Today, there are many options for connecting pipes in pipeline structures. The choice of connection depends on various factors, but the material from which the communication elements are made plays a major role. The second important factor is the type of work environment. It is also worth noting that the operating conditions of the pipeline play a big role.

The connection method is selected depending on the type of pipes, their diameter and the purpose of the future pipeline

Types of connections

All existing pipe connections are divided into two main groups:

- detachable;

- one-piece.

The use of detachable connections allows, if necessary, to disassemble the joint section. Thanks to this property, it is possible to repair and replace the joint without compromising the integrity of the pipes. Detachable joints include threaded connectors (fittings) and flanges.

In the case of permanent joints, it is possible to disassemble the pipeline, however, this will lead to damage to the pipe material. The most popular option for permanently connecting pipelines is welding. In addition, there are a number of other methods: gluing, pressing, installing a socket using cement mortar.

All of the above methods are quite popular and are used to connect pipelines transporting various media: water pipelines, heating communications, gas networks, sewer systems, as well as industrial and technical lines.

Welded joints

Welding is a very popular method of joining individual parts in a pipeline structure. This method is especially in demand when installing technical communications in factories.

The most commonly used method for installing steel pipelines is hot welding.

It is worth noting that not only individual parts in metal structures, but also plastic products can be connected by welding. In some cases, welding is also used to join glass parts.

Depending on the method of exposure to the material, there are two main methods of such connection:

- fusion welding;

- pressure welding.

Fusion welding has many implementation options:

- electric arc;

- simple electric;

- electrobeam;

- laser;

- gas welding.

The most popular among these options is the first one. The use of electric arc welding implies that the heating source is an electric arc. This type of work can be performed in two ways:

- with alternating current;

- with direct current.

Helpful information! Butt welding of the connected pipeline elements allows the work to be carried out at lower financial costs. This is due to the fact that welding equipment is less expensive and also requires less energy consumption during installation.

Metal welding can be done with electric or gas equipment

This type of installation can be carried out using various equipment, so three types of welding can be distinguished:

- manual;

- semi-automatic;

- automatic.

Types of welded joints

There are different methods for welding individual parts in pipeline communications. Let's look at them:

- end-to-end;

- overlap;

- corner;

- with welding of various elements.

The most popular and common are the following welding connections:

- Butt (longitudinal and transverse). With this welding option, backing elements - rings - can be used. The seam in such joints can be one- or two-sided. The latter is used in cases where the part has a large cross-section - more than 500 mm.

- Angular (one-sided and two-sided). This option can be done in different ways. In some cases, corner joints are welded with an edge bevel, and in others - without it.

- Socket-welded overlap clutch. The socket connection is used to join pipeline elements with a high ductility coefficient. These include parts made of non-ferrous metals, as well as plastic elements.

In addition, square pipes, which are used in construction and the production of various furniture, are also connected by welding. They are not suitable for installation of pipelines. This is due to the shape of their cross-section - it worsens the flow characteristics, while round is the best option for pipeline structures.

Butt welding is used for pipes whose diameter exceeds 50 mm

Ways to join metal-plastic pipes and PEX pipes

Metal-plastic elements and PEX pipes are often joined using the same method. Here we will describe in detail the technology for installing heat pipes from the above materials.

The connection of metal-plastic pipes is carried out in two ways:

- using compression fittings;

- using press fittings (pressure testing of heating pipes).

Joining pipes with compression fittings

This type of fitting is more convenient to use. Compression fittings can also be used to assemble cold water supply systems. Installation of a pipeline carrying hot water is also carried out by builders using the mentioned fittings.

When assembling the above-mentioned pipelines, there is no need for special equipment for stitching metal-plastic and polypropylene. In order to connect the pipe parts together, you only need a pair of wrenches and pruning shears.

The heating elements are connected according to the following algorithm:

- Initially, a crimp nut is placed on the end of the pipe on the joining side.

- Next, a split-type ring should be put on behind the nut, and the edge of the ring should be placed at a distance of 1 mm relative to the pipe cut.

- Then the pipe is pushed all the way and secured to the fitting fitting. In this case, chamfering the pipe is not required.

- The crimp nut is installed using wrenches.

Compression Fitting Parts and Assembly Procedure

When tightening the nut, it is not recommended to use excessive force, as there is a high probability of cutting through the pipe.

