Shut-off valves allow you to regulate the flow of liquids and gas and control their supply. One of the designs is a ball valve. It was invented at the beginning of the last century, but was not widely used in everyday life because the fitting quickly failed.

New materials and technologies have made it possible to create strong and durable parts. This significantly reduced the dimensions and weight of the units. Now ball valves and mixers are constantly used in household systems and large pipelines.

Plumbing pipe with ball valves

Types of ball valves

Like any mechanism, such shut-off valves can be different. Some types are more common in everyday life, others are used less frequently, but it is worth considering all of them to provide the reader with more detailed information. The main criteria by which ball valves are divided are:

- threaded connectors;

- throughput;

- type of locking mechanism;

- control method;

- manufacturing material.

A very unpleasant situation in which you cannot do without completely shutting off the main line. PHOTO: proektooo.ru

Threaded connectors and their types

Threaded connectors are used to connect the tap to the pipe and connect it to the system. They can be of three types:

- external - a nut located on the pipe is screwed onto the coupling ball valve on both sides. For sealing, a paronite, rubber or silicone gasket is used;

- internal - the thread is located in the body of the valve. At the same time, it is screwed onto the external thread of the pipe, and the seal is made using flax or FUM tape;

- combined - here there are both previous options, located on different sides.

Ball valve with external thread for a nut PHOTO: fantasticbook.ru

Throughput of shut-off valves

According to this parameter, ball valves can also be divided into three categories - full bore, no bore and reduced bore.

- The full bore mechanism ensures medium flow with virtually no pressure loss. The diameter of the hole in the ball here can be slightly smaller than the size of the pipe (from 1 to 10%). Used in systems where there is no need to reduce flow pressure.

- Non-through valves have an inlet 30-60% larger than the outlet, which significantly reduces the flow pressure.

- Reduced or standard bore products allow you to slightly reduce the pressure of the outlet flow, within 10-30%.

Full bore valve with a nozzle that turns it into a reduced one PHOTO: termoros-spb.ru

Locking mechanism and its varieties

This parameter is not particularly important for a home craftsman, but it is also impossible not to consider it, at least superficially. There are 2 types here.

- Floating ball - the design is applicable only in low-pressure systems and can have a fairly large diameter, up to 200 mm.

- Ball on supports - this is the mechanism used in household taps, both in water supply systems and for shutting off gas lines in private houses and apartments.

The problem with such cranes is the fragility of thin walls - it cannot be overtightened. PHOTO: termoros-spb.ru

Division of valves by type of control

For domestic use, a valve tap is most often used, which allows you to smoothly regulate the flow rate. In addition to it, it is worth noting console mechanisms, which are capable of only rough adjustment, and electronically adjusted valves, used for automatic control.

Materials for manufacturing shut-off valves

For the manufacture of each part of ball water and gas coupling valves, various materials are used, namely

- the housings are made of cast iron, brass, bronze or polypropylene;

- For the ball element, brass, chrome and steel are used;

- the seal can be Teflon or fluoroplastic;

- valves – polypropylene, steel, brass.

The use of a particular material is determined by the characteristics of its use. The most common material (brass) has high anti-corrosion and strength characteristics; steel is much stronger, but is susceptible to corrosion. As for polypropylene, despite its low strength, moisture cannot harm it, and its cost is very low.

Many people consider such taps to be steel, but this is just a coating of brass PHOTO: engineers.com.ua

Gas ball valve for underground installation: selection criteria + operating rules

Pipeline fittings will not be reliable and durable without blocking the flow of the gaseous medium. The gas ball valve is an up-to-date equipment for domestic and industrial gas pipelines. Such fittings are installed on the pipeline and serve to block the flow of gaseous liquid.

Until recently, a plug valve and a sleeve valve were used for the home heating network. According to their passport, they are required to work long enough. For example, the service life of the first equipment was 8 years.

But, after 40 cycles (instead of the promised 400), they began to “lose ground.” The stuffing box turned into mush, and the plug dangled in the body. Even in the closed position it let gas through.

And the gas workers simply removed the plug, leaving the tap as a decoration.

The valves were supposed to operate for 1300 cycles. In fact, after 40 cycles they were leaking gas. Sediment accumulated on them and the flow was not blocked very tightly. They also reduced the throughput pressure of the gaseous liquid.

