The foundation of any building bears the maximum load.

And the durability of a house depends on the strength of its foundation. Under the influence of moisture, concrete is destroyed, which causes deformation of the entire structure over time.

To protect the foundation from the destructive effects of moisture and subsidence of load-bearing walls, it is necessary to take care of high-quality waterproofing.

You can complete the entire range of work yourself, since the choice of building materials today is great. Familiarity with the basic methods of protective measures will help you choose the best option and avoid mistakes when performing waterproofing work.

How to properly waterproof a foundation with your own hands, read on.

Polyurethane mastics for foundations

From time to time, TV channels tell us how somewhere an entire house or part of it suddenly collapsed. We don’t want to scare you, like idle TV people do. But let’s say that there is no “suddenly” in the case of the destruction of a building. Any structure begins with a foundation and rests on it. If it is not strong enough and moisture-resistant, then the house will not last long. The most common cause of foundation failure is dampness, humidity, loose and water-saturated soil, heterogeneous soil, the start of construction of a new house or road nearby. It just seems that the foundation is heavy and will withstand everything. No, it is, first of all, a mobile structure that is sensitive to any loads and changes in the environment. Polyurethane mastic will help protect the foundation from destruction.

Materials for interior work

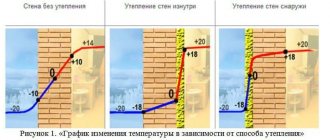

How to protect the foundation from destruction if it is not possible to apply waterproofing from the outside? All that remains is to apply protection from the inside. All of the above materials do not work well. If you glue them to the walls from the inside, then moisture will simply tear off the protective layer over time. In addition, this approach cannot protect concrete from the destructive effects of water. Therefore, the only correct option is to use penetrating waterproofing compounds (impregnations).

Penetrating waterproofing is applied to a damp surface.

The bottom line is that the impregnation penetrates the concrete structure and crystallizes there. As a result, all pores become clogged with crystals, making the material waterproof. The crystals are quite fragile, so even with minimal displacement of the foundation elements, microcracks appear.

Method of applying penetrating waterproofing:

- wet the wall with water;

- Apply the protective composition liberally with a brush;

- keep the work surface damp for three days.

If you do not keep the wall moist, the polymerization of the composition may not be intense enough. As a result, the crystals inside the pores will be smaller, which will negatively affect the waterproofing qualities of concrete. Good to know: “Liquid waterproofing materials.”

Signs of foundation failure

There are several signs that will help identify the problem at the first stage. Usually thin cracks, stains, mold on the walls inside the house, distortions of door and window structures appear on the foundation, then the exterior finish begins to deteriorate, the floor is deformed, some parts of the building collapse, and the soil along the structure collapses. If you notice cracks, it is worth checking the stability of the base.

The most common problem in Russian latitudes is excess moisture. Typically, concrete is used to construct the foundation. It is a porous material that can accept some water. But if there is too much of it, then concrete cannot cope. In addition, moisture can linger inside, freeze and thus destroy the material.

Waterproofing materials

To protect the foundation base from moisture, waterproofing work is carried out. The material varies in reliability, complexity of the device and cost. There are several types of foundation waterproofing:

- locking mastic (combined, polymer, bitumen compositions);

- coloring mixture (special paints);

- rolled products (roof felt, roofing felt).

A protective barrier is created outside and inside the building. The materials used must have good adhesion, fit tightly to the surface, and form a layer of uniform thickness. In this case, you will get reliable protection against excess moisture, dampness, and the formation of fungus and mold.

Selection of waterproofing

There are several main types of waterproofing. To choose the best option for you, you need to understand what type of soil you are dealing with, how deep the groundwater runs, at what depth the foundation is placed, what it is made of, and what size the building is.

There is one simple way that will help you check how deep the groundwater goes. In spring or fall, dig small holes in the place where you plan to build a house. And look to what level the water reaches them. This way you can determine how deep the foundation can be installed.

If you notice that there are a lot of marsh plants and sedges near the site, then water is close.

We decided to build a basement or a basement, which means we definitely need waterproofing.

Very often in such cases, vertical insulation is used together with roll materials based on bitumen. Another option is coating insulation. In this case, polymer compounds are applied to the surface of the foundation. Some recommend using both methods for maximum protection.

