Here you will learn:

- Types of briquetting machines

- Design features of the pressing apparatus

- Manufacturing based on other devices

- Press for making fuel briquettes with your own hands

- The simplest design of a homemade press

- Available methods of creating pressure

At home, the production of briquettes from sawdust is carried out using the same technologies as in the conditions of a production enterprise, therefore, before starting to create home-made equipment to solve this problem, it is necessary to delve into all the technological nuances of the production of this fuel.

Technological scheme for the production of fuel briquettes in industrial conditions

The process of producing briquettes for heating begins with grinding the feedstock, which, as mentioned above, can be sawdust, shavings, as well as agricultural waste: husks of wheat, buckwheat, rice and sunflower husks. After grinding, the raw materials for fuel briquettes are thoroughly dried to a moisture level of about 10%.

The formation of a dense briquette from the initial raw material can be carried out according to one of two technological schemes. To implement each of them, appropriate equipment is required, namely:

- briquetting press;

- press extruder.

Hydraulic press for the production of fuel briquettes without the use of binders

The technology for making briquettes for heating, both in the first and second cases, involves exerting significant pressure on the raw material, as a result of which lignin, a natural component that acts as a binder, begins to be released from the wood. Thus, for the production of briquettes there is no need to use additional adhesives, which allows you to maintain the environmental purity of the fuel.

To produce Euro firewood according to the first technological scheme, a mechanical or hydraulic briquette press is used, capable of generating a force of up to 500 Bar. As a result of such force action, spontaneous heating of the raw materials used occurs and the formation of a dense rectangular bar from it.

The extrusion scheme for the production of fuel briquettes involves the use of a screw press, which is capable of exerting pressure on the raw materials used, the value of which reaches 800–1000 Bar.

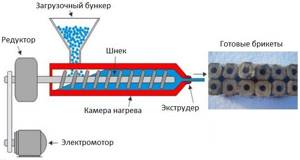

Diagram of the extruder press operation

When implementing this technology for the production of Euro-firewood, the raw materials are loaded into a receiving hopper, which is equipped with a screw briquetting machine. Next, the raw material captured by the screw is pushed into the narrowed channel of the press, where the material is compacted under high pressure. When compressed in the narrowed part of the working chamber of a sawdust screw press, spontaneous heating of the raw material occurs, as a result of which the finished briquette is formed under simultaneous exposure to high pressure and significant temperature. The finished briquette, when pressed on auger equipment, has the form of a hexagonal block, cut into pieces of the required length.

This is how briquettes are squeezed out by an auger

What is the price

The cost of opening such a business is quite high.

To launch the plant, an entrepreneur will need to invest about 7 million rubles. The main expense item is, of course, the purchase of equipment. This will cost about 6.5 million. This will include not only the purchase of devices for the production of granules, but also their installation, configuration, as well as the purchase of raw materials. You will also have to spend money on renting the building (which is about 50 thousand rubles). Also, do not forget about advertising costs, because without an advertising campaign it will be difficult to attract consumers. And networkers are more willing to work with companies that themselves promote their products.

But is it profitable to take on this business at all, since the initial costs are quite serious and impressive? The profitability of this business, according to statistics, is quite high. Raw materials are inexpensive. The main costs are equipment maintenance. The workshop will pay for itself in approximately 2 and a half years.

Preparation of starting material

Briquette press

The main problem when making fuel blocks yourself is the need to grind the starting materials. Of course, when using sawdust, small shavings, or grain husks, this operation is not required. But small branches, shavings, and cardboard waste must be crushed before briquetting until uniform particles are obtained.

For crushing, you can use any household agricultural crusher, in which the hammers are replaced with cutting plates. At a rural farmstead, these devices are usually available and used to prepare feed for domestic animals and poultry.

A city dweller who has a garden or summer cottage will have to find a suitable model in a gardening store. Today, special devices designed for shredding household waste and garbage are also produced.

By purchasing this crusher, a summer resident will be able to use it not only for preparing briquette raw material, but also for other purposes.

Equipment for pellets (with video)

There are companies in Russia that develop equipment, machines, and production lines, including those for the production of fuel pellets and briquettes, which can manufacture equipment directly taking into account your wishes on an individual order. In this video, there is a company that manufactures just such equipment:

Until recently, pellet manufacturers focused primarily on Western consumers. But it turns out that enterprising people have been successfully using such units on their farms in Russia for a long time. OGM-1.5 presses and AVM-1.5 dryers have been working regularly for one of my farmer friends since Soviet times, slightly modernized, with a new set of rollers and dies, they produce a variety of products.

Mini-equipment for pellets is usually multifunctional. By changing matrices, you can produce pellets from straw, hay, husks, and garden waste. This is both waste disposal and the production of raw materials for heating housing, greenhouses, and livestock buildings.

It can also be used to produce feed, fertilizers and many other things needed on the farm according to the required recipe.