How to choose a ball valve?

The following selection criteria should be followed:

- Material of manufacture and appearance of the case

. The preferred option is a product made of brass or stainless steel. A silumin faucet is cheaper, but it is fragile and requires careful handling. - Material for making the sphere

. The locking element must have a mirror-like and absolutely smooth surface. It would be good if it was coated with nickel or chromium. A cloudy sheen or matte finish is not welcome. - Body markings

. A three-way ball valve must contain information about the manufacturing company, nominal diameter and operating pressure. Letters and numbers must be clear and clearly visible, otherwise you may suspect a fake. - Maximum permissible pressure

. It should be selected taking into account the characteristics of the engineering system. At the same time, you need to choose a ball valve with an American one with a reserve. That is, the pressure indicated on it must be higher than that used in communications. - Product weight

. A brass product is always heavier than a steel or silumin counterpart. - Handle shape

. On sale you can find products with a long lever or “butterfly”. The first option is more preferable in situations where the tap has not been turned for a long time. Then you have to make an effort to do this, which in the case of the “butterfly” is problematic. - Price

. Everyone decides this question for themselves, but high-quality products cannot be cheap. - Correspondence of the listed characteristics to the peculiarities of life in this particular country

. In different cities, the temperature of water in heating systems varies, which leaves its mark on the choice of shut-off valves.

Ball valve handle

As already mentioned, it can look like:

- Lever

. A ball valve with an American connection of this type is more practical and easy to use. It allows you to grab it with your whole hand and turn it in the desired direction. If the faucet is “sour”, then this requires considerable effort, but with a lever this is easier to do. - Butterflies

. More preferable from an aesthetic point of view. It is neat in appearance, but to turn it, only two fingers of one hand are used, which will be difficult to move the “stuck” faucet.

It must be said that the pen can have a variety of colors. Traditionally, blue is used for cold water supply systems, and red for hot water supply systems.

Handles designed for gas pipelines are produced in a yellow version. In addition, you can find white products on sale - they are specially installed on radiators and heated towel rails.

The manufacturing material can be either plastic or metal.

Precautionary measures

Even during a simple activity, you can injure yourself if you do not follow basic safety rules:

- Always wear thick rubber gloves to avoid injury to the skin of your hands and nails. Your skin will not dry out;

- Take your time when cleaning fixed surfaces. Sometimes fingers or nails involuntarily hit a hard surface, and the bruise can be severe;

- if your kitchen has an electric stove, unplug the plug from the socket before washing so that you do not accidentally get an electric shock;

- do not leave a pan with cooking detergent on the stove unattended;

- If you decide to resort to household chemicals, be sure to read the instructions and follow them when washing.

Shiny, clean handles immediately give the stove an attractive appearance and speak of the housewife’s neatness. To keep the products clean for a long time, after each cooking, wipe them with a damp cloth or a simple towel. Fresh fat will disappear instantly and will not have to be removed in the future. A stove that is maintained regularly will last for many years and will be in like new condition.

Types of water ball valves

Manufacturers offer a wide variety of shut-off, control and mixing valves.

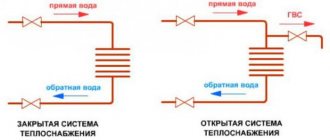

According to the body configuration, locking products are divided into:

- straight;

- corner;

- tees.

Direct ones are the most popular for home use. Angular ones are installed in places where the direction of flow should be changed and its regulation should be provided. This need for plumbing arises when connecting a dishwasher or washing machine. In heating systems when connecting a radiator to the inlet pipe. Tees are installed in a place where it is necessary to cut off one of the flows or redirect the flow.

Based on the type of housing there are:

- with a solid body - they cannot be repaired if broken;

- with a collapsible body - repairable.

For home plumbing, unless the owner is a professional plumber, purchase solid taps. They are cheaper. If they break, they are replaced.

We recommend that you read: Vacuum valve for sewage systems

Products with a moving ball are limited to a diameter of 20 mm. The ball in the locking mechanism is able to move freely. This provides additional sealing, since the ball presses the flow itself against the gasket material.

Based on cross-country ability, ball valves are divided into:

- Full bore - capacity corresponds to the pipeline.

- Reduced - the throughput is reduced due to the smaller diameter of the hole in the locking mechanism. Such taps are placed on heating lines under pressure to mitigate water hammer.

