Ventilation refers to communications, the installation of which is planned at the stage of creating a private house construction project. This is justified by basic sanitary and hygienic requirements. Without proper air exchange, comfortable living is simply impossible.

We will tell you how to insulate a ventilation pipe to ensure its normal operation in winter. From the article we present you will learn which thermal insulation materials meet modern requirements. You will understand how to choose the best option for insulation.

Interested DIYers will find brief instructions on how to install a thermal insulation barrier. Those who decide to insulate the hood themselves will receive information proven in practice. Compliance with our recommendations is a guarantee of a successful result.

Why insulate the ventilation system

Ventilation is designed to remove contaminated air from the room; it provides appropriate sanitary and hygienic conditions for people. A person releases a lot of moisture during breathing; Bathing, washing, drying, ironing, cooking, washing dishes are also associated with water evaporation.

From residential buildings and offices, the air carries away excess moisture, carbon dioxide - a product of respiration, odors, dust, and sometimes smoke that gets into the air due to improper operation or lighting of the stove or fireplace. A hood over a gas stove removes combustion products and food odors.

Regardless of whether there is natural or artificial ventilation in the room, when it leaves the heated volume, the outer pipe cools and moisture from the air settles on the cold walls.

When it comes to stove hood, combustion products containing sulfur oxides, some chlorine, and nitrogen oxides are mixed with the water. When combined with water they form aggressive acids. Few acids are formed, ventilation is not the chimney of a solid fuel unit, but they can damage the ventilation duct or surrounding structures if they leak out through the joints.

Condensation usually flows out into the air intake hole and drips down - onto the floor, walls, onto the stove, and into food.

Thermal insulation of air ducts increases the speed of air movement upward and the quality of ventilation.

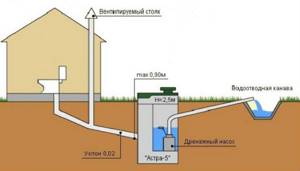

Fan sewer pipes are another type of air ducts that go outside. They remove odors from the sewer system and equalize the pressure in the system when draining a large volume of water. If cast iron or steel pipes are used for their installation, the heat-conducting metal is cooled, lowering the temperature of part of the air duct in the room.

In this case, condensation settles on the outer surface at the top of the room. The result is dirty streaks, wetting of the floor structures, wetting of the insulation in the floor, damage to the decorative lining of the air ducts.

It is also necessary to insulate the air supply ducts to heating units and the supply ventilation ducts - condensate settles on them from above.

Industrial ventilation to a greater extent removes toxic impurities and dust generated during production processes. To effectively remove contaminated air, not only general supply and exhaust ventilation is often used, but also local suction. Sometimes excess heat is removed along with the air. Since industrial systems have greater power and dimensions, thermal insulation of boxes is even more important for them than for domestic systems.

The main goal of thermal insulation of a ventilation system is to ensure that the dew point falls into the insulation and not onto the wall of the air duct, and condensation does not settle on the walls (no matter inside or outside).

In what places should pipes be insulated?

Thermal insulation is necessary for the surface of the air duct outside the heated volume - in the cold attic and on the roof. There is no need to insulate air ducts when passing through an attic or a heated second floor. Supply ventilation ducts, fan ducts, air supply pipes to heating devices are insulated inside heated rooms and buffer zones - basements, storerooms, auxiliary rooms, boiler rooms.

Do I need to insulate ventilation pipes in the attic?

In the attic, it is necessary to insulate the air ducts first. Warmer air moves through the ducts, creating a greater temperature difference between the air in the duct and the air in the attic. Advantages of insulation

The need for thermal insulation of ventilation air ducts, at first glance, is not at all obvious. Previously, in both private and apartment buildings, thermal insulation of ventilation ducts was rare (although brick is also a good insulator). However, this measure helps to avoid many negative aspects associated with the accumulation of moisture in ventilation pipes and shafts.

Negative consequences of lack of insulation

The main unpleasant consequence of missing thermal insulation of air ducts is the settling of moisture on the internal (sometimes external) walls of the air ducts, moisture entering the room, wetting of building structures, insulation in the ceiling or roof.

Water settling on the walls and flowing into the room brings a lot of trouble - damaged flooring or walls, drops above the stove, wet ceilings, insulation, wooden structures.

In northern regions with long, cold winters, condensation can freeze on the walls and block the internal cross-section of the ventilation duct.

Why is condensation dangerous?

Exhaust ventilation condensate differs from condensate in stove and fireplace pipes. The condensate contains almost pure water and dust. Only from the kitchen hood does soot and a small amount of acid-forming oxides enter the pipe. The aggressiveness of such a composition is low, but if it gets on building structures (if there are leaks in the hood duct) and on the hood fan, they will be destroyed more severely.

A stainless steel pipe will corrode a little faster, but in practice this is difficult to determine, because the service life of stainless steel is tens of years. The situation is worse with structures made of galvanized steel - they are less resistant to acids. But this is all theory; in practice, it is difficult to understand that the pipes lasted a year or two or three less than the required period. So don't get too hung up on condensation in your air ducts.

But it is important to install the air ducts themselves correctly and hermetically. Some aggressive substances also end up in the drain pipe. But they do not penetrate into the room, but are washed away by a current of water. The acid solution is not dangerous for plastic boxes.

Purpose of thermal insulation of air ducts

The installation of ventilation ducts and air ducts is subject to technical rules that dictate the choice of pipes, their placement, connection methods and mandatory thermal insulation if communications pass through unheated areas.

