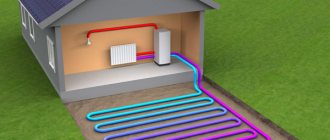

In this article we will connect an electric boiler with a solid fuel boiler to one radiator circuit. That is, this is probably a scheme for small houses. We will analyze a multi-circuit circuit - with several branches of radiators - in the next article. An electric boiler and a solid fuel boiler are installed in the same system so that the first smooths out the inconvenience of using the second. As a rule, with this combination, the solid fuel boiler is the main one, and the electric one is the auxiliary one.

For heating in this case, you can use an alternative source of electricity or another type of fuel. There are options that allow you to switch the system from electric to solid fuel or gas boiler.

This type of autonomous heating, the popularity of which is steadily growing. It is considered more economical to operate than radiator systems. A heating circuit made of a narrow plastic pipe is laid in a screed under the floor covering. If you plan to use the same heater to provide hot water to the water supply system, you will have to take a model with a heating element.

They can be used for TP, but additional installation of a mixing unit will be required to cool the coolant to an acceptable level. In any case, a hydraulic comb containing such a unit will be needed for the correct installation of heating of this type.

Heating control is performed using a temperature sensor that determines the current temperature of the coolant. There are automatic control modules that allow you to additionally take into account the heating of the air in the room. For a warm floor to function successfully, a number of important elements are needed. For example, the pipe for each individual circuit must be solid; no joints are allowed.

Why do you need an electric boiler piping?

It is necessary to carefully calculate the length of such a structure, taking into account the layout of the TP contour. To do this, you can use special formulas to perform the calculations manually. It is convenient to use calculators available on specialized websites.

After entering information about the area, layout and other characteristics of the transformer substation, the program will provide the necessary information. Usually the estimated length of the pipe is slightly increased to have a small margin. If it seems too short, you'll just have to buy a new one. Heated floors require a filtration system to ensure that the coolant is sufficiently clean.

One of the significant reasons for using an electric boiler for heating is the possibility of using double tariffs for the use of electricity.

Reducing fees during the night period allows you to significantly reduce costs.

Two-pipe heating circuit with electric boiler

You will need to purchase and install a two-tariff meter. It is worth noting that double-circuit models of equipment with heating elements supply hot water to the collapsible tap with a characteristic noticeable delay. As a result, some of the heat is lost, which reduces the effect of saving electricity. It makes sense to supplement such a design with an external heat accumulator that can maintain the high temperature of heated water for a long time. Such a device is quite effective when using a two-tariff meter.

Water is heated at night, stored warm and used during the day, energy consumption during the day is reduced, as well as electricity bills. Although using an electric boiler as a heating device is considered too expensive, its advantages are obvious. Such devices are safe for people and the environment, operate automatically, are accessible and easy to use.

If the type of heating system is chosen correctly and all its components are professionally installed, the boiler will operate for a long time without unnecessary costs. Do you have experience using an electric boiler to heat your home? For a wall-mounted model, the installation locations of fasteners are marked on the wall and holes are drilled. During the work, it is important to check the horizontal position of the fasteners using a building level. Before starting work, make sure that the wall can withstand the entire boiler filled with water.

Electric boiler for heating a private house using heating elements

This is the most common design, widely used for many decades in the private sector and industry. Its production was mastered not only by well-known enterprises, but also by folk craftsmen.

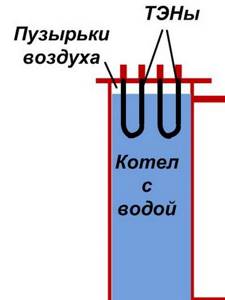

Principle of operation

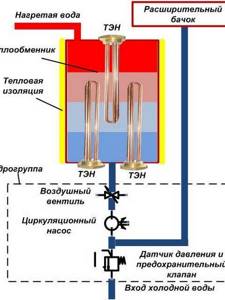

The boiler is filled from a sealed metal container with water, heated by built-in heating elements with current conductors in the form of bent insulated tungsten filaments, placed inside a metal tube body resistant to hot, humid environments. Its ends are equipped with tips for threaded connections with the boiler lid, and threads for connecting electrical wires.

An electric current passing through a tungsten spiral creates heat, which is transferred through the insulating layer to the metal of the tubes and only then to the coolant.

With the correct selection of components, the initial efficiency of the thermal system can be increased to 80%, when 20% of the electricity is irretrievably lost.

Features of operation

It should be noted that ordinary water contains many salts of various chemical elements, which, when heated, precipitate, forming scale on the walls of heating elements, boilers and pipelines, which impairs heat transfer, clogging pipes and containers. As a result, the efficiency of the heating system decreases by up to 30%, and energy costs for heating increase sharply.

When water is heated, dissolved gases are released from it. The bubbles reach the top of the container, where an air cavity is formed, further separating the heating element body from the coolant. In this place, due to deterioration in heat removal, overheating of the metal of the housing may occur with burnout, leading to a violation of the tightness and breakdown.

Therefore, it is recommended to place and orient the heating elements in such a way that they do not fall into the zone of the created air cavity and are always covered with coolant. For this purpose, an electric boiler for a private house using heating elements is produced with heating elements located in the lower part (less often) or on the side in a horizontal plane (more often).