Briquetting Line Suppliers

| № | Name | Cost, pcs. | Provider |

| 1 | Imported new line-plant for the production of pellets from 1500 kg/hour | From 9 million rubles. | LLC RosIndKo (St. Petersburg) |

| 2 | Press Ruf for the production of fuel briquettes (volume not specified) | 180 thousand rubles. | LLC "Chernomorsky Trading House" (Krasnodar region) |

| 3 | Hydraulic press for the production of fuel briquettes Nestro, new | 600 thousand rubles. | Private person |

| Hydraulic press for the production of fuel briquettes Nestro, used | From 90 thousand rubles. | Private person | |

| 4 | Used briquetting press PB 400 kg/h | 390 thousand rubles. | LLC NGSBP (Krasnodar region) |

| 5 | Press for fuel briquettes from vegetable raw materials, 35-180 kg/h, made in Germany | 850 thousand rubles. | Agro-industrial technologies (Yurga, Kemerovo region, Russia +7) |

| 6 | Impact press for sawdust briquetting GC-1000 at 0.8…1 t/h | 3.25 million rubles. | LLC Eurasia-Vostok (Blagoveshchensk) |

| 7 | Dryer type AVM-650, new. | 150 thousand rubles. | Private person |

| 8 | Drying type AVM-650, used. | 90 thousand rubles. | Private person |

| 9 | Aerodynamic dryer SAD-0.6-1.2 with a capacity of 600 kg/hour | 1.3 million rubles. | LLC Stankostroitelny (Voronezh) |

| 10 | Chinese low power lines up to 250 kg/hour | 200 thousand rubles. (per unit of equipment in the line) | Private person |

| 11 | Chinese medium power lines from 500 kg/hour | 2.5 million rubles | Private person |

Press for making fuel briquettes with your own hands

The purchase of ready-made equipment for the production of briquettes, depending on its capacity, will cost from 300 thousand to 1 million rubles.

Of course, for a private owner who wants to start producing this fuel purely for his own needs, such costs are impractical, since they will not pay off soon. It would be more correct to make a press from scrap materials, especially since there is nothing complicated in its design.

You can build the necessary equipment from scratch or use ready-made mechanisms.

Homemade machine

Scheme

Homemade lever and screw presses do not require the use of purchased products, but they cannot boast of significant compression force. It is proposed to assemble a press based on a hydraulic jack or the same press.

It can be equipped with an electric motor or a manual drive:

- We will attach the punch to the hydraulic installation. Its dimensions must correspond to the dimensions of the matrix in which the raw materials will be compressed into a briquette.

- We will make the matrix itself from a thick-walled pipe - this is the simplest option. Holes will be made in its walls to allow air and moisture to escape.

- We will equip the matrix with a removable bottom. Having removed it, the finished briquette can be pushed out with a punch into the receiving tray.

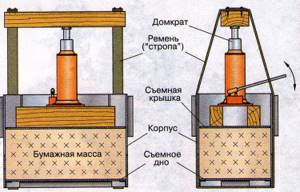

Drawing diagram for the production of briquettes from soaked paper pulp

The working mechanism is placed in a housing equipped with two handles for easy transportation.

Necessary materials

In addition to the hydraulic installation, you will need some types of rolled steel:

- Channel.

- Equal angle corner 100x100 mm.

- Sheet thickness 3 – 6 mm. A punch will be cut from it. The thickness of the workpiece depends on the diameter of the matrix: the larger it is, the thicker the punch should be.

From the same sheet we will cut out a removable bottom for the matrix.

- A pipe with a diameter of 25 - 30 mm - the punch rod will be made from it.

- A thick-walled pipe is a blank for the matrix. The diameter depends on what size briquettes the user wants to receive. The thinner they are, the higher their density, but the productivity of the machine will decrease.

- A large diameter pipe is a blank for the mixer body. If there is no suitable pipe, the drum can be made from a sheet of tin.

- Galvanized steel for the manufacture of trays.

In total, you will need two trays - for loading the prepared material into the matrix and for receiving the finished briquettes.

Manufacturing and assembly instructions

The order of operations in the manufacture of the press looks like this:

- It is necessary to weld the base of the device from the channels.

- From the corner we make 4 racks 1.5 meters long. They are welded vertically and with the same pitch.

- Next, you need to make a drum from a pipe or sheet of tin in which the raw materials will be mixed. If you have a broken washing machine, the drum, as well as the bearings, can be removed from it.

- The drum must be attached to the stands. If possible, it should be equipped with an electric motor. If the motor is too high-speed and it is not possible to reduce the rotation speed of the drum to an acceptable value due to the difference in pulley diameters alone, a gearbox should be used.

- It is necessary to attach a tray under the drum through which the prepared material will be fed into the matrix.

- In the walls of the pipe used as a blank for the matrix, it is necessary to make several holes with a diameter of 3 - 5 mm. They must be distributed evenly so that air and water are squeezed out throughout the entire volume of the briquette.

- A flange must be welded to the bottom of the matrix, to which the removable bottom will be screwed. This bottom is cut from a steel sheet in the form of a disk with eyes.

- The matrix is welded or screwed to the base under the loading tray.

- We cut out a round punch from a steel sheet. This is simply a disk whose diameter allows it to freely enter the matrix.

The rod is made of a pipe: a diameter of 30 mm is sufficient. One side of it is welded to the punch, and the other is attached to the hydraulic unit.

Next, the entire assembly should be attached to the racks exactly above the matrix.

To reduce the time spent on removing the finished briquette from the matrix, and thereby make the machine more productive, a spring with a disk of the same diameter as the punch can be welded to the bottom of the matrix.

After turning off the hydraulic unit and removing the punch, the product will be pushed out automatically by the spring.

Design features of the pressing apparatus

A homemade briquette press is a mechanical unit. Its key elements:

- Work table-bed. All structural parts of the press will be fixed on this basis.

- Support frame. Regulates and directs the force that a person exerts on the press.

