A classic fireplace perfectly warms a room, but cannot heat the entire house for a long time, because its heat capacity is small.

Fireplace stove with water circuit - diagram

Only a modified fireplace stove with a water circuit, with connected radiators in all rooms of the house, can cope with this task.

The area that such a circuit can heat depends on the thermal power of the fireplace, the number of radiators installed and the total volume of water in the system. We will tell you in this article how to choose and install a fireplace stove with a water circuit, read carefully and follow absolutely all the requirements!

Fireplace design

The fireplace to which the water circuit is connected has a number of features in its design. Since it must heat water, a metal heat exchanger is placed inside. Water circulates inside it, its temperature rises under the influence of fuel combustion. The heat exchanger is made in the form of a coil or labyrinth.

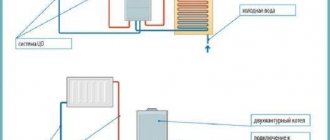

Installation with an accumulator makes it possible to select coolant as needed. In addition, this allows you to connect the system to the water supply for organizing hot water supply.

Installing a tank inside a fireplace will cause an unjustified increase in the dimensions of the fireplace. Typically, the battery is installed directly at the outlet of the pipelines from the heat exchanger. The tank itself is located next to the fireplace. To prevent the metal of the heat exchanger from being destroyed by an open flame, it is placed between two walls of the fireplace. Another option is to immerse the coil in the fireplace cavity, which is filled with water. This design is called a water jacket. It is suitable for installing a heating system for small cottages.

Finished metal devices

A fireplace stove with water heating, consisting of a metal base, occupies a leading place in the rating due to its versatility and ease of installation. As a rule, they do not require a mandatory foundation. As is known, several types of metal circuits can be used for heating. For example, if ordinary sheet fireplaces can be installed directly on the floor, without additional reinforcements, then cast iron fireplaces are heavier and require a foundation.

By the way, even despite such an important factor as the base, cast iron fireplaces are more durable in this regard. After all, their susceptibility to corrosion is extremely low. However, they are relatively fragile if a large temperature change occurs. For example, if you “throw” a cup of cold water into a boiler, the likelihood that a crack will appear is huge. Also, do not forget that cast iron itself is not afraid of shocks; it is fragile. In addition, do not forget that the difference in the configurations of metal devices also lies in the fact that they may differ in the location of the installation of the water “jacket”.

Model range of similar fireplaces and their average prices

- The Kratki Antek PW 8 kW fireplace insert is made of cast iron, fired by wood and costs $800.

- The German firebox Lina FD 6757 produces a thermal power of 9 kW, is made of steel, weighs 220 kg and will cost the consumer $5,300.

- The Russian Elba 600 stove from the manufacturer Meta produces a power of 10 kW, weighs 82 kg and will cost the buyer $280.

- For a French stove Supra Classigues 148C made of cast iron with a power of 13 kW, made in a classic style, you will have to pay $2,500.

- Alpha 700 from the Russian manufacturer Ecofireplace has a power of 15 kW, is made of steel and finished with fireclay, and costs $460.

- For a French Sequin Panoramic stove with a power of 17 kW you will have to pay 2800 US dollars.

- The 18-kilowatt Vega from Ecofireplace with a simple modern design, made of steel and fireclay, costs $2,300.

- The French-made Invicta 800 Chaudiere is made of cast iron and steel, has a power of 20 kW and costs $2,350.

- The Polish 30-kilowatt Kratki Amelia is made of cast iron, weighs 200 kg and costs $2,100.

Thus, it is clear that the cost of a furnace depends not only on its thermal power, but also on the country of manufacture, design, and the amount of metal used in the manufacture.

Advantages of fireplace stoves

First of all, it is worth comparing the main characteristics of traditional stoves and conventional fireplaces:

- Heating rate. The oven is quite large in size and after heating for a very long time it becomes a good heat accumulator, continuing to give off heat for several more hours. The fireplace heats up very quickly and heats the room in the shortest possible time, but after the fuel burns out, the heating effect disappears as quickly as it appears.

- Firebox type. The combustion chamber of the stoves is closed with a small blind door, which increases the efficiency of draft and significantly reduces the likelihood of smoke entering the room. Fireplaces use an open firebox, the area of which is usually almost half the area of the façade of the structure. An improperly designed or installed chimney can cause a backdraft that can fill the room with smoke.