According to the method of connection to the pipe, they are distinguished:

- Threaded. The thread can be the same on both sides (external, internal). Or different, when on one side it is external and on the other internal.

- Combined - on one side there is a thread (any), on the other there is a fitting.

- Designed for welded joints. These are rarely used in the home plumbing system.

- Flanged - have flanges at the ends and are a main version of the locking device.

In individual water supply systems, the first and second types of ball valves are mainly used. The threaded connection is easy to install and can be quickly disassembled if necessary.

According to their performance characteristics, ball valves are distinguished:

- low and high temperature;

- for operation under different pressures, from 16 to 40 atm.

Manufacturers offer a wide selection of ball valve sizes, from standard ½ inch to 200 mm valves.

Based on the material of the case, they are distinguished:

- steel;

- brass;

- polymer - made of unplasticized polyvinyl chloride.

Brass ones are the most expensive, but also the most reliable. Their service life is longer than that of steel (they do not corrode in an aquatic environment). There are no restrictions on the scope of use like plastic ones.

Steel ones are rarely used when installing home communications. Their main area of use is industry.

Polymer ball valves are widely used in the installation of individual water supply systems. Manufacturers offer a range of sizes from 20 mm to 63 mm. The service life of polymer ball valves is guaranteed for 15 years. They are not subject to corrosion. They have a reliable locking mechanism with a floating ball. The push-in connection allows the unit to be dismountable.

We recommend that you read: How to properly secure a sewer pipe to a wall - types of fasteners and installation methods

Classification of ball valves

Attention should also be paid to the fact that there are several varieties of the locking mechanism in question. They are divided according to the following criteria:

- Based on the principle of attachment to the pipeline. The valve is attached to the pipe through couplings, flanges or fittings. There are also versions that are welded to the pipe. In everyday life, the coupling type is most often used; it is capable of withstanding a fairly high load, but not as large as in the central gas supply network or oil crossing. Flange is used when laying networks for the transportation of oil and gaseous substances.

- The locking mechanisms in question are also classified according to their special purpose. The most common are reversible ones, designed to redirect flows, with housing heating and a leakage control system. In everyday life, design options are used that allow you to control leaks - when installed, you can significantly increase safety

- According to the body material. Another important classification is the type of material used in the manufacture of the case. The case is designed to protect the mechanism from environmental influences and also acts as a kind of barrier. Most often, the body is made of steel 20, alloyed alloys 09G2S and 12Х18Н10Т.

- An important point is also the diametrical size indicator. On sale there are versions marked DN 10-50 and higher. The selection of the locking mechanism is also carried out according to the diameter of the pipeline: it is not recommended to use transition elements.

- The nominal pressure in the PN system is 1.6 MPa and 4.0 MPa. In addition, you can purchase products for central gas or oil supply systems, where the pressure can be very high.

This classification should be taken into account when selecting the most suitable shut-off valve.

Operational Features

Considering this locking mechanism, the following points can be noted:

- High tightness. The body is made by casting, which determines the high insulating qualities.

- The use of metal and special alloys made it possible to reduce the weight of the structure.

- Increased reliability. As previously noted, an articulated crane can be used for many years without malfunctions.

- The temperature regime of the working environment can vary over a fairly wide range.

- Special performance qualities determine that the crane can withstand ambient temperatures from -60 to +80 degrees Celsius. That is why the faucet in question can be installed both inside and outside. Strength and other performance properties remain virtually unchanged when temperature changes.

- Well-known manufacturers of hinged locking structures provide a fairly large guarantee.

As practice shows, articulated cranes can last for more than 10 years.

Types and designs

Depending on the design of the closing mechanism, this corner fitting is:

Ball - having a lock in the form of a ball with a through hole. If the ball in the housing cavity turns with a hole perpendicular to the flow axis, then the flow of the medium stops. The tightness of the product when closed is ensured by elastic rings fixed to the saddles and fitting well to the ball. May have internal or external threads. The design diagram of a BUGATTI ball valve made in Italy can be seen in photo 1.

One of the varieties of ball corner fittings is the American valve. They combine a standard product with a ball valve and a quick-release type of connection, which is a design of two fittings separated by one gasket. To secure the connection, they use a hexagonal union nut made of brass.

