History of appearance and principle of operation

Within just 1 second, each of the electrodes collides with the others up to 50 times, changing its sign.

Thanks to the action of alternating current, the liquid does not divide into oxygen and hydrogen, maintaining its structure. An increase in temperature entails an increase in pressure, which forces the coolant to circulate. To achieve maximum efficiency of the electrode boiler, you will have to constantly monitor the ohmic resistance of the liquid. At classic room temperature (20-25 degrees), it should not exceed 3 thousand Ohms.

Do not pour distilled water into the heating system. It does not contain any salts in the form of impurities, which means you should not expect it to be heated in this way - there will be no environment between the electrodes to form an electrical circuit.

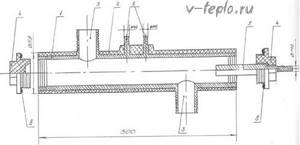

Design of an ion (electrode) boiler

Ion boilers are very simple devices. Essentially, it is just a metal housing into which an electrode is inserted. There are no adjustments or moving elements in it, there’s not even anything to break. They are:

- single-phase;

- three-phase.

In single-phase boilers there is one electrode, and in three-phase boilers there are three. The electrode is always supplied with phase (plus). Zero (minus) can be applied either to the housing or to the second electrode (if it is provided in the design). Grounding is also required to be connected to the housing. You can’t do without it, otherwise you’ll get an electric shock. It is important that the phase and zero electrodes do not contact each other. The only bridge for electricity should be the coolant. Naturally, the case has two holes for liquid circulation.

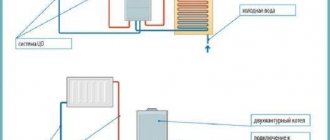

Diagram of a heating system for an ion boiler

The ion heating element must be turned on by special installation electrical personnel with a clearance group, since this is due to the electrical safety requirements of the equipment.

To carry out commissioning work, you can use the diagram provided by the manufacturer.

General connection diagram for an ion boiler

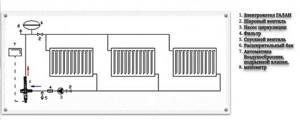

For installation you will need:

- Ion boiler.

- Ball shut-off valve for the possibility of closing the coolant in an emergency or changing the heating medium in the system.

- Centrifugal electric pump for circulating coolant in the heating network.

- Filter for cleaning the coolant from suspended substances.

- A drain valve for draining water from the system is installed at the lowest point of the return pipeline.

- Expansion tank to protect against network breaks due to thermal expansion of the coolant.

- Control and protection unit.

- Air intake.

For the normal functioning of an ion heating boiler, water of a strictly defined composition is required. If the boiler will be installed in an existing heating network, before the first start-up it will be necessary to replace the coolant and add a special inhibitor. The water itself must be distilled.

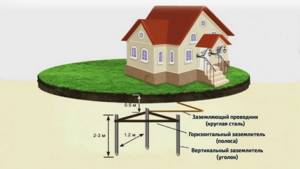

Do such boilers need to be grounded?

Production standards for the operation of an ion boiler unit require the mandatory installation of a grounding system that complies with the PUE, for the reason that in the event of a current leakage, this system cannot be protected using an RCD.

The grounding copper conductor must have a diameter of 4.0 to 6.0 mm, and the system resistance cannot exceed 4 ohms. The electrical wiring is connected to the “0” terminal located in the lower part of the boiler structure.

All accessible electrically conductive parts of the boiler unit and heating network are grounded, this can extend the service life of the heating source. Corrosive wear of the grounding system cannot exceed 50%.

The structure of the grounding system must not be painted or covered with dielectric coatings. A heating system equipped in accordance with the requirements of the PUE is a reliable and efficient source of thermal energy.

How to choose an ion boiler

The required power unit is selected from the condition that 1 kW of thermal power is sufficient to heat an area of 10 m2. You need to add approximately another 20% to the calculation to take into account the heat losses of the object.

In addition, before choosing, you need to clarify what function it will perform in the heat supply scheme, as the main source of heat or auxiliary to maintain the temperature at night or during periods of extremely low outside temperatures.

It will also be necessary to take into account the electrical load mode of 220V or 380V, and the possibility of an intra-house electrical network carrying the load through such a boiler. To select a specific model, you will need to take into account the heating scheme, so if the house has a “warm floor” system, the boiler power is selected 30% more.

The best manufacturers

Due to their advantages, ion boilers remain very popular sources of heat supply on the Russian market.

They are produced by a number of domestic factories, and there are also models from Western manufacturers.

General overview of the most popular brands:

- "Galan", a boiler unit from a Moscow company. The company produces several basic models on a 220 V network: "Ochag", "Turbo" and "Geyser", and on a 380 V network - "Vulcan". For the devices you will need to buy a main control unit "Navigator", a circuit breaker "ABB", a thermostat "BeeRT", which controls the performance of the circulation electric pump.

