Autonomous heating systems are becoming increasingly popular.

The development of private housing construction, the emergence of remote residential areas in which there is no possibility of connecting to centralized heat supply lines, contribute to an increase in the number of users of independent home heating systems.

High demand has provoked an increase in supply - there is a huge selection of heating equipment on the market, manufactured in different countries and with different prices.

At the same time, the prices practically do not correlate with the performance qualities of the equipment, which complicates the choice and requires some knowledge regarding the qualities of gas boilers.

Let's consider one of the interesting and successful options - the Conord floor-standing gas boiler.

Floor-standing gas boilers Conord

The Russian company Conord, whose head office is based in Rostov-on-Don, has been producing heating equipment for about half a century.

Analysis of trends in the development of modern heating technology and Russian operating conditions led Conord engineers to a completely different understanding of the tasks of heating equipment.

Unlike Western manufacturers, who rely on increasing functionality and the presence of additional systems, Russian technologists have tried to simplify their gas boilers as much as possible, eliminating all insignificant components and parts from the design.

As a result, a number of floor-standing energy-independent boilers were obtained, optimal for use in Russian conditions. They are reliable and stable, the lack of additional functions has not somewhat deteriorated performance, but, on the contrary, has increased the demand and preference of users.

Preparatory stage

The correct solution to the question of how to light a gas boiler should begin with checking the connection according to the diagram of all necessary equipment - this is:

- Pipeline decoupling.

- Batteries, heated floors, boiler and other consumers.

- Pumps.

- Expansion tank.

- Filtration installations.

- Thermal sensors.

- Control, monitoring and safety unit.

- Uninterruptable power source.

Installation, connection and testing of the system before a test run is carried out according to the following algorithm:

- A separate branch of the electrical network for the unit is being installed.

- The place where the boiler is installed is checked. The device should be placed at the recommended distance from the wall, window and door to avoid malfunction due to cooling and drafts. The base must be strong and perfectly level, verified by the building level. There should be no flammable materials or substances located nearby.

- The unit is connected to the water supply. The equipment pipes are freed from plugs and connected to the piping using filter modules with ball valves.

Connecting a gas boiler to pipelines Source utepleniedoma.com

- A gas pipeline is connected from the central gas main. The procedure is always carried out by gas service specialists, followed by installation of a meter with a seal.

- The chimney is connected and its draft characteristics are checked.

When all elements are connected, the unit is de-energized and, together with the system, is filled with coolant. After this, the equipment and pipes are checked for leaks. Then the thermostat is turned to the maximum level - as a result, the indication of switching operating modes should turn on.

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Types

Conord floor-standing gas boilers do not need to be connected to the power supply. This means that the use of fans or pumps is eliminated.

The combustion chamber of all units is of an open type (atmospheric), circulation of liquids occurs either naturally or using an external circulation pump.

The fundamental difference in design is only the functional features:

- Single-circuit boilers designed for heating.

- Double-circuit, capable of preparing hot water for household needs simultaneously with heating the coolant for the heating system.

IMPORTANT!

Most single-circuit models can be connected to an external indirect heating boiler, which makes them capable of providing hot water to the home in larger volumes than double-circuit models.

In addition, there are differences in the design of the heat exchanger:

- Steel heat exchangers 3mm thick.

- Cast iron components with increased efficiency.

In addition, there are different types of control automation. These are mechanical gas supply and adjustment units.

Exist:

- Italian SIT nodes. In the boiler marking they are designated by the letter S.

- Thermohydraulic elements. They are designated by the letter N.

Recently, American-made components have been installed in some boiler models, which expands the range of boilers. In the marking they are designated by the letter M.

Pre-launch process

The sequence of actions to prepare for startup depends on the type of gas boiler being installed. It can be single-circuit or double-circuit, with a closed or open combustion chamber, floor-mounted or wall-mounted. The first launch is always associated with an increased level of responsibility and risk, so it must be carried out in compliance with all the nuances and subtleties.