- Drive unit. Can be manual or mechanical (hydraulic or electric motor).

- Punch. This is a drive element that has a direct impact on the bulk raw material.

- Forming container. Must have perforations.

The simplest press is equipped with a screw manual drive. Pressure is applied to the workpiece by tightening the screw. Its productivity is quite low, so this press has not gained wide popularity among the people. Time and energy are wasted on loading and unloading and tightening the screw. A briquette press with a long lever and the function of independently squeezing the finished brick outward looks comparatively more advanced. Such a machine can be improved by complicating the design with a hydraulic jack.

Advice. To speed up the pressing process, a second matrix mold is welded onto the work table.

Production scheme

The production of pellets occurs in several stages:

- First, the incoming raw material goes through the first stage of grinding, breaking it into fragments 25*25*2mm. This stage is necessary for more uniform and faster drying. Raw materials are fed into the crushers by a scraper; they should be stored on a concrete floor to prevent the ingress of soil, sand and stones.

- Then the semi-finished product is brought to a moisture content of 8-12% in belt or drum dryers. In all technology, this is the most energy-intensive process, but the quality of the fuel depends on the degree of moisture content of the raw materials. On average, it takes 1 MW of energy to bring 1 ton of raw materials to the required humidity. To reduce costs, bark or other substandard raw materials can be burned in dryers.

- The resulting mass is finely crushed (particles no more than 4 mm, for high-quality granules 1.5 mm) using hammer mills.

- If during the drying process the moisture content of the raw material drops below 10%, the semi-finished product is moistened with finely dispersed water or steam. Steam is necessary for hard wood (oak, etc.) or for stale raw materials. For soft wood or quality raw materials, water is sufficient. Screw mixers are usually used at this stage.

- The resulting product is pressed. The press can have a flat or cylindrical die. The size of the matrix determines the performance of the installation. The amount of raw material produced per unit of time also depends on the diameter of the granules.

- The pellets heated during pressing are cooled. During cooling, their moisture content decreases, which improves quality.

- The granules are sifted and packaged. Sometimes they are stored in bulk in bins, but in order to maintain the quality unchanged, it is advisable to package the products in large bags - big bags, which are delivered to the consumer. The highest quality products are packaged in bags of 20-25 kg.

General information about briquettes

The raw material for this type of biofuel is small wood waste, mainly sawdust. Of course, you can burn them this way, but it’s not very convenient, it takes a lot of fuel and it burns out quickly. And all because the density of wood pulp is low, much more heat will be produced if the raw material is pre-compressed. This is the briquette production technology.

First, sawdust and other waste are processed, crushed and dried. The humidity of raw materials before pressing should be in the range of 6-16%, which is ensured by drying equipment. Then comes the actual production of fuel, which is done in two ways:

- Using a hydraulic press, the raw materials are formed into rectangular or cylindrical briquettes. The process takes place at pressure from 30 to 60 MPa and high temperature;

- Using the extrusion method on a screw press, a 4- or 6-sided briquette is extruded from the finished mixture under a pressure of about 100 MPa. The product undergoes heat treatment.

It should be noted that the production of fuel briquettes from sawdust does not involve the addition of binding components to the mixture. Under the influence of high pressure and temperature, the particles are glued together by lignin, which is found in any wood. The result is “bricks” or “sausages”, whose calorific value is up to 5 kW/kg. The production process is shown in the video:

Financial plan

Investments in a business project

To organize production, the following investments in rubles are needed:

- registration of an enterprise – 10,000;

- certification – 30,000;

- production line – 2,950,000;

- transportation, installation and commissioning of equipment – 590,000;

- additional inventory – 100,000.

Total: 3,000,000 rubles

Current expenses

Monthly costs for the production of each ton of fuel in rubles will be:

- raw materials – about 750;

- electricity – 450;

- salary – 400;

- depreciation – 240;

- packaging and transportation – 120;

- other expenses (rent, transportation, etc.) – 200.

Total: 2160 rubles.

Sales revenue

The productivity of the mini-plant with a standard eight-hour working day allows the production of up to 60 tons of pellets per month. The wholesale cost of a ton of products is about 6 thousand rubles. As a result, your monthly income will be 6000x60=360000 rubles.

The cost of producing 60 tons of pellets will be 2160x60=129600 rubles. Thus, the net profit will be 360,000-129,600 = 230,400 rubles.

Comparative characteristics of briquettes

| Type of fuel | Calorific value, MJ/kg |

| Anthracite | 26,8-31,4 |

| Brown coal | 10,5-15,7 |

| Coal | 20,9-30,1 |

| Gas | 27 |

| Peat (humidity 20%) | 15,1 |

| Diesel fuel | 42,7 |

| Wood (humidity 40%) | 6-11 |

| Briquettes (from sawdust) | 16-29,5 |

Each type of briquettes has its own characteristics and advantages. And although all of them are excellent for heating in domestic conditions, it is still worth familiarizing yourself with their characteristics in more detail in order to choose the best option.

Forms of fuel briquettes

Wood briquettes

This type of briquettes is obtained by pressing various wood waste - dead wood, sawdust, shavings, substandard wood. Before pressing, the waste is heated to a certain temperature, as a result of which an adhesive substance, lignin, is released from the cells. Thanks to lignin, briquettes acquire high strength and retain their shape during transportation and storage.