Joining pipes using press fittings

Press-type fittings for metal-plastic pipes, as well as cross-linked polypropylene, make it possible to reliably connect parts of the heating system. Unfortunately, this design cannot be separated in the future. To perform installation in this way, you will need to use a special press tool.

In order to connect the previously mentioned heating elements using fittings, you should follow the following instructions:

- A clamping threaded sleeve must be placed on the end of the pipe.

- Then an expander with the required cross-section is placed into the pipe until it stops.

- The expander handles are slowly connected to each other and fixed in this position for a short time.

- The fitting is inserted into the pipe. Due to its unique molecular composition, the pipes undergo shrinkage, which will help tightly fix the fitting to the pipe.

- The pipe is securely pressed onto the fitting using a manual or hydraulic press.

Crimping using a special tool

Threaded connections

But what to do in cases where it is not possible to carry out welding work? There are quite a few ways to join pipeline elements without welding. The most popular option is threaded installation. Pipe threading is done using cutting machines or an ordinary die. If it is necessary to apply threads to a product with thin walls, use the rolling method.

If you follow all the rules for installing a threaded joint, you will get a durable and sealed structure. Let's consider the main advantages of using such a connection:

- ease of installation.

- the ability to repair or replace without damaging the pipeline;

- installation is carried out without the use of special equipment.

In addition, there are several thread parameters that determine its operation:

- cutting step;

- depth;

- direction.

The pitch determines the distance between the top of the coil and its base. Depth is a parameter that is determined as follows: the distance between the base of the coil and its top is measured. The direction of the thread is an important point; if you ignore it, you may encounter problems when installing the pipeline structure. The thread has two directions:

- right;

- left.

Many types of pipes are equipped with threads; they are used where it is necessary to create a reliable but detachable connection

Thread sealant and sealing

In places where pipeline elements are connected, liquid can flow and gas can escape. To protect yourself from such situations, seal the threaded connections of pipes with thread sealant. The product may look different, but its purpose is the same - to seal joints.

Teflon tape

Among the many sealing materials we can highlight:

- Teflon tape, which is the simplest sealant;

- mastic or red lead paint in combination with tow. This seal has been used for several decades, and is still relevant today;

- sealants containing special solvents.

Important! Choose a high-quality seal that will provide a reliable threaded connection, which is especially important when laying gas pipes.

A one-component paste is also used, with which you can easily achieve reliable sealing of not only threaded, but also other types of fittings and risers.

Important! Work with this sealant is accompanied by quick installation and maximum accuracy. The substance does not shrink and does not pollute the internal cavity of risers.

The great advantage of the material compared to Teflon or tow is that with the help of paste, minimal gaps or cracks in the system are ideally filled, which ensures absolute tightness. This cannot be said about Teflon tape, which can collapse under dynamic loads and contaminate the internal pipe space.

Working with tow is accompanied by some inconveniences in the form of contamination of risers and floors. In addition, it is characterized by strong creep and shrinkage.

Other types of pipe joining without welding

The use of threaded connections is the most popular and widespread method of installing pipeline structures without welding. However, there are other types of pipe connections that are worth paying attention to.

The choice of method, as a rule, depends on the material from which the pipeline is made. All pipes can be divided into two types:

- flexible;

- hard.

The first group includes products that consist of various polymer materials: polypropylene (PP), polyethylene (PE), as well as metal-plastic products. The second group does not have such ductility and includes: steel, cast iron, polyvinyl chloride (PVC), copper, etc.

Important! When installing flexible pipelines, greater coverage of the pipe material is required to ensure a reliable connection than when implementing joints in rigid pipelines.

Threaded pipe connections: pros and cons

The option using threads has its advantages and disadvantages.

On the positive side, threaded connections differ:

- versatility, which consists in the fact that they can be used for twisting risers of various diameters;

- ease of installation, since to carry out the articulation procedure you do not need to be a professional or have any special knowledge. It is enough to have basic skills in handling a wrench or pipe wrench, or other simple skills in this industry;

- lack of sets of special tools or devices;

- resistance to loads, reliability in operation;

- ease of dismantling the entire pipe structure (if necessary);

- tightness, which is ensured by the presence of sealing materials and compliance with basic rules for laying pipelines.