- Electrode ion boilers Beryl, a Russian manufacturer, are available in 2 standard sizes for a 220/380 V network and, accordingly, with a power of 9/33 kW. It has a top-mounted power supply unit, which simplifies installation and maintenance. It is necessary to additionally purchase a “Euro” CSU unit, which allows for stepwise control of the coolant heating power every 200 W.

- Electrode boilers of the EOU brand of a domestic manufacturer, with a power range from 2 to 120 kW, in a 220/380 V network.

- "Forsazh" of the Ukrainian manufacturer are equipped with a special protective casing that increases safe operation and has a designer appearance. It is presented in 5 modifications for a 220 V network, with a power from 3.0 to 20 kW, which are equipped with an ECRT control unit.

- STAFOR, a Latvian manufacturer, complies with EU requirements. The design has a number of innovative solutions, including the use of a “Faraday cage” with distribution of safety and working zero. Together with it, it is possible to buy a branded coolant and a specialized additive STATERM POWER, which allows timely adjustments to the chemical composition of the electrolyte to regulate the efficiency of the boiler.

Main characteristics

The main technical characteristics of the ion heating boiler can be found below:

- • The minimum power of the equipment cannot be lower than 2 kW (it is enough to heat rooms up to 80 cubic meters), the maximum reaches 50 kW (suitable for heating large industrial premises up to 1600 cubic meters);

- • The power of units with one phase varies from 2 to 6 kW, with three - from 9 to 50 kW;

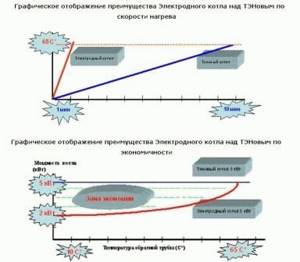

- • Energy consumption reaches its nominal level at 75⁰ temperature inside the boiler. At temperatures exceeding the specified one, energy consumption increases and does not correspond to what is stated in the data sheet.

- • The dimensions of a standard domestic boiler are usually no more than 320 mm in diameter, 600 mm in length and 12 kg in weight.

Advantages of an ion boiler

The primary advantages of using an ion boiler

To install an ion (electrode) boiler, you do not need to give up the use of gas connected to your home. The main thing is the presence of wiring from radiators and highways. It is worth noting that electrode boilers, as a rule, play the role of secondary devices in the house. If the cost of the gas tariff shows an increase in indicators, then it is recommended to use the ionic system as the primary source of heating the room.

Let's consider the positive characteristics of an ion electrode heating boiler:

- Reliability, or fire safety;

- Quiet operation;

- No need for a separate room to install the device – compactness;

- The presence of combustion products is not provided - an environmentally friendly operating principle;

- Autonomy of room heating;

- No complex manipulations during the system installation process;

- High degree of efficiency;

- Efficiency rates up to 99 percent;

- Possibility of operating an ion boiler on gas.

The presence of a built-in automatic system helps set the optimal temperature, which is maintained in the room for the required time. To increase the efficiency of the device, it is necessary to program the heating system to reduce the temperature on weekdays when there are no people in the room.

Many users of the ion boiler note the effectiveness and reliability of the emergency safety system, which activates the automatic shutdown of the boiler. Owners of an electrode boiler identify another advantage of the device - the absence of short circuits.

Recommendation: it is safer to purchase coolants from the direct manufacturer of the device.

Disadvantages of using an ion boiler

- Lack of constant power supply;

- High electrical power is required to activate the boiler;

- High requirements for water quality;

- Requirements for grounding the device - reducing the risk when operating the device;

- Maintain water temperatures of 70 degrees so that flow rates are minimal;

- Installation of a water pump that will circulate water in the coolant.

Recommendations:

- During the calculation process, the following must be taken into account: 8 liters of coolant must correspond to 1 kW;

- Used coolants must be properly disposed of. Draining coolant into a reservoir/sewer/ground is prohibited;

- Before carrying out installation work, it is recommended to clean the structure of the lines as much as possible with clean water, or with special chemicals intended for cleaning the lines.

- The acceptable temperature is 50-70 degrees - all technical information is indicated in the passport of the heat-heating device.

How to install an ion boiler

Most often, a gas or solid fuel boiler is used to heat a private home. If none of the options suits you, choose ion heating boilers. The technical characteristics of this type of boiler will pleasantly surprise you, because this device works thanks to a special method of heating water in the heating system.

Technical characteristics of the ion boiler

During operation, water ions move in chaos between the anode and cathode located inside the boiler. The current generated between them helps accelerate the ions and thus heats the coolant. Cathodes and anodes are made from a special durable material that does not rust.

The housing is made hermetically sealed to avoid a breakthrough if the system is connected incorrectly. The complete set of the heating device consists of a heating element, a relay protecting the boiler and a special thermostat that allows you to regulate the temperature.