Wood briquettes

The advantages of briquettes over solid wood are obvious:

- the density of briquettes is constant and amounts to 1240 kg/m³, the density of wood depends on the species and ranges from 150-1280 kg/m³;

- maximum humidity of briquettes is 10%, wood – from 20 to 60%;

- when burning a briquette, the volume of ash is 1% of the total mass, wood - 5%;

- when burning, a briquette emits 4400 kcal/kg, wood - 2930 kcal/kg.

In addition, wood briquettes have other advantages:

- pressed wood does not spark when burning and emits very little smoke;

- a constant temperature is maintained in the boiler;

- briquette burning time 4 hours;

- the coals remaining after combustion are excellent for cooking over an open fire;

- the correct shape of the briquettes simplifies their transportation and storage.

Such fuel is sold not in cubic meters, like wood, but in kilograms, which is much more profitable.

Prices for Eurofirewood Briquettes

Eurofirewood Pini-kay

Coal briquettes

Coal briquettes

This type of briquettes is obtained from screening out coal. First, the screenings are crushed, mixed with a binder, and then compressed under high pressure.

The main properties of such fuel:

- coal briquettes do not smoke;

- do not emit carbon monoxide;

- burning time in conventional boilers is from 5 to 7 hours, with controlled air supply – 10 hours;

- suitable for use in domestic conditions;

- have a compact shape;

- when burning they release 5200k/cal and maintain a constant temperature;

- maximum ash volume – 28%;

- have a long shelf life.

Coal briquettes are the most optimal fuel in harsh winters, when pressure drops in domestic gas systems due to low temperatures. Briquettes burn at any temperature, the main thing is that there is a constant flow of air.

Prices for WEBER coal briquettes

WEBER coal briquettes

Peat briquettes

Peat briquettes

To make briquettes, peat is dried, heated and pressed under high pressure. The result is neat, light, dark-colored bricks. With an adjustable air supply, peat briquettes maintain the temperature for 10 hours, which is very convenient for heating the house at night.

Basic properties:

- suitable for all types of ovens;

- heat transfer is 5500-5700 kcal/kg;

- ash volume 1% of the total volume of the briquette;

- affordable price;

- minimum amount of impurities in the composition.

The ash that remains after fuel combustion can be used as an effective lime and phosphate fertilizer. For many owners of private households, this factor is decisive when choosing heating briquettes. Since peat is a flammable substance, it should be stored at a safe distance from open fire and heating devices. Even dust spilled from the packaging can ignite and cause a fire, so briquettes must be handled correctly.

Husk briquettes

Husk briquettes

Sunflower husks, buckwheat and rice husks, rye waste, oats and even straw are widely used to make fuel briquettes. The most common are briquettes made from sunflower husks, since the production of oil leaves a large percentage of waste. The maximum moisture content of husks for pressing is 8%, which increases heat transfer and reduces combustion time.

Sunflower briquettes

Specifications:

- briquette density is 1.2 t/m³;

- heat transfer – 5200 kcal/kg;

- ash volume from 2.7 to 4.5%.

Additional benefits:

- absence of harmful impurities;

- affordable price;

- long burning time;

- ease of storage and transportation.

Methods of promotion and sales

Of course, the segment of private owners using solid fuel boilers with a power of up to 100 kW is gradually growing, currently consuming about half of domestic production. However, in the near future, the retail share of the pellet market will significantly decrease due to the emergence of a new class of buyers of fuel pellets, burning them in boilers with a capacity of 250–1000 kW for heating factory workshops, greenhouses and warehouse complexes, business centers, residential buildings and even cottage villages.

When listing the most effective distribution channels for fuel pellets, the following options can be mentioned:

Business premises

Pellet production is a business completely dependent on raw materials. Therefore, uninterrupted delivery of materials for recycling should be organized. When organizing a business, there is no need to build a new workshop; it is enough to rent space at a sawmill. Such proximity will provide a huge advantage and savings on transport costs.

The production room must be spacious, have good ventilation and have an area of 80 m2, and comply with all fire safety standards. Communications for production require electricity and water.

If you were unable to set up your production in close proximity to the sawmill, you should carefully consider transport links and the availability of the necessary raw material base.

Step by step: how to make briquettes at home

If your goal is not hard work with a good profit, but needs related to heating only your home, purchasing equipment is not very practical. The units cost from 300 thousand to a million, that is, they will not pay off soon. The press can be made manually, by yourself, of your own production. And here there are two options for the development of events - to make a press from scratch, or to use a ready-made existing mechanism.

In addition to components of plant origin - wood waste and husks of various agricultural crops - coal dust can be used to make briquettes

So let's say you're making abs from scratch. To create a force suitable for compressing raw materials, a lever or screw mechanism is needed. A lever press can even be made of wood, but a screw press will require steel blanks and a lathe.

Of course, it is easier to work with a ready-made mechanism. For example, suppose you have a jack or a hydraulic press. This device must be supplemented with a matrix and a punch. But no matter how cool the press you make with your own hands, it will not be able to achieve the effort required to produce lingin. Therefore, binders will have to be added to the raw materials. The easiest option is cheap wallpaper glue.

You can also add clay in proportions of 1:10; some types of soaked paper are also used. For example, corrugated cardboard - it already contains lingin, and in contact with moisture its fastening properties appear. Interestingly, if we are talking about making briquettes at home, then the material is not dried, but soaked in water for better gluing of the particles. And the finished briquette is dried in the fresh air.

