We live in a time of innovation and technology. Construction, like all other industries, moves in kilometer-long steps. And it pleases us with new materials for insulation and more. More recently, an excellent alternative to traditional external insulation has appeared - this is the insulation of the exterior of the house facade with thermal panels.

This segment has not existed for long, but has already gained popularity among residents of our country. It is a well-known fact that most of the heat is lost through the walls and they need insulation. This problem exists both in apartment buildings and in private ones.

This technology will allow you to get rid of many problems that appear during the cold seasons. You can forget about cold rooms and dampness. In this article I will tell you what thermal panels are and what advantages they have.

What are thermal panels

This is a complex finishing material, a universal product, a system for insulation and facade cladding. A panel with a clinker decorative part is considered a classic, but today on the market you can find a wide variety of products using dry mixes, polymer compounds... all for the sake of cost, and very often, at the expense of quality!

The main differences between the panels are their basis:

- Minvata;

- Polyurethane foam, or PPU for short;

- Expanded polystyrene–PPS;

- Oriented strand boards - OSB;

- Cement particle boards - CBPB!

The last two types are far from insulating material, since they are based on a durable slab, on which a decorative layer is installed during production. Therefore, in the class of thermal panels, only slabs based on polyurethane foam, mineral wool or PPS remain!

External, decorative part:

- Clinker;

- Fake diamond;

- Polymer materials;

- PVC;

- Marble chips and others!

© derevyannyydom.ru

Some manufacturers allow the use of additional reinforcing elements, reinforcement for bases, as well as special embedded plates in thermal plate designs to improve the quality of installation!

"Fride"

Only natural materials are used as decorative finishing of panels (clinker tiles, stone, porcelain stoneware, facade ceramics). Product connections are “tongue and groove”. Insulation materials – polyurethane foam and polystyrene foam.

| Model | Dimensions, mm | Insulation thickness, mm | Cost per sq. m, rub. |

| With glazed ceramics “Falcon FN03” | 1508 × 528 | 30, 60, 80 | From 2 361 |

| With porcelain stoneware Estima AN01 | 1560 × 624 | 30, 60, 80 | From 2 547 |

| With clinker tiles Opoczno Shadow Red | 1530 × 600 | 30, 60 80 | From 2,786 |

| With large-format clinker tiles “Natur” | 1490 × 525 | 30, 60, 80 | From 2,055 |

| With Novplit stone Dolomite peach yellow-pink | 1220 × 650 | 30, 60, 80 | From 3 770 |

Advantages of thermal panels

- High-quality thermal insulation. The thickness of the working insulation layer of the material is, on average, 40-100 mm. Facade finishing materials can be manufactured to order according to the buyer's requirements. At the same time, most manufacturers use PPS, polyurethane foam, basalt in their production - high-quality insulation materials with low thermal conductivity;

- Ease of use. Thermal plates are ready for installation. An adhesive base and through fasteners are all that is required. Many materials are designed for tongue-and-groove installation, while others are combined end-to-end on the wall surface. The panels can be cut to size and shape using a grinder and a knife. Also, it is possible to order a ready-made kit for covering the structure, if you are completely confident in the accuracy of the measurements;

- Environmentally friendly products. Apart from the shortcomings when operating conditions change, most of the stated examples actually use environmentally friendly raw materials. Finished materials receive certificates after passing the laboratory. But it’s worth remembering that we’re talking about offers from official manufacturers, not garage entrepreneurs;

- Wide temperature range during installation work. Installation of facade slabs can be done in any season of the year, at a time convenient for the craftsmen and the customer. This applies to dry installation, without glue. If, as the technology requires, you use an adhesive base, you will need to comply with the rules for using the selected adhesive;

- High density and strength of the material. PPS and PU foam can have sufficient density to obtain a hard and indestructible surface. Therefore, it will be difficult to damage such a facade, especially with a clinker decorative surface;