Flaws:

- if there is no thread on the parts, it is necessary to apply it, which can cause additional difficulties, since not everyone has the skills to cut it and not everyone has sets of special tools;

- when the joints have to be frequently mounted and dismantled, rapid wear of the threaded section of the line part is possible;

- There are times when it is necessary to lock the threaded part, since the fitting may gradually unscrew itself.

Taking into account all the pros and cons, in some situations the best option is to use a threaded connection of steel pipes, and in others, other types of joints of pipeline structure elements. This means that there is no ideal way to connect steel risers: all methods are good if they ensure reliability and tightness of the pipeline.

Important! When choosing a method for joining pipe structures, take into account what material the pipes are made of, the location of the possible connection of parts, operating conditions of the pipeline, and what properties the joining of elements of the pipeline system should have.

Important! For galvanized pipes, only a threaded connection is suitable, since during welding work the galvanization will be damaged, after which the riser will be easily exposed to corrosion.

Connecting flexible pipes without welding

Often, in order to install a pipeline without the use of welding equipment, special connecting elements - fittings - are used. Fittings for flexible pipes must have a large reach to make a reliable and airtight joint.

Compression fittings allow you to create a tight connection without welding or threading

As a rule, fittings are used in flexible pipelines that have small or medium cross-sections (from 20 to 315 mm). For parts with a diameter above 315 mm, a fitting joint is not practical. This is due to the fact that the reliability of such a connection is quite low.

For joining low-pressure polyethylene (HDPE) products, special compression fittings are mainly used. The joining of individual elements in a pipeline structure using compression products allows for quick installation, which is also inexpensive and simple.

However, compression products are most often used to connect small diameter pipes. Medium-diameter pipes are connected using couplings. The coupling is perhaps the most common fitting option.

Pvc

Statistics say that when repairing utility networks, about 75% of old risers are replaced with PVC (polyvinyl chloride) pipes. The laying of new communications is also most often carried out using PVC risers. Why is their popularity growing so much?

The fact is that:

- The installation of the main line can be done by yourself. This fact distinguishes risers from similar products made from other materials;

- their cost is quite affordable, which helps save significant money;

- products are durable and reliable;

- the structures are resistant to corrosion processes, which contributes to a long service life.

You can join PVC pipes using:

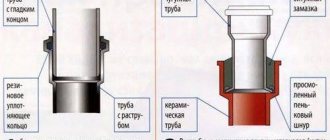

- bells In this way, sewer risers are connected, and rubber rings act as a seal. They can be lubricated with anaerobic sealant, which will significantly enhance the sealing process;

- flanges Such fastening is indispensable in the presence of pipelines that are subject to disassembly associated with frequent periodic maintenance work. This applies to temporary mains, to pipelines that are often moved;

- thermistor type welding, which is used when joining pipes with diameters of 20 mm or more. In addition, cold welding (adhesive bonding) is often used. The procedure is carried out using a special glue, which should be applied with a brush along the entire length of the inner surface of the fitting and along the circumference of the pipe.

Important! Before cold welding, it is necessary to chamfer the ends of the bonded risers at an angle of 15 degrees. To carry out the procedure, chamfered incisors are used.

Connecting rigid pipes without welding

As mentioned above, inelastic pipes are often joined using threads. But there are methods that allow you to connect individual elements of rigid pipelines without the use of welding and threading. Docking without welding equipment is permitted on parts with a diameter of up to 600 mm.

If it is not possible to cut a thread on a rigid pipe or use welding for joining, then the pipeline is mounted using couplings

In order to install a rigid structure without the use of welding equipment, couplings are usually used. The coupling joint allows you to connect the following pipe options:

- equal in diameter;

- with different diameters;

- from various materials.

The connection obtained using such a fitting is characterized by high strength characteristics and good tightness. If it is necessary to connect two pipes without welding and threading, as a rule, special devices are used - flanges. They are also widely used for connecting various equipment to pipes.

Flange connections are recommended for use in cases where a specific section of the pipeline requires frequent inspections or periodic repairs. This is due to the fact that such a clutch is easy to disassemble and reassemble. It includes:

- two connecting flange elements;

- sealing ring;

- nuts and bolts.