Read also: How to unscrew a rusty self-tapping screw

Granulator device

The granulator is similar in design to an electric meat grinder with one difference: the knife is located on the outside, behind the matrix grid.

During the granulation process, the raw material mass is loaded into a hopper, from which it is pushed under pressure through a mixture heated to 110 degrees. matrix. The movement of the screw ensures that the mixture is pushed, creating pressure and pressing the crushed and moistened raw materials against the matrix.

Upon reaching a critical volume value, the compressed raw material is forced through the holes of the matrix. A special cutter cuts the granules to the required size. Plastic capsules cool down, maintaining their shape.

You may also be interested in information about how to keep Indian ducks at home.

The operating principle consists of sequential operations:

- supplying crushed feed from the hopper to the rotating shaft;

- compression;

- pressing through the matrix;

- cutting with a knife;

- entering the receiving bowl.

The diameter of the holes in the grid determines the diameter of the capsules. Depending on the power of the electric motor, the diameter can be from 5 to 10-15 mm. The distance at which the knife is installed after the grate determines the length of the granules.

The video shows how the granulator works and works:

Main parts of the granulator:

- loading hopper;

- screw;

- matrix;

- knife;

- drive shaft;

- gearbox;

- electric motor;

- bed;

- receiving bunker.

But how to breed ducks at home for beginners and what you should pay attention to is indicated here. All parts of the device are made of metal

All parts of the device are made of metal.

The specific characteristics of the thickness and diameter of the matrix, the diameter of the screw, and the power of the electric motor are determined together.

The units offered by manufacturers can be used for preparing not only feed, but also pellets (fuel pellets made from sawdust).

Main characteristics of granulators offered by manufacturers:

The maximum power of manufactured units is 30 kW with a productivity of more than 1000 kg per hour. The weight of the installation is more than 500 kg.

But what the blue favorite duck looks like and how to properly breed it at home is indicated here.

Device cost

- with a 2.2 kW electric motor – from 53,000 rubles;

- 7 kW – from 83,000 rubles;

- 15 kW – from 190,000 rub.

Advantages of industrial granulators:

- reliability;

- duration of operation;

- versatility;

- efficiency;

- safety;

- convenient service.

The high cost of units manufactured in industrial conditions forces livestock breeders to make devices in a handicraft way, using improvised means.

But you can read here how broilers are raised without feed and what feed should be used.

Available methods of creating pressure

There are three common ways to achieve pressure that are well suited for a homemade fuel briquette press: using a lever, a hydraulic jack or a screw. Each of them is good in its own way, and their implementation in practice is not very difficult.

Use of muscular strength and leverage

Usually a metal pipe is used as a lever. It should not bend under the influence of human muscular strength. For example, a reinforced water pipe with a diameter of 40 or 50 mm with a wall thickness of 4 - 4.5 mm is suitable.

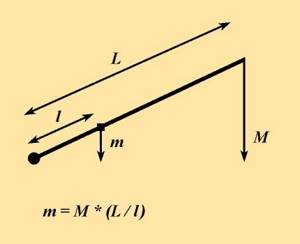

Formula for calculating the piston pressure force (m) depending on the force applied by a person (M), the distance from the piston to the lever attachment point (l) and its total length (L)

The length of the lever and the distance from the fulcrum to the connection with the piston are chosen not only based on achieving the desired pressure. Another important parameter is the depth of immersion of the piston into the glass (h, cm).

It is calculated using the formula:

h = R * (l / L)

Here R (cm) is the height to which the end of the lever will fall.

It is advisable to make the structure in such a way that the depth of immersion of the piston is sufficient to form a briquette without repeated compression with preliminary addition of material. This will greatly increase the production rate.

The required immersion depth of the piston (h, cm) can be calculated knowing the initial dry (q1) and briquetted (q2) density of the raw material and the height of the glass (H):

h = H * (1 – q1 / q2)

If for some reason an error occurs (usually due to incorrect determination of the initial density of the raw material) and the depth of immersion of the piston is not enough to impart the required hardness to the product, then it is not necessary to digest the entire structure.

You can either reduce the height of the glass, or, adding sawdust, press one briquette in two or three passes.

Application of hydraulic jack

To create strong pressure, hydraulic devices are used, such as the usual bottle jacks. As a rule, in a household where there is a car or other equipment, such hydraulic units are available, but their carrying capacity may be insufficient.

The design of a typical hydraulic press consists of a frame and a movable beam on which a jack is placed. The system returns to its original position due to the action of springs

Jacks are inexpensive. Thus, models designed for 30-40 tons can be purchased for less than 5 thousand rubles. And with such indicators it is already possible to obtain briquettes of large cross-section or several (3-5) copies of regular size at once.

To produce several briquettes at the same time, the required number of molds are placed in a row. The middle moving frame must be strong so that it does not bend over time. It is best made from an I-beam or thick-walled profile pipe.

The pressing process itself takes longer than when using a lever design. However, the use of a powerful hydraulic jack allows one to achieve much greater specific pressure on the workpiece. The briquettes are more even and dense and already have an attractive presentation.