- Chimney design. Furnaces use a rather complex configuration of smoke exhaust ducts, thanks to which most of the heat ultimately enters the room. Fireplaces are usually connected to almost straight chimneys, which are practically incapable of retaining heat within the building.

- Efficiency The heat output of heating stoves usually ranges from 60 to 80%, while the efficiency of fireplaces rarely exceeds 50%.

- Decorative properties. A traditional stove is a purely utilitarian design, and it is very difficult to integrate it into the interior (the situation is partly saved by good finishing). A fireplace, even the simplest one, by the mere fact of its presence makes the design of the room more sophisticated.

Modern solid fuel boilers and fireplaces with a water circuit combine all the positive qualities of their predecessors, resulting in the following list of advantages:

- Efficiency from 80% (connected with your own hands to a water heating circuit, a fireplace can produce an efficiency of up to 92%);

- The firebox closes hermetically, and the door itself is made of transparent heat-resistant glass, which allows you to look at the live fire;

- The design of the chimney is designed so that the heat transfer of the device is maximum;

- Excellent visual characteristics and a variety of models, allowing you to harmoniously integrate the fireplace-boiler into any interior;

- Relatively light weight - wood-burning fireplaces for a home with a water circuit can be installed on a regular floor (even wood) without installing a separate foundation;

- Small dimensions, which make it possible to use such equipment even in rooms with limited space;

- The ability to combine a fireplace stove with a water heating circuit allows you to maintain a comfortable temperature throughout the house;

- The cost of ready-made fireplace stoves is relatively low when compared with the cost of installing a brick stove or fireplace;

- Simple installation - if you wish, you can install a fireplace stove with a water heating circuit even with your own hands.

Choosing a fireplace stove - what to look for

When a room is not heated well enough, dampness and mold appear, which negatively affect interior items and also cause damage to metal products. To avoid such problems, it is necessary to carefully study the features of this type of equipment at the selection stage. There are many differences between them in terms of:

- power class (wood, electricity, gas);

- method of location (to the wall, in the corner, built-in, separate);

- functionality (classic, fireplace, barbecue);

- firebox (open or closed);

- chamber material (cast iron, steel, inset).

When selecting a heating device, the owner must decide:

- with type of fuel;

- how many rooms will the unit be needed and where will it be located;

- what the chimney should look like and where to install it.

Power

As a rule, the larger the structure, the more it needs more radiators. The fundamental difference between a standard stove or fireplace is that the manufacturer indicates two values: the total thermal power and the heating device itself.

For an average three-room house with parameters of 80 m2, it will be reasonable to install a 6 kW device. Another way to calculate the approximate power: a 10 m2 room with a ceiling height of up to 2.6 m needs 1 kilowatt-hour to heat.

Using the same scenario, you can determine how much fuel is consumed on average. To do this, the following data is taken: 1 kg of hardwood logs with a moisture content of no higher than 20% supplies approximately 3.5 kilowatts of heat.

Material: steel or cast iron

Steel products are lighter, so they can be easily installed directly on the floor. They are not afraid of sudden changes in internal temperatures; the devices tolerate mechanical stress well.

However, they have a significant problem with the thickness of the walls: due to the thinness, there is a risk of corrosion occurring in a short time. After the fire and coals have gone out, the stove cools down quickly.

Cast iron devices have thick partitions and heavy weight, so when purchasing certain models you will have to prepare a foundation. This option is only possible if there is no concrete floor on the first floor. But cast iron is not at all prone to corrosion and provides heat for a long time after being turned off.

The negative aspects include the poor resistance of the material to sudden temperature changes. If this happens, the product may burst. Also, the heating device is quite fragile and cannot withstand strong shocks, which complicates its transportation and further operation.

How are fireplaces with air ducts constructed?

An air-heated fireplace is simpler compared to similar equipment that has a water circuit. That is why it is much easier to make the first option in artisanal conditions than to make a fireplace with water heating with your own hands. This explains the popularity of the air circuit in private homes. This wiring is an excellent alternative way to heat a room when the main one (gas or electric boiler) has stopped functioning for some reason.

Air heating method.

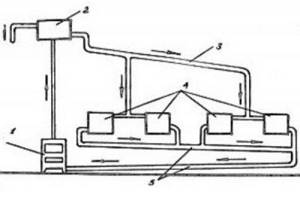

Fireplaces for air heating of a house are similar in structure to their counterparts that have a water circuit. Of interest is the process of removing combustion products from the system.