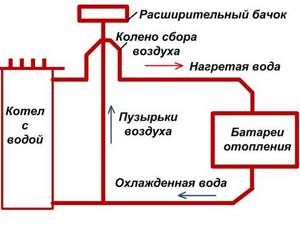

Another technical method for protecting the housing from contact with the released air is to form a special high elbow near the pressure pipeline to accumulate air bubbles and subsequently remove them, as well as installing an expansion tank in the return line.

In order to regulate heat output, cascade connection of heating elements with electrical switching devices is used.

Design

The schematic diagram of the boiler is shown in the figure. On it, the outlet of the hot coolant is brought up to remove the resulting air bubbles in order to protect the upper heater. At the same time, the lower heating elements are always flown around with water and heat is uniformly removed from them.

This is what modern wall-mounted electric boilers look like.

They are equipped with complex devices that automate the entire technological process. The boiler includes:

- a special circulation pump for pumping water through pipelines;

- thermal insulation of the tank to reduce losses and maintain the operability of the process cabinet equipment;

- control unit with sensors providing operating temperature for normal and emergency modes.

Installing a heating boiler on the wall is simple.

On top of the highway there is a safety block with control devices.

A modern electric boiler for a private home is produced in a special cabinet along with connected components installed at factory stands.

But there is a cheaper option for a boiler without a cabinet. Its acquisition necessitates the further purchase of a circulation pump, expansion tank, safety unit, control and automation systems. This equipment will need to be installed, secured, configured to work together, which may lead to additional costs.

Purchasing equipment that is factory-installed and mounted in a single cabinet may end up being a less expensive option.

Heating devices with heating elements

The most common, affordable and popular options for electric heating boilers: they heat the coolant with heating elements, are not demanding on the quality of water in the system, and are repairable. If there are automatic control systems, they are safe and easy to operate. You can hang and connect most single-phase devices yourself, following the instructions from the manufacturer. To piping boilers with a power of over 3.5 kW, it is necessary to involve a specialist - he is able to assess the condition of the electrical wiring and heating circuit.

Teplo-NTM LLC, EVPM model range - from 2,970 to 16,145 rubles.

The EVPM line is represented by 8 basic models, which differ only in the number and power of the installed heating elements. The temperature range of the coolant at the outlet is the same for all eight models.

The simple design and intuitive controls allow you to independently monitor the operation of devices, clean, configure, or even perform block repairs. The relatively low cost of the models is due to the small number of components.

Even the most powerful models, in the basic configuration, have neither sensors, nor a remote control unit, nor a circulation pump.

Keep in mind that when replacing a block of heating elements, you should save the sealing rubber (carefully remove it from the groove on the old block) or prepare a new one in advance. Because a new block is usually supplied without a seal. Technical characteristics of EVPM boilers

| Characteristic | Meaning |

| Serial power options, kW | 3, 6, 9, 12, 18, 24, 36, 48 |

| Outlet coolant temperature, 0C | 35 – 85 |

| Maximum pressure in the heating circuit, atm | 2.5 |

| Acceptable coolant | Tap water, ethylene glycol based solutions |

| Dimensions (HxDxW), mm | 710x180x654 |

| Basic version | Light indication, three-stage power adjustment, temperature adjustment. |

First start-up of the EVPM boiler:

Alvin EVP – from 3,599 to 12,272 rubles

The EVP model range consists of 10 devices with different numbers of heating elements and different powers. Each boiler is equipped with manual control. The minimum of equipment involved in the design of the device and its maintainability, the ability to include any suitable circulation pump in the circuit are absolute advantages.

The disadvantages are weak terminal connections and not the most reliable design of the capillary thermostat.

If there are any signs of breakdown, immediately check all contact groups for quality connections. Because only 10% of malfunctions in Alvin EVP boilers occur in the control electronics and heating elements. In other cases, poor contact on the connections is to blame. Technical characteristics of the Alvin EVP line

| Characteristic | Meaning |

| Serial power options, kW | 3, 4.5, 6, 9, 12, 15, 18, 24, 30, 36 |

| Outlet coolant temperature, 0C | 1-89 |

| Maximum pressure in the heating circuit, atm | 3 |

| Acceptable coolant | Tap water, low temperature liquids for CO |

| Dimensions (HxDxW), mm | 540-670x140-170x280-460 |

| Basic version | Emergency indication, overheating protection, three-stage power adjustment, temperature adjustment. |

Unpacking the Alvin EVP boiler:

ZOTA “Lux” for single-phase network – from 16,290 to 18,600 rubles

The “Lux” line offers 5 similar-sized devices of varying power, which can be powered from a single-phase power supply. The digital control unit allows flexible adjustment of operating parameters. It is possible to integrate a GSM module into the system for remote activation, monitoring the current status and changing settings.

The main disadvantage is the price. Which makes these comfortable, but far from the most powerful models of electric boilers inaccessible.

Please note that the user menu with an impressive range covers all parameters.