Installation of steel pipes

Steel pipes can be joined together using the following methods:

Threaded connection

In this case, it is recommended to use threaded connections of heating pipes in those places of the heating pipeline where it is possible to check the reliability of the joining of pipes to facilitate further repairs of the heating system. In most cases, pipe carving is done using special tools, although the manual method also occurs here.

In order to carry out this procedure, it is initially necessary to remove the outermost part of the pipe, providing the necessary length allowance for the thread. Then use a die to cut the threaded connection. The operation is carried out using a tool fixed on a die holder.

Working with the above device looks something like this:

- The pipe is secured in a vice to prevent twisting.

- The die is carefully placed on the tip of the pipe. In this case, you should be extremely careful to avoid distortion in the connection.

It is also worth listing some recommendations here:

- To make work easier, the surface of the pipe is treated with automotive oil.

- If there is a need to cut threads on a section of pipe located close to the wall, then in this case you will have to resort to die holders with a ratcheting mechanism, which will allow you to completely rotate the tool along its axis.

- In the case of sealing the connections of individual elements of the heating system, a special winding is used for plumbing-type heating pipes.

- Before tightening the threaded connection, you should check the mating ends for stuck chips and burrs.

Rewinding steel pipe threads

Welding connection of heating pipes made of steel

When installing a pipeline, steel pipes are most often joined using an electric welding machine. In this case, the named process involves the presence of metal electrodes, which serve as conductors and act as an “additive” that connects the weld.

Non-standard methods of connecting pipes

In addition to the traditional methods of joining pipes, which are the most common, there are also some special installation methods. Pipes can also be made of non-standard material, which requires a special connection.

Sockets are most often used to connect sewer systems

Let's consider the following docking methods:

- gluing;

- bell joint;

- quick connectors.

The first option is used if the structure is made of plastic. The gluing method allows you to obtain a strong and hermetically sealed permanent connection. Joining pipes in this way is done by applying a special glue to them.

The socket connection is used, as a rule, when installing non-pressure sewer systems. In such systems, wastewater moves naturally at an angle, without the use of a special pump. Depending on what material such a pipeline is made of, there may be a detachable or permanent socket connection. The detachable version of the socket coupling is used when installing plastic communications, and the one-piece version is used when installing cast iron pipes. The socket is sealed in cast iron structures using a cement composition or special sealants.

Helpful information! Quick-release or quick-release connections are installed if the operational features of the communication require its frequent disassembly.

Let's look at the main options for quick-release connections:

- clamps equipped with a fixing wedge;

- cam (Camlok);

- ISO connection.

Flexible pipes and hoses can be connected using quick connect fittings such as Camlok

These clutch options are easy to install and have good strength characteristics.

It is also worth noting that for joining pipes that are used for industrial purposes, the following joints are used:

- nipple;

- telescopic;

- articulated.

The first option is used in cases where it is necessary to connect pipes with any measuring equipment, and the second - when joining rigid pipes equipped with flexible elements. The hinged type is used in the construction of highways with complex shapes. This connection allows you to compensate for the effect of twisting the pipeline.

How and what to seal pipe joints with

Types of seals, sealing methods

To prevent leakage of the pipeline working fluid, it is necessary to properly seal the pipe twists.

When threading steel pipes, the following are used as seals:

- gasket This method of sealing a threaded connection requires relatively thick end pipe cuts. The presence of smooth pipe ends can never ensure tightness. When using a rubber or plastic gasket, this problem is successfully solved. This option is ideal in case of articulation using a union nut;

- winding The materials can be linen strands, polymer threads, FUM tapes in combination with hardening sealants, paints, pastes.

When installing plastic risers, a sealing method is used based on the deformation properties of the material. The essence of this method is that a plastic pipe with an external thread is screwed into a riser with an internal thread. During deformation, plastic contributes to excellent filling of the intermediate space, eliminating the appearance of gaps.

When it comes to pipeline structures with high pressure, cylindrical threaded pipe connections are not entirely appropriate here. In such cases, a conical type connection is used. The principle of connection is that when screwing in, the pipes are tightly pressed until the gap completely disappears.

Materials for sealing joints

To make the joint impenetrable, the following are used as seals:

- flax (tow);

- asbestos;

- FUM tape;

- natural drying oil;

- whitewash;

- minium;

- graphite lubricant, etc.