An ion boiler allows you to install several closed heating systems in one room. This heating device is compact and can be mounted in any more suitable place. The efficiency of such a boiler is almost 100 percent.

Installing a cathode and anode in the system allows energy losses to be reduced to zero. 20 square meters per hour consumes about one kilowatt. During boiler operation, the water in the system heats up much faster compared to other types of boilers. The low start-up inertia allows the coolant in the radiators to be heated to the required level in a short period of time. In addition, the boiler has increased protection against power surges. If there is no coolant in the heating system, the boiler does not fail.

Installation of an ion heating boiler

Before purchasing a boiler, you need to calculate the heated area in the room. For example, you can take an area of 48 square meters with ceilings of 2.6 meters and high-quality thermal insulation.

The area, that is, 48, is multiplied by the height from floor to ceiling, that is, by 2.6. From this it is calculated that to warm up one meter it will be 0.025 kilowatts. A boiler with a power of 3 kilowatts is enough to heat the entire room.

- To shut off the coolant in case of system failure or replacement of the coolant, a ball valve is installed.

- To ensure uniform circulation and distribution of water across the batteries, a circulating pump is installed.

- The filter cleans the incoming coolant into the boiler from scale and rust.

- A drain valve is mounted on the return pipe at the bottom to remove water from the system.

- An expansion tank is required to collect excess water that is generated when it is heated in the system.

- The automatic module for turning on the boiler starts the boiler with the specified parameters.

- After this, the air intake is installed.

For an ion boiler to operate in the correct mode, water must have a certain density. When replacing any boiler with an ion one, you first need to drain the old water from the system and fill it with new one. In addition, an inhibitor is added to it. Distilled water is taken for the heating system.

To connect the boiler to the heating system, steel pipes without galvanization are used. After 120 centimeters from the boiler, the pipeline can be made of a different material.

An ion boiler allows you to quickly and efficiently heat a room, so read the technical specifications carefully. You can install the ion boiler yourself if you carry out the calculations correctly and follow the step-by-step instructions.

Don't miss: Bubafonya Oven.

Design features

An ion electrode boiler differs from a conventional boiler in the absence of a heating element, and therefore the heating of the system is carried out entirely due to the characteristics of the special coolant. Instead of a heating element, a block with electrodes is installed in the unit, which serves as the main heating element. Such a replacement made it possible to solve the problems of fragility and low efficiency associated with the operation of most electric boilers.

Despite the seemingly primitive design, the ion heating boiler boasts fairly high efficiency, practicality in use and an almost zero accident rate, which for many private homeowners are decisive factors in favor of choosing such a unit. In addition, if you have the desire and some experience, you can make an ionic electric boiler with your own hands. It is enough to understand the principle of its operation, familiarize yourself with a schematic representation of the design and prepare the necessary materials and tools.

So, externally, such a boiler is a solid steel pipe coated with a layer of polyamide. The following are connected to the product body:

- • coolant inlet/outlet pipes;

- • power supply and grounding terminals;

- • electrode made of a special alloy and insulated with polyamide nuts;

All connector locations are equipped with additional protection against current leakage with rubber gaskets. As you can see, special attention is paid to electrical insulation.

A number of manufacturers equip their ion boilers with automatic control systems. It is the controllers, which include built-in protection against power surges in the network, a starter unit and an electronic thermostat, that allow you to maintain the specified temperature of the coolant, thereby reducing energy consumption. Control can be either direct or remote using GSM channels (in more expensive models).

As for the principle of coolant movement inside the boiler, there are closed and open ion boilers.

Simple DIY ion boiler

Having become familiar with the features and principle by which ion heating boilers operate, it is time to ask the question: how to assemble such equipment with your own hands? First you need to prepare the tools and materials:

- Steel pipe with a diameter of 5-10 cm

- Ground and neutral terminals

- Electrodes

- Wires

- Metal tee and coupling

- Persistence and desire

Before you start putting everything together, there are three very important safety rules to remember:

- Only the phase is supplied to the electrode

- Only the neutral wire is supplied to the housing

- Reliable grounding must be provided

To assemble an ion electrode boiler, just follow the following instructions:

- First, a pipe 25-30 cm long is prepared, which will act as a body

- Surfaces must be smooth and free of corrosion, nicks at the ends must be cleaned

- On the one hand, electrodes are installed using a tee

- A tee is also necessary to organize the outlet and inlet of the coolant

- On the second side they make a connection to the heating main

- Install an insulating gasket between the electrode and the tee (heat-resistant plastic is suitable)

- To achieve a tight seal, the threaded connections must be precisely adjusted to each other.

- To secure the zero terminal and grounding, 1-2 bolts are welded to the body

Having put everything together, you can embed the boiler into the heating system. Such homemade equipment is unlikely to be able to heat a private home, but for small utility areas or a garage it will be an ideal solution. You can cover the installation with a decorative casing, while trying not to restrict free access to it.