That is, you can always find a comfortable combination. Don't listen to "experts" who advise replacing the factory firmware. Changing the parameters of the engineering menu is a sure way to damage expensive equipment. Technical characteristics of the single-phase ZOTA “Lux” line

| Characteristic | Meaning |

| Serial power options, kW | 3, 4.5, 6, 7.5, 9 |

| Outlet coolant temperature, 0C | 20 — 90 |

| Maximum pressure in the heating circuit, atm | 6 |

| Acceptable coolant | Purified or distilled water |

| Dimensions (HxDxW), mm | 730x160x290 |

| Basic version | Sound and visual indication, programmable control unit with a wide range of tasks, 2 temperature sensors, GSM module. |

Video review of ZOTA boilers of the “Lux” line:

Evan Warmos M – from 26,780 to 44,660 rubles

The Warmos M line consists of 8 models of different power, each of which is characterized by uniform dimensions and extended equipment. Stainless steel heating elements and their alternating switching on (“rotation”) when the boiler is operating at low power are the most effective measures to increase the service life of the device.

A decent level of operating comfort can be increased by adding a GSM or Wi-Fi module and temperature sensors to the system. After some time, the overall positive impression is spoiled by significant noise during operation of the device.

Keep in mind: the hum from the boiler is caused by the accumulation of scale on the heating elements.

There is no reason to blame the manufacturer for selling low-quality products. Technical characteristics of Warmos M boilers

| Characteristic | Meaning |

| Serial power options, kW | 7.5, 9.45, 12, 15, 18, 21, 24, 30 |

| Outlet coolant temperature, 0C | 30 — 85 |

| Maximum pressure in the heating circuit, atm | 4 |

| Acceptable coolant | Water and antifreeze liquids |

| Dimensions (HxDxW), mm | 635x245x380 |

| Basic version | Circulation pump, self-resetting thermal switch, light indication, pressure and dry running sensors, stepwise power control, temperature setting, thermomanometer. |

Video review of Warmos M from the manufacturer:

Protherm Skat – from 38,300 to 47,500 rubles

The “Scat” line consists of 8 wall-mounted single-circuit models for heating, which have the ability to work together with “Proterm” storage boilers in a hot water supply system.

The boiler is purchased separately, and to connect it it is recommended to use the original kit (3-way valve, actuator, wiring, bracket and seals) - in this case, the boiler automation fully controls both DHW and heating.

Different potentials of heating elements and 3-stage adjustment of each of them allow you to heat water with an accuracy of 2.5 °C. Thanks to the same system, a gradual increase in power is realized. Therefore, even with rapid heating of the coolant, sudden voltage drops in the network are excluded.

The choice is made difficult by the different number of power levels of devices: 6 for 6, 12 and 14 kW equipment; 9 – for 9, 18 and 21 kW; 12 steps only for 24 and 28 kW.

Please note: the manufacturer’s recommendation to leave a free distance of 0.8 m from the top of any Skat model is not mandatory.

You can do less, but to replace the heating elements you will have to dismantle the entire boiler. Technical characteristics of the Protherm Skat line

| Characteristic | Meaning |

| Serial power options, kW | 6, 9, 12, 14, 18, 21, 24, 28 |

| Outlet coolant temperature, 0C | 30 — 85 |

| Maximum pressure in the heating circuit, bar | 3 |

| Acceptable coolant | Tap water, ethylene glycol based solutions |

| Dimensions (HxDxW), mm | 740x310x410 |

| Basic version | Circulation pump, digital and color indication, three-stage power adjustment of each heating element, temperature setting, built-in expansion tank, safety valve. |

Video review of an individual heating system with a Protherm Skat boiler:

Vaillant eloBLOCK VE – from 40,100 to 50,400 rubles

Electric boilers of the eloBLOCK VE series are designed to serve traditional and low-temperature heating systems. The devices are distinguished by modern design and microprocessor control.

The advantage of a microprocessor-based control unit is expressed in increased functionality. When a storage tank for the DHW circuit is included in the system, microprocessors also provide control of the hot water temperature.

In addition to the high cost of the boiler itself and its maintenance, the disadvantages include the fact that the manufacturer’s warranty only applies if the equipment is installed by specialists from authorized centers.

Please note - to obtain profitable heating, eloBLOCK VE is best used with a heat accumulator and a two-tariff meter.

Technical characteristics of the Vaillant eloBLOCK VE line

| Characteristic | Meaning |

| Serial power options, kW | 6, 9, 12, 14, 18, 21, 24, 28 |

| Outlet coolant temperature, 0C | 25 — 85 |

| Maximum pressure in the heating circuit, bar | 3 |

| Acceptable coolant | Reliable information about the permissible coolant is available only to an authorized service center. |

| Dimensions (HxDxW), mm | 740x310x410 |

| Basic version | LED display, three-stage power adjustment, frost protection, weather-compensated control, anti-blocking built-in pump, temperature adjustment. |

Video review of eloBLOCK VE from an official dealer:

Harness

What should an electric boiler wiring diagram include?

| Circulation pump. It forces the coolant to move along the circuit, ensuring uniform heating of the radiators. |

| Expansion tank. Its function is to accommodate excess coolant that expands when heated. Without a tank, excess pressure in the circuit may well rupture the pipes or boiler heat exchanger. |

| Safety valve. Its task is to discharge excess coolant into the drainage in an emergency situation (when water boils due to the pump stopping or in the event that the capacity of the expansion tank is insufficient). |

| Automatic air vent. It removes air that impedes circulation and creates hydraulic noise. |

| Pressure gauge. Needed for visual monitoring of pressure. |

How to choose the right devices for a heating system with an electric boiler? Instructions are at your service.