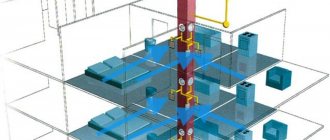

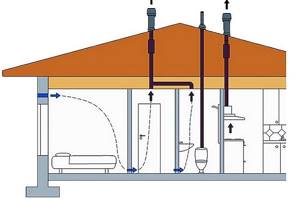

Ventilation pipes run throughout the entire space of the house: they start in the basement, which is often used as a technical or utility room, and end above the roof.

Not all rooms of the house are heated. Often the temperature in the basement and attic is low, which causes problems, the main ones being heat loss and condensation.

Ventilation diagram in a private house. If you are careless about the thermal insulation of the attic and roof, you will have to make more efforts to insulate the air ducts located under the roof

The rules for arranging ventilation are set out in SNiP 41-01-2003 . There you can also find information about heating and air conditioning in general.

Thermal insulation of household ventilation air ducts performs 4 functions:

Image gallery

Photo from

Function #1 – reduction of heat loss

Function #2 – prevention of condensation

Function #3 – providing fire resistance

Feature #4 – noise and vibration reduction

Each of these functions is very important. For example, condensation can cause big problems for home owners. Moisture that forms on the outer walls of pipes causes corrosion of the metal and in a short period of time can lead to the complete replacement of some ventilation sections. Mold forms on the walls of the attic, destroying the wood and creating an unpleasant odor.

Internal condensation is no less dangerous. Moisture seeps through the walls of pipes into living spaces and also causes negative consequences: it increases the overall level of humidity, causes deformation of wooden furniture and decoration, the appearance of fungus and mold, and poor health among residents.

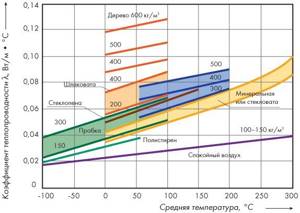

A graph showing the dependence of the thermal conductivity coefficient of modern insulation for ventilation on the air temperature in unheated and residential premises

Both the decrease in temperature in the bedrooms and extraneous noise that disturbs sleep are all the result of cooled ventilation pipes. If you are familiar with the problems listed above, then you can cope with them yourself by insulating the air ducts. First you need to choose the right thermal insulation material.

Internal or external insulation - which is better?

And how do you imagine internal thermal insulation? Just imagine the installation and operation of air ducts with internal insulation:

- It is extremely difficult to insert foam shells into a pipe; It is simply impossible to insert mineral wool shells and reliably isolate them from passing gases. Theoretically, the installation of insulation can only be carried out in parallel with the installation of the pipe - mount a module, insulate it, mount the next module, and so on, but how, I wonder, can you repair or dry the internal thermal insulation in emergency situations?

- After squeezing the heat insulator into the pipe, it must be secured. How?

- Ventilation is not a chimney, but the air ducts also need to be cleaned sometimes - dust, sticky soot from a frying pan, spiders with cobwebs have not been canceled. All materials that can be inserted inside the duct are soft (compared to steel or plastic pipes) and can be damaged when cleaning.

- Increasing the diameter of the air duct by 100-150 mm will also be expensive - stainless steel is expensive. Plastic, of course, is not so expensive, but installing an air duct with plastic thermal insulation extending beyond the roof is a dubious idea. Holes in walls and ceilings will also have to be enlarged. This issue should be resolved at the building design stage.

The question of choosing between external and internal thermal insulation of air ducts is always decided in favor of technologically advanced external insulation.

Methods and materials for insulation

According to their design, ventilation systems are divided into two categories:

- household engineering networks. The equipment is a small piping with a low level of branching; it operates on the basis of natural draft or on the principle of a forced air exchange system. Household models are used in furnishing homes and office buildings;

- industrial waste stream removal systems. Air ducts of this category are used in buildings with an extensive ventilation network with powerful fan installations, for example, in station buildings, factory floors, airport terminals, and shopping centers.

Methods of thermal insulation of air ducts and current materials are determined depending on the norms and requirements of SNiP.

Insulation of a household ventilation system

Thermal protection of air exchange pipes of a household network is carried out using traditional materials and a new generation of insulation, including:

- mineral wool;

- Styrofoam;

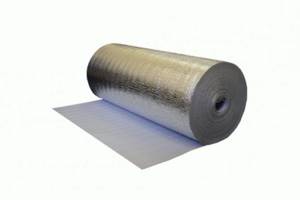

- foamed polyethylene - penofol - with foil coating;

- asbestos in the form of mortar or slabs.

Mineral wool

The fibrous material has an extremely low thermal conductivity coefficient, but is highly hygroscopic and easily loses its performance when exposed to moisture. Mineral insulation is used in combination with a waterproofing material, for example, a special membrane with a foil surface. Most often, mineral wool in the form of rolls with a layer thickness in the range of 40-80 mm is used to insulate air ducts.

Styrofoam

Expanded polystyrene boards are relevant for thermal protection of ventilation ducts of square or rectangular cross-section.

Foamed polyethylene

Factory-made cylindrical penofol shells are highly efficient and easy to install. Rolled material is used by fastening with clamps or wire. Foamed polyethylene has a lower heat capacity than mineral wool and is sold in the inexpensive segment. The pipe will have to be wrapped in several layers of this insulation due to the small thickness of the material.

Asbestos insulation

Asbestos solution is used to insulate pipes of any cross-section. An important condition for the use of an insulating composition in the outdoor sector of the ventilation duct is the installation of a box made of tin or roofing felt for protection from external influences.