- Application of the material in any region of the country. The operating temperature range for the materials used is from -80°C to +60+80°C. At least that's what most manufacturers say, who sometimes quote even more impressive figures;

- The materials are not subject to destruction due to the external environment, corrosion and decomposition, or exposure to pathogens. But these conditions work if the technology is followed, the jointing is correct and waterproofing, vapor-permeable materials are used;

- Long service life. Manufacturers claim both 30 and 50 years. By default, this is possible, but if the panels are installed correctly, and every 5-6 years inspection, revision, maintenance work is carried out and the required repair measures are taken;

- Additional soundproofing of premises. When installing thermal panels based on polyurethane foam and basalt, the performance will be higher than when working with polyurethane foam;

- Complex works. You can save a lot of time on facade work if you choose warm panels. Their installation replaces wall leveling, decorative finishing, insulation... and all these processes taking into account their technological features. In our case, it is enough to install the slabs on the facade;

- Light weight of the finished system. The average panel weight is 5-7 kg per square meter. In most cases, the facade does not need to be strengthened, there is no need to install a complex and expensive load-bearing frame, or worry about the fact that during installation work the old wall will crumble and crack;

- Attractive appearance. Most thermal panels are really beautiful, and even original. Imitation of brick, stone, and other materials, plus a huge palette of colors and shades of different depths!

"Ermak"

In the production of Ermak panels, laser cutting of materials is used, which makes it possible to achieve precise dimensions and good joints of the tongue-and-groove type. The company offers panels in individual sizes and in standard versions. Clinker tiles are supplied from manufacturers ADW, Stroher, Foshan Red Lion Ceramic Co. Insulation – extruded polystyrene foam.

| Model | Dimensions, mm | Insulation thickness, mm | Cost per sq. m, rub. |

| Ermak – KSK | 1 000 × 480 | 40 | 1 980 |

| Ermak – Red Lion | 1 000 × 486 | 40 | 2 500 |

| Ermak – Cerrad | 1 000 × 650 | 40 | 2 600 |

| Ermak – ADW | 1 000 × 486 | 40 | 3 600 |

| Ermak – Paradyz | 1 000 × 650 | 40 | 3 600 |

Disadvantages of thermal panels

- Compared to some types of facade finishing - cost. But often the price remains at an acceptable level;

- Difficulty in identifying quality material. There is too much choice, in addition, there is a difference in characteristics;

- The ability to create a thermos effect in a structure that is to be finished;

- Serious requirements for accuracy of work. If the base layer is damaged, this part of the panel can be thrown away;

- Damaged panels are beyond repair and cannot be restored;

- Lack of vapor permeability in the case of choosing slabs based on EPS, maintaining normal indicators for materials with a different base;

- Quite controversial material according to experts who find a lot of marketing inconsistencies!

Installation technology

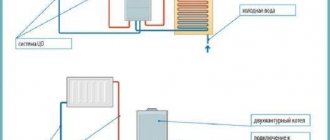

Do-it-yourself installation of thermal panels is possible in one of the following ways:

- If the unevenness of the walls is no more than 30 mm vertically, installation is carried out directly on a clean surface using dowels (plastic, metal, etc.).

- If the geometry of the base is distorted or you plan to install it on wooden walls, then a pre-fixed structure made of a metal profile or a wooden block with a cross-section of 30-55 mm will be required.

When working without lathing along the base, a base profile is marked along the entire perimeter 15-25 cm below the floor level. The lower plane of the first panel at this height avoids the formation of cold bridges. The main thing is to comply with all basic installation requirements.

Thermal panels: myths and reality, what to pay attention to

It is possible to collect a certain amount, deliver the panels to the work site within a day, and within a week, with just two or four hands, complete the insulation and finishing of the house. But you should pay very close attention to what manufacturers write and what consultants of online stores and representative offices say. Sometimes, more than 60-70% of words should be ignored. It is for this reason that you need to consider the myths and real qualities of thermal panels, studying the indicated advantages of the material!