Chamber I. It is located under a metal convector. It is equipped with a fan that supplies hot air. The latter comes from the combustion zone. Chamber I is equipped with a number of pipes. They are mounted to the side walls of the fireplace chimney. These tubes end in valves. Such a device is necessary if the electricity is turned off and the supply ventilation stops working.

Camera II. Through it, cold air is drawn in through the side fan grilles of the outer shell of the fireplace. Cold air is warmed by the metal body of the heating element and pipes through which combustion products are removed. The chimney can heat up to 700°C. It is here that the final combustion of the gas formed as a result of fuel combustion and solid particles occurs.

In order to significantly increase the heat exchange between the chimney and the cold air entering chamber II, the surface of the first is increased by means of ribbed hoops. The chimney is also equipped with a damper. With its help, you can mechanically regulate the draft in the fireplace, and therefore the intensity of combustion. From chamber II, warm air is either evenly distributed in the space near the fireplace through special openings, or enters air ducts that diverge from the heating element throughout the house.

Chamber III. Decompression chamber. It is necessary to ensure that heating with a fireplace with an air duct is safe. It plays the role of an insulating space between the ceiling of the house and the hot smoke exhaust chamber.

Air-heated fireplace surround.

How does a fireplace work? The operating principle of a fireplace with air ducts is based on the correct supply of fresh air from outside and the timely removal of combustion products.

Air supply to the fireplace can be done in two ways:

- directly from the living space;

- using an air duct from outside the house.

The first method is easy to install. To do this, it is necessary to correctly calculate the area of the room where the fireplace is installed, according to the power of its combustion chamber. So, to burn 1 kg of wood, 8 cubic meters of air are needed. Based on this, it is easy to calculate that a heating element with an average power should be installed in a room with a cubic capacity of at least 30 cubic meters. Otherwise, unfavorable conditions for human life and even an emergency situation are created in the house.

The advantage of the second method is that there is no dependence between the power of the equipment and the cubic capacity of the room where it is installed. In this case, combustion air is taken from the street. To do this, round or rectangular air ducts made of galvanized steel or PVC material are laid under the floor in the house to the fireplace. There should be a grill at the end of the pipe facing the street. It protects the air duct from rodents and insects. Filters are also important in this case. They are designed to clean the supplied air from dust. They are mounted in the valve directly in front of the fireplace.

Pros and cons of water stoves-fireplaces

Fireplace inserts and stoves with a liquid heat exchanger have a number of advantages:

- independence from electricity and gas - firewood is used for stowage;

- compact dimensions, suitable for any area of the room;

- Can be used for heating and cooking;

- maintaining a comfortable temperature in a large house;

- uniform distribution and supply of heat to distant rooms;

- high efficiency with minimal fuel costs;

- operation of stoves with a circuit and a tank for hot water supply;

- safety - the outer parts of the housing with lining do not heat up;

- connection to a radiator heating system.

A stove fireplace with a water system has several disadvantages:

- minimal automation of brick and metal models;

- time spent on laying the firebox and igniting the fire;

- formation of soot, soot and smoke when using firewood from coniferous trees, cherry, willow;

- rapid cooling of steel modifications;

- Not all units are suitable for burning coal.

You can heat the stove with logs made from hornbeam, aspen, birch, beech or special briquettes.

Advantages and operating features

Such fireplaces have many advantages: they are easily installed into an existing heating system, can heat large areas, are durable and easy to use, are fireproof and, when using an open system, do not require connecting power sources.

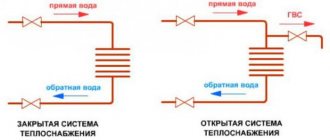

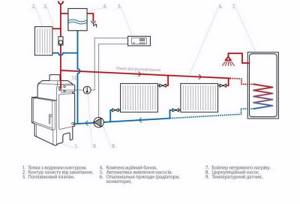

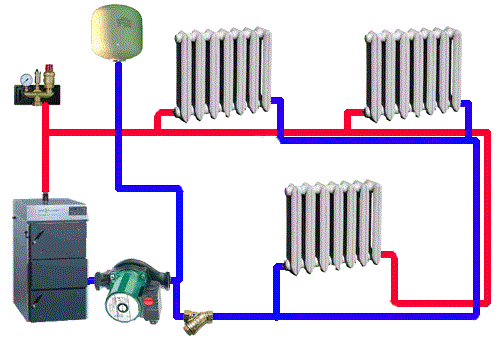

Fireplace stoves with a water circuit can be used to heat a building if used with one of two existing systems:

- an open system in which the coolant is not directly heated;

- a closed system with direct heating of the thermal fluid.