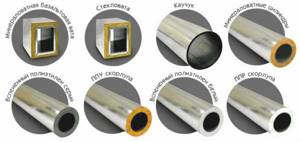

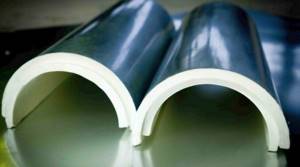

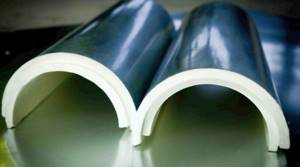

Thermal insulation shell

Shells in the form of cylindrical blanks for pipe insulation are made based on various components, including:

- glass wool;

- basalt wool;

- rubber;

- foamed polyethylene;

- expanded polystyrene;

- polyurethane foam.

Monolithic shell models are used during the installation of ventilation pipes. Collapsible versions and modifications of cylinders with a cutting line are installed on existing ventilation duct units. Thermal insulation shell is especially relevant in places where pipes are laid through a wall or floor slab. The cost of the shell varies depending on the base material: polyurethane foam models are sold in the expensive segment, while analogues made of mineral wool and polyethylene foam are offered at relatively affordable prices.

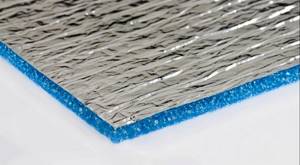

Self-adhesive insulation

Penofol grade “C” with a foil surface has a polyethylene film with an adhesive composition on the back side. Self-adhesive thermal insulation for air ducts is presented in most construction stores in Moscow and the regions, and is in demand as an effective material for self-insulating ventilation pipes.

Penofol grade “C” - material for thermal insulation of air ducts

Thermal insulation of industrial ventilation networks

The same insulation materials in the form of rolls, slabs and solutions are in demand here as for thermal protection of a household ventilation system. However, unique technological developments, for example, polyurethane foam, are also relevant for industrial insulation of air ducts. The air-foam composition is applied under high pressure using special equipment. The foam structure easily adheres to the pipe, tightly envelops the base, providing an effective thermal barrier.

A new word in the design of industrial ventilation systems is air ducts with factory-made thermal insulation. Among the offers of well-known brands for the production of climate control equipment there are ready-made models of pipes and assemblies with various thermal insulation materials in the form of mineral wool, penofol, polyurethane foam and expanded polystyrene.

Insulation for domestic premises

Below I will consider their types of insulation for ventilation ducts.

Mineral wool

This is usually called glass fiber wool. Flexible mats of different thicknesses are usually used. Durable, does not rot, does not decompose, and is not afraid of ultraviolet radiation. Cannot be used at high temperatures - for thermal insulation of chimneys with high flue gas temperatures and industrial chimneys.

Mineral wool must be covered on top with a shell - fiberglass, roofing felt, penofol, and insulated from moisture.

This is not the best type of thermal insulation - after a few years the wool cakes, in addition, it absorbs moisture. But with a well-assembled ventilation duct, it can be used indoors, but not for thermal insulation of supply ventilation. A serious drawback is that this is precisely the type of insulation that during installation contaminates everything around with small fragments of glass filaments.

Basalt wool

Basalt (stone wool) is made from basalt melt. This is a higher quality type of mineral thermal insulation, resistant to aggressive environments, high temperatures, ultraviolet radiation, and moisture. Belongs to the group of non-combustible materials.

Basalt wool is produced in the water of mats, slabs, and pipe shells. If the finished products are not covered with a shell, the mats and slabs must be covered additionally. Self-adhesive boards with an adhesive layer are produced. The disadvantage of basalt thermal insulation is that it absorbs moisture.

Foamed polyethylene

Available in the form of sheets up to 10 mm thick, shells and bundles. Shells and sheets may have a foil coating. The cheapest of all types of thermal insulation.

Disadvantages: not available in large thicknesses, burns, is not resistant to high temperatures and ultraviolet radiation. Plastic, durable material. Not as flexible as rubber. Practically does not absorb moisture and does not allow steam to pass through. Very widely used in construction.

Foamed synthetic rubber

A relatively new flexible closed cell foam. Sheets, thin plates, and pipes are produced. Thermal insulation pipes made of rubber are designed for air ducts with an outer diameter of up to 160 mm. Layer thickness – up to 32 mm. There are products with a self-adhesive layer. Operating temperature – from -200 to +175 °C.

Self-extinguishing material. Poorly absorbs water and allows steam to pass through. The big advantage is flexibility. Foamed rubber is very convenient for thermal insulation of non-circular air ducts, fittings, and joints of air duct elements. The disadvantage is that the price is higher than that of mineral wool or polyethylene.

Expanded polystyrene

Expanded polystyrene is the correct name for the granular white foam familiar from childhood. Often called penoplex. There are expanded (foam plastic) and extruded, or extruded - denser and stronger sheets, products (shells) of different colors.

Expanded is called polystyrene foam, extruded - penoplex or expanded polystyrene. Shells are produced for pipelines with a diameter from 32 to 160 mm. The thickness of sheets and shells can reach 100 mm.

Penoplex is a frozen foam made from closed air bubbles with a diameter of 0.1-0.2 mm. Does not absorb water at all and does not allow steam to pass through. Refers to self-extinguishing materials. Density from 25 to 70 kg/m³. For thermal insulation of air ducts, low-density products are used.