Protection of the foundation from heaving

First you need to understand the concept of “soil heaving”. This phrase is used to describe those soils that have a lot of moisture in their composition, which means that with the onset of severe frosts they can increase in volume and rise, according to the simplest physical laws. When building houses on such heaving soils, a cushion of gravel, special washed sand or gravel-crushed stone bedding is placed under the base of the foundation. A foundation created from these non-heaving materials prevents the buoyant forces of frost heaving from affecting the lower part of the foundation. It is important to remember here that with a significant increase in the water level in the ground, this can be in the autumn or during snow melting, water saturated with particles of unnecessary silty-clay soil accumulates around the bedding. Moving along with water, soil particles penetrate directly into the bedding and thereby clog it, slowly turning normal soil into heaving soil. After several years of operation of the foundation, it again ends up on the ground, which becomes deformed when it freezes. You can prevent siltation of the bedding by using special filter materials such as fiberglass or Taipara. They allow water to pass through well, but prevent the penetration of tiny silt-clay particles into the bedding. One of the ways to reduce the activity of heaving soils is to organize drainage. It allows you to reduce soil moisture due to a decrease in the water level in the soil. The traditional design of a drainage system consists of several drainage pipes that are placed in a layer of wash gravel that retains large soil particles. The pipes are laid with a slight slope, which in turn ensures the flow of water into a well or simply a sewer pit.

A filter material is placed around the drainage pipes, which does not allow even the smallest particles to pass through and therefore ensures the efficient operation of the entire drainage system without time-consuming cleaning. Protection of the foundation from freezing is carried out in the same way as when preventing the impact of heaving soil.

Polyurethane mastic or bitumen

There are many types of waterproofing compounds on the market. Thanks to the development of the chemical industry, these products are becoming more and more advanced. If previously you could only rely on bitumen, now there are more durable alternatives.

What is the difference between bitumen and polyurethane mastic? Bitumen is one of the oldest building materials, accessible and cheap. Polyurethane mastics appeared on the market not so long ago, but they are distinguished by their strength and elasticity, which lasts for many years. Bitumen loses these properties very quickly. Its strength lasts for several years, then the physical and chemical properties of the material weaken. Polyurethane mastics can last more than 40 years.

You can easily waterproof your roof, foundation, floors, etc., using hand-applied polyurethane coatings of the Khimtrust PUMA-K and Khimtrust PUMA-S brands. In terms of physical and mechanical properties they are not inferior to polyurea. You can also choose almost any color. #polyurethane #waterproofing #polyurea #polyurethane mastic #mastic #chemical trust #spraying #polyurethane foam #insulation #thermal insulation #roofing #foundation #repair

Publication from Himtrust (@himtrust_ru) Sep 28, 2021 at 4:47 PDT

Polyurethane is not only resistant to moisture, atmospheric pressure and chemicals, but also resists abrasion.

What to choose? If we are talking about large-scale work, then it is cheaper to use bitumen, for example, for the construction and repair of roads. Polyurethane is needed where we are faced with non-trivial tasks. For example, it is necessary to insulate an overpass, foundation, bypass, or roof.

How to do it yourself with different types of foundation?

For waterproofing work, you can give preference to one option or intelligently combine them with each other. There are several types of waterproofing:

- penetrating;

- roll;

- coating;

- screen

Based on the conditions of construction work, the best option is selected or several of the ones presented below are combined.

Impregnating or penetrating

For this type, materials are used that can crystallize, penetrating 1-2 cm into the concrete structure. The resulting layer has hydrophobic properties and protects the surface from capillary moisture. The strength and frost resistance of the foundation increases and its corrosion is prevented.

Among the materials with anti-capillary protection:

- Hydrotex;

- Penetron;

- Aquatron-6.

They are actively used for treating the internal surface of basements and basements.

It is recommended to apply the composition to wet concrete, so during the construction stage there is no need to wait for the surface to completely dry.

For this:

- Clean the surface from dust and dirt.

- Moisten joints, cracks and seams with water.

- Prime the surface with Panetron.

- Apply Panekrit solution in an even layer.

- When the solution has set, moisten the surface with a spray bottle and apply a second layer of Panekrit.

For the external wall of the foundation, it is necessary to apply the impregnating material in 2 layers, and for internal treatment one is enough.

Pasting with roll materials

Ruberoid is the most popular of the roll options. It is used as a complement to the coating method, and also as a separate material. Initially, the strips can be glued both horizontally and vertically:

The surface is treated with mastic or bitumen primer to bond the materials.- The hanging edges of the horizontal waterproofing are folded down and fused with a torch.

- The strips of roofing material heated by the burner are fixed on the surface. The overlap is 10-20 cm.

- The first layer of roofing felt is treated with bitumen mastic. A second layer of roofing material is glued perpendicular to the first layer of strips with the strips overlapping each other.

The market offers polymer-based roll materials, such as:

- "Rubitex";

- "TechnoNIKOL";

- "Gidrostekloizol";

- "Stekloizol";

- "Technoelast".

