One of the main disadvantages of a solid fuel boiler is the limited ability to automate the operation. The exception is boilers with pellet burners: they can operate autonomously.

It all depends on how the fuel supply is organized. Those who heat with coal or wood have a more difficult time: one stash is unlikely to last more than a day. Even in long burning mode.

One of the popular solutions is to install two boilers in the house. We are talking about devices that run on different types of fuel. Coal, firewood, liquefied or natural gas, electricity, fuel oil - in principle, all this can be combined in various variations.

In some cases, heating with two boilers allows you to expand the functionality of the system, in others - to provide a backup heat source in case of repair of the main device or to increase the overall heating output in severe frosts.

We will analyze several diagrams for connecting two boilers to understand which of them will work and which are not worth wasting time and money on.

If the house has mains gas

Heating with natural gas is considered the cheapest and has a high level of automation. If the house is connected to the main line, it is obvious that such a boiler should be made the main one. Let's consider options for backup heat sources:

- Electricity.

Pairs perfectly with all types of gas appliances. The source can turn on when the coolant temperature drops or on command from the room thermostat. Electric heating has two disadvantages: limitations on allocated power and price. - Diesel fuel.

In terms of automation level, diesel burners do not differ from electric heating elements, but their operation requires a complex fuel storage and supply system. It is advisable to use this type of heating equipment in large commercial or industrial boiler houses, and not in everyday life. - Pellets.

A boiler with a pellet burner can easily solve the problem of backup heating. Starting in automatic mode is possible if it has an electric ignition heating element (candle). Otherwise you will have to do this manually. A pellet bunker requires additional space. - Coal.

A solid fuel boiler “in reserve” is an attractive solution at a price, but difficult to implement. Ignition and reloading can only be done manually. If a double-circuit wall-mounted boiler is used as the main heating, then it is almost impossible to integrate a coal boiler into the system.Pay attention to the design of the first device: it has a membrane expansion tank. This means that the heating system must be closed. Solid fuel boilers are used primarily in open heating systems. During coal combustion, the temperature in the system rises to high values, and the coolant increases in volume. If the system is closed, the pressure will rupture the heat exchanger, pipes or expansion tank membrane. Of course, you can install a relief valve, but then a lot of coolant will be lost. One solution for closed systems is the installation of an additional expansion tank, which will require increasing the area of the boiler room.

Connecting a floor-standing gas boiler will be easier. Most of them can run on open systems. Please note that these two boilers take air for combustion of fuel from the boiler room. If a mode of simultaneous operation of devices is provided, then the volume of the room and the productivity of the supply ventilation must correspond to their total power.

Another difficulty is the volume of the heating system. For normal operation of a solid fuel boiler, you need several times more coolant than a gas boiler. The problem can be solved by installing a heat accumulator.

- Natural gas.

There are heating systems with two or more boilers that run on natural gas. This solution is suitable for large commercial facilities where the volume of heat consumption varies over a wide range. Some manufacturers of such equipment make modular boiler rooms for several apartment buildings. If necessary, the modules are sequentially turned on or off in automatic mode.

Installation Requirements

Almost all combination boilers are manufactured in a floor-standing design and require a separately equipped boiler room. In addition, when installing them, it is necessary to comply with a number of fire and electrical safety requirements, as well as compliance with SNiPs. Below are the main installation features.

Room

- Availability of a reinforced individual foundation for installation of boiler equipment.

- Compliance with fire safety standards.

- Dryness in the boiler room, protection from moisture penetration.

- Non-combustible wall material.

- The minimum distance between the boiler and any wall is 300 mm.

Chimney

- Sealing of joints.

- No cracks or other mechanical damage.

- Insulation that prevents the formation of condensation and ice, which can lead to blockage of the chimney duct.

- The head is at least 500 mm high.

Circuit

Here it is important to eliminate the possibility of contact with water of any current-carrying elements, if any. Also a mandatory requirement is the correct selection of the cross-section of the supply wiring, which is calculated based on the total power of the equipment being powered and the current consumed.