The instructions for the gas boiler contain simple explanations according to which you need to start a specific model. The gas boiler must by this time be connected to communications in accordance with the agreed project. The first start-up is carried out after connecting the heating system into a single whole and installing equipment, radiators, and pipes.

Gas boilers with a closed combustion chamber do not require a large chimney. Also, their positive characteristic is the ability to be located close to the wall with a gap of 2 cm, which allows you to save space in the apartment

According to fire safety rules, the gas boiler should be located in places protected from the possibility of ignition, away from flammable objects and materials. In this case, the heating unit should be located at a certain distance from the wall and floor. The exact distance value is individual for each boiler and is indicated in the instructions.

Wall-mounted models are hung on anchors so that there is a small gap between them and the plane of the wall. The boiler must be installed strictly exactly at the water level. Distortions and tilts of the equipment are unacceptable.

After installing the gas boiler to the wall, it is necessary to connect the device to the pipe supplying cold water. To do this, you need to remove the plugs from the receiving pipes.

In addition, a coarse water filter and a mud filter are installed at the inlet of communications to the boiler, which will protect the internal pipeline of the unit from clogging and sedimentation. Ball valves are installed on all pipes when piping.

Installing and running pipes to the boiler is an important task. The end result should not only be beautiful and aesthetically pleasing, but also provide easy access to key parts of the system

Before starting the boiler, an important step is to install a gas pipe to it. This work cannot be carried out independently. You will have to invite craftsmen from the GorGaz branch with which you have a service agreement.

Gas workers will calculate the required length of the pipe, lay it, install a gas meter and seal it. In order for the device to work for a long time and not smoke, you need to take care of the supply of good gas.

Also, for a gas boiler, for safety reasons, it is advisable to install a separate power line with its own automatic circuit breaker installed at the entrance. A socket should be placed close to the device, at a distance of 30-50 cm from the body. Grounding must be done; it will protect users from receiving electric shocks in the event of a breakdown on the housing.

Reliable and high-quality pipes are the key to the longevity of the heating system. You should buy pipes and radiators only from trusted manufacturers. A cheap product in this case will only bring problems

A boiler installed in a private house is equipped with its own chimney. It should go outside through the wall or through the attic space to the street. The chimneys of boilers in city houses up to five floors are connected to a public smoke shaft.

Depending on the specific device, the amount of work required to install the chimney varies. Some devices with a closed chamber are also equipped with a pipe to supply air to the combustion zone.

Upon completion of all preparatory work, you need to fill the heating system and the boiler itself with cold tap water. After filling, the system is checked for leaks. Then a remote control panel and a thermostat are mounted on the wall, to which temperature sensors are connected.

Features of filling the system with water

Before you ignite the gas boiler and activate the system, you need to properly fill the heating system and all its elements with water. To begin filling the heating equipment and the circuit connected to it with water, first disconnect the boiler from the power supply. We still need to turn off the gas supply.

Next, you need to turn on the water by opening the valve or tap that supplies cold water, as well as the make-up tap located at the bottom of the boiler. The exact location of the make-up tap is indicated in the instructions for the device.

The technician checking the system must definitely go around all the rooms along the pipes and radiators and check them for the presence of water leaks. If a leak is detected, you need to shut off the water supply and begin to fix the problem.

Before filling the system with water, you need to make an additional bypass of all heating devices and make sure that all connections are tight and tight.

You can drain the water from the system completely or shut off the corresponding link. Then you need to unscrew the leaking pipe connection, drain the water or screw in the plug. Afterwards, the necessary material and tools are prepared, the plugs are unscrewed, and the pipe is tightly reconnected to the radiator using sealant. Next, you need to check the tightness of the system again.

The intake of water is accompanied by a characteristic sound. It is important to unscrew the valve slowly and gradually, avoiding sudden movements. If you open the tap suddenly, there is a high probability of air pockets occurring. Simultaneously with the system being filled with water, the gas boiler pressure gauge shows the current pressure in the system.