Photo of a crane - American

- Conical - with a locking element made in the shape of a truncated cone. Such devices operate more smoothly than ball-based products.

- Valve. The design of this type of valve includes a shutter in the form of an elastic gasket and a worm mechanism that presses the rod and locking element to the seat with a hole. As a result, the gasket will block the passage. By rotating the handle, the flywheel can again set the rod in motion, which will lift the shutter and open the passage hole. The advantage of installing a valve in pipeline systems is its maintainability and the ability to use it not only to block the passage, but also to regulate the pressure. The disadvantages of such products include rapid wear of the movable gasket.

Radiator. The products are designed for manual adjustment of the coolant flow force entering the radiators. In their group they are divided into:

- balancing (regulating) valves. In heating systems, they are usually installed on the return line to the radiator; on the supply line, it is advisable to install a ball valve;

- thermostatic models (with thermal head). The principle of its operation is based on the thermal expansion of media. The main element of the device is a bellows filled with a substance with a high expansion coefficient in a liquid or solid state. The bellows is connected to the valve using a rod. When the thermal head heats up, the bellows lengthens. It exerts an impact through the rod on the valve, which blocks the flow. When cooling, the siphon shortens and opens the passage hole;

- devices with a thermostat that allows you to control coolant flow.

Cross-sectional photo of a thermostatic valve:

Expert advice

- If the design of the system involves placing a tap and an angle nearby, then it is better to replace them with this type of fittings. This solution will save money and simplify the installation process.

- The model should be selected depending on the location of the pipeline. There are products designed for installation only on vertical risers and on horizontal sections.

- It is advisable to add an end valve to the irrigation hose with a device designed to concentrate or disperse the flow of liquid. The product will be more efficient in operation.

- Devices with a thermal head should not be covered with furniture or finishing materials and should not be exposed to direct sunlight.

Technical description

The first thing to consider is the design of the ball valve.

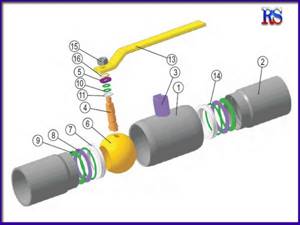

Structure

Gas ball valve design

| Designation in the figure | Name |

| 1 | Hull part. Most often found in brass or steel. |

| 2 | Connection pipe. May have a threaded or welded connection. |

| 3 | The throat part. The rod passes through itself. |

| 4 | Connecting rod. Connects the handle and the ball together. |

| 5 | Restriction washer. |

| 6 | Check ball. Directly closes and opens the passage. |

| 7 | Saddle. Positions the ball in the desired location. |

| 8 | Ring support. Holds the saddle. |

| 9 | Spring. |

| 10 | O-ring seal. |

| 11 | Ring. |

| 12 | Flange. |

| 13 | Lever. |

| 14 | Seat seal. |

| 15 | Fixing nut. Holds the handle. |

| 16 | Stopper. |

Principle of operation

Steel hollow ball

The most important and basic part of the gas valve under consideration is the shut-off ball, which has a through hole equal to the diameter of the connecting pipe and is connected to the switch handle by a rod. The instructions for the operation of such a mechanism are elementary:

The instructions for the operation of such a mechanism are elementary:

- The person, with a slight movement of his hand, turns the handle 90 degrees.

- The rod transmits this movement to the ball.

- The wall changes to a hole, creating a free passage.

Advantages

Ball gas valve KShG made of steel

Ball valves for gas pipelines have a whole range of positive aspects:

- Relatively low price. This is achieved due to the simplicity of the design, eliminating the use of expensive components.

- Light weight. Does not weigh down the pipeline, which allows you to limit yourself to standard pipe fastenings.

Conventional fastening for gas pipeline

High reliability. In manufacturing, only high-strength materials are used.

The reliable brass body of the gas ball valve is not subject to corrosion processes

- High speed and easy DIY operation. Just a short turn of the handle is enough to change the position from “open” to “closed” and vice versa.

- No maintenance required. Such shut-off valves can be safely installed in hard-to-reach places.

- High tightness of flow shutoff. The closed position of the valve guarantees complete sealing of the gas pipeline.

- Possibility of installation even under water. In this case, the penetration of liquid into the system is absolutely excluded.