If the main source of energy is coal or wood

In areas where there is “no smell” of main gas, coal and wood boilers are most often used as the main source of heating. Devices running on electricity or liquefied gas are usually placed in reserve. This expands automation capabilities and increases battery life.

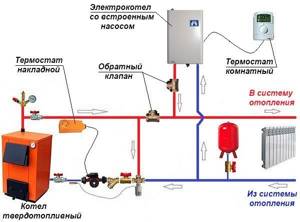

If there are two boilers in a house, one of which is solid fuel, connected to one circuit, the system works as follows:

- The coal boiler starts in manual mode and runs until the fuel runs out.

- If reloading is not performed, the coolant temperature drops. When the value is set by the user, the backup boiler is automatically turned on.

What is important to consider before installing such heating equipment?

Before installing such a heating system in your home, you should fulfill several important requirements. The boiler, as well as the entire system, must be installed:

- in a separate room;

- at a sufficient distance from the walls;

- only on a concrete foundation.

When the boiler and its elements are placed in an isolated room, this guarantees your safety. Under no circumstances should any objects, clothes, or shoes be stored in such a room. In short, there should be no flammable elements near the boiler other than fuel for equipment or boiler components.

Of course, if you are not a professional in this matter, then it is best to turn to the experts for help with installation. They will do their job efficiently and without any complaints. At the same time, if you have certain skills, you can take on this work yourself. All necessary materials and tools can be purchased at the store where the boiler was sold.

Manual or automatic switching?

When connecting two boilers to one system, you can use automatic or manual switching to a backup source. Of course, any customer of a heating project will want to get the first option, which, by the way, is not always advisable. Let's look at this using examples of heating schemes with 2 boilers “gas-electricity” and “wood-electricity”.

- Gas-electricity.

In both devices, built-in thermostats are responsible for maintaining the coolant temperature at a given level. They are installed at the outlet of the heat exchanger in the boiler body. In some cases, control is transferred to a room thermostat or weather-dependent automation.In a gas boiler, the thermostat turns the burner on and off; in an electric boiler, this function is performed by the heating element. Automatic switching to reserve is also performed at the command of the thermostat.

Let's consider the following situation: the gas boiler (main) is running. After some time, the coolant warms up to the set temperature and the burner turns off. The heat is released into the room, and soon the temperature in the system drops again. The thermostat activates and gives the command to turn on. Question: restarting the burner or introducing a reserve? The situation is not a stalemate, there are solutions, but they are rarely used in domestic heating, since this leads to an increase in the cost of the system.

Both electric and gas boilers are highly reliable. Usually such a pair is switched manually. In most cases, the reason for starting a reserve is a planned shutdown of the main boiler.

- Wood-electricity.

If one of the two boilers in a private house runs on solid fuel, then automatically switching to heating from electricity will be the only correct solution. The situation with fuel burnout was discussed above.

Switching methods

There are two ways of piping boilers operating in pairs:

- sequential;

- parallel.

When implementing serial piping, the boilers are connected one by one; installation and arrangement of additional nodes and lines is not required. The first device warms it up as the coolant moves, the second one brings the water to the required temperature.

This option is rarely used and only for low-power heaters. It is considered irrational, since it is impossible to dismantle one boiler for repairs without turning off the other. The circuit is inoperative if even one of the two units malfunctions. To modernize and improve efficiency, additional fittings are used and a bypass line is installed.

Serial wiring

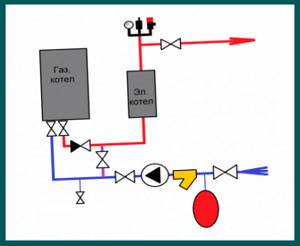

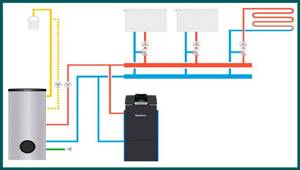

With parallel piping, two flow connection points are arranged on the direct coolant supply and on the return. The boilers operate independently of each other. In this case, it is possible to install an automatic control unit and a hydraulic switch.

Parallel harness

Serial or parallel connection?

Connecting two boilers can be done using two fundamentally different hydraulic circuits: in series and in parallel.

- Serial connection.