Tolerates negative temperatures well and is not resistant to ultraviolet radiation. Very durable - without ultraviolet radiation it can last 50 years or more. Previously, industrial refrigerators and rooms - refrigeration chambers - were insulated with granular polystyrene foam. They have already lasted 60 years, but when disassembling the refrigerators, the foam looks like new. They produce ready-made shells for thermal insulation of pipes of different diameters.

Styrofoam

Polystyrene foam - expanded polystyrene foam - is a familiar white lightweight packaging material made from individual grains. Low density and strength, easily disassembled into grains, can take on a little water. Used for thermal insulation of only well-fixed air ducts.

It is necessary to protect it from ultraviolet radiation, do not touch it - in principle, the thermal insulation will stand for two or more decades. If you have a choice, it is better to choose extruded polystyrene foam - it is denser and does not absorb water at all.

Asbestos boards

Foam asbestos boards have low thermal conductivity and density, can operate at temperatures up to 400 ° C, are resistant to ultraviolet radiation, and do not absorb water.

Previously, due to its natural qualities, asbestos was very popular as a building material. It has now become clear that asbestos is a carcinogen, and its entry into the body is harmful. Therefore, it cannot be used inside buildings; external thermal insulation with asbestos should also be abandoned.

PIR boards

PIR is one of the most promising thermosetting materials. Polyisocyanurate is a polymer material similar in composition to polyurethane. Externally similar to polyurethane.

This is a rigid material with closed cells, low thermal conductivity, does not absorb moisture, and is non-flammable. Its UV resistance is higher than that of polyurethane. Operating temperature range – from -75 to 120 °C. Service life - more than 50 years. Rigid sandwich panels are made from it. In the world it wins approximately 3% of the market for thermal insulation materials.

In our country, PIR thermal insulation is not very widespread yet. They produce slabs with cladding - steel sheet, aluminum foil, fiberglass, kraft paper. Slabs with soft cladding are used like other thermal insulation; air ducts can be installed directly from slabs with hard lining. This type has special tongue and groove or quarter locks (like a tongue and groove board).

Where to choose

It is important to insulate the air ducts, and it is advisable to choose thermal insulation that has no disadvantages, is easy to install, and inexpensive. The most promising material is PIR boards. But they cannot be used to insulate a round air duct.

Mineral wool absorbs moisture and can create additional difficulties, and is also inconvenient to install. Asbestos is carcinogenic - we don’t use it. Foam rubber is quite expensive, you will have to wind several layers. Penofol - you will also need several layers. Penofol or rubber are good for thermal insulation of difficult places - joints, corners.

In practice, the choice comes down to the use of extruded polystyrene foam - in the form of slabs for square air ducts or shells for round ones. Expanded foam has very little strength, so it can only be used where no one will touch it - in the attic or basement.

How to insulate a hood in a private house

Thermal insulation of a hood is no different from ventilation insulation. The air temperature above the stove is not too high, there is no danger of fire or melting of the thermal insulation, and there are no special fire safety requirements for the hood. Therefore, you should not complicate the choice of material - the same polystyrene foam is quite suitable.

Self-adhesive insulation for indoor air ducts

I would like to dwell separately on self-adhesive insulation for ventilation, as a very convenient option for doing the work yourself. First of all, it is necessary to indicate that this is grade “C” penofol. On one side, foamed polyethylene is trimmed with foil, on the other, with polyethylene film, on which an adhesive composition is applied. The latter is covered with another layer of film, which is removed before installation.

Self-adhesive thermal insulation material is simply cut to the required size, which should correspond to the perimeter of the air duct, and then they cover the pipe with it, pressing it with their hands to its surface. The edges of the insulation are overlapped up to 5 cm and covered with foil tape.

Insulation for industrial systems

For insulation of industrial ventilation air ducts, all the materials described earlier in the section on domestic premises and some other products are used.

Polyurethane foam

Polyurethane foam is polyurethane foam, a very common synthetic elastomer. For thermal insulation of air ducts, solid polyurethane foams are mainly used. They are used to produce all kinds of pierced mats and shells for insulating round pipelines.

Often the shells are covered with a shell made of galvanized steel, fiberglass, polyethylene, or fiberglass. Polyurethane foam is resistant to moisture, has high strength, durability, and is not resistant to ultraviolet radiation. Operating temperature range – from -60 to +80 °C. A good thermal insulator, and also affordable. The method of spraying polyurethane foam onto insulated surfaces is also used. In everyday life, foam is used in aerosol cans; in production, industrial units are used.

In terms of price, this is a relatively inexpensive thermal insulation option. If selected in aerosol packaging, the price increases. Products made from polyurethane foam are also produced for large-diameter pipes.

Thermally insulated air ducts

Installation of air ducts with applied thermal insulation is much faster than traditional assembly with subsequent insulation. But their price is much higher. For insulation, polyurethane foam coated with fiberglass, fiberglass, or polyethylene is usually used.

What is better to choose

The choice of thermal insulation for industrial pipes depends on many conditions:

- Air duct sizes.

- Air duct shapes.

- System locations. In the workshop and ventilation chamber (and now also in the heat recuperator) most of the system is often located, only small pipes for air intake or exhaust are located outside the room. It can be cold in the workshops in winter, down to negative values, so the air ducts in the room require thermal insulation.

- Exhaust gas temperatures and fire requirements.

- It depends on whether a new workshop is being built, an old production facility is being modernized, or thermal insulation of air ducts is simply being installed in an old workshop.