Consumer Reviews

Ion boilers have both pros and cons. Positive user reviews point to the benefits discussed earlier. These are cost-effectiveness, ease of installation, safety, reliability, etc. Negative reviews from users using a flow-through ion heating boiler in the heating system indicate such disadvantages as the complexity of repair work and maintenance of the device, the need to use an additional pumping group of equipment, and the need for constant monitoring of electrical conductivity coolant, etc.

As you can see, reviews of electrode heating boilers are quite contradictory, so the consumer should carefully study the technical characteristics and operating features of a particular model before purchasing. The process of heating the coolant in ion boilers is fundamentally different from the operating principle of other types of electric heaters.

Through the use of innovative technologies, the developers managed to achieve impressive performance qualities of the ion boiler.

By integrating an ion heater into the circuit, the property owner can count on bonuses in the form of low heating bills and the ability to quickly and evenly heat the home.

Advantages and disadvantages of ion heating boilers

The obvious advantages of electrode boilers include the following:

- efficiency (heating of the coolant occurs almost instantly, efficiency approaches 100%);

- durability (scale does not form);

- compactness, ease of installation (overall dimensions and weight of boilers are significantly less compared to heating elements);

- possibility of automatic regulation (correct setting of the digital block allows you to save about 40% of electricity consumption);

- safety of operation with correct installation (if the heating system depressurizes or a liquid leak occurs, the movement of ions will stop and the boiler will not work);

- no noise;

- environmental safety (no combustion products, no need to store fuel resources);

- no need to re-equip the existing system;

- there is no need to coordinate the installation of the boiler with the boiler inspection authorities;

- not a high price.

Like any equipment, ion heat generators, along with their advantages, have their disadvantages:

- preparation of water poured into the heating system (certain parameters are set for water that must be strictly followed);

- there is no possibility of using alternative types of coolants (distilled water, oil, antifreeze);

- to create normal operating conditions for the boiler, constant circulation of liquid in the system is necessary;

- the anti-corrosion material of the electrodes provides them with a long service life, however, it is necessary to constantly monitor their condition and replace it on time;

- high cost of electricity.

Characteristics: advantages and disadvantages

The design is simple and elementary, but has a number of unique properties:

- small installation dimensions, with significant equipment power;

- independently creates pressure in the system, which makes it possible to use it without injection pumps;

- completely anti-emergency system - overheating is not possible, operation stability does not depend on the coolant level;

- Convenience of temperature control - the automation will do everything itself: temperature sensors will work when needed;

- voltage drops in the power supply network do not affect the performance and safety of the system - it will produce less or more energy;

- the highest efficiency - the maximum of all existing heating devices;

- absence of radiation negative for life and health;

- easy to integrate into heating as an additional or backup source.

To be objective, let's consider the disadvantages:

- operates only on alternating current, since direct current causes electrolysis;

- it is necessary to monitor the condition of the electrolyte (salt water) - distilled water is not acceptable, since it is a universal conductor, and requires a specific resistance for operation;

- in the absence of grounding, it is prohibited to operate the installation - it is dangerous to life;

- any resistance (resistor) decreases its nominal value as the temperature increases, and as a result, when heated to 75 ° C, the boiler significantly loses power, but the current increases;

- requires periodic cleaning of working elements, as losses begin to occur due to scale on the electrode(s);

- once every 2-3 years, replacement of the electrode(s) is required;

- with an extensive heating network, a pressure pump is required;

- insufficient water level in the heating system is critical, since water with salt impurities corrodes the metal;

- the complexity of physiological adjustment of water resistance - this is very difficult to do without a specialist;

- servicing the circuit requires special knowledge, skills, and special equipment.

Installation and operation

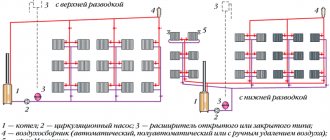

When installing an electrode boiler, the main condition is the presence of working automatic air vents, a pressure gauge and a safety valve. The shut-off valves should be located near the expansion tank.

When installing, make sure that the tank is in a vertical position. In this case, the first 1.2 m of pipe must be made of metal, but the rest can be made of any material.

It is best not to install climate control and thermoregulation system sensors yourself, but to entrust this work to specialists.

Features of installation of ion boilers

A prerequisite for installing ion heating boilers is the presence of a safety valve, pressure gauge and automatic air vent. The equipment must be placed in a vertical position (horizontal or at an angle are not allowed). At the same time, about 1.5 m of supply pipes are not galvanized steel.

The zero terminal is usually located at the bottom of the boiler. A grounding wire with a resistance of up to 4 ohms and a cross-section of over 4 mm is connected to it. You should not rely solely on RAM - it cannot help with current leakage. The resistance must also comply with the rules of the PUE.