The operating pressure must be found in the instructions for using the boiler. When the pressure reaches the operating range, you need to stop the water supply by closing the valve. Typically, the operating range of the boiler is a pressure value of 1.5 - 2 atmospheres.

It is recommended to fill the system with water in the warm season. If the temperature outside is sub-zero, you should preheat the room using a portable radiator to about 20 degrees Celsius.

Removing air pockets

Upon completion of the filling stage, the system must be checked for air pockets, excess air must be bled off and, if necessary, cold water must be added. If you do not bleed off excess air, the radiators will not heat up enough, since there will be a space in them that is not filled with heated coolant.

The Mayevsky tap is a simple device that is a needle valve. It is used to bleed air from the batteries.

To make the first start successful, you should go around each radiator with a screwdriver or other tool and bleed the air from the heating devices. Some batteries are equipped for this procedure with an air vent, a Mayevsky valve, which can be controlled by hand.

The air from the pipe system and the heating devices connected to it is drained until water flows. While the air flows, a characteristic hissing sound is made.

For convenience, it is worth preparing in advance a basin or ladle into which the water will be drained, as well as a rag, which is then carefully used to cover the stream of water so as not to stain the wall or nearby appliances. After the air has been released, you need to tighten the radiators tightly so that water does not leak from them.

Modern boilers are equipped with devices that allow you to automatically remove air pockets from the heating system. However, such devices do not always effectively cope with the task assigned to them. Therefore, you often have to bleed the air manually.

Having completed bleeding the air from the closed heating circuit, they begin to fill the space freed from air pockets with water. Without this operation there will be no working pressure in the system, because it is not filled enough.

To replenish the circuit with water, connect the unit to the power supply, open the feed tap and press the “Power” button. In this case, the pump should start and the boiler burner will try to ignite. However, after a couple of seconds, the electronics will block all attempts, and the display will display an error code, because gas does not flow to the injectors.

This procedure will need to be repeated several times. It will be necessary to recharge until all the air comes out of the pipes and devices of the boiler, as well as the circuit connected to it. When the stage of filling the system and freeing it from air pockets is completed, you need to check the pressure and open the gas supply.

The circulation pump ensures the movement of the coolant. The manufacturer is prohibited from performing any manipulations with it independently, otherwise the warranty obligations automatically become void. If the pump breaks down, simply replace it

Before igniting the boiler, the gas engineer carefully checks that the connection diagram corresponds to the design solution on the basis of which it was assembled. The technician once again makes sure that the pressure in the system corresponds to the parameters recommended by the manufacturer. Tests the tightness of all communication lines and their connection points.

Checking and flushing the system

In order to ensure the high quality of the work performed and prevent possible water leaks, plumbers recommend performing a pressure test of the system before starting the boiler. This procedure will require expensive equipment - a pressure pump. However, there is no need to buy it, as it will only be needed for half an hour to check the system.

You can borrow such a device from friends or rent it. You can also use the service of an on-call technician who will independently check the system and correct any problems that have arisen if necessary.

The purpose of pressure testing is to identify leaky areas of the system and eliminate them. A system that has gone through this process is guaranteed to serve for a long time and will not fail at the most inopportune moment.

There are two methods of crimping: with a water column or with compressed air. The essence of the procedure is pumping air or water into the system to establish a pressure level in it approximately one and a half times higher than the working one. After pumping, it is necessary to record the pressure value on the pressure gauge and wait 10 - 15 minutes.

Before performing pressure testing, it is important to take into account the characteristics of all elements that make up the heating system. In addition to checking the functionality of the system, it is also important not to damage its structural elements with excessively high pressure.

If at the end of this period of time the pressure remains at the same level, then the system is considered pressurized and has no leaks. If the pressure has dropped, then you need to identify the place where water is leaking and eliminate this problem. Then carry out the procedure again.