Pump

It is selected according to two parameters - pressure and performance.

Pressure is a parameter that can be safely ignored in the vast majority of cases. Its minimum value for younger models is 2 meters, and this is quite enough to operate the heating circuit of a private house of any reasonable size.

Elevator (thermal) unit of an apartment building. The pressure difference between the beginning and end of the heating circuit is 0.2 kgf/cm2, which corresponds to a pressure of 2 meters.

How to choose pump performance?

Its minimum value is calculated using the formula Q=0.86R/Dt. Variables in it (from left to right):

- Productivity (m3/hour);

- Thermal power of the circuit (total battery power or boiler power) in kilowatts;

- Temperature difference between supply and return pipes (degrees).

Let's, as an example, calculate the productivity for a boiler power of 12 kW at 70 degrees in the supply and 50 in the return.

Q=0.86*12/20=0.516 m3/hour.

With many circulation pumps, the performance can be adjusted.

Expansion tank

In closed (not exposed to the atmosphere) systems, a membrane tank is used, part of the volume of which is filled with air or nitrogen. The air chamber is separated from the coolant chamber by an elastic membrane. When heated, the practically incompressible liquid is forced into the tank and compresses the gas in the air chamber.

The simplest way to select the volume of the tank is to take 10% of the volume of the heating circuit. The latter can be calculated by draining the filled heating system into a measuring container.

Standard charging pressure (nitrogen or air pressure in the air chamber) is 1.5 kgf/cm2. It can be increased by simply pumping it up with a bicycle pump through the spool.

The spool (top) allows air to be pumped into the expansion tank using a bicycle pump.

Valve

The response pressure of the safety valve is equal to the upper threshold of the permissible pressure in the system (usually 2.5 kgf/cm2).

Air vent and pressure gauge

The only requirement for them is the range of the pressure gauge scale. It should show a pressure of at least 4 bar (4 kgf/cm2).

The valve, air vent and pressure gauge form a safety group.

Location

Where are the strapping elements located?

- Pump - in front of the boiler, in the area with the lowest temperature;

- Safety group - at the outlet of the boiler, where, when circulation stops, pressure in the circuit begins to increase;

- Expansion tank - at any point in the circuit, but no closer than 2 filling diameters from the pump impeller when installed in front of it and 8 filling diameters after it. The price of violating this requirement is accelerated wear of the membrane caused by constant pressure fluctuations in the tank due to turbulence (vortices) of the flow.

Piping of the Galan electrode boiler: the pump is located directly in front of the boiler, the safety group is after it, the expansion tank is after the safety group.

A special case

In many heating element boilers, the safety group, pump and expansion tank are located directly in the body of the device, which turns it into a full-fledged mini-boiler room.

Such a boiler is connected to a gap in the heating circuit. As additional piping, you only need a pair of ball valves at the inlet and outlet: they allow you to remove the boiler without dumping the entire volume of coolant.

Piping of an electric mini-boiler room - ball valves at the inlet and outlet.

In this case, the readings of the pressure gauge and thermometer are displayed on the indicator on the front surface of the device.

When the boiler is turned on, the indicator on the front panel shows the coolant parameters.

Some features of dead-end heating devices

To avoid mistakes, avoid rework and unnecessary consumption of materials, you need to know the following nuances:

The calculation of the power and throughput of any heating system, including a dead-end heating system, is carried out based on the internal diameters of the inlet and outlet pipes. The drawings and diagrams indicate symbols that are not known to everyone. So, if there is an inscription DU 20, then it indicates the internal diameter of the pipe or connecting element. And the Ø33x3 icon indicates the outer diameter of the pipe and the thickness of its wall

This is important to know in order to avoid mistakes when purchasing. If an extensive dead-end network is being constructed, then shut-off and control valves are installed at the inlet and outlet of each arm. It is recommended to install taps equipped with a device for draining air and excess water. It is important not to confuse thermostat modifications for batteries

Devices intended for use in gravity systems are endowed with greater throughput. The supply pipeline should be installed from pipes of various diameters. It should gradually decrease from first to dead end. The slope must be observed when arranging all systems. Only for natural circulation of the coolant it will be larger, approximately 5 mm per 1 m of pipe, for forced movement - less. 2-3 mm per meter of length is enough.

The dead-end heating system is easy to install and affordable. You can install it in a one-story house yourself, if you have some plumbing skills. This only applies to the wiring itself. Since the gas or electrical part is permitted by law only to be carried out by professionals who have special permits and approvals.

Radiator connection diagrams

For ordinary people who do not think about how radiators are connected in their own home, it does not matter what circuit is used. The main thing for them is warmth in the house. But, as practice shows, it is the connection diagram of radiator batteries that affects the quality of heat transfer. And there are two schemes: one- and two-pipe.