If local suction is insulated in hot shops, then it is often necessary to use mineral and basalt wool - they have the highest operating temperature. The cost of materials is also of considerable importance.

When thermally insulating air ducts in an old production facility, you should take into account the expected service life of the equipment and the building as a whole: if this period is 15-20 years, then perhaps you should not choose modern expensive materials, but make do with more budget-friendly options. It’s a completely different matter when launching new lines or workshops - it makes sense to use ready-made thermal insulation or pipes with a potential service life of 50 years.

Nowadays, ready-made shells with a coating layer are being chosen more and more often. They do not need to be protected from ultraviolet radiation or atmospheric moisture.

Indications for insulation of air ducts

Most often, the following factors motivate urgent action to insulate the ventilation system:

- rust formation on pipes;

- violation of the tightness of the air exchange channel;

- reducing the intensity of fresh air flow;

- detection of moisture on walls and ceiling areas along the path of ventilation equipment.

Experts note that it is better to insulate air ducts during the installation of the pipeline in order to ensure efficient operation and durability of the equipment.

Advantages and disadvantages of ready-made insulated pipes

The main disadvantages are the price and a limited range of standard sizes. For large production systems, pipes may not be suitable. But in a private house, factory-insulated pipes make work much easier. The big advantage is quick and easy installation.

The considerable price is also a moot point: if you count the cost of installing a conventional pipe, its thermal insulation and labor costs, it will be more expensive. Another drawback is that such products are sold only in large stores, while penofol and shells made of PPU or PPS lie literally on every corner.

Ventilation aerators

Installation of roof aerators

A roof aerator is a modern and convenient type of ventilation. It is a pipe covered with a cap on top. Aerators remove steam, moisture and stagnant air, providing ventilation for a cold attic in a private home. Aerators are installed on roof slopes, where air movement is ensured by differences in temperature and pressure, replacing ridge vents. Aerators can be continuous or point. Point aerators are equipped with fans and guarantee good air movement. Outwardly, they resemble fungi.

Continuous aerators are a plate along the ridge with holes. Being covered with a roof on top, they are practically invisible and provide intense air movement due to the large area of the holes.

Various types of aerators are created specifically for roofing from:

- bitumen shingles;

- flat roof;

- metal ceramics;

- ceramics.

Aerators are installed only where eaves vents are provided. There are other conditions for their installation:

- Only roofs with a slope of 15 - 45 degrees are suitable;

- a distance of at least 30 cm is maintained from the chimney or wall;

- aerators look 25 cm above the slot at both ends of the ridge;

- point models are mounted no further than 50 cm from the ridge.

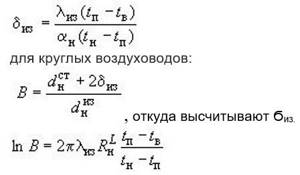

How to calculate the thickness of insulation

The thickness of the thermal insulation is calculated according to SP 61.13330.2012 Thermal insulation of equipment and pipelines (SNiP 41-03-2003), Appendix B.2.4 and B.2.3.

When calculating, the thickness of the pipe wall is neglected, since it is small, and metal also has high thermal conductivity. The indoor temperature is assumed to be 20 °C, outdoor temperature is the minimum winter temperature, relative humidity is 70% for residential premises and 100% for bathrooms, toilets, saunas, and laundries. We calculate the estimated temperature difference (in the ventilation duct and on the surface of the thermal insulation) at a given humidity.

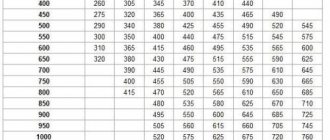

Table B.4

| Design difference, °C | Relative humidity , % | |||||

| 40 | 50 | 60 | 70 | 80 | 90 | |

| 10 | 13,4 | 10,4 | 7,8 | 5,5 | 3,5 | 1,6 |

| 15 | 14,2 | 10,9 | 9,1 | 5,7 | 3,6 | 1,7 |

| 20 | 14,8 | 11,3 | 8,4 | 5,9 | 3,7 | 1,8 |

| 25 | 15,3 | 11,7 | 8,7 | 6,1 | 3,8 | 1,9 |

| 30 | 15,9 | 12,2 | 9,0 | 6,3 | 4,0 | 2,0 |

The thickness of the heat insulator is calculated using formulas.

For rectangular and square ventilation ducts:

- λiz – thermal conductivity coefficient of insulation;

- αн – heat transfer coefficient; accepted for surfaces with a high emissivity equal to 7 W/(m2*°C), for surfaces with a low emissivity equal to 5 W/(m2*°C);

- tв – temperature of air masses inside the ventilation duct;

- tо – air temperature;

- tп – temperature of the thermal insulation surface;

- diz – diameter of thermal insulation;

- dtr – diameter of the air duct;

- Rн – thermal resistance of thermal insulation (tabular data).