© Euro clinker

- Low price of thermal panels. It’s a little different, because the price is quite high compared to consistent insulation with foam plastic or mineral wool with additional finishing. Therefore, this factor should be checked. More precisely in financial terms, thermal plates, depending on the base and decorative layer, as well as the overall quality of the material, can cost from 500 rubles to 9,000 rubles per square meter. When asking prices, you need to clarify how much it will cost to prepare the walls and actually install them;

- The best thermal insulation material. Indeed, thermal conductivity indicators are minimal. But only comparatively. In addition, a reduction in heat loss is guaranteed only if the calculated data for insulation in each individual region is observed. Standard warm slabs from 40 mm are suitable for warm regions and already insulated houses. For the middle zone, if the house is built of brick, expanded clay concrete or foam blocks, you can use a thickness of 100 mm. It is already more difficult to talk about high-quality thermal insulation of panel houses, since the thickness of the insulating layer may not be enough. But, as an additional comprehensive finishing, the option is still not bad;

- Possibility of insulating weakened facades without preparation. Considering the weight of the panel, yes, but if you think about additional drilling of the facade, you should be careful. Flimsy walls that show cracks will need repairs anyway. Therefore, if you ignore the preparatory work, you can get shifts and cracks in the finished finish. In general, if the walls are bad, you need to repair them, be sure to think about the causes of cracks on the surface. And these, in most cases, are problems with the foundation;

- Installation on a facade without glue, or installation on a facade without dowels. Saving on this or that installation material is irrational in financial terms; it is minimal. But by excluding an additional method of fastening, craftsmen increase the risk of damage to the finishing layer in the near future. Experts note thousands of facades that have fallen from walls only because of savings on fasteners and adhesives;

- Installation in autumn and winter. Maybe! But it is not the time of year that plays a role, but the temperature during the work. Correct installation is only possible down to -10°C;

- Warranty 10 years, 20 years, 50-100 years. There is no such guarantee. Read the contract carefully, as well as the warranty addendums. Neither mineral wool nor EPS will last 100 years. The average service life is from 15 to 25 years;

- PPS thermal panels are an environmentally friendly material that does not react to external influences. Yes, PPS in its normal state does not emit radiation; the entire composition, according to laboratories, is within acceptable standards. But heating the foam, its combustion and melting lead to the release of toxic, deadly substances. In addition, foam plastic and derivatives of this material are destroyed under the influence of temperature changes, ultraviolet radiation, and moisture. The material crumbles and crumbles;

- When insulating walls with thermal panels, there will be no condensation on the walls. Yes, but only if the insulation is carried out according to the rules of technology, which is based on the basic materials for the production of the slab. A shift in the dew point and a lack of vapor permeability lead to wetting of insulation materials, dew and condensation, as well as loss of original physical and mechanical properties;

- Installation of panels on any surface. This means not only the material, but also its geometric position, because every second consultant claims that it is possible to level the walls with the panels themselves. But this is only possible if the craftsman is highly professional, when he lays out the materials, takes measurements and checks the levels after installing each individual slab. If you work on curved walls yourself, the result will not be the best. It is necessary to first prepare the surface, or use a frame for installing facade finishing;

- Savings on heating up to 80%, or 2-3 times or more. Empty promises, since to achieve such indicators, initial construction is necessary taking into account energy-efficient technologies, as well as thermal insulation rules for an energy-independent house. And this is at least 200 mm of insulation along the walls of the house, which are also made of materials with low thermal conductivity. In addition, to achieve such results, it is necessary to qualitatively, according to construction calculations, insulate the floor, ceiling or ceiling, install energy-saving windows and appropriate entrance doors;

- Thermal panels do not need to be repaired. No! At least once every 3 years, a thorough inspection will be required, because loss or cracks of the seams will lead to external moisture having access inside the material and under it, to the wall of the building. And this is a direct direction to a major overhaul in 5-7 years, if you ignore the initial problems;

- Thermal plate does not rot, does not become moldy. Corners, crevices, joints, cracks are susceptible to pathogenic effects. This flora just needs to create comfortable conditions, and it will be able to settle even under the façade decoration!