How to make a one-pipe heating system for a private house with your own hands

First of all, you need to understand why it is called that. In essence, a single-pipe is a ring with a boiler in the center. The pipes are laid close to the floor in a circle, with batteries connected to them. Each of them takes the coolant from one side from the lower pipe and squeezes out already cooled water into the same pipe from the other opposite pipe (lower).

Let's face it, it's not the best option, because it has one significant drawback. The radiators far from the boiler receive coolant with a significantly reduced temperature. That is, the batteries closest to the boiler will be hot, the ones farther away will be warm. This means that some rooms will be cool.

Single-pipe with connection of radiators to one circuit

But if a private house is small with 3–6 rooms, then a single-pipe heating system in it is justified due to the ease of installation with your own hands, plus a small number of pipes, shut-off valves and fittings. That is, this is the most economical option in terms of construction. Although the scheme and procedure for installing single-pipe heating are considered simple, the responsibility of the operations carried out is still high. This is especially true for systems with natural coolant circulation

It is important to accurately observe the slope of the pipework.

Two-pipe scheme

This water system is more complex for installation work, plus it uses more materials. But it works much better than a single-pipe one. Purely structurally, the layout of the pipes in it consists of two circuits: supply and return. It should be noted that both pipelines are blind and are connected to each other only through radiators and a heating boiler. From the names themselves, it becomes clear that heated coolant is supplied to the radiators through the supply circuit, and cooled coolant is discharged to the boiler through the return circuit.

In this case, radiators can be connected to the supply circuit in different ways. Option one is a circuit with lower wiring. This is when the coolant supply pipe runs along the floor with a connection to the upper radiator pipes. The return is carried out right there, but with a connection to the lower pipes of the heating batteries.

Two-pipe with bottom wiring

The second option is a top-wiring scheme. This is when a pipe riser is drawn upward from the boiler, which goes into a circuit that distributes the coolant to the radiators. The latter is mounted under the ceiling or in the attic. The return line is installed, as usual, at floor level or in the basement.

It is necessary to indicate that the upper distribution is two options for distributing pipes from the riser.

- When one horizontal pipe is laid, and risers of small diameter pipes are lowered from it to the radiators from above.

- When a collector is installed on the riser, from which each battery has its own circuit. Such a system is called a collector system. Although people often hear other names - spider or ray circuit. By the way, experts believe that this is the best option for a private home if the task is to install heating yourself. It is the most effective, but also the most expensive in terms of pipe consumption.

Two-pipe with top wiring

Pay attention to the photo above. It clearly shows sections of the heating system, where “1” is the general circuit, “2” is the main riser from the boiler, “3” is a horizontal section with a slope, usually located in the attic

“4” are risers that supply coolant to the radiators. “5” are risers that remove coolant from the batteries and “6” is the return line.

And there are two more types of two-pipe systems - with horizontal wiring and vertical. The first is used for one- or two-story buildings, the second for multi-story ones. A distinctive feature of the second before the first is the presence of a high riser, from which supply circuits are distributed among the floors.

Solving some problems in the operation of electric boilers

The first, which is logical, is the pipeline. The entire load falls mainly on the pipes through which cold and hot liquids flow, and sometimes hot steam. Therefore, all soldering points and the quality of the pipes must be very good. A stray current will always flow through the pipes, which will pierce through the metal. Over time, metal-plastic will lose its metal component in places of breakdown, and all-metal pipes will become covered with rusty spots. Nothing can help avoid this. The only material resistant to this scourge is plastic, but it should not be used in electrode and induction systems. Otherwise, you just need to check the condition of the pipes from time to time in order to carry out replacement and repair if necessary. This is also required once every few years. The second unreliable (relatively) element of the system is the temperature and water pressure control relay. Every few years they break down and require replacement. Such repairs are not very cheap, but guarantee stable operation of the electric boiler for several more years. If the temperature relay becomes unusable, then the heating element may malfunction and the temperature in the system may increase. As a result. Instead of liquid, hot steam will flow through the pipes, which can rupture the pipeline. A similar problem can arise due to the presence of a large amount of air in the system, due to which the pump will run dry.

Sequence of work

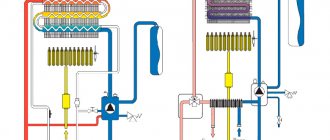

A typical piping diagram assumes the location and sequence of equipment installation, the pipe system, the type and type of equipment, the number of circuits, the type of heating elements, the electrical circuit with equipment and protection devices. When the heating system has a high resistance, for example, multi-circuit heating or a “warm floor” system, then a circular electric pump is installed.

- First, install the boiler securely on the wall or floor. The heating element unit is fixed at least 1.5 m from the floor level, induction or electrode devices are fixed lower, according to the piping conditions.

- Install the distribution manifold from the boiler.

- Attach pipes of the required diameter to the inlet and outlet pipes of the EC.

- A three-way valve with a mixer function is installed to regulate the temperature of the coolant.

- Mount the circulation pump on the return line.

- Install heating boiler protection devices, consisting of 2 valves and a pressure gauge installed at the outlet of the EC.

Piping diagram of a natural circulation system

A typical heating system for objects based on the principle of natural coolant circulation requires the installation of the following basic elements:

- Room thermostat for temperature regulation;

- heating devices - radiators and convectors;

- open type air tank;

- shut-off and control valves and taps for feeding the network circuit.