Depending on what system will be used in the house, it is necessary to choose a fireplace. This should be taken extremely seriously, since the wrong choice of fireplace can result in very sad consequences.

Open system

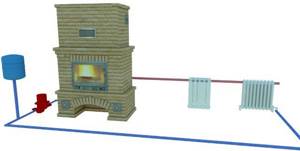

In an open system, the coolant, which can be antifreeze or water, moves in the coil. The coil is located in the open nozzle of the furnace boiler. An open expansion tank in such a system is installed as high as possible - most often it is mounted under the roof itself. The movement of the coolant in an open system is carried out according to the principle of natural circulation - ordinary gravity directs the coolant into the heat exchanger. The remaining heated coolant flows back into the expansion tank.

This heating system may be familiar to many residents of Russia - it was most often used in the Soviet Union for heating private houses and dachas, building a cast-iron radiator into an open fireplace. Such a heating system does not require additional equipment, but, alas, it is not suitable for large areas: when heated, water loses its specific gravity, and the pipes exhibit significant hydraulic resistance. For these reasons, closed-type systems have replaced this heating model. True, there is a way to somewhat mitigate the disadvantages of an open system - to use auxiliary plate heat exchangers that transfer heat from the fireplace coolant to the heating pipes.

Closed system

In case of equipment of a closed system, the thermal fluid will be heated in the most closed part of the boiler furnace. From the expansion tank (the tank must be a membrane type), the coolant moves to the heat exchanger located in the fireplace. Heating up to an average of 80 degrees, the coolant is supplied to the storage boiler, from where it moves into the heating pipes. In a closed-type system, water or antifreeze is no longer driven by gravitational forces, but by an ordinary circulation pump.

If there is no heat transfer for some reason, the coolant in the system may boil, causing the pump to stop working. The pressure in the water circuit of the fireplace will increase significantly, which can completely damage the entire system. To prevent such breakdowns, another coil is installed in the firebox, into which cold water can be supplied to reduce the temperature of the circulating coolant. A thermostat is installed in the water circuit itself, which will drain the coolant from the system into the sewer when it overheats.

When choosing fireplace stoves with a water circuit, primary attention should be paid to which heating system it will be used with, since the safety of the entire house and its occupants depends on this. Otherwise, such fireplaces are as safe as other types of heating equipment, but they differ in one important aspect - they bring real comfort to the house!

Water circuit connection

You can connect the fireplace to the existing heating system in the house. Pipes for water supply and drainage, as well as a chimney pipe, are connected to the fireplace. If it is necessary to heat the floor for a private house, additional pipes for water circulation are installed in the boiler.

When connecting the water circuit, the following important points must be observed:

When connecting the water circuit, the following important points must be observed:

- installation on a flat surface. If it is not possible to level the floor on which the fireplace will stand, you can use adjustable legs. Uneven installation entails operating hazards and a significant reduction in the efficiency of the fireplace;

- mandatory check for leaks after filling the system with water. First, you should check all pipe joints without applying pressure. Then, turning on the circulation pump, once again eliminate leaks and leaks in pipes and joints. It is also necessary to ensure the tightness of the chimney by covering the joints with heat-resistant sealant;

- checking the operation of the fireplace and water heating. Do not be alarmed by the smell from the fireplace when you first light it - it will disappear within a short time. It is necessary to check the correct operation of the automation: how accurate is the regulation of the water temperature in the radiators, is it possible to regulate the speed of its supply.

Tips for choosing a stove

Recommendation number one: to heat the coolant in the water heating network, use a solid fuel boiler. If necessary, buy a long-burning model with a loading chamber volume of more than 100 liters. Modern TT boilers direct 75-80% of combustion energy to heat water and hardly raise the ambient temperature.

If, for various reasons, you want to install a stove with a heat exchanger, listen to the following tips:

- A cast iron or steel potbelly stove is well suited for a small cottage with an area of 40-80 m². The heater is enough for convection heating of the central room; place radiators in adjacent rooms.