A reliable sealant when twisting steel pipes onto threads is strands of flax impregnated with red lead or white lead. This connection is easy to install and reliable in terms of sealing. The seal has been used for a very long time and does not lose its popularity today, despite the emergence of artificial analogues.

For those who have little experience in installing fittings and pipes, we suggest that under no circumstances use flax without paint.

At first, the joint will not allow moisture to pass through. But several months will pass, the flax fibers will get wet and begin to decompose. Therefore, the quality of all connections will deteriorate, and in another month or two, water will leak at the junction.

Important! The fibers must be thoroughly impregnated with red lead or whitewash so that not a single dry strand remains.

When operating pipelines with a working environment temperature higher than the boiling point of water, the best sealant option is asbestos thread together with flax strands. To do this, they are impregnated with a mixture of graphite and natural drying oil.

Important! You need to coat the joint with the strands first with red lead, and then with whitewash, and not vice versa.

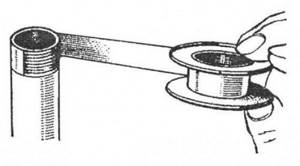

Before use, the strands are combed out so that the fibers can be separated well.

Important! The strands must be wound “behind the thread” and then soaked with paint. If you lay the tow against the cutting direction, then when screwing on the coupling it will all come out to the sides and you will have to start all over again.

Important! To avoid clogging of the risers, you need to ensure that the tow does not hang from the end or get inside the riser.

Many people use FUM tape, which is in no way inferior to old traditional materials - tow with paint.

Sometimes there is no tightness at the junction of the risers. To eliminate this defect, you need to replace the sealing material, and clean the threaded area from dirt and sealant residues. After this, rewind the linen thread, FUM tape or other sealant, and assemble the structure.

Pastes and sealants of chemical origin are used as additional sealants, which will help strengthen this section of the pipeline.

Features of connecting profile pipes

Profile pipes have good strength and relatively low weight, so they are often used for the installation of frame structures, as well as for other construction purposes.

The shape of profile pipes can be:

- rectangular (the most common shape);

- square;

- ovoid (oval);

- others (more complex forms).

The most reliable way to create structures from profile pipes is to fasten them by welding

Electric arc welding is usually used to connect square pipes. There are also special connections that are made using bolts and rivets. Square and rectangular pipes are joined using the same methods.

In addition, various parts can be joined to such pipes. This joining is carried out using self-tapping screws. These elements do not require preliminary holes.

Connecting profile pipes without welding

Joining of profile pipes can be carried out without the use of welding equipment. How to connect profile pipes without welding:

- use of a crab system;

- fitting connection.

The crab system for pipes consists of connecting brackets and fixing elements. The connection in this case is made using nuts and bolts and ultimately forms an “X”, “G” or “T”-shaped profile structure. With this connection you can connect from 1 to 4 pipes, but only at right angles. They are as strong as welded seams.

A fitting connection is used when it is necessary to make a branch from the main pipe. There are several types of pipe connectors that allow you to mount workpieces in different configurations. The main ones:

- coupling;

- corner;

- tee;

- cross.

Crab systems are most often used when installing simple outdoor structures, such as a greenhouse or shed

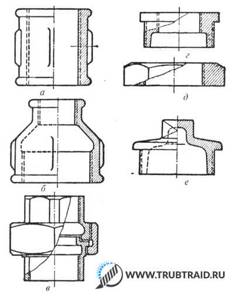

Malleable cast iron and connecting parts made from it

The most common ductile iron parts for connecting steel pipes and other pipeline parts are: A) straight couplings B) reducing couplings C) coupling nuts D) fittings E) locknuts E) plugs.

To completely seal the system with a threaded connection, it is necessary to use sealants, for example, gaskets. In addition to them, for other types of fastening additional parts are used. If it is necessary to connect the elements of the pipeline using flanges, that is, without a coupling, then in addition to gaskets, bolts are also needed.

When connecting risers at an angle, they use connecting parts made of ductile cast iron: straight and transition angles, tees, crosses.

Important! The connection will be of high quality and function flawlessly for a long time if, when installing parts, you use parts with straight ends that will be placed at right angles to the connecting parts.

You should pay attention to the threads on the parts, which should be free of burrs and clean.