If the heating system is completely new, there is no need to prepare the pipes - they must be clean inside. When the boiler crashes into an already operating main, it is necessary to flush it with inhibitors. The markets offer a wide range of products for removing deposits, salts and scale. However, each manufacturer of electrode boilers indicates those that it considers best for its equipment. Their opinion should be followed. By neglecting flushing, it will not be possible to establish the exact ohmic resistance.

It is very important to select heating radiators for the ion boiler. Models with a large internal volume are not suitable, since 1 kW of power will require more than 10 liters of coolant. The boiler will constantly work, wasting some of the electricity in vain. The ideal ratio of boiler power to the total volume of the heating system is 8 liters per 1 kW.

If we talk about materials, it is better to install modern aluminum and bimetallic radiators with minimal inertia. When choosing aluminum models, preference is given to primary type material (not remelted). Compared to the secondary one, it contains fewer impurities, reducing the ohmic resistance.

Cast iron radiators are the least compatible with an ion boiler, since they are the most susceptible to contamination. If it is not possible to replace them, experts recommend observing several important conditions:

- The documents must indicate compliance with the European standard

- Installation of coarse filters and sludge traps is required

- Once again, the total volume of coolant is produced and equipment suitable in terms of power is selected

Difficulties in operation

Branded coolant from the manufacturer Galan. At the time of writing, the cost of such a canister is about 2,200 rubles.

- Proper operation in accordance with the requirements implies the use of high-quality coolant with a balanced chemical composition and all the qualities of the electrolyte. Manufacturers recommend using liquids specially prepared for these purposes that have good ionization, sufficient heat capacity and anti-corrosion properties. It is possible to pour ordinary tap water into the heating system, but this usually leads to a decrease in efficiency and rapid corrosion of all metal lines of the heating system. In addition, over time, any coolant loses its properties and requires replacement after 3-4 years, which also causes additional hassle and expense.

- As we have already mentioned, the effect of electric current on ferrous metals and stainless steel significantly accelerates the corrosion process, which reduces the life of the heating system. Therefore, in conjunction with electrode boilers, it is generally not recommended to install steel or cast iron radiators - only aluminum or bimetallic ones. Otherwise, the lifespan of radiators is literally reduced several times.

- The phases of the electrical network are connected to the electrodes, and zero is connected to the body of the electric boiler, so reliable universal grounding is required and it is not recommended to limit yourself to installing an RCD. If the grounding is poor, dangerous potentials may appear on pipes and batteries. In addition, it is necessary to ensure the quality of the wiring in the house, since high-power equipment creates a serious load on the electrical network and causes voltage fluctuations. However, this is not a feature of ion electric boilers, but in general of any electrical equipment with a power of 4-6 kW.

To summarize: if you are not ready for additional installation work and operating features of electrode boilers, it is better to pay an additional 20-30% of the cost and choose a heating element electric boiler, which is what we recommend doing. Today they occupy about 90% of the electric boiler market. But with a competent approach, there is also a choice in favor of ion-type boilers, the advantages and disadvantages of which are summarized below.

Boiler ION

Only electrode heating boilers are produced under the ION brand. There is an important distinctive feature of the company. They do not claim that their boilers are 30-40% more economical than heating elements, taking into account that both operate with an efficiency close to 100%.

For ION boilers, the coolant requirements have been slightly changed. The best results are achieved with a conductivity of at least 3 kOhm/cm, which is achieved by a higher salt concentration in the solution. But in return, the manufacturer guarantees the durability of the electrode for up to 30 years, which is several times higher than the durability of the main element from Galan and several orders of magnitude higher than the durability of homemade steel electrodes.

There is no division of boilers into lines with characteristic names. The manufacturer claims to have boilers with a capacity from 2 kW to 36 kW. Devices from 2 to 12 kW can be connected to a single-phase 220V network, and boilers from 6 kW to 36 kW are made for three-phase 380V power.

| Technical data | unit. | Heating device "ION" | |||||||||

| Power | kW | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 |

| Voltage | volt | 220 ~ ± 10% | |||||||||

| Type of current | single-phase, alternating | ||||||||||

| Voltage frequency | Hz | 50 | |||||||||

| Heated room volume | m³ no more | 120 | 180 | 240 | 300 | 360 | 420 | 480 | 540 | 600 | 750 |

| Heated area | m² no more | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 |

| Coolant volume in the heating system | liters, no more | 80 | 120 | 160 | 200 | 240 | 280 | 320 | 360 | 400 | 480 |

| Coolant | water | specific resistance of the coolant at a temperature of +15 C ° is not less than 1000 Ohm x cm. | |||||||||

| Hot water lift height | meters, up to | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 13 |