- Small sizes. They allow the product not to stand out against the background of the pipe itself and simplify its installation, which can easily be performed by 1-2 people.

Ball valve on gas pipe

- Attractive appearance. The only part that stands out is the handle, which can be made in the form of a butterfly or an elongated lever. In any case, the technical unit looks quite aesthetically pleasing.

- Easy to install. Both threaded and welded connections are possible.

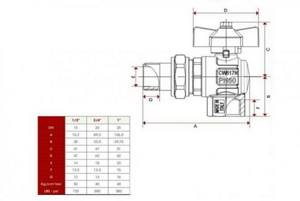

Technical data

Valve with butterfly handle and nominal bore 15 mm

Let's look at the parameters of the classic model for installation on a home gas pipeline:

| Parameter | Meaning |

| Section | 1.5 cm or ½ inch |

| Number of turns on a threaded connection | 6-7 |

| Tightness indicator | Class A |

| Withstand pressure | Not less than 6 MPa |

| Permissible temperature | From -20 to +130 degrees Celsius |

| Housing material | Brass grade LS-59-2 |

| Handle type | Butterfly |

| Handle color | Yellow in accordance with the gas pipeline designation rules |

| Gasket material | Fluoroplastic |

| Threaded connection for pressure gauge | G ½ / G ½ |

| Types of threaded connections | Inner-outer and inner-inner |

| Product height | 5.8 cm |

| Length including handle | 6.7 cm |

| Body length | 6.7 cm |

| External diameter | 3.3 cm |

Possible varieties

It should also be noted that gas ball valves may differ from each other in some features, namely:

If possible, carry out repairs. There are dismountable and all-welded samples.

In addition, there are models that have an electric drive, which allows you to automate the process of closing and opening it.

Characteristics

The main technical characteristics are the following product parameters:

- nominal diameter - from 15 to 50 mm;

- maximum operating pressure - from 10 to 16 atm.;

- type of connection to pipelines - coupling, flange, welded or combined (one of the pipes is welded);

- thread type - internal or external;

- type of control of the locking element - handle - butterfly or lever;

- material of body parts;

- operating temperature range - from -20ºС to 150ºС (depending on the material used to manufacture the device);

- seal tightness class.

The main dimensions of products can be determined from the table:

Types of ball valves

Locking units are distinguished according to several parameters.

According to the method of passage of the transported material, they are distinguished:

- full bore;

- reduced (standard passage).

For full bore ball valves, the hole in the ball, assembly body and pipe has the same diameter.

Standard bores have a hole in the ball one size larger than in the pipe and body. This protects against dynamic impact when closing and allows you to mix liquid from different sources. For example, an articulated ball mixer for bath and kitchen with one handle that regulates the supply of hot and cold water and their ratio.

According to the methods of installation into the system, the following types of cranes are distinguished:

- coupling;

- flanged;

- for welding.

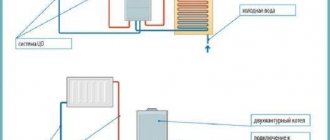

Coupled ball valves are threaded ball valves that are screwed directly onto a metal pipe or adapter in the case of a plastic pipeline. Widely used in the installation of household plumbing and heating systems. The system is easy to assemble with your own hands.

Flange fittings are suitable for large diameter pipelines operating under high pressure. Welded ones are small in size. They are installed in systems with high requirements for tightness.

According to their purpose and operating environment, there are gas valves, for cold and hot water, steam, and acid-resistant. The unit body can be solid or collapsible.

Ball valves are installed not only on home systems. They are mounted on large-diameter oil and gas pipelines. You cannot turn such valves by hand. And the distance between them can be several kilometers. Therefore, various control methods are possible:

- manual;

- with gearbox;

- with electric drive;

- hydraulic;

- pneumatic.

The gearbox increases the applied force and allows you to manually close a large valve or smoothly regulate the flow of the transported substance. The electric motor can be controlled from a distance. The electric actuator can be installed on large cross-section pipelines, as well as for remote control.

Ball products are distinguished by body material:

- brass for gas and water domestic systems;

- steel ones are the cheapest;

- made of stainless steel, practical;

- acid-resistant cast iron;

- polypropylene for plastic pipelines.

Ball valve with flange

Sources of danger

There are, in fact, only two of them.

The fact is that independent work related to opening the gas pipeline will inevitably lead to a gas leak.