They are more expensive than roofing felt, but are characterized by increased wear resistance and elasticity. When using them, the surface must be treated with mastic. The use of rolled materials is justified for external processing of the foundation.

Coating

The application method is simple. It is necessary to prepare the surface for applying a plaster solution or polymer mixture. The stages, tools for application and the complexity of the work depend on the selected material. There are several types of coating waterproofing.

Liquid rubber spraying

An excellent alternative to adhesive waterproofing is treating foundation walls with liquid rubber. This material:

- has good adhesion to concrete;

- seamless;

- durable;

- non-flammable.

The one-component composition is sold in hermetically sealed buckets. “Elastopaz” is applied in 2 layers, it takes at least a day to dry, after which a second layer is applied. “Elastomix” is applied in 1 layer, mixed with an adsorbent activator before use, and dries for 2 hours.

But you can’t store the solution; you need to use it all at once:

- Before application, clean the surface from dust, prime,

- Apply a layer of rubber with a roller, brush, spatula or spray in 1 or 2 layers (depending on the material).

- After drying, to protect the rubberized surface from construction debris and stones contained in the soil for backfilling, it is recommended to cover the foundation with geotextile fiber.

Bituminous

The most common and affordable method of foundation waterproofing is the use of bitumen resin. The material penetrates the pores of concrete, protecting the walls from water.

For this:

bars with waste oil are placed in a smelting vat in a ratio of 7:3;- the container is placed on the fire until the bitumen is homogeneously dissolved;

- the mixture is applied with a brush or roller to a previously leveled, cleaned and dry surface;

- the surface is carefully processed from the base of the foundation to 20 cm above the ground;

- The material is applied in 2 layers so that its thickness at the end of the work is 30-50 mm.

The vat with bitumen should not cool down, because when reheated, the mixture will be less effective. This protection provides a barrier to moisture for 5 years, after which pure bitumen begins to crack and burst. But a line of bitumen-polymer materials is offered on the market.

These are mastics of different consistencies:

- For hot application.

- For cold application.

- liquid polymer solutions.

Apply polymer mastic using a spatula, roller brush or spray on a surface pre-treated with primer. Such materials are a little more expensive, but also more durable than bitumen in bars. The second layer of mastic is applied only after the first has completely dried.

Work on applying the polymer material continues until the required thickness of the waterproofing is achieved. The mastic layer should be 5 mm for houses with a foundation up to 2 m and 10 mm for depths up to 5 m.

Plastering

You can protect the foundation walls from moisture and level their surface with special plaster mixtures containing moisture-resistant components:

- asphalt mastics;

- hydroconcrete connections;

- polymer concrete.

For this:

- The previously prepared surface is primed.

- The walls are plastered along the lighthouses.

- After drying, for protection, backfill with oily clay is performed or a clay castle is made.

To increase the strength of the waterproofing layer, it is recommended to apply the plaster using a hot method.

Screen

This material is based on clay, so this method is a modern alternative to a clay castle. This waterproofing method is universal and can be used for any type of foundation. Screen moisture protection can be used both as a main product and as an addition to the coating or roll version.

Bentonite granules included in the mats expand 15 times when in contact with water and turn into a gel that fills cracks, preventing moisture penetration.

For high-quality waterproofing, the following requirements must be met:

- mats are mounted on the prepared surface with an overlap of 15 cm;

- panels from a mounting gun are adjusted to the walls with dowels in a checkerboard pattern;

- To ensure a tight fit of the waterproofing screen, a reinforced concrete pressure wall is erected.

Bentonite slabs must fit tightly to the surface. Over time, the paper backing of the mat will break down and the clay will form a tight ring around the foundation, providing effective protection.

Clay castle

A pressure wall is erected from thick dense clay or baked brick near the underground part of the foundation. The width of the lock is 40 cm, the depth is 150 cm. This design protects the foundation of the house from moisture penetration. Well-compacted clay upon contact with water increases in volume and does not allow water to pass further.

How to do it:

- A trench is dug around the foundation along the perimeter of the building at a distance of 60 cm.

- Replaceable formwork is installed.

- Crushed stone is poured to the bottom.

- Well-pressed fatty clay is compacted tightly.

- The mixture is laid out in layers.

- A blind area is made on top.

You need to use rich loam or well-kneaded compacted clay. The second layer is laid when the clay has reached the consistency of plasticine.

Polyurethane mastic from Khimtrust

has developed its own polyurethane mastic, which can be used not only for waterproofing foundations, but also roofs, swimming pools, tanks, basements, terraces, balconies, tunnels, as well as under screed and tiles, for repairing old bitumen insulation.