Table B.3. Approximate values of Rн, m °C/W

| Nominal pipe diameter, mm | Indoors | On open air | |||||||

| For surfaces with low emissivity | For high emissivity surfaces | ||||||||

| at coolant temperature, °C | |||||||||

| 100 | 300 | 500 | 100 | 300 | 500 | 100 | 300 | 500 | |

| 32 | 0,50 | 0,35 | 0,30 | 0,33 | 0,22 | 0,17 | 0,12 | 0,09 | 0,07 |

| 40 | 0,45 | 0,30 | 0,25 | 0,29 | 0,20 | 0,15 | 0,10 | 0,07 | 0,05 |

| 50 | 0,40 | 0,25 | 0,20 | 0,25 | 0,17 | 0,13 | 0,09 | 0,06 | 0,04 |

| 100 | 0,25 | 0,19 | 0,15 | 0,15 | 0,11 | 0,10 | 0,07 | 0,05 | 0,04 |

| 125 | 0,21 | 0,17 | 0,13 | 0,13 | 0,10 | 0,09 | 0,05 | 0,04 | 0,03 |

| 150 | 0,18 | 0,15 | 0,11 | 0,12 | 0,09 | 0,08 | 0,05 | 0,04 | 0,03 |

| 200 | 0,16 | 0,13 | 0,10 | 0,10 | 0,08 | 0,07 | 0,04 | 0,03 | 0,03 |

| 250 | 0,13 | 0,10 | 0,09 | 0,09 | 0,07 | 0,06 | 0,03 | 0,03 | 0,02 |

| 300 | 0,11 | 0,09 | 0,08 | 0,08 | 0,07 | 0,06 | 0,03 | 0,02 | 0,02 |

| 350 | 0,10 | 0,08 | 0,07 | 0,07 | 0,06 | 0,05 | 0,03 | 0,02 | 0,02 |

| 400 | 0,09 | 0,07 | 0,06 | 0,06 | 0,05 | 0,04 | 0,02 | 0,02 | 0,02 |

| 500 | 0,075 | 0,065 | 0,06 | 0,05 | 0,045 | 0,04 | 0,02 | 0,02 | 0,016 |

| 600 | 0,062 | 0,055 | 0,05 | 0,043 | 0,038 | 0,035 | 0,017 | 0,015 | 0,014 |

| 700 | 0,055 | 0,051 | 0,045 | 0,038 | 0,035 | 0,032 | 0,015 | 0,013 | 0,012 |

| 800 | 0,048 | 0,045 | 0,042 | 0,034 | 0,031 | 0,029 | 0,013 | 0,012 | 0,011 |

| 900 | 0,044 | 0,041 | 0,038 | 0,031 | 0,028 | 0,026 | 0,012 | 0,011 | 0,010 |

| 1000 | 0,040 | 0,037 | 0,034 | 0,028 | 0,026 | 0,024 | 0,011 | 0,010 | 0,009 |

| 2000 | 0,022 | 0,020 | 0,017 | 0,015 | 0,014 | 0,013 | 0,006 | 0,006 | 0,005 |

| Notes 1 For intermediate values of diameters and temperatures, the value is determined by interpolation. 2 For coolant temperatures below 100 °C, data corresponding to 100 °C are accepted. | |||||||||

Insulation on the street

- If the flexible air duct was insulated in the past, then the insulated layer will have to be dismantled.

- The surfaces are cleaned of adhesives and other protective materials.

- If sheet or roll material is used as insulation, then it is immediately wrapped around the flexible air duct in one or several layers. This depends on the thermal insulation requirements. In this case, the best option is self-adhesive insulation.

- If polyurethane insulation is used, then a reinforcing frame made of metal or synthetic mesh must be installed underneath it. The frame is pulled over a flexible duct, and the ends are fastened together with bolted fasteners. Sometimes metal tape clamps are used as fasteners.

- The most difficult thing is to lay insulation in the form of mats on the flexible air duct. Fastening is also done with clamps or tape, or knitting wire.

- Now the insulated air duct must be covered with protective material. Firstly, it must be waterproofing, durable and reliable with a long service life. Secondly, a durable protective layer that will not be torn off by the wind, precipitation or other negative factors of nature. Most often this is a casing made of galvanized sheet or aluminum sheets. Today, manufacturers are increasingly using neoprene protection.

How to properly insulate

Properly carried out thermal insulation of ventilation air ducts should include all the necessary elements. Insulating materials must fit tightly to the surface of the pipe, the inner diameter of the shells must coincide with the outer diameter of the pipelines. All layers must be securely and tightly fastened, nothing should dangle or sag.

Indoors

Inside the premises, it is mandatory to insulate the air supply ventilation ducts, the so-called “pipes with a negative surface temperature”, and the fan ducts. Metal pipes can cool to negative temperatures: at the top - due to high thermal conductivity; from below - rarely, because the air in the underground sewerage system is usually above 0 °C.

The vent pipe is rarely cooled at the top indoors in private homes, but insulation in the unheated attic and roof is necessary.

Thermal insulation of an air duct with a negative surface temperature in this case includes:

- thermal insulation layer;

- vapor barrier layer;

- cover layer;

- fastenings

The covering layer usually also serves as a vapor barrier layer. Galvanized steel, fiberglass, roofing felt, penofol, neoprene, and thin aluminum sheets are used as the covering layer. Sometimes copper sheets are used for decorative purposes (on the roof). For fastening, ready-made clamps, wire, and aluminized construction tape are used.

On the street

The design of thermal insulation for pipes with a positive surface temperature must necessarily include:

- thermal insulation layer;

- cover layer for plastic insulation – with ultraviolet protection;

- fasteners.

In principle, the same materials are used as for internal thermal insulation.

Thermal insulation cylinders

Insulation of ventilation pipes can be done using special cylinders (shells), which are made of mineral wool, expanded polystyrene, polyurethane foam and polyethylene foam. They are used only for round pipes. They are selected by diameter and come in several varieties:

- One-piece with a longitudinal section;

- Consisting of two parts;

- Three;

- Four.

The type of cylinder is selected taking into account the diameter of the air duct. The larger it is, the more parts the shell has. For example, a plastic pipe with a diameter of 110 mm, which is often used in the ventilation system of private houses, is closed with a cylinder in the first position. It is simply opened along the gap and put on the pipe, secured with tape.