Raw materials

- Sawdust and shavings. Sawdust pellets are considered granules of the first category and are characterized by the lowest ash content in combination with a high specific heat of combustion. They can be used in any heating boilers, including low-power installations. The wholesale cost of sawdust starts from 100–150 rubles/m³;

- Woodchips. For the production of fuel pellets, waste from sawmills, as well as crushed remains of substandard wood, are often used. Due to the presence of bark and roots, this raw material is less valuable, since the content of such impurities leads to an increase in ash content. The average cost of wood chips is from 150–200 rubles/m³;

- Peat. Not only pellets are produced from high-moor peat, but also peat briquettes, which can be burned both in boilers designed for this purpose and in ordinary fireplaces. The ash content of peat granules is within 3%, which allows them to be classified in the second category and successfully used in industrial installations. The average cost of peat is 290 rubles/m³;

- Straw. This raw material for the production of pellets has the highest calorific value combined with an ash content of 4–10%. Therefore, straw pellets serve as fuel mainly in large thermal power plants equipped with specially designed boilers. The cost of straw is from 340 rubles/m³;

- Agricultural waste. Pellets can also be made from waste from processing agricultural crops - sunflower, buckwheat, corn, flax. With an ash content of 2.5–7%, this type of fuel requires the installation of an automatic boiler cleaning system. The cost of sunflower husks is 180 rubles/m³.

The quality of raw materials should be assessed in accordance with several main criteria that determine their suitability for further processing:

- The source material should not contain any solid impurities (stones, sand, metal), debris and non-combustible mineral residues;

- The raw materials must include lignin and organic resins;

- The moisture content of the material should not exceed 35–40% (otherwise the production process is greatly slowed down and drying costs increase).

Application of briquettes and their features

Euro-firewood made using handicraft methods is considered a highly environmentally friendly product, because the purest wood processing materials are used as raw materials. Briquettes burn completely, with virtually no smoke, which makes the use of such combustible material optimal for heating a home. For example, to heat a house with an area of 150 m² in winter, about 20 kg of briquettes per day is required, which corresponds to 0.02 m³. Heating of premises, in particular baths and saunas, occurs in a short period of time, which is the main feature of this type of fuel.

For heating stoves and fireplace structures, as well as heating boilers of classical design, the best option is to use euro-wood from sawdust.

Another advantage is the fact that the material has a constant combustion temperature from the beginning of the process to its end. After the briquettes burn out, no ash remains, which reduces the number of cleaning procedures for the boiler or furnace. Euro firewood has a high density (approximately 1.3 t/m³), as well as low hygroscopicity, which makes it possible to equip storage rooms in small rooms as close as possible to the furnace structure or boiler. Fuel wood briquettes have a calorific value similar to coal.

Equipment for the production of pellets

The main role in the technological process is played by the machine for the production of pellets, which is also the most difficult to manufacture. It will not be possible to completely make a granulator with your own hands, since to manufacture the matrix and rollers you need metalworking machines - lathe, milling, drilling and grinding. So there are 2 options: buy a ready-made matrix-roller pair or order it from the craftsmen.

The matrix pair for the pellet press should be made of high-carbon steel St45 or St50, or even better alloyed with manganese HVG or 65G. Moreover, after processing, the parts must undergo a hardening process in order to achieve a hardness of 58-60 units. To make a matrix for a granulator, you need to maintain all the dimensions indicated in the diagram:

You can use simpler steel for the roller shaft - St3, 10 or 20, and there is no need to harden it. But the working parts of the rolls must be made from the above grades, followed by hardening, and then mounted on the shaft through bearings, as shown in the photo below.

Now let’s talk about what you can use to assemble the housing and drive for a homemade pellet granulator. The matrix pair must be placed inside a cylindrical body, which is made of sheet metal or a pipe with an internal diameter of 200 mm. The drive shaft is inserted into the matrix hole and secured with a key, and below you need to make a platform for the finished pellets. The assembly diagram of the pellet granulator is shown in detail in the video:

To rotate the shaft, you need to take an electric motor with a power of at least 5 kW, and the drive can be assembled from an old automobile gearbox from a Volga or Moskvich with part of the rear axle. On the side where the driveshaft is to be connected to the gearbox, a pulley is installed, rotated by a belt drive from an electric motor. Both units are attached to the same frame, as described in the video:

Note. In this design of a press for making pellets with your own hands, the shaft rotates the matrix, and the rollers remain stationary. The pulleys must be selected so that its rotation speed is no more than 250 rpm.

Homemade crusher

It’s good when it is possible to obtain good small wood waste from some production for pressing pellets. If this waste contains small branches or slabs, then to grind them you will need additional equipment - a crusher. There are many homemade structures, but most of them cut wood into chips that are too large, from which it is impossible to make pellets at home.

We present to your attention a simple wood waste crusher made from 3 dozen circular saws for a circular saw with carbide tips. All saws are mounted on one shaft in such a way that the teeth of each subsequent one are slightly offset relative to the previous one. A pulley and 2 bearings at the edges are placed on the same shaft, after which the entire structure is fixed to a frame made of angles or pipes.

As you understand, the productivity of the unit is low, but such a wood waste crusher will produce sawdust suitable for the production of pellets. If you have a circular saw on your farm, then the chopper can be adapted to its frame, as is done in the photo:

Sawdust dryer

To ensure that home-made wood pellets do not crumble at the exit from the granulator matrix, it is necessary to ensure the minimum moisture content of the raw materials. In industry, this occurs in various drying chambers. At home, craftsmen have adapted to assembling drum-type sawdust dryers, since their design is the simplest, as shown in the diagram:

Several iron barrels, welded to one another, are mounted on a frame with a slight inclination to one side. Blades are welded from the inside to the walls of the barrels to mix the raw materials. On one side, hot air is supplied inside such an improvised drum using a gas or electric heat gun. The rotation of the drum is carried out by an electric motor through a gearbox or a reduction belt drive.