Please note that before installing a new unit, flushing a circuit that has been in operation for several years must be done. All ]gas equipment[/anchor] warn that installing a gas boiler in an old circuit that has not been cleared of mineral deposits is prohibited. Failure to comply with the rule will result in the boiler owner losing his warranty.

This process is carried out in two stages. Initially, rough washing is carried out. In this way, the largest contaminants are removed. The pressure in the system when flushing should be about 3.5 atmospheres. After the water is agitated under pressure, it is released from the system through a drain valve.

In this case, the coarse filter often becomes clogged. It may need to be washed once or twice. Finish washing is carried out using pressure pumps.

After finishing washing, you need to check the coarse filter. It must be uncontaminated. Supplying contaminated water to the boiler is highly undesirable

After completing the preparatory work, you can start launching the device.

Advantages and disadvantages

The advantages of floor-standing gas boilers Conord are considered to be:

- Reliability, simplicity of design, absence of unnecessary parts and components.

- Initially designed for operation in Russian conditions.

- Easy to control, stable operation.

- Attractive appearance, compact size.

- The non-volatile design eliminates the risk of system shutdown in the event of a sudden power failure.

- Low price.

The disadvantages of boilers should be considered:

- The need to ensure a technological slope of the heating system, allowing the liquid to circulate naturally.

- Difficulty in ignition, which is done manually.

- The need for periodic maintenance.

NOTE!

The disadvantages of Conord boilers are typical for all such devices and can be attributed to specific design features.

Heating system elements

In country houses it is better to use water heating. This method is considered traditional. Heat is supplied to the house using a coolant, which can be heated by various energy carriers.

Such a system includes the following components:

- heating system devices;

- heat source;

- pipeline network.

If you do not have the time and opportunity to handle heating yourself, then contact the GWDE Engineering Company. Specialists in the installation of engineering systems will perform their work efficiently and will provide a guarantee for up to 7 years.

Full work is impossible without such equipment as:

- expansion tank;

- buffer capacity;

- circulation pump;

- distribution manifold;

- automation devices;

- hydraulic separator;

- heating boiler.

It is important that for a water heating system a mandatory piece of equipment is an expansion tank. Everything else is installed if required.

Series and models

There are two main series of Conord boilers:

- KSts-G. This is a series of single-circuit boilers with a steel heat exchanger KSC means Steel Boiler with a cylindrical Gas heat exchanger.

- KSts-GV. Double-circuit models, the letters GW mean Gas Water Heating.

Both series can be produced with different types of automatic control, which in the marking is indicated by the last letter:

- S - stands for Italian automatic SIT.

- N - thermo-hydraulic automation.

- M - American-made automatics.

In addition to these series, Conord produces a line of floor-standing gas boilers KCH-G, single-circuit, with a cast-iron heat exchanger. They can be connected to an external boiler and produce large quantities of hot water.

The power of all models is in the range of 8-50 kW and is selected in proportion to the size of the house. Usually the calculation is 1 kW per 10 sq. m. area.

Starting an open heating system

It is easier to fill an open heating system. No special tools needed. It is enough to determine the upper point of water in the expansion tank. You will need an assistant to monitor the air valves.

Feeding an open system

Work rules

The liquid is drained through the drain pipe located at the lowest point. If necessary, the circuit is flushed. Filling the system is performed in the following sequence:

- Shut off the drain valve.

- Open the air bleed valves.

- Distillate is slowly poured into the expansion tank.

Tank for open type heating

Continue to fill the system with short breaks so that the air rises evenly to the surface. Filling is carried out until liquid begins to flow out of the air valves. The valves close.

Add water to the expansion tank up to the mark. Do not fill the expander completely. When heated, the volume of liquid increases, and water will begin to pour out over the edges of the tank. The maximum coolant level is 2/3 of the internal volume of the tank.

System check and maintenance

After completing the work, bleed the air from the radiators. Each air valve is checked in turn. Add the required amount of water to the tank.