Insulated pipes for ventilation using this technology are a guarantee of their effective protection, plus ease of work. It should be added that the exit of the air duct to the street, as well as the street area, can be insulated with cylinders. The only requirement is the installation of a protective box.

As for the price component of the insulating material, it should be noted that the cheapest shells here are made of mineral wool, polyethylene and polystyrene. The most expensive polyurethane foam. Today, manufacturers offer this type of material made from foam rubber. Insulated ventilation pipes with them are the best, but very expensive option.

Recommendations from experts

If mineral wool is used outdoors, it must be carefully waterproofed. Roofing felt is often used for this purpose. If you use ready-made shells made of PPS or polyurethane foam, then in dark rooms you don’t need to use the top covering layer at all. Do not coat or glue plastic insulation onto bitumen or bitumen primer (mastic). External insulation made of PP, PPU, PPS cannot be covered with bituminous shingles for decorative purposes. You can wrap it.

Particular attention should be paid to waterproofing the passage of the air duct through the roof. Master flash is ideal for waterproofing this unit. Ventilation passages through the attic floor also need to be insulated.

Thermal insulation of cold air supply ventilation ducts up to the point of entry into the room or heat recuperator (or heating device for incoming air), as well as a section of the air supply duct to the boiler, fireplace, stove up to the point of entry into the heating device, is important. Exception: coaxial chimneys. When laying air ducts between joists in the floor, thermal insulation of sufficient thickness is necessary, otherwise the floor structures will get wet and rot.

When installing ready-made shells, ready-made glue is used as a sealant. The technology for installing thermal insulation of air ducts can be clearly seen in the video:

Mineral wool and foamed polyethylene

If you use mineral wool with an outer foil layer, you will not only be able to make the structure more efficient, but also protect it mechanically

It is important to consider that cotton wool gradually cakes, and over time it will begin to crumble, so you must be careful when working with it

Thermal insulation of air ducts is often carried out with foamed polyethylene. Such work is cheaper, since the cost of materials is lower. The insulation is thin, so the pipe must be wrapped with polyethylene several times. According to its characteristics, this material is similar to foam rubber. Among roll options, mineral wool insulation is considered a priority.

Insulation of pipes: work procedure

When insulating ventilation with polystyrene foam shells, the following is carried out:

- clarification of the dimensions of the ventilation pipe, in particular the internal diameter;

- making cuts with a knife (or a saw);

- covering the pipe cylinder (shell) with fragments, displacing them by a couple of centimeters;

- closing with force the tongue-and-groove locking joint of the parts on the sides.

The structure (shell) is easy to install and dismantle in case of work on the pipe.

Work on insulation with foamed polyethylene in the form of a finished shell of a ventilation pipe comes down to the following:

- taking the necessary measurements of the pipe: so that the insulation fits tightly onto the surface of the air duct;

- finding a special seam on the capsule and separating it along this seam;

- fixing the shell on the insulated pipe;

- insulating joints and seams with adhesive or tape.

Protection made from fire-resistant polypropylene or polyurethane foam is performed as follows:

- dimensions are determined;

- Semi-cylindrical sections are cut from a solid workpiece with a reserve for the covering layer;

- a capsule is formed from cut fragments around the pipe;

- the resulting joints are hermetically fastened with bandages.

If the ventilation opening in the house is in the shape of a rectangle:

- select the required thickness of roll or slab insulation (for example, basalt fiber);

- cut and cut to size into fragments that are convenient to arrange for cladding;

- with the help of pre-calcined steel wire, the pieces are held together;

- the seams are hermetically sealed with strips of foil with an adhesive layer applied to it.

Thermal insulation for ventilation using any of these methods, despite all the positive aspects, has one weak point - “cold bridges”. It is important to prevent violations of the work technology and the prerequisites for their formation during the installation process. To do this, the joints between ventilation ducts and house structures are especially carefully insulated, otherwise the expected effect of insulation will be reduced.

Home ventilation is an important system that ensures normal living conditions. But in order for it to work according to the given parameters, it is necessary not only to install it correctly, but also to carry out additional measures related to the insulation of air ducts. It is important to understand here that insulated air ducts mean, first of all, the complete absence of condensation, which destroys metal products. But this is only one of the reasons why insulation work is carried out.

Criteria for choosing insulation for ventilation insulation

You need to know what and how to insulate ventilation pipes. When choosing, preference is given to the thermal resistance of the material. The main role of the insulation is to bring the temperature on the surface of the pipe as close as possible to the amount of air leaving it. In this way, condensation can be avoided. For these purposes, materials based on mineral fiber (stone and mineral wool, fiberglass), foam elastomers, as well as polyacrylates are used: polystyrene - a product of the polymerization of styrene, polyurethane, etc.

Insulation based on metal and glass threads obtained from inorganic components is supplied to the retail chain in the form of slabs or rigid (semi-rigid) roll materials. The choice is simplified by a wide range of insulation materials with different densities, prices and thermal insulation characteristics. The undeniable advantage of mineral wool insulation is its resistance to rotting and fire resistance.

Attention! If you don’t know how to insulate a ventilation pipe in the attic, especially if it is not heated, use special sections of mineral wool for external cladding specifically for pipes. At the same time, the inner surfaces of the hoses are insulated with fiberglass treated with a special impregnation.