The “return” of the first boiler is connected to the “supply” of the second. That is, the coolant passes sequentially through both heat exchangers. Collaboration can be organized in two different modes:- The first boiler always works, and the second is “added” during periods of increased heat consumption.

Input of reserve, or more precisely, additional power, is automatic. This scheme is rarely used. The depth of power modulation in most modern boilers is sufficient to configure them to operate in the off-season and in severe frosts. In addition, the practice of using a sequential circuit in domestic heating shows that the downtime of the second boiler most often turns out to be above 90nbsp;%. - Either the main or reserve boiler is working.

Switching is done manually. In the wiring diagram of two boilers, bypasses must be provided. In design, they resemble the contours on radiators in a single-pipe heating system. The bypass redirects the coolant flow “past” the heat exchanger. Thus, one of the boilers can be dismantled for repairs. To do this, you do not have to stop the system or drain the coolant. - Parallel connection.

When two boilers are connected in parallel, the “feed” of one is connected to the “feed” of the other. The same thing happens with the “return”. Shut-off valves must be installed on each branch of the pipeline. When manually switching to reserve, it is enough to shut off only the “return” from the main boiler. If it has an expansion tank, an open "feed" will allow it to remain in the system.Automatic switching will require the installation of two check valves and a three-way valve with a servo drive. This solution will be more expensive than others.

One of the typical mistakes when designing a sequential circuit, when only one of the boilers has a built-in circulation pump (CP), is the decision to pump the coolant only with it. If you turn off the supply to it and open the bypass, the pump will no longer work. In addition, the hydraulic resistance of a “foreign” heat exchanger may be significantly higher, and the central heating unit will not be able to cope. Therefore, in the piping of two boilers there should also be two pumps.

Features of the scheme of primary-secondary rings

This scheme provides for the organization of a primary ring through which the coolant must constantly circulate. Heating boilers and heating circuits are connected to this ring. Each circuit and each boiler is a secondary ring.

Another feature of this scheme is the presence of a circulation pump in each ring. The operation of a separate pump creates a certain pressure in the ring in which it is installed. The assembly also has a certain effect on the pressure in the primary ring. So, when it turns on, water comes out of the water supply pipe, entering the primary circle and changing the hydraulic resistance in it. As a result, a kind of barrier appears on the path of coolant movement.

Since the return pipe is connected to the circle first, and after it the supply pipe, the coolant, having received considerable resistance at the supply pipe, begins to flow into the return pipe. If the pump is turned off, the hydraulic resistance in the primary ring becomes very small and the coolant cannot float into the boiler heat exchanger. The piping continues to work as if the disconnected unit did not exist at all.

For this reason, there is no need to use one complex automation system to turn off the boiler . The only thing that is needed is to install a check valve between the pump and the water return pipe. The situation is similar with heating circuits. Only the supply and return lines are connected to the primary circuit in the opposite order: first the first, then the second.

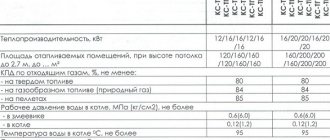

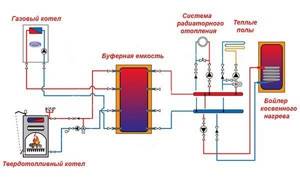

Universal combined scheme

This system has the following harness:

- Two common collectors or hydraulic collectors . The first one is connected to the boiler supply lines. To the second - return lines. There are shut-off valves on all lines. There are circulation pumps on the coolant return pipes.

- The membrane tank is connected to a large return manifold.

- The indirect heating boiler is the link between two collectors. On the pipe that connects the boiler to the supply manifold , there is a circulation pump and a shut-off valve. The pipe connecting the boiler to the return manifold also has a valve.

- The safety group is installed on the coolant supply manifold.

- The make-up pipe is connected to the manifold, which is located on the hot water supply line. To prevent leakage of hot coolant through this pipe, a check valve is installed on it.

- A certain number of small hydraulic collectors (there may be two, three or more) . Each of them is connected to the above-mentioned common manifolds. These hydraulic reservoirs and large reservoirs form the primary rings. The number of such rings is equal to the number of small hydraulic collectors.