Bleeding air

When operating an open system, it is necessary to remember that the warm medium is constantly in contact with air and, accordingly, evaporates. Therefore, it is worth periodically looking into the expansion tank. If the level drops, you just need to add enough water.

Before checking, be sure to turn off the boiler and wait until the water cools to room temperature. Do not add media to hot water. Use liquid with a temperature of up to 40°.

Specifications

Let's look at the parameters of Conord boilers:

| Parameter | Meaning |

| Boiler type | Gas heating |

| Installation method | Floor |

| Feature Set | Heating and hot water supply |

| Efficiency | 90 % |

| Unit power range | 8-50 kW |

| Combustion chamber design | Open (atmospheric type) |

| Fuel type | Natural or liquefied gas |

| Heat exchanger material | Stainless steel 3 mm, cast iron |

| Energy consumption | Absent |

| Service life declared by the manufacturer | At least 15 years |

| Guarantee period | 3 years |

Video description

Video instructions for starting a gas boiler:

- Timing. To eliminate excessive fuel consumption, it is necessary to adjust the gas supply intensity using the control module according to the instructions.

Helpful information! The first time after startup, the heating will inevitably work with a certain amount of air, which in practice will be manifested by characteristic sounds. Since it is impossible to remove all the air from the system. However, over time, this effect will disappear due to the operation of the bleed valve on the expansion tank. The main thing is to periodically check the pressure; it should be within the recommended range.

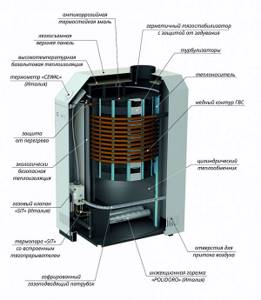

Device

The design of Conord floor-standing boilers is simplified as much as possible. The main elements are a gas burner and a heat exchanger, which together heat the coolant into the heating circuit.

Air intake and smoke exhaust occurs naturally, due to stove-type draft . The coolant circulation is natural and occurs due to the upward movement of hot layers of liquid.

The operation of all components occurs exclusively on a mechanical basis, which eliminates the risk of the boiler stopping due to failure of the electronics, sudden power outage, burnout of any elements, etc.

This is the main feature of Conord gas boilers - reliability and complete independence from external energy sources.

Possible malfunctions when starting the boiler and methods for eliminating them

Failures of gas equipment with electronic controllers can only be repaired by a specialist. If, despite following all the rules, the new gas boiler does not start, the user can independently eliminate the simplest faults.

Cannot turn on igniter

The failure occurs for several reasons:

- the insulator is dirty. To eliminate damage, wipe it with a clean, dry cloth. Heavy stains can be removed with solvents. The element is wiped dry;

- formation of soot deposits in the space between the body and the spark plugs. In this case, no spark appears. You need to tap on the gas supply channel.

If, when the igniter is on, gas does not flow when you turn the knob, there is a risk of problems with the solenoid valve, thermocouple, thermostat or supply valve. These breakdowns are repaired by a specialist.

Advice! If you find a web, you need to unscrew the nut and carefully remove it.

Water does not heat up

The complexity of the breakdown depends on the type of boiler:

- Deposits form on the walls of mechanically controlled contour models. The DHW circuit is washed with hot water and detergents;

- electronic gas boilers do not heat water due to breakdowns of electronics or flow sensors.

Important! Only a professional should troubleshoot electronic equipment.

Clock appears

The failure is typical for devices that heat the coolant at high power.

To prevent the cost of paying for gas fuel and premature wear of the automation, the supply intensity is reduced. You need to adjust it according to the instructions by turning the screw on the valve or using the buttons on the control panel. Correct and consistent activation of the gas boiler will create a comfortable temperature. By following the recommendations of experts, you can easily carry out the first launch of equipment that will be effective in cold and damp weather.