- At a certain concentration of natural gas or propane-butane mixture in the air, it will become unbreathable.

- Long before this, the gas-air mixture will become explosive. The slightest spark when turning on an electrical appliance, triggering any relay (for example, a convector thermostat) or clicking a light switch will lead to exactly the consequences that we tried to warn the reader against in the first section of the article.

The rules that will help avoid negative consequences are quite obvious.

- All work is carried out with windows wide open throughout the entire apartment or house. Yes, yes, regardless of the time of year. Don’t be afraid that your favorite cactus will freeze: if everything goes well, forced ventilation will last no more than 10 minutes.

- The room must be completely de-energized. What the instructions relate to is, I think, clear from the previous explanation. Take it seriously: as already mentioned, the cost of a mistake can be the highest.

Selection of gas valves

If a malfunction is detected in the operation of the gas valve, it is recommended to replace the device as soon as possible. First of all, you need to select a new valve. When choosing, experts recommend considering:

- type of valve;

- basic device parameters.

Kinds

The gas pipe valve can be:

cork. The body of the plug valve contains a conical element driven by a flywheel. There is a hole in the conical element (plug), which, when combined with a hole in the pipe, allows gas to flow to the equipment. The seal acts as a sealing material that seals the connection between the faucet and the pipes;

Sectional view of a cork valve

spherical The design of a ball-type gas valve differs from a plug valve in that the locking mechanism is based on a ball made of durable metal. The ball has a hole, which, when the flywheel is turned, is located along the gas pipeline and in this way passes gas to the consumer.

Gas pipeline valve with ball locking mechanism

Experts recommend using ball valves for domestic gas pipelines, as they are more reliable.

According to the method of connection to pipes, a household ball valve can be:

threaded The valve is connected to the gas pipeline pipes with a threaded connection;

Valve installed with threaded connection

flanged. The connection to the pipes is made using flanges, which in turn are fixed with bolts;

Gas valve fixed with flanges

welded, that is, installed using a welding machine.

Gas valve installed by welding

Threaded and flanged valves are reusable, that is, if necessary, you can remove the device from the gas pipe, check its functionality, carry out repairs and install it in its original place. The welded valve can only be installed once.

Basic selection parameters

To select a gas shut-off valve, it is recommended to pay attention to the following factors:

- pipeline diameter. The shut-off element of the valve must completely block the pipe in the apartment. If the valve is larger or smaller, the tightness of the tap will not be complete;

- pitch and diameter of the thread on the pipeline. To quickly replace the device, it is necessary that the specified parameters completely match. Otherwise, you will need to purchase and install additional adapters;

- the material from which the gas pipeline valve is made. It is more advisable to purchase brass taps, as they have a longer service life. You can also find silumin, zinc and plastic taps on sale. You can distinguish the material used to make the valve by weight. Brass faucets are heavier than faucets made from other materials. In addition, you can inspect the place where the thread is cut. Brass has a yellow tint, and all other materials (except plastic) are gray;

Gas valve made of nickel plated brass

- The valve body must be free of chips, sagging, cracks and other defects. The presence of these factors indicates non-compliance with the rules for manufacturing the product, which will lead to a reduction in service life;

- It is more advisable to purchase valves from well-known manufacturers. For example, you can choose cranes manufactured by Bugatti (Italy), Dungs (Germany), Broen Ballomax (Poland).

Following simple rules when choosing a gas valve will allow you to choose a reliable device with a long service life.

Cleaning the Solenoid Valve Thermocouple

What to do if the electric ignition does not work? It consists of a thermocouple and a valve device located in the plate. The thermocouple, in turn, consists of an iron visible part and a cap in which the electromagnetic coil is located. It starts working when it warms up. The thermocouple is located next to the burner. This malfunction is usually relevant for gas stoves. You may have encountered a problem where, when you pressed a button, the gas ignited, but as soon as you removed your finger, it went out. You need to clean the thermocouple. When the burner heats up, a current appears, which is restrained by the valve. It prevents the flow of gas from stopping. If the gas dies out, the thermocouple cools, causing the valve to close. Take sanding material and sand the thermocouple. This usually helps. If this solution does not help, you should replace it with a new one. If this method of solving the problem turns out to be ineffective, then you will have to contact specialists to fix this problem.