The technology for piping an electric boiler with natural movement of the medium is simple and accessible for self-installation. It is simplified due to the absence of a pump to move the coolant.

Heated water moves along a contour made with strict observance of slopes, thanks to the physical laws of movement of hot and cold media. It is applicable for individual heating of one-story buildings with small heating areas.

Forced circulation piping

In this scheme, the circulation pump is additionally connected: a bypass line, power supply, shut-off and control valves and a security system with temperature and pressure sensors. This is the most optimal scheme for automatic control of heating and hot water levels. The owner of the facility can choose different temperatures for different rooms, although this will require an increase in the cost of heating due to the cost of electricity to operate the pump.

Algorithm for piping an electric heating boiler, diagram of a heating element electric boiler:

- The outlet pipes are connected to the network pipeline through ball valves and an American connection.

- A membrane-type expansion tank and a mesh filter are installed in the return line to filter suspended sludge and debris in the network water.

- To clean the mud pan, a ball valve is installed in front of it.

- A circulation pump is installed in circuits with forced circulation; if it is not included in the boiler delivery set, then it is purchased additionally, the selection is carried out according to the volume of water that is cooled along the boiler contour and indicated in the passport.

- A safety group is installed: a pressure gauge, an air vent and a safety relief valve that prevents pressure from increasing in the system.

Convector heating

What is a convector? Outwardly it looks a lot like a regular radiator, but at the same time it works completely differently.

If the radiator mostly works on radiation, that is, it heats up and emits heat, then the convector passes streams of cold air through itself, heats it to the desired temperature, and “blows out” warm air. The word convector comes from the word convection (mixing). Thanks to its operating principle, a convector can quickly warm up a room and just as quickly change its temperature.

There are a great variety of electric convectors. In fact, 90% is produced in China and packaged under various luxury brands. Cheap convectors are usually “famous” for drying the air due to the simplified design of the heating element. Expensive convectors already come with a more well-designed heating element. There is no such problem there.

Installation of convectors is extremely simple. Place it under the window. Install either on the wall or on the floor. Supply electricity and start working.

Many devices come with their own thermostat. Therefore, you can adjust the temperature of the device without any problems.

Convectors are:

- Floor-standing – when installed on the floor. Available on legs, on wheels, with floor mounts

- Wall-mounted – mounted on the wall accordingly

- Skirting - replace the baseboard and are mounted around the perimeter of the walls

How to do heating yourself - option for two wings

It was said earlier that the heating system has two options, one and two pipes. The most common and best for heat conservation is the two-pipe one. It is also represented by two types: dead-end and passing. In a dead-end circuit, the coolant in the supply pipe moves towards the flow of liquid in the return, i.e., simply put, the coolant moves in one direction. This scheme is called a Tichelman loop.

If the length of the pipes is large, then the entire wiring is divided into two parts or, as they say, into two wings. This scheme is especially popular in private homes and country houses.

The length of both parts or wings must be made the same, and all radiators in this network are connected using valves. This will allow you to quickly and efficiently regulate the water supply.

Otherwise, the installation is similar to all others and does not require any special features.

Installation nuances

First of all, it should be said that there are two types of systems with an electric heat generator:

- With natural pressure on the coolant (the electric boiler is located at the bottom of the circuit).

- With forced circulation (you can find a video with a detailed analysis of pump installation on the website). The boiler can be located at any point in the chain (except for the highest).

Many private home owners install not one, but two electric boilers. "just in case". If the backup device does not operate at full capacity, then the electric boiler is installed in parallel, so that both generators work with the same power.

Equipment installation rules

Installation and connection of the boiler to the system should begin after passing the design stage, when a place in the house has been prepared for the unit. If you install it in violation of the requirements, the specialists of the gas distribution company will not connect the equipment to the gas main.

General requirements at the design stage

The basic standards for installing gas equipment are prescribed in SNiP 42-01-2002. Supporting information is also contained in the already invalid, but useful SNiP 2.04.08-87.

Usually all the rules are taken into account by the design engineer, but it is also useful to know them for yourself. The room for the boiler can be a kitchen if the power of the device ranges up to 60 kW. A separate or attached combustion chamber is relevant for units with a power rating of up to 150 kW.

Additional standards for the installation of gas equipment are given in SNiP on boiler installations, as well as on heating, ventilation, and air conditioning

The premises requirements are as follows:

- The minimum room height is 2 m, volume is 7.5 m3. If there are two or more gas appliances, the parameters change to 2.5 m3 and 13.5 m3, respectively.

- Not suitable for installation: basements, balconies, bathrooms, corridors, rooms without windows.

- The walls of the room must be covered with non-flammable materials or protected with special panels.

- Lighting: per 10 m3 of room there is at least 0.3 m2 of window. In the event of a gas explosion, the windows are an easily removable structure, which increases the safety of equipment operation.

- It is necessary to have grounding and a cold water pipeline.

- The cross-section of the chimney corresponds to the power of the installed equipment.

- The space left around the device is: in front - from 1.25 m, on the sides (if maintenance is necessary) - from 0.7 m.

- The distance from the vertical chimney to the unit is maintained - no more than 3 m.