Khimtrust PUMA (1k) mastic is available for purchase in wholesale and retail quantities. If the surface for waterproofing is not so large and you need to make minor repairs, then you can buy a liter or three-liter jar of mastic. You pay for your purchase through the online store on the company’s website, then the product arrives at your home. You save your time on going to hardware stores, markets and standing in queues.

You can also order the color of mastic that best matches the color of your home. At the same time, the moisture resistance indicator will remain unchanged. High adhesion allows you to protect almost any surface from external influences.

Protecting the foundation from rain

Most often, different brands of primers are used for these purposes, which create a strong protective film on the foundation that prevents the penetration of moisture from the air. It is best to apply the primer in several layers, allowing each to dry first. The best option would be to impregnate the outer part of the foundation with a primer every year.

In addition, it is necessary to protect the foundation waterproofing from mechanical damage. This is achieved by ensuring that there is no heavy load on the waterproofing and it is not subject to deformation.

Some people are concerned about the actions that are taken when water flows under the basement in the spring, if waterproofing is not done immediately. In this case, you need to remove water from the house by any means, especially when there is a lot of it. This is done by digging out drainage ditches and drainage systems. If water gets into the basement, then after eliminating its further entry, the wet areas are dried using electric heaters and other similar devices.

Possible protection options

There are several technologies to protect the foundation from destruction:

- Removing excess moisture from the soil using a drainage system.

- Creation of a waterproofing layer.

The possible methods do not cancel each other out; in certain cases they are used together. At high humidity, enhanced protection is required.

Anti-corrosion measures are provided for by technological standards at the production stage of structures. During the manufacturing process, chemical components are added to the working composition. Under actual operating conditions, the anti-corrosion protection indicators are adjusted downwards. Therefore, at the zero construction cycle, all necessary methods are considered.

Possible types of anti-corrosion measures (two levels of protection are determined) are set out in SP 28.13330.2012.

Drainage of rain and melt water from the construction site is mandatory to avoid waterlogging of the soil. A vertical layout of the site is carried out, giving a special slope.

The method of protecting the foundation from water is selected after hydrogeological studies.

External treatment of foundations with anti-corrosion compounds

The following materials and compositions are actively used here:

- Aerosol thin coatings with varnish or paint.

- Mastic coatings.

- Pasting films.

- Polymer cladding.

- Liquid impregnation.

- Hydrophobization method.

- Use of biocidal compounds.

Paint and varnish coatings protect against exposure to liquid and gaseous media. Such a film only protects concrete from external factors, it also serves as a barrier to microorganisms and rodents, and also neutralizes the effects of moisture.

Mastics based on epoxy resins and bitumen are now very popular. The compositions are applied with a brush or spray, the drying time depends on the composition and ambient temperature, the depth of penetration into the concrete depends on its structure and can be up to 10 cm or more.

Pasting films are recommended for use in soils with a high groundwater content, as well as near industrial enterprises with high volumes of aggressive wastewater. For example, columnar foundations immersed in water are additionally covered with polyisobutylene films and plates.

Also highly effective are polyethylene film and rolled petroleum bitumen (roofing felt).

How does water and moisture affect the foundation of a house and does it need waterproofing?

Waterproofing the foundation is not just important, but very important and must be done, otherwise you risk the gradual destruction of your foundation and the possible appearance of cracks on it. Basically, the foundation is destroyed due to exposure to water, moisture and aggressive environments. If it is not properly protected, the structure of the concrete (or brick) from which it is made will absorb moisture and water, which will freeze in winter at sub-zero temperatures and thaw in the spring, forming pores, voids and microcracks in the concrete. These microcracks and voids will increase with each season and can subsequently lead to the formation of more serious cracks and damage.

Here it is important to know that if waterproofing work is carried out correctly on the outside of the structure and materials are selected correctly, then water will not be able to penetrate the concrete and, accordingly, will not be able to destroy the foundation from the inside. Concrete is a sponge for water; it absorbs it, which will subsequently not only have a negative effect on it, but will also lead to the destruction of metal reinforcement. Which, in the end, will lead to a decrease in the strength of the foundation, as well as the penetration of moisture and liquid into the interior of your home.

Why and how is the basement waterproofed?

Waterproofing is the protection of part of the structure and surfaces from water; for the base, the procedure is carried out both inside and outside.

In addition to its main purpose, waterproofing helps save the building from other aggressive liquids, corrosion, and keeps materials intact.