- The heating circuits depart from small hydrocollectors. Each circuit has a miniature mixer and circulation pump.

Multi-fuel boilers instead of a two-boiler system

An alternative to connecting two heating boilers is to install one multi-fuel boiler. The obvious advantages of this solution are:

- coordinated operation of all boiler elements,

- saving space in the boiler room,

- simple diagram of connection to the heating system,

- possibility of automation of work,

- lower costs for purchasing equipment.

produces universal boilers of various capacities, capable of operating on different types of fuel. We can select equipment for heating homes with permanent and temporary residence. One example of a successful development is the Kupper PRO line of universal boilers. We have been producing them since 2015 and receive only positive feedback from customers. The line includes 4 models with power from 22 to 42 kW. Boilers can be configured to burn the following types of fuel:

- Firewood and coal.

There is a supply of secondary air and a transition to a long-term combustion mode (up to 10 hours with a full load of coal). - Pellets.

Automatic fuel loading allows you to do without owner intervention for a long time. - Natural gas.

If you wish, you can buy an additional gas burner with Italian automatic equipment from us.

Also, all boiler models have built-in heating elements, and if necessary, you can set up an automatic switch to electric heating. You can get advice from specialists by calling on our website.

The best manufacturers

Ratings of combination heating boilers can include dozens of models from a variety of manufacturers. Among them there are those that are especially popular among buyers and are rightfully considered one of the best.

Protherm

This European manufacturer of heating boilers is distinguished by a wide range of products, numbering more than 90 items, including heat generators of almost every type, including innovative condensing models. Products are supplied to more than 25 countries from Europe, Asia and Africa, where they have earned the trust of consumers.

Protherm boilers are certified according to ISO 9001, have an affordable price for a wide range of buyers and a wide range of models. In addition, the manufacturer provides professional service both through its own services and through partner companies, whose employees must undergo special training.

Roda

The products of the German manufacturer Röda are represented on the domestic market by electric, gas, solid fuel and, of course, combination boilers. Roda is European quality climate control equipment with service throughout the Russian Federation and a wide network of dealers.

Roda solid fuel boilers all have natural draft, and the combustion intensity is adjusted using a thermomechanical regulator. On the other hand, you can retrofit the heat generator with automation. It is also possible to install a control unit and a forced air intake fan.

ZOTA

The domestic manufacturer ZOTA offers customers, among other things, combined heating boilers using wood and coal with the ability to connect heating elements as an option.

They have an affordable price tag, and there are models with a hotplate. Some solid fuel heat generators fully provide long-term combustion, amounting to 8–12 hours, depending on the type of energy carrier.

Teplodar

Another domestic manufacturer that offers customers not only boilers, but also stoves and even fireplaces. Teplodar has been working in the heating industry for 20 years and has more than 50 patents for unique developments.

High-quality materials are used in production, and the reliability of the products is confirmed by various certificates. The model range includes horizontal heat generators of the “Comfort” series with a spacious firebox designed for firewood up to 50 cm long.

© 2021 All rights reserved

Installation of a gas heating boiler: characteristics and scope of work

Gas-powered units are installed both in the kitchens of city apartments and in specially designated areas of private houses. The boiler installation technology involves the following steps:

- system design;

- selection of equipment;

- arrangement of space for installation of the unit;

- pipeline assembly;

- placement of radiators according to the diagram;

- installation of additional equipment, for example, a circulation pump;

- pressure testing;

- commissioning

Installation of boilers: the cost of the service depends on the type of equipment

The choice of the heating system, and, consequently, the heating boiler model, always remains with the consumer - we will install any boiler that he chooses. Today, there are 4 types of fuel in which heating units operate - solid, liquid, gaseous and electricity. Whichever one is preferred, before choosing the current boiler model, you need to find out:

- power of the purchased equipment - the volume of the premises, natural heat loss, efficiency, option for transporting the coolant and other factors are taken into account;

- in the absence of an autonomous hot water supply (boiler or boiler), you can purchase a double-circuit unit that will not only perform the function of heating the room, but will also provide water heating.