- A fireplace insert or iron stove, equipped with panoramic glass, will be a successful decoration in the living room. One condition: use the product as an additional heat source, and place the main load on a gas or wood heat generator. Then you will be able to maintain cleanliness and order around the potbelly stove.

- When building a house, definitely install a brick stove. This is the best option compared to iron heaters.

- Theoretically, the power of the fireplace insert is enough to heat an area of 100-120 m². Practice shows: without the help of a second heat generator, it will have to be loaded with firewood at intervals of 3-4 hours. Therefore, expect a smaller heating area.

How to select a design and calculate the heat exchanger area in a brick version of the furnace:

- If the register is located inside the firebox, 1 m² of its area can transfer up to 10 kW of heat to water. Example: you need to heat 80 square meters of space - you will need about 8 kW of energy and a heat exchange surface of 0.8 m².

- The coil in the chimney duct is not as effective. Expect a heat output of 400-500 W per 1 m² of register.

- For ease of cleaning, it is better to make the boiler flat - in the form of a tank with inlet pipes. Ribbed structures made from round pipelines are more difficult to clean. For installation inside the flue, weld the register from profile pipes.

- The heat exchanger material is low-carbon steel St10...St20 with a thickness of 4-5 mm. It is allowed to use heat-resistant and stainless steel 2-4 mm, but it must be cooked in an inert gas environment - argon.

- It is strictly not recommended to use ready-made cast iron batteries. Reasons: the metal cracks from temperature shock, and the seal between the sections will burn out over time and leak.

Home craftsmen are constantly putting forward various ideas for improving heaters. The option with steel flat batteries used as furnace water heaters is worthy of attention. Watch the video for an overview of the wizard:

Construction of fireplaces with a water circuit

All work can be divided into two stages:

- Construction of the body of the heat source, that is, the fireplace itself;

- Installation of heat exchanger.

Construction of the fireplace body

The construction of the fireplace body should begin with the search for a formal masonry scheme. When choosing materials, give preference to those that allow you to build a fireplace with a water jacket. To ensure tightness, steel sheets are usually used.

The construction of a fireplace begins with the installation of the foundation. To fill it you will need:

- Boards for installation of formwork;

- Ruberoid;

- Crushed stone;

- Sand;

- Cement.

The size of the base should be slightly larger than the dimensions of the future fireplace. To ensure waterproofing of the finished foundation, roofing material is laid on it. After this you can start laying. Fire-resistant bricks are used for the construction of the building; the firebox is assembled from a heat-resistant fireclay grade. A special clay mixture is used as a solution. It is not recommended to make it yourself. Experts use ready-made dosage formulations.

The masonry should be assembled from horizontal main rows

At this stage, it is important to ensure accurate positioning in the horizontal plane. After this, the ash pan is assembled, then the craftsmen lay out the fireplace insert

The final part of the installation differs significantly from the construction of a classic fireplace. At this stage, installation of the heat exchanger is required.

Heat exchanger organization

The simplest type of heat exchanger is a small tank with two flanges for connecting pipes. Cold water enters through the first pipe, heated water is discharged through the second. Due to the harmful effects of open flames, temperature changes, and the negative effects of combustion products, it will not last long. The material for the heat exchanger must be sheet steel with a thickness of at least 4 mm.

The exact dimensions of the tank are determined by the design of the fireplace. To increase efficiency, it is recommended to use coil-type heat exchangers. Such designs consist of sections and registers, assembled in the form of a labyrinth.

After the heat exchanger is manufactured, it is built into the body of the fireplace. After this, special stands are formed on which the tank will rest. Installation is carried out in such a way that the heat exchanger flows are outside the fireplace. This allows for repairs in the event of a breakdown.

After installing the heat exchanger, the assembly of the fireplace fuel chamber is completed. It is covered with masonry with the obligatory organization of a smoke hole. Finally, a chimney is erected.

After the masonry has completely dried, which will take at least 10 days, the system can be filled with water for the first time. During initial start-up, it is necessary to check for leaks. In an open system, leaks lead to a decrease in the volume of water, but in a closed system they will cause a lack of circulation.

If the fireplace will be used as a backup heat source, a system must be provided for turning on and off the circuits from it. Using a bypass valve allows you to stop the water supply.

How to build with your own hands?