Hydrophobization: process features

Hydrophobization will not only protect the foundation from moisture, but will also allow it to breathe. For this process, water repellents are used - organosilicon compounds that are diluted with organic matter or water. Among them there are those that not only protect the material from moisture penetration, but also provide additional protection from dirt and dust.

- Walls impregnated with a water repellent are also protected from graffiti drawings, from this we can conclude that the protection is quite reliable. After all, you can often see graffiti on the walls of serious establishments, but this means additional costs for repairs.

- Also, the foundation and walls treated with a water repellent become more frost-resistant, their thermal insulation increases, their service life increases and the microclimate in the building improves due to the fact that the materials can “breathe”.

- This impregnation will protect the surface from mold, because fungus will not form on a dry surface. When using colorless impregnations, the natural color of the building material does not change and lasts much longer than without such a coating.

- Some formulations allow you to process wet materials. Efflorescence, which is the name given to salts contained in building materials and which appear on the surface over time, will never appear on the treated building walls and foundation.

The essence of the protection is that after treatment, a hydrophobic coating is formed on the surface, a thin polymer film, which, when exposed to water, closes the pores and prevents moisture from entering inside. Water repellents remain in the pores of the material for many years, that is, it also provides long-term protection.

Return to contents

Repair, installation and waterproofing works depending on the type of foundation

It is best to entrust the work of installing proper waterproofing to an experienced and professional organization; it will be the one who will be able to not only choose the correct method for installing or repairing a waterproofing coating, but also carry out its installation correctly.

It is the correctness and adherence to the installation technology that determines how well the foundation of your building will be protected and how long this protection will serve you without the need for repair or replacement. Do not forget that if the waterproofing is installed incorrectly, it will most likely have to be repaired after a year or two, and these are serious additional costs associated with the following work:

- Dismantling the made blind area (if any)

- Development of soil around the underground part of the house, to its entire depth

- Dismantling wall insulation (if any)

- Removing the old waterproofing coating

- Installation of new waterproofing

- Reinstallation of insulation

- Backfilling of soil and restoration of the blind area

Important: Most waterproofing coatings cannot be repaired locally, since it is impossible to determine from the location of the leak from the inside where the water is entering from the outside, so the entire coating must be completely replaced.

You can find 7 rules on how to find a professional waterproofing company or contractor and not make mistakes in the article - Contractors, companies and firms for waterproofing and drainage

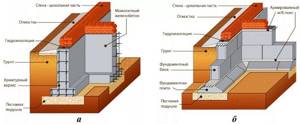

Waterproofing strip foundation

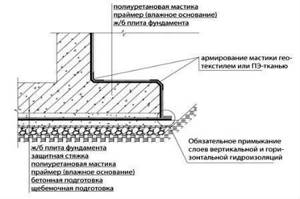

The strip foundation can be made of FBS blocks or poured from concrete. When insulating a strip foundation, it is necessary to take into account both horizontal and vertical waterproofing. Horizontal protection is installed on the horizontal surface of a strip of FBS blocks or concrete and serves as a cutoff between the strip foundation and the future walls of the house. This cutoff will prevent capillary moisture from rising and being absorbed into the walls. Vertical protection is applied to the vertical surface of the tape located below the ground level.

The following materials can be used as a waterproofing composition:

- Welded;

- Coating;

- Liquid rubber – recommended;

- PVC membranes;

Strip foundation waterproofing scheme

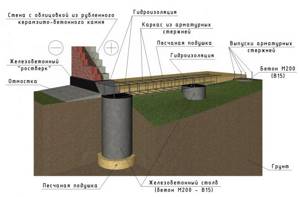

Waterproofing of columnar and pile foundations

In this type of structure, only horizontal protection needs to be provided. Installation of waterproofing is carried out on the surface of the grillage or supporting element. The main task of insulating pile foundations is to prevent capillary rise of moisture and its further impact on the walls of the house.

For this type of structure you can use materials such as:

- Fused insulation;

- Coating mastics;

- Membranes;

- Liquid rubber.

Scheme of waterproofing grillage and columnar foundation

Pile foundation waterproofing scheme

Monolithic slab foundation

When constructing this type of foundation, it is necessary to provide high-quality and reliable waterproofing of the horizontal base, since subsequently repairing the protection made will be impossible.

The following products can be used to waterproof a monolithic slab:

- Welded bitumen membranes;

- PVC membranes;

- Bitumen mastics;

- Liquid rubber – recommended.

Important: When installing any type of foundation, it is recommended to install a high-quality drainage system around it at a depth of 0.3-0.5 m below its level. The drainage system located just below the foundation will take in the water that will approach it from the side and the water that is located under it. This will relieve the water pressure on the concrete and increase the lifespan of the waterproofing system.