| Efficiency | %. before | 99 | |||||||||

| Outlet temperature | C°. before | 95 | |||||||||

| Operating pressure | mPa | 0,2 | |||||||||

| Technical data | unit. | Heating device "ION" | |||||||||

| Power | kW | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | 30 | 36 |

| Voltage | volt | 220/380 ~ ± 10% | |||||||||

| Type of current | single-phase, three-phase, alternating | ||||||||||

| Voltage frequency | Hz | 50 | |||||||||

| Heated room volume | m³ no more | 360 | 540 | 750 | 900 | 1080 | 1260 | 1440 | 1620 | 1800 | 2250 |

| Heated area | m² no more | 120 | 180 | 250 | 300 | 360 | 420 | 480 | 540 | 600 | 750 |

| Coolant volume in the heating system | liters, no more | 240 | 360 | 480 | 600 | 720 | 840 | 960 | 1080 | 1200 | 1440 |

| Coolant | water | specific resistance of the coolant at a temperature of +15 C ° is not less than 1000 Ohm x cm. | |||||||||

| Hot water lift height | meters, up to | 6 | 9 | 12 | 15 | 18 | 20 | 20 | 22 | 22 | 24 |

| Efficiency | %. before | 98 | |||||||||

| Outlet temperature | C°. before | 95 | |||||||||

| Operating pressure | mPa | 0,2 | |||||||||

Especially for heating systems that include aluminum radiators, it is proposed to use the drug ASO-1, which can increase the conductivity of the coolant and eliminate the consequences associated with aluminum, especially recycling.

Anode (ionic) heating boilers

Energy-saving technologies remain a priority in all areas. They show the greatest efficiency in the field of heating. This approach is associated with a constant rise in fuel costs. Equipment manufacturers offer various options for heating devices. One of them is anode heating boilers.

Design features

In order to understand what we are talking about, let us recall the student and/or military background of many of those who are now reading this article. We are talking about a method of boiling water, for which some used a boiler, while others used a simple homemade design. These are two blades, fixed at a short distance from each other and connected by a 220V power cord. When this “boiler” was placed in water, heating occurred literally within 2-3 seconds and violent boiling began. This is precisely the principle on which an anode heating boiler works.

Don't miss: Single-pipe natural circulation heating system

A homemade boiler is an analogue of a modern ion boiler

Please note that conducting experiments with heating water is dangerous to life and health. On the one hand, a short circuit may occur, on the other hand, a person runs the risk of electrical injury (electric shock).

The convenience of using such devices lies in the fact that parallel installation of electrode heating boilers into an already existing heating system, which works, for example, with a gas boiler, is allowed. The coolant in both cases remains the same. But manufacturing companies produce not quite standard heaters, in which water is simultaneously used as both a coolant and a heating element.

The main elements of the module are:

- steel tube;

- inlet/outlet pipes;

- terminal for connecting wiring;

- heating electrodes;

- high quality insulation.

Cathode heating boilers have a powerful steel body on the outside. The walls are made of sheet metal up to 4 mm thick. Several electrodes up to 20 mm are located inside the household structure. They are made of a refractory alloy that has a long service life.

Modern electrode ion boilers do not have an intermediary material between the anode and cathode. Heating from both terminals occurs directly from the coolant itself, water. Accordingly, there is practically nothing to “burn out” inside the cavity. The scale that appears on the tubes in electric electrode boilers after long-term operation is cleaned off with ordinary sandpaper.

Difference from heating elements

The individual characteristics endowed with electrode heating boilers allow them to be distinguished from heating elements:

- in heating elements, at the initial stage of start-up, the working tubes are heated, and electrode boilers, made by hand or purchased in a specialized store, begin to heat the water immediately after start, which reduces inertia;

- ion heating boilers have positive reviews, as they are 20-0% more economical than devices with heating elements;

- thanks to alternating current with a frequency of 50 Hz, the electrodes move between the terminals and create a chaotic movement that promotes heating; this feature reduces the starting current for the electrode heating boiler, reducing the load on the electrical network

The anode and cathode change places at a speed of 50 r/sec

- A do-it-yourself electrode boiler made or produced at a factory has smaller overall parameters than other household analogues.

Such features ensure significant distribution of this heating system.

Positive performance characteristics

Homeowners do not have to completely give up gas if the premises already have wiring from radiators and mains installed. Often such ion heating boilers play a duplicate role in finished systems. Although, if the cost of gas rises faster, then they can be used as the main source of heating.

Their positive properties include:

- high degree of reliability;

- temperature is controlled automatically;

- real efficiency reaches 99%;

- installation of additional equipment may not be carried out;

- startup and operation in systems designed to operate on gas;

- increased efficiency.

An electric electrode boiler operates exclusively on alternating current. Switching to constant voltage is not allowed.

Thanks to the built-in automation, the set optimal temperature is maintained for the specified time. You can increase energy efficiency by programming the system to lower the temperature on weekdays when no one is home, and raise it in the evening and on weekends.

According to reviews, electrode boilers have a good emergency shutdown system. If a possible coolant leak is detected, the device will automatically turn off. Also, short circuits do not occur in these heating devices.