There are quite a lot of offers on the modern market of such equipment. The cost of a unit with a capacity of 14 kW for heating housing with an area of no more than 140 sq.m. starts from 23,000 rubles. A device with a higher power of 26 kW for heating a home of 200 sq.m. and more starts at 230,000 rubles. To save money, you can make a fireplace with water heating yourself.

You can make the stove body yourself from natural stone or brick, and if you have welding skills, you can weld such a fireplace from metal sheets yourself. In any case, before starting work on arranging a fireplace stove, it is necessary to study the standard design of this unit, as well as the basics of stone or brick laying.

After this, you can begin building a fireplace with a water circuit:

- First you need to lay a solid foundation, reinforced with a reinforcing belt. In this case, this foundation should not be in contact with the general foundation of the house, and its width should exceed the width of the base by approximately 10-12 cm.

- Then you need to arrange the formwork into which to pour the concrete. Concrete is poured 7-10 cm below floor level.

- After the concrete has hardened, you can begin laying the furnace using a solution of sand, clay and water. When constructing the first two rows, cement is also added to the solution.

- Before standing the top of the fireplace, you need to place a heat exchanger inside the structure and connect it to the water heating system.

- After this, the top and smoke exhaust system are constructed. When installing a chimney, you should use bricks with an exceptionally smooth side.

So, making a fireplace stove yourself is quite possible, but this process requires strict adherence to all technological rules and regulations, as well as effort and time. Any error or inaccuracy during construction can affect the efficiency of the heating device.

Distinctive features

Photo of a fireplace with a water heating circuit

What do you need to know about a fireplace with a water circuit? Let's consider all the main nuances.

- The design of a classic fireplace can use an open or closed firebox. Open fireboxes have little heat transfer, so using them as the main equipment for heating the entire house is irrational. The power is enough to heat one small room at most.

- Fireplaces with closed fireboxes, which include thermal fireplaces, are characterized by increased efficiency and high efficiency.

- The difference between a fireplace with a water circuit and a traditional fireplace with a closed firebox is the presence of double metal walls. Inside them there is a coil heat exchanger.

- The heat exchanger is connected to a water jacket - a water heating system. Due to this design, the fireplace can simply heat and decorate one room, or act as heating equipment for the entire house.

- An additional feature of a thermal fireplace is heating water for hot water supply at home.

- You can use traditional firewood to operate the thermal fireplace. Although, to increase efficiency and heat transfer, it is recommended to burn with special briquettes based on sawdust. They give off heat well, leaving a minimum of ash.

WATER CIRCUIT

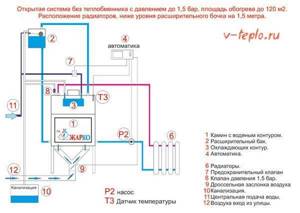

Actively used Zharko thermal fireplace systems allow you to provide your home with heat and hot water with your own hands. Zharko water circuits have approximately the same design compared to their analogues. Therefore, the design principle of a thermal fireplace with water heating is identical.

- The body of the fireplace itself is made of cast iron or boiler steel. If it is cast iron, then the wall thickness should be up to 8 millimeters, and 4-5 millimeters of boiler steel will be enough;

- The outer walls of the thermal fireplace are coated with special fireproof paints. This allows you to maintain the original appearance of the fireplace for a long service life;

- Between the two walls of the fireplace there is a water circuit - a jacket. Typically the system can hold about 40 liters of water;

- The inside of the firebox is lined with fireproof tiles;

- Air channels are located between the walls of the firebox. They allow the required amount of air to be supplied to the firebox to ensure the combustion process;

- An irreplaceable element of a thermal fireplace is a heat exchanger, also located between the walls of the firebox;

- When air is heated in air ducts, it spreads throughout the premises through special channels;

- The water heated by the heat exchanger coil is sent to the heating system;

- If the homeowner requires it, in addition to the heating system, water from the heat exchanger can be used for hot water supply.

Main stages of construction

The fireplace stove that heats the rooms is made from the most durable materials. Brick or steel with a thickness of 3 mm or more can be used as such material. The first stage of construction is work on preparing a working drawing. To do this, you need to select the location for the future installation of the fireplace and take the necessary measurements. Next, you need to calculate the main dimensions of the structure, and then transfer them to the graphic part.