These facts are not given in order to scare the buyer or offer him alternative materials, pointing out some unrealistic advantages. And to increase attention to each individual fact, and the correct perception of advertising descriptions of materials from different manufacturers. If you do everything correctly and according to technology, with the preparation of surfaces, the choice of materials, the use of high-quality fasteners and materials for sealing seams, facade finishing with thermal panels can really last up to several decades in excellent condition!

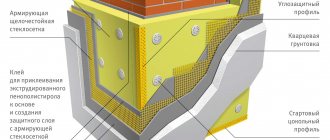

Surface preparation

- The walls of the house, corners, and the basement of the building are prepared for the installation of the material. To do this, all crumbling parts are removed, cracks are opened for further cleaning and drying;

- After cleaning, prime the surfaces, which will wash away dust layers and create a durable layer. It is done with a wide brush – a brush, at least 2 layers are needed;

- If necessary, the wall is plastered. For minor damage - with an appropriate spatula, for serious problems - using beacons or by machine;

- The finished plaster layer is additionally coated with a primer;

- Putty for installing thermal plates is optional.

Installation of facade thermal panels

- Along the base line, a galvanized profile of the appropriate size is attached, which will be the starting strip for thermal plates;

- Ready-made facade finishing elements are installed under the profile, along the base;

- Along the line of the installation profile, under its lower edge, an ebb is mounted, protecting the base part from water. After covering the walls with panels, the seam above the ebb should be sealed with a waterproof sealant for external use;

- The plates are installed sequentially, from right to left, from bottom to top. It’s more convenient and correct. Start of installation - from the corner. Here you can use special corner elements;

- Mounting holes are drilled in the finishing embeds, and on the opposite side, at the base of the PPS, markings are made for umbrella fastening with a special pen drill of the appropriate diameter;

- An adhesive composition is applied to the back side of the slab. It is advisable to do this over the entire surface using notched spatulas. There is another way - baiting the slab and point injection of foam glue using a glue gun;

- The slab is pressed against the wall according to the markings. Holes in the wall are drilled through the finished markings of the fastenings. Dowels are installed in the mounting holes, with which the slab is attached. Next, on the right side of the slab, where the holes for umbrella fastenings are marked, the umbrella plug is installed. All the plugs are driven into the wall, pressing the slab. It is adjustable according to the markings. You may need to move it minimally to the right or left, up or down, or align it diagonally;

- After alignment, fastening nails are installed in the mounting holes, which are driven inward, tightly pressing the thermal panel against the wall;

- The next panel is installed, which is inserted into the grooves of the first one, and is gradually adjusted according to the markings and levels. Its fastening is similar!

Additional items

When purchasing thermal plates, the package includes corner elements, installation and hidden installation systems, special frames, corner and decorative elements for finishing window and door openings.

The use of elements for doors and windows is calculated immediately, but can be used after the main work on the walls, or simultaneously. Depends on the choice and technical features!

You can insulate a residential building or other structure with thermal panels yourself. The process is interesting and not so complicated. But it is important to initially decide on the price and characteristics of the material, perform the correct calculation and approach the process responsibly. This is the only way to get a successful result!

Cost of panels for exterior finishing

The building materials market is too vast, which is why façade materials vary in cost. The price depends on a number of factors:

- country of origin (the further away the company is based, the more expensive);

- material type;

- type of decorative layer.

Thus it turns out:

- Holland, Germany, Finland are the most expensive (about 3 thousand per m2);

- Poland – from 1.5 to 1.8 thousand per m2;

- Domestic manufacturer – about 1.2 thousand.

Thermal panels are a convenient material for effectively insulating a room. When choosing, you need to take into account many nuances: structural characteristics, vapor permeability and much more.