The coolant for such equipment can be purchased directly from the manufacturer, who will provide the appropriate quality composition.

Disadvantages of the system

In addition to the advantages, each system has its disadvantages. Ion electrode boilers have the following disadvantages:

- increased requirements for electrolytic water quality;

- it is necessary to carry out mandatory grounding of the device in order to reduce possible risks of working with an electrical device;

- it is advisable to maintain the water temperature in the system no higher than 70-75 0 C in order to reduce energy consumption;

- the cathode and anode need periodic descaling to ensure greater efficiency for the ionization process;

- the system requires mandatory coolant circulation, so a water pump must be installed in it.

Voltage drops are not dangerous for the boiler itself, but they are necessary for the accompanying automation. A UPS or, at a minimum, a surge protector will help you avoid damage from an unstable network.

Rules for safe operation

The optimal water temperature for operation is 50-75 0 C. This information is indicated in the device passport. In closed and open systems, expansion tanks must be used.

The outlet from the boiler to the expansion tank in an open system should not have any shut-off valves.

Do-it-yourself installation of an electrode boiler into the system must be accompanied by the installation of an automatic air valve, a pressure gauge for measuring the operating pressure and an explosion safety valve at the highest point of the system.

It is possible to install it in the heating circuit as an additional heating source, but in this case it is necessary to bring the quality and type of coolant into proper condition.

Not all radiators can work with ion boilers, and the quality of the coolant is suitable for some. With very big reservations, cast iron radiators can be used.

When installing, one and a half meters of supply pipes to the boiler must be made of non-galvanized metal. After this section, the use of metal-plastic is allowed.

Grounding according to PUE standards is mandatory. The cable should have a cross-section of 4-6 mm. Its minimum electrical resistance must be no higher than 4 Ohms.

If possible, the entire system of pipelines and consumers should be flushed with clean water before installation. It is allowed to use special chemicals to help clean the lines.

After the coolant has been used up, it must be properly disposed of. It is not allowed to discharge it into sewers, water bodies or into the ground.

When making calculations, they are guided by the following parameter: 8 liters of coolant must correspond to 1 kW. To operate in the 10 l per 1 kW mode, the device will be turned on almost constantly, which may negatively affect its performance properties.

The best European electrode heating boilers

It so happens that European brands deserve more trust from us. Objectively, some models are indeed an order of magnitude better than domestic ones, but lack of adaptation to our conditions makes them fail very quickly, and repairing them is not always profitable.

Buderus Logamax E213-10

A model from a famous German brand, which is traditionally distinguished by its impeccable performance, high quality, reliability and durability. Power 9.9 kW, recommended for connection to a three-phase network with a maximum current of 15 A for three phases. Wall installation. The package includes a circulation pump and an expansion tank.

Buderus Logamax E213-10

Let us highlight the main advantages of this device:

- light weight and compact dimensions.

- Easy installation - brackets included.

- steel body with excellent thermal insulation.

- Efficiency 99%.

- The kit includes a 7-liter expansion tank, a circulation pump, a safety valve, a pressure control sensor, and a blocking sensor that protects the housing from overheating.

Minus - Buderus Logamax E213-10, like all German equipment, is designed for a stable voltage in the electrical network. Therefore, for long-term operation of the device, you need to take care of purchasing a stabilizer.

The cost of the unit will cost on average 38,000 rubles.

Operating instructions Buderus Logamax E213-10

Protherm Skat 24 KR 13

One of the best electrode boilers of the Czech brand, the power of which is 24 kW. The single-circuit model for wall mounting is distinguished by functionality, safety in operation and durability. Can be connected to a “warm floor” system or a boiler for heating hot water. The package includes 4 heating elements, a circulation pump and a 7-liter expansion tank.

Protherm Skat 24 KR 13

Let's highlight a few more advantages of the unit:

- electronic control with power indicator, display and thermometer;

- 4 power levels;

- Possibility of temperature control in the range of 30-85°C;

- overheating safety system;

- high efficiency – 99%;

- soft start function;

- presence of a safety valve and air vent.

Among the minuses, it is worth noting that the boiler is too noisy and needs to be connected through a voltage stabilizer.

Cost – from 43,000 rubles.

Operating instructions for Protherm Skat 24 KR 13

Evan Warmos QX-18

One of the best domestically produced electrode boilers, which some users call a mini-boiler room - one device contains heating elements, a membrane tank, and a circulation pump.

Evan Warmos QX-18

Let us note the strengths of the device:

- LCD display at the bottom of the case;

- convenient control panel, which is hidden behind a special door;

- the operation is controlled by a microprocessor, but the boiler can also be switched to manual control;

- suitable for heating residential and industrial facilities;

- silent operation;

- emergency condition indication;

- coolant pressure and level sensor.

Like any other device, the Evan Warmos QX-18 also has disadvantages - heavy weight, large dimensions, frequent capacitor failures, mandatory connection through a voltage stabilizer.

