Panel steel heating radiators KERMI ThermX2

Made according to all European standards, they have a wavy profile surface and are notable for their low price. They are only suitable for closed heating systems. The small volume of hot water coupled with high heat output makes these devices most suitable for autonomous heating. Moreover, it is better to use them in systems where the coolant is not excessively hot.

These radiators are made using the latest patented X2 technology, which significantly increases the efficiency of heating devices. By doubling the radiation of the infrared spectrum, this technology made radiators very comfortable. Heating time has accelerated by about a quarter, and savings have increased by 11%. The meaning of the X2 principle is that the front panel heats up first, and only after that the back panel. For more information about this, see the video below.

Video. Technical features of Kermi steel panel radiators

After joining the panels into a body, the finished product is first thoroughly degreased, then it is phosphated. The final finishing is done using electrostatic painting. The top layer of paint is processed at a temperature of 180 degrees. This makes it durable. The shiny coating gives the batteries an elegant look.

The radiator has screen grilles on the top and sides. They can achieve a significant increase in heat transfer efficiency - by 60%. The set includes 4 pads designed for attaching equipment.

There are 2 lines of Kermi panel radiators, which differ in the location of connection to the heating network. Radiators from the Kermi ThermX2 Profil-K (FKO) line are connected to the side. And devices such as Kermi ThermX2 Profil-V (FKV or FTV) are designed for connection from below.

Side-connected Kermi ThermX2 Profil-K

These radiators are equipped with convectors, and their panels are made of two profiled steel sheets connected by welding. There are screens on the sides, and an overhead grill-type grill on top. Radiators with a side connection type are marked with the letter combination FKO. To connect to the system on the sides, the Kermi Profil-K FKO device has four pipes with internal threads (1/2″ diameter). The radiator can be connected to the pipes from any side.

Technical characteristics of heating radiators Kermi ThermX2 FKO:

- Connecting thread: 4 x G1/2” (internal)

- Height: 300, 400, 500, 600, 900

- Center distance: total height minus 50 mm

- Length: from 400mm to 3000mm

- Depth: type 10 and 11 - 61mm, type 12 - 64mm, type 22 - 100mm, type 33 - 155mm

- Working pressure – 10 atm. (1.0 MPa)

- Crimping pressure – 13 atm. (1.3 MPa)

- Max. coolant temperature: 110°C

- Operating temperature – 95°

Bottom-connected Kermi ThermX2 Profil-V

All of these radiators have a thermal valve built into the design. Its thread is right-handed, with a pitch of M30x1.5. The temperature controller is not included in the package; it must be purchased separately. The thread of the pipe is external, its diameter is 3/4″. The center-to-center distance is 5 cm. This design is intended for two-pipe heating systems. If you need to connect to a single-pipe system, then purchase special fittings.

Technical characteristics of Kermi ThermX2 FKV:

- Connecting thread: 2 x G3/4” (external),

- Radiator heights: 300, 400, 500, 600, 900

- Radiator length: from 400mm to 3000mm

- Distance between supply pipes: 50mm

- Radiator depth: type 10 and 11 - 61mm, type 12 - 64mm, type 22 - 100mm, type 33 - 155mm

- Working pressure – 10 atm. (1.0 MPa)

- Crimping pressure – 13 atm. (1.3 MPa)

- Maximum coolant temperature: 110°C

- Operating temperature – 95° C

In addition to connection methods, panel radiators also differ in type. In total, Kermi produces 5 types of steel panel radiators:

Type 10 is single-row, has a depth of 6.1 cm. There is no cladding or convector. Manufactured by pre-order only.

Type 11 - single-row, lined, depth - 6.1 cm. There is one convector.

Type 21 – double-row, lined, with a depth of 6.4 cm. One convector.

Type 22 – double-row, lined. Two convectors.

Type 33 – three-row, lined. Three convectors.

The most popular and frequently used is type 22.

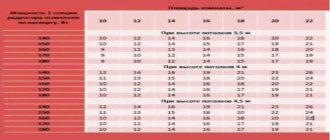

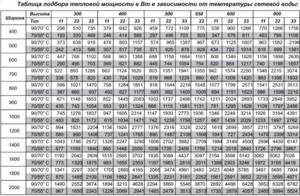

Kermi radiator power table

Standard thermal power of Kermi radiators

Dependence of power on the type of radiator

As can be seen from the table, the “spread” in power depending on the type of radiator, with equal height and length, is very significant. This is explained quite simply, the digital designation of the type means the number of panels and fins between them.

- Type 10 – one panel.

- Type 11 - one panel with one fin plate.

- Type 21 - two panels with one fin plate between them.

- Type 22 - two panels with two fin plates between them.

- Type 33 – three panels with three fin plates.

This is how a “small” type 33 radiator can have the same power as a large type 11 radiator.

Calculation table for Kermi radiators

This table allows you to select Kermi radiators by power depending on the type of heating system. Why do the table show exactly the specified heating circuit temperatures?

- 105/75°C – high-temperature heating system; this temperature ratio in the supply and return circuits is typical for centralized heating systems (from combined heat and power plants and boiler houses).

- 90/70°C – the temperature regime is typical for houses with centralized heat supply from small boiler houses.

- 75/65°C - actually duplicates the first table, the most popular mode for modern heating systems, most often this is individual heating based on gas and solid fuel boilers.

- 55/45°C - this temperature ratio in the supply and return circuits is typical for low-temperature heating systems based on condensing gas boilers and heat pumps. These are the most energy efficient heating systems available today.