Manufacturing based on other devices

If there is no desire to create a press for making briquettes from scratch, then you can try to rework some other device for such a mechanism. This can be a jack or a small hydraulic press, which is additionally equipped with a punch and a die.

It is important to understand that all home-made installations are not capable of providing the pressure at which lignin production occurs. As a result, a number of third-party additives are added to the original mass, including:

- inexpensive adhesive (for example, for wallpaper);

- clay (for 1 part of raw materials take 10 parts of waste);

- soggy paper or corrugated cardboard.

When producing a machine for briquettes, it is important to take into account such a stage as grinding raw materials. Manual cutting of the material is not recommended, since such manipulation takes a lot of time and effort. Instead, it is recommended to use additional devices, for example, a shredder from an old activator washing machine, into which knives are placed. You can also buy a rotary machine. Its task is to grind plant components.

Another important point is the grinding of raw materials; manual cutting of the material is not recommended, since such manipulation takes a lot of time and effort.

To successfully manufacture a lever or screw press, you do not need to purchase additional parts. However, such devices do not have special operating properties. A press made from a hydraulic jack, on which an electric or manual drive is installed, will be more effective.

A punch is added to the finished equipment, the dimensions of which are comparable to the dimensions of the matrix where the pressing takes place. To create the matrix, take a thick-walled pipe in which holes are made for the ventilation system. The matrix is additionally equipped with a removable bottom - it can be removed after receiving the finished briquette.

Homemade press

If you have a drawing and certain design skills, you can make a press for fuel briquettes with your own hands.

There are two types of homemade devices for briquetting - those operating from a jack and those with a manual drive.

A description of the assembly of the structure will help you understand how to make a press and which option is best to use.

Manual

To make a hand press, you need a punch. It is constructed from thick metal sheet. A pressure lever is attached to the material, and the structure is secured using hinges.

The punch is installed in a special form. Usually it is made square. The mold is made from metal. Using a thin drill, holes are drilled in the bottom and sides to allow moisture to escape during the pressing process.

To collect the released water, a container is used in which the finished press is installed.

From the jack

To obtain higher quality solid fuel and improve the design of the press, a hydraulic jack is used.

The manufacturing process of such equipment consists of the following stages:

1. The base for the press is formed from the channels. All metal parts are fastened by welding.

2. Racks are attached to each corner of the prepared base in a vertical position. Each support is taken 1.5 meters high.

3. The mixer is welded to the stands. The drum can be made from a pipe with a large diameter or take a ready-made part from an old washing machine.

4. A galvanized steel tray is fixed under the mixer, from which the raw materials will penetrate into a special mold.

5. Holes are created in the thick-walled pipe intended for the matrix. They should be evenly distributed throughout the circular contraction. The width of each opening should be from 3 to 5 millimeters.

6. At the bottom of the mold, a flange is fixed using a welding machine, to which the bottom is screwed.

7. The finished form is connected to the base.

8. After this, a punch is cut from steel sheets. It should have the same shape as the matrix. Using a rod, the punch is connected to a hydraulic element.

The assembled mechanism is fixed on top of the form to the racks. The tray is fixed at the bottom.

To speed up the process of removing pressed briquettes, it is recommended to weld the disk and spring to the bottom of the matrix. It must match the diameter of the punch. This mechanism will allow you to automatically push out finished products after turning off the hydraulics.

Pressed wood raw materials require drying. The lower the moisture content of the briquettes, the better they burn. In addition, dry briquettes have higher heat transfer.

Self-made compact fuel can significantly reduce the cost of heating your home. Ready-made briquettes can be used both for the boiler and for the stove. But it should be borne in mind that the quality of the product largely depends on the density indicator.

It is almost impossible to make compressed firewood using homemade equipment that will burn for a long time and give off a large amount of heat.

Therefore, if you need to use fuel with high performance, it is better to purchase it in specialized stores.

Types of briquetting machines

When thinking about which press for making briquettes will be the best for working at home, it doesn’t hurt to familiarize yourself with the design and operating features of today’s most popular models of installations so that you can choose the best option. This list includes:

- A hydraulic machine, which is the most budget and affordable of all existing presses. The low price of such equipment is due to the fact that the fuel packages produced with its help are too loose and often disintegrate into small fractions during the combustion process, not producing strong and lasting heat.

- Screw press for sawdust. Making a structure of this type with your own hands is not so easy, since it has a fairly high level of complexity in manufacturing and involves the use of certain elements such as a screw, which resembles a steel spiral rod in conventional meat grinders. Nevertheless, all the efforts made will certainly be worth it, since briquettes made on screw-type installations have a high density and the ability to burn for a long time.

- A mechanical impact press is one of the most common types of design for homemade briquette production, as it is not too difficult to manufacture. As for the finished product, the output is something between fuel packages made on a hydraulic and auger installation.

- Press granulator, which is used for processing animal feed. Such a machine is also perfect for pressing fuel raw materials, but on the condition that only its fine fraction will be processed.

When organizing a home production of briquettes for heating, you should take into account its potential power, the volume and characteristics of the available materials that will be processed by the press, as well as the availability of available tools for constructing a home-made installation. A detailed study of the pros and cons of different types of installations will also help you make the right decision.