Ventilation must also be provided. Natural is calculated at the rate of 3 room volumes per hour. When organizing a supply air system, combustion air is added to this value (the parameter is indicated in the boiler passport).

The requirements apply not only to premises. The distance from the attachment to the nearest structures is also regulated. This information is indicated by the manufacturer in the equipment instructions.

If a double-circuit boiler is installed on a wooden wall, a sheet of roofing steel (0.8 - 1 mm) or a mineralite slab is attached to it. If the equipment is not located in the kitchen, asbestos is also possible

Floor-standing boiler models are installed on non-combustible bases. If the surface is wooden, a metal backing is required.

It is recommended to place the device as close to the gas pipe as possible. The use of special hoses is acceptable, but they should not be very long. Bellows hoses up to 5 m are available on sale; they are allowed for installation, but according to European standards, the length is limited to two meters.

Documentation preparation process

After a general familiarization with how to technically correctly connect double-circuit gas boilers, you can begin preparing documentation. The first stage is obtaining technical specifications. It is necessary to contact the regional gas service with a statement indicating the expected volume of blue fuel consumption per hour.

Technical specifications are issued in 1-2 weeks. The document is a permit to connect housing to the gas main.

The second stage - according to the technical specifications, an equipment installation project is developed. The third is approval of the prepared documentation by engineers of the gas distribution company.

The project includes both the installation diagram of the boiler itself and the laying of a gas pipeline from the connection point to the main line. If we are talking about a private house, a drawing of communications on the site is added

The boiler technical passport, operating instructions, certificates, and an expert opinion on the compliance of the device with all standards are submitted to the regulatory organization. The necessary papers are provided by the manufacturer of the double-circuit boiler.

Coordination of documentation can happen in a week or last up to 3 months, it all depends on the complexity of the project. In case of refusal, the inspection is obliged to provide a list of edits to eliminate the deficiencies. If all requirements are met, stamps are affixed and you can begin connecting the equipment.

Heating system elements

But the sizes of such devices are usually quite large, which limits the possibilities when choosing a place to install them. You can assemble a water heating system for a private house with your own hands, but this will require precise calculations and a boiler piping diagram

Such mats are absolutely safe to use and are easy to set up. And please note that if you use antifreeze, it must be changed every 5 years. Except for one thing - the high cost of energy

In addition, electric boilers differ in power. There are the following types of two-pipe schemes: dead-end: the pipeline network is divided into branches, arms along which the coolant moves along the lines towards each other; associated two-pipe system: here the return manifold is, as it were, a continuation of the supply, and the entire coolant flows in one direction, the circuit forms a ring; collector beam. But the sizes of such devices are usually quite large, which limits the possibilities when choosing a place to install them. After passing through the upper radiators, the coolant flows to the lower radiators, and only after that into the return pipe passing along the first floor. The difference usually lies in the fuel used - gas, coal, pellets, firewood. A single-pipe vertical heating scheme for a private house with a gas boiler can be implemented without forced circulation of the coolant.

Comments

Foil is used to distribute heat evenly across the floor surface. Disadvantages: high cost of energy - this is the most expensive of all existing heating methods.

The temperature level will remain at the same values, and it will be comfortable to be in the room. Even if you heat the house yourself, be sure to consult with the designers regarding the type and method. The floor-standing boiler must stand on a flat surface, it must also be non-flammable.

Electricity is traditionally the most expensive type of heating compared to gas and solid fuel. Do you have experience using an electric boiler to heat your home? From there, the coolant goes down to the radiators, gives them part of its heat, and then is sent through the return pipe to the heating boiler. This home heating connection diagram is not complicated. Do-it-yourself installation of an electric boiler Before installing the boiler, you need to choose a place for it that would allow you to easily and correctly install the heating system pipes, conveniently connect, maintain and control the operation of the boiler itself. Electric boiler overview and connection

Price for 1m2 of work

It is difficult to independently take into account all the nuances and correctly install the heating network around the house. It is much better to entrust this work to specialists who will offer the best option and a set of additional equipment. Based on experience, designers and installers are able to correctly place emphasis depending on the customer’s wishes: to provide heating with maximum efficiency and ease of use, or to strive to save money on work and installation.

The cost of the work includes separate installation of the boiler, connection of additional equipment, pipe routing and installation of radiators. Each item has its own price list, according to which the cost of all work on equipping the heating system in the house is calculated.

| Type of work | units | Cost, rub. |

| Installation of a heating boiler with a power of up to 50 kW | PC. | 12000-20000 |

| Installation of a boiler with a power of over 50 kW | PC. | 25000-50000 |

| Security group installation | PC. | from 1500 |

| Expansion tank | PC. | from 2000 |

| Circulation pump | PC. | from 2000 |

| Installation and connection of the comb (collector) | PC. | from 1500 |

| Pipe routing D16-25 | linear meters | 60-85 |

| Pipe routing D32-40 | linear meters | 75-90 |

| Pipe routing D55-63 | linear meters | 90-120 |

| Pipe routing D75-110 | linear meters | 100-150 |

| Installation and connection of the radiator | PC. | 2000-5000 |

| Installing a thermostat | PC. | 500 |

| Pressure testing according to the requirements of the boiler equipment manufacturer | from 4500 | |

| Commissioning works | from 3500 |

Routing pipes from the boiler to the radiators can average 300-500 rubles per linear meter, taking into account laying, connection, passage and wall grooves. Prices are indicative for Moscow and the region.