Watch a video on how to properly turn on and start a gas boiler

User manual

Operation of Conord boilers does not require any specific actions from the user.

It is only necessary to maintain cleanliness, periodically (once a year) carry out maintenance and clean the boiler from soot and other combustion products . The boiler is ignited in two stages, using a pilot (ignition) burner.

Procedure:

- Set the regulator to the operating position (spark symbol).

- Press the handle all the way and simultaneously press the piezo ignition button several times without releasing the handle.

- After a flame appears on the ignition burner, release the handle.

- If ignition fails, the procedure is repeated.

The piezo ignition function is not available on all Conord boiler models. Some of them are lit with an ordinary match, similar to the principle of a gas stove .

Download instructions

Download instructions for Conord gas boilers.

Replacing the coolant: reasons and frequency

Replacing water in a closed and open heating circuit is carried out:

- During the first heating start.

After installation, the system is filled and started

- After seasonal drainage.

- When starting after repair work.

Regular topping up of liquid is required during operation if it has not been drained after the heating season.

Why drain your home system?

A question for which there is no clear answer is whether it is necessary to drain the circuit annually after the end of the heating season? The decision depends on the type, age and material of manufacture of the main elements - pipes and radiators, as well as on the total volume of liquid.

Each type has its own frequency of media replacement

Most often, systems with old cast iron radiators are drained for the summer. The reason is the appearance of a leak after the boilers are turned off. The old cast iron ribs are connected to each other by threaded connections with old gaskets. When there is hot water inside the batteries, the seals expand, providing a stable seal at the seams.

Repair of cast iron radiators

After the water cools, the material from which the gaskets are made naturally contracts and begins to flow at the junction of the ribs. But prolonged idle time of old radiators without water is fraught with accelerated corrosion; the rust inside the radiator and old pipes crumbles in a dry environment, and can damage the entire riser.

In closed new circuits, filling the heating system is not a costly process. But it is not recommended to completely drain the liquid every year - this is not necessary.

Frequency of replacing and topping up fluid in the heating system

How often do you need to change the fluid in your heating system? A few general rules:

- In open-type circuits of private houses, it is enough to simply add water if the system is sealed, without subjecting the old communications to stress tests in the form of long dry periods. Replacement is necessary only in case of emergency repair or preventive sealing, after washing.

If a leak occurs, it is necessary to drain the water and carry out repairs.

- Closed heating systems require preventive flushing and replacement of the coolant after several years.

The frequency of filling with new liquid depends on the characteristics of the water, the service life of the synthetic coolant, and the general condition of the system. If the extreme points are very airy, it is recommended to identify the cause - find the location of the leak and check the tightness of the heating network. Typically, water changes are carried out every few seasons.

Basic faults

The design of Conord boilers is very simple and does not have many details. This can significantly reduce the number of weak points in the design and reduce the number of malfunctions .

The heat exchanger and ignition equipment are usually considered to be the most loaded and most likely to fail. The heat exchanger is susceptible to lime deposits. The additional layer isolates the coolant from the walls, reducing heating efficiency.

It is necessary to increase the combustion mode, which increases the load on the external part of the heat exchanger, which fails faster . The ignition equipment fails due to thermocouple failure or other reasons.

There is also a constant danger of burner nozzles becoming clogged with soot, which can be eliminated by periodically cleaning the boiler.

Two-pipe heating system

Do-it-yourself installation of solid fuel heating in a private house using this scheme is considered more effective than the previous option. Despite the complexity of execution and high cost, the system has a significant advantage: uniform distribution of heat across all batteries and the creation of comfortable living conditions.

A two-pipe system involves connecting a pipe with hot water to each heat exchanger and discharging the cooled coolant through a separate return pipe. In this case, the simultaneous supply of coolant allows each radiator to be evenly heated, regardless of its location relative to the boiler.

This scheme requires more materials due to the complexity of the pipe layout.