A cast iron coupling has a low collar around the entire perimeter of the end circumference, which serves to increase the strength of the part, unlike its steel counterpart, which does not have such an element.

The quality of connections depends not so much on the sealing methods and materials, but on the craftsman and the quality of his work. If he is responsible, neat, has basic plumbing knowledge and skills in working with a wrench or pipe wrench, then you won’t find a better specialist. If you follow the basic rules for installing pipeline systems, the pipeline will function for many years. This can be confirmed by anyone who has at least once installed a pipeline system, even the shortest and simplest one.

Try it yourself, experiment and see that you are the best specialist in installing pipeline systems using the threaded method of connecting pipeline elements.

How to connect pipes from different materials?

In some cases, it is necessary to connect products that are not homogeneous in material. There are special options for these purposes.

How to connect a polypropylene (plastic) pipe to a metal one?

Many people ask the question: how to connect polypropylene pipes with metal ones? There are several popular methods for this:

- thread;

- flange pipe connection.

In the first case, the coupling of pipes of heterogeneous material is carried out using couplings. One end of such a coupling is equipped with a thread, and the other has a smooth surface for joining with polypropylene.

The flange method involves the use of flanges. This connection is made using studs and bolts.

Note! Flanges are used in structures that are often disassembled during operation.

How to connect metal-plastic pipes with metal ones?

The most popular options in this case are:

- press fittings;

- compression fittings.

In the first case, the connection between pipes of heterogeneous material can be made in two ways:

- sliding press fitting;

- crimp coupling.

It is important to remember that connecting metal-plastic pipes with metal and other pipes of heterogeneous material is quite a responsible undertaking and should be carried out by specially trained specialists. Incorrect installation of the connecting element will lead to an emergency in the pipeline.

Options for joining copper pipes

When assembling heating, various installation methods are used. Thus, the joining of copper pipes is carried out using a dismountable and non-dismountable method. In the first case, flanges, threaded fasteners, and fittings are used that lock automatically. When constructing a non-separable heating system, they resort to pressing, soldering and welding.

Welding joint

Let's look at the process of welding copper pipes. This joining technique is applied to pipes with a diameter of 108 mm or more. The wall thickness of the heating material must be at least 1.5 mm. In this case, it is only necessary to carry out welding work end-to-end, and the proper temperature should be 1084 degrees. It is worth adding that this heating installation option is not recommended to be done with your own hands.

Today, builders use several types of welding work:

- Gas welding using oxygen acetylene torches.

- Welding with consumable electrodes, performed in an environment of inert gases - argon or helium.

- Welding that uses non-consumable electrodes.

In most cases, the arc welding method is used to join copper elements. If the pipes that are planned to be used for pipeline assembly are made of pure copper, then it is necessary to use infusible tungsten electrodes in an environment of argon, nitrogen or helium. When welding copper elements, the process must proceed quickly. This will prevent the formation of various oxidations on the metal base of the pipe.

Welding joining of copper pipes

To give strength to such a connection, upon completion of the joining work, it is recommended to carry out additional forging of the resulting connections.

Connection by flaring

It happens that the use of welding torches when installing heating systems creates some inconvenience. In this case, it is recommended to resort to flaring of copper pipe connections. This installation method will be detachable, which will play a positive role in the event of forced heating assembly.

An operation of this kind will require the presence of a flaring device. We will try to describe in detail how to connect heating pipes by flaring below:

- first, the tip of the pipe is cleaned in order to remove from its surface any burrs and burrs formed when cutting the material;

- a coupling is fixed on the pipe;

- then the pipe is inserted into a clamping device, with the help of which further flaring is carried out;

- then you should begin to tighten the tool screw until the angle of the pipe end reaches 45 degrees;

- Once the pipe area is ready for connection, you should bring the coupling to it and tighten the nuts.

You can learn more about the process from the presented video.

Press connection method

In addition to all of the above methods for installing heating pipes, there is also a pressing method. To join the copper elements in this case, it is necessary to insert the previously prepared end of the pipe into the coupling until it stops. After this, you will need to use a hydraulic or manual press to fix the pipes.

If the heating is planned to be assembled from thick-walled pipes, press fittings with special crimp sleeves will be required. These elements make it possible to compress pipes and fittings for heating from the inside, while external seals provide excellent tightness of the structure.