Source

Emergency piping of an electric boiler

Regardless of the thermal circuit piping scheme used, it must provide the ability to adjust and control when the power supply is turned off. In the event of a lack of electricity, uninterruptible power supplies or battery-powered equipment are usually used.

Battery wiring diagram

Even if the power supply is stable, it is important to periodically check the status of these devices and, if necessary, charge them, since they may not work at the most necessary moment. For example, there is pumping equipment that circulates the coolant in normal mode, but the built-in function of charging its own 12V batteries allows it to be kept in constant readiness during a power outage

When this happens, the pump uses the batteries. But this is a temporary measure, because if the electricity goes out for a long time, the forced circulation will stop. Therefore, it is considered useful to provide a thermal circuit with natural circulation.

Models of electric boilers

The principle of any electric boiler is the conversion of electricity into heat. Electric units are not the most cost-effective, but the efficiency of their use is 95-99%, which is quite good for such units. Such boilers are divided into three types according to the type of coolant. Let's talk about each of them in more detail.

Electric heating element boiler

Electric heating boilers equipped with heating elements operate on the principle of an electric kettle. Water passes through tubular heating elements - heating elements. Acting as a coolant, it passes through the entire heating system, circulating using a pump.

One of the advantages is its compactness, neat appearance and the ability to be mounted on a wall. The installation process will not cause any particular difficulties, and operation is comfortable and simple, thanks to thermostat sensors. Automation allows you to maintain the required heating, focusing on data from sensors that measure the ambient air temperature.

The coolant can be not only water, but also a non-freezing liquid, thanks to which scale will not form on the heating elements, which cannot be avoided by using water.

Attention. Scale formed on heating elements impairs the heat transfer and energy-saving properties of an electric heating boiler. This option for heating a house is also good because it has a low cost.

For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately

This option for heating a house is also good because it has a low cost. For the convenience of regulating electricity consumption, it is equipped with several heating elements that can be turned on separately.

Electrode electric boiler

The operating principle of an electrode electric boiler for heating a house is completely different from the previous model. The liquid is not heated by a heating element. An electrode installed in the housing gives the liquid an electrical charge, under the influence of which the molecules are split into negatively and positively charged ions. The coolant has its own resistance, which provides intense heating. Either water or a special compound (similar to antifreeze) is poured into the system.

This type of electric unit for heating a house is completely safe; if a liquid leak occurs, it will simply turn off. Electrode models are very compact (looks like a small cylinder with pipes), equipped with sensors for measuring ambient air temperature, and controlled automatically.

Maintenance of this model comes down to replacing the electrode, since they gradually dissolve as they work, which worsens the heating of the house. It is also necessary to ensure that the circulation pump is working properly so that the liquid in the system does not boil. Correct and efficient operation of an electrode electric boiler for heating a private house is only possible with prepared water - it must have the required resistivity value. Measuring them yourself is not always convenient and easy, just like preparing water. Therefore, it will be easier and more reliable to buy a liquid specially designed for use in electrode boilers.

Connection of equipment with other boilers and heat accumulator

To integrate a heat generator into the system, you need to use a circuit with two check valves, a surface-mounted thermostat and a room temperature controller. This heating boiler piping scheme will allow the cooling coolant to be captured and redirected to the heater after the heating element has been turned off.

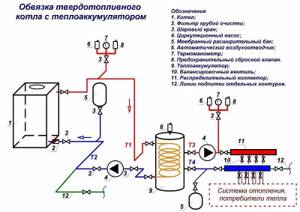

Let's look at how to connect an electric boiler to a solid fuel boiler in stages:

- While solid fuel equipment (SF) operates as the main one, the electric boiler is auxiliary and operates in standby mode.

- After the fuel burns out, the temperature in the room drops. As soon as the heat level drops to the standard set by the owner, the room thermostat will turn on the electric heater.

- A surface-type thermostat will note a decrease in the temperature of the coolant in the return pipeline and turn off the pump.

- After adding the next portion of fuel, heating is restored, the thermostat turns on the pump. The electric boiler sensor “detects” the heated coolant and will not start the equipment into operation until it receives a command from the thermostat.

To make the installation of an electric boiler into the system clearer, watch the video from professionals.

On a note! The shown method of how to install an electric boiler into a heating system is also useful for piping gas and diesel equipment. In this scheme, the equipment is auxiliary, not main.

It would not be superfluous to integrate a buffer tank or heat accumulator into the circuit. This equipment will store energy while generating excess energy and then redistribute the heat supply when needed. For example, when the boiler operates at full power at night (in the case of electric boilers, it is more profitable to do this at night tariff), the accumulated heat will be enough to maintain a comfortable temperature during the day.

A mixing unit with a three-way valve will perform the task of redirecting the coolant at the required temperature to the radiators. Thermal accumulators maintain a heating level of up to +80 C.. +90 C. When installing water heated floors in rooms, it is necessary to equip a second mixing unit that heats the coolant to +45 C - this is the established water heating indicator for underfloor heating circuits.