Advantages and disadvantages of models

Most often, households and small production shops use hydraulic presses, which can operate from an individual or a common (group) drive. As a rule, such devices have the following advantages and disadvantages:

- Almost any construction waste can be used for processing in a hydraulic press, including wood, wood shavings and sawdust, plywood residues, dry leaves, etc.

- Compared with other processing units, the hydraulic press has the lowest noise level during operation.

- The high strength and reliability of the design contributes to the most accurate supply of raw materials and almost instantaneous processing, despite the fact that some units boast the presence of a speed regulator.

- The only drawback of such equipment is the low density of the briquettes produced.

That is, a hydraulic press is more suitable for those people who are simultaneously involved in the woodworking industry and do not suffer from a lack of raw materials. If there is not so much material for making fuel briquettes, then it is better to take a closer look at any other design that will allow you to produce denser briquettes that can burn for a long time and well.

An alternative to a hydraulic press can be a screw installation, which not only crushes the material into dust, drying it at the same time, but also ensures its maximum density at the outlet due to the strong pressure created inside the unit. It is worth highlighting the following pros and cons of the screw machine:

- The device boasts the highest efficiency compared to any other analogues.

- Processing raw materials in screw installations allows us to obtain the highest quality briquettes of an ideal shape with a characteristic cavity inside, which perfectly withstand transportation over long distances and do not crumble during the combustion process.

- One of the disadvantages of such a press is the need to maintain certain operating conditions to ensure a full-fledged work process. For example, a drop in the internal temperature inside a unit can quickly stop a production cycle.

- The cost of such equipment is usually very high, so many owners have to look at more budget-friendly and less productive units.

Making a screw machine will only be possible for experienced craftsmen who know how to use a lathe. In addition, to construct this complex device you will need only the strongest and highest quality steel.

The best option may be an impact mechanical machine, which, in addition to sawdust, is capable of processing straw, stone and wood, coal dust, dried flowers and any other raw materials of various shapes and sizes. The productivity of such equipment significantly exceeds those demonstrated by a hydraulic press, but is inferior to a screw machine.

In this case, the processing process can be automated as much as possible and not be given as much attention as servicing a screw-type unit requires. At the same time, the cost of such machines is too high, so many craftsmen make such structures on their own. As for granulators, they are most often used for processing the smallest raw materials, although some craftsmen use similar installations for double processing, first crushing the raw materials and only then proceeding to compact them into fuel packages.

Comparison of pellet production technologies

Made from wood

Stages of wood pellet production:

- Coarse crushing of wood waste in a hammer crusher.

- Drying chopped wood in a drying drum.

- Fine crushing (bringing it to wood dust).

- Control of humidity in the mixer (if necessary, supply steam or water).

- Pressing and granulating fuel pellets in a granulator press.

- Cooling of finished cylindrical granules in a cooler (temperature 70-90°C).

- Packaging and packaging of finished products in bags.

From sawdust

The production of sawdust pellets proceeds as follows:

- Dry the sawdust so that its moisture content does not exceed 12%.

- Take a sieve and sift the sawdust so that no debris (small stones, leaves, etc.) gets into the granulator.

- Grinding sawdust in a hammer mill.

- If the humidity is below 8%, the crushed sawdust must be fed into the mixer (increase the humidity to 8-10%).

- Granulation of sawdust pellets.

- Cooling and drying of granules in a cooler.

- Packing sawdust pellets in paper bags.

From straw

Production of straw pellets:

- Straw chopping (length up to 4 mm).

- Re-crushing in a mill crusher.

- Drying in a tumble dryer.

- Control of the humidity of chopped straw in the mixer (water or steam supply).

- Pressing and granulation of straw flour.

- Cooling straw pellets in a cooler.

- Packaging of straw pellets.

From the slab

Slab pellets are produced as follows:

- Processing of slabs in a chipper (chip length up to 50 mm).

- Crushing wood chips in a hammer crusher.

- Drying slab chips in a drying drum (humidity from 8% to 12%).

- Fine crushing in a mill crusher (to the state of wood dust).

- Control of humidity in the mixer (if humidity is below 8%, steam or water is supplied).

- Granulation of slab wood flour in a granulator press.

- Cooling of cylindrical slab granules.

- Packing of slab pellets into bags.

From peat

The manufacturing technology for peat fuel pellets is as follows:

- It is necessary to lay out the peat so that it can dry naturally.

- It must be cleared of debris (plant roots, leaves, stones).

- Grinding peat in a crushing machine.

- Dry the peat mass in a dryer to a moisture content of no more than 12%.

- Re-grind (finely crush) in a crushing mill.

- Feed the crushed peat mass into a granulator press with a built-in mixer for peat granulation and steam treatment.

- Cool the peat pellets in a cooling column.

- Pack the finished fuel pellets into bags.

Material manufacturing technology

The production of fuel briquettes consists of several stages:

1. First you need to grind the waste that will be used for the production of elements.

2. Dry clay should be added to the same container, which will serve as a binding link.

3. Now you need to add water to this mixture. Moreover, the gruel should not be too liquid or thick. In any case, the mass should mold well. In addition, the density of the briquette depends on the amount of water.

4. The resulting mixture must be poured into the mold and flattened with a press. Make sure that as much water as possible comes out of the slurry. After this, the resulting products must be thoroughly dried in the sun. In order for them to be durable, each element should be covered with paper or rags. After complete drying, all briquettes can be stacked together.