When the drawing is ready, you can begin to make markings according to which the foundation will be created. First, the floor is partially dismantled, a pit is dug in the shape of a rectangle, its depth should not exceed 0.5 m. The bottom of the resulting hole is filled with brick crumbs or crushed stone. Next, a layer of cement is poured, and the horizontalness of the poured layer is carefully checked using a level. The cement must dry completely. On a completely dried layer of poured cement, it is necessary to lay 2-3 layers of roofing material, which acts as a waterproofing agent, which helps to completely eliminate the influence of moisture.

Specifications

European manufacturers of fireboxes with a water circuit manufacture them according to the German DIN+ standard. In Russia, it is necessary to take into account not only these standards, which determine the technical characteristics of stoves, but also heating standards. It is better to understand the features of fireplace production and their capabilities using the example of Spartherm Varia 1V H2OXL. The dimensions of the stove are exactly the same as they would be if it did not have a heat exchanger: width - 75 cm, height - 123 cm, depth - 55 cm.

To calculate the compliance of the technical characteristics of the stove with heating needs, a house with a total area of 160 square meters was selected as an example. meters. According to Russian heating standards, at a temperature outside the window of -27 degrees Celsius, spend 1 square meter on heating. meters you need no more than 50 W every hour. The rated power of this firebox is 14 kW, of which 10 kW is provided by the heat exchanger, 4 kW by thermal radiation. There are two glasses in the firebox door: the inner one has a film that reflects heat, so as not to overheat the building and not burn the skin when touched; the outer one is decorative.

The calculation period is 5 days, during which the stove will heat the house all day. In 12 hours, the fireplace produces 14 kW hourly, of which 8 kW is spent on the heating needs of the house (radiators, etc.). 1 kW is spent on heating water for domestic use. The boiler accumulates the remaining 5 kW every hour. On average, throughout the day it can accumulate about 60 kW, which will be used to heat the house at night. To accumulate such an amount of heat, the storage boiler must have a volume of at least 700 liters.

How it works - video guide

Where is it used?

Water fireplaces have become an alternative heating source to other systems in country houses, dachas, and cottages. It is advisable to install it in those monasteries where people rarely live or where gas cannot be supplied or there is no possibility of installing electric heating devices. However, this is not the only reason for its installation.

You can make a fireplace-stove with a water circuit with your own hands to refine and decorate the interior, and then enjoy a live fire on cold evenings, and as an alternative source of heat supply.

Compact dimensions are another advantage of this design. The thick walls warm up well when the stove is burning, and after it goes out, they retain heat for a long time.

Boiler for heating water

As a rule, the above heating method is not enough. And this is not surprising. To obtain the best performance in practice, specialized Russian-made stoves and fireplaces are used. Such stoves are notable for the fact that heating occurs directly below. That is, when the heating source is located below, you can take advantage of the advantageous location and install a hot water boiler on top in the firebox of the stove.

Practice shows that the advantages of using this heating method appear almost instantly. Even if it is thirty degrees below zero in the yard, the room will be warmed up only due to the fact that you will have to heat the stove twice. The process of heating the room using heating and cooking stoves occurs during a pause between fireboxes. At this time, the radiators cool down, giving off heat for several hours in a row. The use of this method is also beneficial due to increased efficiency. Its level is 80-85 percent. Improved results are achieved due to the fact that heat is better removed from the water furnace, the boiler design has been modernized, and the working surface area has been expanded. (See also: Fireplace heating at home)

The flue gases that pass through the chimney have a high temperature as they are heated in the firebox. When passing through the chimney, gases strongly touch the surfaces of the chimney pipe. The process occurs in such a way that the inner walls of the lower heating chamber are not influenced, warming up with the same intensity. The walls that are in contact with the chamber accumulate heat. When there is a break between the two fireboxes (it lasts 6-8 hours, depending on the heating), the walls give off heat to the water boiler, maintaining its constant temperature.

This type of heating can be used to heat small rooms, just as in the case of kratki biofireplaces. The optimal level of comfort is achieved through a double firebox. Only then will furnace heating with a water circuit significantly save the fuel needed for work. Compared to a conventional stove, this stove can save up to 50 percent of fuel. Even heating with factory-made boilers with a water circuit is not as efficient as the above scheme.

Fireplace installation

In order for the stove to start heating the room, you need to connect it to the heating system. For this, special tools and materials are used:

- Stand for installing a fireplace.

- Expansion tank.

- Copper pipe to attach the structure.

- Controller to control the heating process.

