipment, which is also beautiful, which will decorate the interior design of the room.