Technique of work execution. Step-by-step instruction

When thermally insulating air ducts that are located outside the heated premises, insulation is carried out from the outlet to the deflector. If the pipe goes through the attic and passes through the roof, it must be insulated along the entire length of the section in the attic. The same requirements apply to the zone that goes through an unheated room.

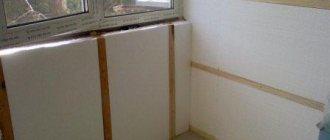

The heated supply system is equipped with appropriate material throughout. The use of boxes is often resorted to in attics. Thermal insulation in this case has the form of casings and consists of foamed polyethylene. Among the advantages of this approach are the affordable cost and the ability to purchase goods at any hardware store. It is recommended to select a casing based on the size of the pipe.

Foamed polyethylene can deteriorate when exposed to ultraviolet radiation. To eliminate this effect, it is necessary to cover the outside of the structure with aluminum kitchen foil. When insulating supply air ducts, it is necessary to measure the diameter and height of the system from the outside. Next, prepare a casing of the required size. If an umbrella is installed, it must be removed. The casing is stretched to the base of the pipeline. The umbrella can then be returned to its place.

Foil is applied to the system from bottom to top. This will increase the service life of the structure. Using copper or stainless steel clamps, you can fix the winding. If the work is carried out in central Russia, this solution is best suited. If we are talking about a more severe climate, you will need reinforced insulation like mineral wool. It works well on domestic and industrial ventilated ducts. If desired, the material can be used inside and outside. A typical example is Isover coatings.

Soundproofing materials

Sound insulation for air ducts are materials that can simultaneously perform the functions of thermal insulation. As mentioned above, if thermal insulation was carried out in unheated rooms or on the street, then it is worth talking about sound insulation right away.

As for internal heated premises, various techniques are used on an industrial scale, ranging from covering with traditional sheet materials such as plasterboard, asbestos sheets and others, to high-tech noise absorbers based on polymers and rubber. In private housing construction, they do not follow the path of complicating the processes being carried out. Therefore, foam or fiber sound insulators are most often used. For example, a good option for insulating air ducts is glass wool winding. Fortunately, these days they are sold in rolls, trimmed on one or both sides with foil.

Foam rubber rolls should not be discounted. It has already been mentioned as a good insulation material. It has good technical characteristics in terms of noise absorption, therefore, by installing it as thermal insulation, we can safely say that noise is reduced.

Interior work

The technological process for insulating air ducts inside a building is identical to that used for external work. The only difference is that there are no negative factors in the form of climate phenomena.

However, if the lines are laid in places with high humidity, it will not be possible to do without additional protection. As for private houses or apartments, there is no reason to worry about a negative environment, and the work will not be much different from treating walls or floors.

At the initial stage, thermal insulation for internal air ducts consists of installing a membrane, which will have a waterproofing effect. Then you need to fix the insulation, on top of which another layer of membrane is fixed, or better yet, aluminum foil. Both of these materials will play an important role as a vapor barrier.

PIR foil insulation for air ducts

When installing air ducts for ventilation, air heating and air conditioning systems, it is necessary to use high-quality insulation, which will ensure the required level of thermal insulation, sound insulation, and fire safety.

Traditional types of insulation used to insulate air ducts have a number of disadvantages: large weight and dimensions, complexity of installation, short service life, and the presence of harmful substances in the composition.

To avoid such problems, it is recommended to use PirroVentiDuct for organizing air duct systems - PIR foil insulation developed by PirroGroup specifically for the economical, quick and reliable installation of thermally insulated air ducts.

PirroVentiDuct is a slab of polyisocyanurate foam, covered on both sides with aluminum foil with a thickness of 60 microns. Installation of air ducts using PirroVentiDuct is carried out directly on the construction site using rigid thermal insulation boards, eliminating the need to use a metal frame. PIR boards are produced at the PirroGroup plant according to the customer’s technical specifications and are accompanied by specifications, which allows for quick and high-quality assembly of an air duct structure of any shape.

Installation of an air duct from PirroVentiDuct slabs

Advantages of PIR board insulation for thermal insulation of air ducts

- A light weight. Air ducts made of PirroVentiDuct foil insulation are 6 times lighter than metal ones, and can be used under load limits on the building’s load-bearing structures.

- Quick installation. Installation, dismantling and replacement (if necessary) of air ducts made of foil insulation is carried out in the shortest possible time, reducing the time for general construction and commissioning work. The installation of air channels can be done by one employee, which reduces the cost of work by 15% compared to metal duct systems.

- Compact sizes. Air ducts made from PIR foil insulation have compact dimensions due to the exclusion of an additional layer of insulation from the design. In addition, there is no need to create space for installing thermal insulation on a metal box.

- Reliability and durability. PirroVentiDuct can be used for ducts with air mass velocities ranging from 2 to 20 m/s and are calculated similarly to ducts made of galvanized metal. Stability of geometric dimensions, consistently low thermal conductivity (λ25=0.023 W/m•K), fire resistance (flammability group G1) ensure the efficiency of air ducts made of PIR boards for the entire service life (up to 30 years).

- Environmental Safety. PirroVentiDuct foil insulation for air ducts is made from environmentally friendly materials: polyisocyanurate foam, aluminum, glue, silicone. The internal lining of aluminum acts as a vapor barrier, preventing the appearance of condensation, the accumulation of dust, the development of bacteria and the occurrence of mold.

- Soundproofing. PIR boards do not have the effect of resonating vibration of the walls and contribute to the attenuation of low-frequency sound waves.