The operation of a two-pipe system can be organized according to a collector or beam scheme. In any case, heating installation from a boiler in a private house should be carried out by an experienced specialist.

In the first case, a collector is installed in the attic, thanks to which the working medium is evenly distributed throughout the pipes of the heating system. Cranes designed to cut off circuits are also installed here. This allows you to repair any area without affecting the operation of the entire system.

However, such a reliable and efficient system still has a drawback. It consists in the need to use a large number of materials, including shut-off valves, pipes, sensors and control devices.

The radial wiring option involves installing a supply pipe at the highest point of the room and installing bends to each radiator.

Price range

Conord boilers belong to the group of inexpensive equipment. Prices for units fall within the range of 11-47 thousand rubles, which is significantly cheaper than imported units.

A big bonus is the energy independence of the boilers, which frees the user from the need to purchase a voltage stabilizer as unnecessary.

IMPORTANT!

Purchasing water filters is necessary, especially for residents of regions with hard water. You also need to enter into a guarantee agreement, which you will also have to pay.

Removing air pockets

No matter how carefully the system is filled, air pockets will inevitably form in it. Therefore, the next stage in solving the question of how to ignite the boiler is bleeding the air. It is performed according to the following scheme:

- Air is sequentially bled from the radiators, starting from the top to the bottom. Special valves are opened one by one - as a rule, these are Mayevsky taps - until coolant begins to flow from them.

- Next, the procedure is transferred to the circulation pump.

- The panel on the front side is removed from the unit and a cylindrical element with a slot for a flat slot is found. The cover is loosened by turning the fasteners with a screwdriver.

Bleeding air from the circulation pump Source ytimg.com

- The boiler starts and heating is established - at the same time the pump should begin to emit a buzzing and hissing sound - indicating the presence of air pockets.

- When water begins to exit the cylindrical element, its lid tightens. Then the procedure is repeated 2-3 more times.

- Then it closes and the front panel is assembled.

Further, before starting the gas boiler, the system must be supplemented with coolant. Since during the procedure of bleeding the air plugs, its partial loss occurred.

Features of filling the system with water

To turn on the heating system, you must first fill it with coolant, i.e. water, which, after heating, will begin to circulate. A feature of modern equipment is that special manual recharge is not needed. During the first launch, you need to carefully check everything so that further work proceeds smoothly and accurately. Not only a pump is built into the boiler body, but a special tap near the pipe for supplying cold water to the system. When cold water is supplied, noise is heard, this is quite normal, there is no need to panic.

During filling, you need to monitor the pressure in the system; special sensors and pressure gauges are provided for this. Modern equipment necessarily has such additional elements, so there is no need to purchase them separately. As the gas boiler fills, the mark on the sensor rises. When it reaches 1.5-2 atmospheres, it is necessary to stop the supply of cold water, i.e., filling is completed. The pressure parameter may be different, since everything depends on the equipment manufacturer and its requirements for the operating pressure in the system. But this is not the final filling; replenishment is necessary as the heating system is freed from air pockets.

Return to contents

Pressure testing and washing

Pressure testing is not always done due to the lack of a special pump and the reluctance to call a team, but if the heating fails in the midst of cold weather, the costs can be much higher!

It is especially important to check a new system and one that, on the contrary, has been in use for several years.

The cost of crimping in construction companies is from 3,000 rubles.

Additionally, they may charge a fee for visiting the site (about 2 thousand rubles). By the way, a manual pressure testing pump will cost 4.5 – 6 thousand rubles.

Briefly about the main thing

Before lighting a gas boiler, it is necessary to perform a number of preparatory procedures:

- Connect and check the equipment.

- Fill with coolant.

- Eliminate air pockets.

- Carry out pressure testing and flushing of the system under the action of a pressure pump.

Next, in accordance with the manufacturer’s instructions and recommendations, the unit is started for the first time. During operation, it is necessary to monitor the operation of the boiler and the system, and in case of failure, promptly correct the malfunction.

Ratings 0