- Thermal protection is a sensor that protects the stove from boiling. That is, when the water temperature reaches 90˚C, the water is transferred to the circuit.

- Anti-explosion valve. In other words, this protects the furnace from excessive pressure increases.

- Connecting elements: valves with couplings, sanitary technical connections that are used during installation.

- Heat exchanger , if the connection form is open.

Types of fireplaces with a water jacket

Today, water fireplaces come in various designs. Depending on the type, devices are divided into brick, metal and combined.

Brick

Brick fireplaces are the most popular. They will fit perfectly into any interior and are easy to use and maintain. There are some nuances that need to be taken into account when installing such devices. During the masonry process, the heat exchanger is first installed, and then connected to the water circuit.

Compared to cast iron fireplaces, brick ones are not as expensive, and they look more aesthetically pleasing in modern homes. In addition, metal devices must be installed subject to certain rules, while masonry fireplaces can be installed anywhere.

Metal

Metal or cast iron fireplaces are difficult to make with your own hands, and the cost of ready-made structures is not affordable for everyone. They are capable of heating the room not only by spreading the coolant, but also by heating the surface of the housing. However, when installing such fireplaces in living rooms, you must follow certain safety rules. Therefore, if the fireplace should serve as a decoration, and not just a heating element, then it is better to give preference to brick or combined options. In addition, heavy cast iron installations require laying a foundation, and this is an extra cost. The advantages of such fireplaces are their durability.

Metal fireplace with water jacket

Combined

A combined water fireplace is made of a metal firebox, which is closed by a door made of fireproof material. The top of the heating device is lined with bricks. Such stoves are most often used in country and country houses.

The combined fireplace looks very attractive and copes well with its main task - heating. It will significantly reduce heating costs and improve comfortable living in the house.

Where is this type of fireplace stove used?

This unit has become an alternative to other heating systems for country and country houses and apartments. It is also convenient for installation in a house where people do not live permanently or where electricity or gas cannot be used for heating. But this is not the only reason to install a fireplace stove in your home: the unit is a compact piece of equipment with attractive decorative properties.

In the evening you can sit in a chair and watch the live fire play. At the same time, it is protected by the transparent glass of a closed firebox and is both a decoration of the room and a coolant heater for the heating system. All the functions of a cozy, beautiful home are combined in one building. Compact dimensions are another advantage of this heating equipment. At the same time, it has thick body walls that warm up well and retain the heat of an already extinguished firebox.

Water heating

Fireplaces work effectively in water and air heating systems. Fireplaces with steam heating are theoretically possible, but practically difficult to implement. Since it requires heating water to + 95 degrees in a short period of time in a volume of at least 100 liters.

Open view

As already noted, fireplaces with water heating function quite successfully. The design features benefited them: they did not lose any aesthetic value, increased efficiency and increased usefulness.

Since the water heating system is operated in two types - open and closed; from a safety point of view, the first is preferable for fireplaces. An open system involves gravity circulation of the coolant and the presence of an open expansion tank. In the event of a critical expansion of the volume of water (antifreeze), it will be drained into the sewer (sump).

For normal operation, the installation of the fireplace heating system must comply with certain requirements:

- connecting an open type expansion tank above the fireplace;

- correct slope of the distribution pipes - supply towards the radiators, return towards the fireplace;

- The fireplace heat exchanger should be located below the center of the radiators.

Although forced circulation can be organized in an open system, then it will become energy dependent.

Closed view

Closed water fireplace heating systems do not have such conventions. They circulate the coolant forcibly using a pump, and the expansion is compensated by a membrane-type tank. On the other hand, a closed system requires additional safety measures - installation of thermal protection and a safety (explosive) valve.

An important point is the possibility of combining open and closed systems, when the fireplace acts as an additional heating source. Then a plate heat exchanger is used for connection, in which heat transfer occurs between the fireplace circuit and the heating system circuit.

Fireplace connection diagrams

- Open. In this case, there must be a special expansion vessel, which must be located above the furnace and work as communicating containers. Then the water that is heated in the furnace is transferred from the heating system, passing through a heat exchanger.

- Closed. The hearth is connected immediately to the heating system, without passing through the expansion tank and heat exchanger.

The scheme is selected depending on certain situations. Experts believe that the open form of the system has increased security, but it is not always possible to connect it technically.

Autonomous fireplace heating scheme