The cost of the device is from 49,000 rubles.

Operating instructions Evan Warmos QX-18

"Galan" Vulcan 36

was one of the first to begin developing such a family of heating devices, using developments in the military space industry and patented engineering solutions. For a quarter of a century, even the first line of devices has not failed and continues to function.

"Galan" Vulcan 36

Model power 36 kW, suitable only for three-phase network. The maximum current for three phases is 27.3 A. The control is mechanical; the boiler is installed only on the floor.

This model “Vulcan” 36 has many advantages, let’s highlight the main ones:

- ease of maintenance and operation.

- safety and reliability - if an electric short circuit occurs, the current supply wires overheat, the set temperature is exceeded, or a coolant leak occurs, the boiler turns off.

- the coolant volume is 600 liters, the volume of the heated room is 1700 cubic meters.

- affordable cost - the average price is 11,000 rubles.

"Galan" Geyser 15

A safe and productive single-circuit electrode boiler, which is often preferred by owners of country property. Equipment power 15 kW, suitable only for three-phase network. The maximum current for three phases is 22.7 A. The control is mechanical; the boiler is installed only on the floor. As an additional option, it is possible to connect external control.

"Galan" Geyser 15

It is bought due to the following advantages:

- Simplicity and ease of use - even a beginner can understand the device.

- light weight of the structure and compact dimensions - only 5.3 kg.

- large heating area - up to 180 sq.m.

- electronic automatic control - the presence of a control unit that allows you to create an interval for heating the coolant.

- ability to connect to a room temperature indicator.

- The average price of the device will be 7800-8000 rubles.

The best Russian electrode heating boilers

The big advantage of domestic equipment is that it is perfectly adapted to real-life operating conditions - with voltage fluctuations, unstable current, etc. At the same time, in terms of price, maintenance costs, unpretentiousness and reliability, it will give a head start to most competitors.

"Galan" Vulcan 36

was one of the first to begin developing such a family of heating devices, using developments in the military space industry and patented engineering solutions. For a quarter of a century, even the first line of devices has not failed and continues to function.

"Galan" Vulcan 36

Model power 36 kW, suitable only for three-phase network. The maximum current for three phases is 27.3 A. The control is mechanical; the boiler is installed only on the floor.

This model “Vulcan” 36 has many advantages, let’s highlight the main ones:

- ease of maintenance and operation.

- safety and reliability - if an electric short circuit occurs, the current supply wires overheat, the set temperature is exceeded, or a coolant leak occurs, the boiler turns off.

- the coolant volume is 600 liters, the volume of the heated room is 1700 cubic meters.

- affordable cost - the average price is 11,000 rubles.

Operating instructions "Galan" Vulcan 36

"Galan" Geyser 15

A safe and productive single-circuit electrode boiler, which is often preferred by owners of country property. Equipment power 15 kW, suitable only for three-phase network. The maximum current for three phases is 22.7 A. The control is mechanical; the boiler is installed only on the floor. As an additional option, it is possible to connect external control.

"Galan" Geyser 15

It is bought due to the following advantages:

- Simplicity and ease of use - even a beginner can understand the device.

- light weight of the structure and compact dimensions - only 5.3 kg.

- large heating area - up to 180 sq.m.

- electronic automatic control - the presence of a control unit that allows you to create an interval for heating the coolant.

- ability to connect to a room temperature indicator.

- The average price of the device will be 7800-8000 rubles.

Operating instructions "Galan" Geyser 15

RusNIT 208M

, Ryazan. Can be used as the main or backup heat source in a house or domestic premises with an area of up to 80 sq.m. Power 8000 W.

RusNIT 208M

Specifications:

- three-stage power adjustment - 30%, 60% or 100%;

- the heat exchanger and heating element are made of stainless steel;

- antifreeze or distilled water can be used as a coolant in the system;

- the presence of a thermal switch that prevents heating of the coolant above 90°C;

- can be connected to a circulation pump;

- Manufacturer's warranty – 2 years.

Among the disadvantages, we note the manual selection of power, difficulties during connection, requiring certain skills.

The cost of the unit is from 15,000 rubles.

Operating instructions RusNIT 208M

RusNIT 208M

, Ryazan. Can be used as the main or backup heat source in a house or domestic premises with an area of up to 80 sq.m. Power 8000 W.

RusNIT 208M

Specifications:

- three-stage power adjustment - 30%, 60% or 100%;

- the heat exchanger and heating element are made of stainless steel;

- antifreeze or distilled water can be used as a coolant in the system;

- the presence of a thermal switch that prevents heating of the coolant above 90°C;

- can be connected to a circulation pump;

- Manufacturer's warranty – 2 years.

Among the disadvantages, we note the manual selection of power, difficulties during connection, requiring certain skills.

The cost of the unit is from 15,000 rubles.