Using these tables, you can calculate Kermi radiators, which will guarantee that their heat output matches your needs.

Steel tubular design radiators Kermi

In addition to panel radiators, Kermi also produces tubular steel radiators of various sizes and designs.

Such devices not only effectively heat the room, but also serve as an excellent decoration. German design radiators are able to satisfy the most demanding customer. In our country they are used mainly for heating bathrooms, replacing simple heated towel rails with them.

The beautifully intertwined steel pipes running in horizontal and vertical directions are a sight to behold. With all this, they are also very durable - after all, laser welding is used to connect the pipes to each other. There are two types of these heaters:

- Water-type radiators have a working pressure of up to 10 atmospheres, and pressure testing - up to 13 atmospheres. Thermal power varies from 0.01 to 2 kilowatts. The most productive models can provide heating for a room up to 20 m2.

- Electric radiators are convenient because to connect them you do not need to radically change anything in the heating system. There will be no unnecessary fuss with the pipes, nor with the installation and connection to the hot water supply. And in the summer, when the warm water will probably be turned off, such an electric radiator can help out. Now let's look at their main models.

Radiators have 5 connection types:

To obtain different thermal power of Kermi radiators , panels and fins are combined in several options, and have different power (heat transfer). To choose the right size and power you need to know what each of them is. According to their structure, Kermi steel panel batteries are of the following types:

- Type 10 - This type has only one coolant panel. These are the lowest-power and lightest models without cladding, single-row radiators with a mounting depth of 61 mm ;

- Type 11 - Single-panel with convective fins, with cladding, with installation depth - 61 mm ;

- Type 12 - Two panels and between them one plate with corrugated metal, cladding, fast flow, installation depth - 64 mm;

- Type 22 - Perhaps the most popular type of Kermi radiators, two-panel, with two fin plates, with lining, installation depth - 100 mm ;

- Type 33 - Three-panel. The most powerful class, but also the largest. It has three panels, to which three fin plates are connected, have a fast flow, with lining and have an installation depth of 155 mm .

Design Features

Any panel radiator consists of steel plates connected in pairs. The plates are stamped with channels through which the coolant moves. There are two horizontal channels - one at the top, the other at the bottom, and a large number of vertical ones. The plates connected in pairs are assembled into radiators one, two or three pieces at a time. To increase heat transfer, convective fins—corrugated steel sheets of small thickness—can be welded to them. They are located behind the front panel and do not spoil the appearance, but are covered with lids on the sides and top.

This is a variant of the heating panel with a corrugated front panel

Kermi batteries are made the same way. The order in which the coolant is supplied differs. It's parallel for everyone. This means that the liquid at the same temperature is supplied to all panels in the radiator. This feeding method works very well at high network temperatures. But as soon as the temperature decreases (warming, for example), the radiators become almost cold.

In Kermi panel radiators, the coolant supply is sequential and this technology is called Therm-X2. This means that the hottest flow is supplied to the first panel, and then to the second and third. Thus, the heated part is the part that faces the room. And the second and third are increasingly colder. In this case, most of the heat goes into the room, and non-production costs for heating the wall behind the radiator become much lower. Therefore, at the same coolant temperature and the same size, Kermi batteries heat the room 25% faster.

The new Therm-X2 technology makes it possible to warm up the room well even in low-temperature operating modes. This feature makes it possible to use Kermi flat panel radiators not only with traditional heat sources. They work very effectively with low-potential sources: with heat pumps of any type, solar panels and collectors.

Some people may find a smooth front surface more attractive.

Another new feature has been used in these radiators. The company installs balanced control valves. Balancing parameters were determined as a result of research. All bottom-connected steel radiators are supplied from the factory with balanced and adjusted thermostats (the thermal head must be purchased separately). By installing such a heating device, you get a stable temperature in the room: the amount of coolant required to maintain the temperature is supplied to the collector. You need to change the setting if you are not satisfied with the selected mode. Using a thermostat is not only comfort, for individual systems it is also an opportunity to save money: only the required amount of fuel is spent on heating.

There are some other features in connecting Kermi radiators. There are options for side and bottom pipe supply. Moreover, the bottom one can be not only right or left, but can also be located in the center. This allows you to make the wiring without being tied to the presence of heating devices. They can generally be installed after finishing the finishing work (you just need to first secure the brackets to the wall).

Selecting a radiator based on calculation

Steel radiators

Let's leave out the comparison of different types of heating radiators and note only the nuances that you need to have an idea about when choosing a radiator for your heating system.

In the case of calculating the power of steel heating radiators, everything is simple. There is the necessary power for an already known room - 2025 watts. In this case, look at the table and look for steel batteries that produce the required number of watts. Such tables are easy to find on the websites of manufacturers and sellers of similar products.

Here is an example of such a table:

The table indicates the type of radiator; in this example, we will take type 22, as one of the most popular and quite worthy in terms of its consumer qualities. And a 600x1400 radiator suits us perfectly. The power of the heating radiator will be 2015 W. But it’s better to take a little more than a little less power

Aluminum and bimetallic radiators

In this case, there is one important difference in calculating the power of radiators. Aluminum and bimetallic radiators are often sold in sections

And the capacity in tables and catalogs is indicated for one section. Then it is necessary to divide the power required to heat a given room by the power of one section of such a radiator, for example:

2025/150 = 14 (rounded to whole numbers)

And we got the required number of sections of such a radiator for a room with a volume of 45 cubic meters.