Here you will learn:

Traditional solid fuel boilers are not capable of providing long-term combustion of up to one or two days or more.

And even impressive combustion chambers do not adequately solve this problem. Its solution will be the Stropuva boiler - equipment from a Lithuanian brand. The principle of surface combustion is used here, ensuring long-term operation from a single load of fuel. In this review we will look at:

- Construction of Stropuwa boilers.

- The principle of their work.

- Technical characteristics of the equipment.

- Popular models.

At the end of the article, user reviews will be given.

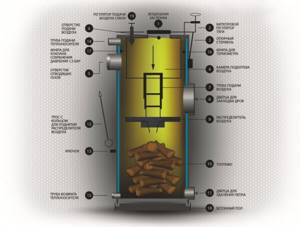

How do Stropuva boilers work?

Let's see how it is customary to start a traditional solid fuel boiler. First, we ignite small chips, and when they take up the flame, we begin to throw full-fledged firewood into the firebox. Our heat source is located below, under the wood stack. This is where the combustion spreads. As a result, the firewood burns out in a matter of hours, and a lot of thermal energy often flies away into the chimney.

Stropuwa boilers are built on the top combustion principle. In this way they are similar to Bubafonya wood stoves - here the wood is lit from above, not from below. The prototype of these furnaces were Stropuva boilers, which have a similar operating principle. Depending on the power of the selected unit, the combustion duration can be up to several days.

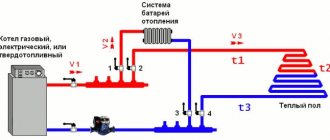

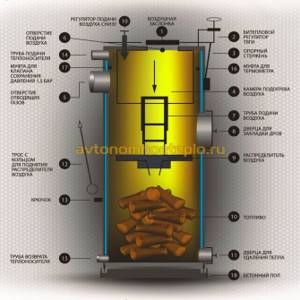

The Stropuwa boiler consists of the following elements:

- Combustion chamber – starts from the very bottom of the equipment.

- Heat exchanger – here a “jacket” of the “pipe-in-pipe” type is used. The coolant flowing through it ensures efficient heat intake and transfer to the heating system.

- Air distributor - it is located above the combustion zone and supplies air to it.

- Draft regulator – allows you to adjust the heating temperature of the coolant.

- Air heating chamber - it is responsible for heating the air masses supplied to the combustion zone. This design ensures efficient combustion of wood.

Air is taken in through a damper, combustion products are removed through a pipe in the rear (the chimney is connected to it). There are two doors in the front part - for loading fuel and removing ash.

The Stropuva solid fuel boiler has a long burning time. On one load it can work for up to several days - it all depends on the heated area, the current operating mode and the thermal power of the unit. Dried firewood, pellets, fuel briquettes or coal are used as fuel. According to the manufacturer, the burning time on coal is up to 5 days.

Instructions on how to make a Stropuva boiler with your own hands

Heating of a private home » Boilers and boiler equipment » Solid fuel boilers

Device diagram

Long-burning stoves are an option that allows you to use solid fuels, one load of which lasts for several days. Simple designs require two bookmarks per day, and complex ones require one bookmark every few days.

In any case, long-burning solid fuel stoves are an economical option that operate for a very long time without human intervention. There are several models that are common in many regions of Russia - these are Bubafonya and Stropuva. One of their distinguishing features is their simplicity of design. Is it possible to make a Stropuv boiler with your own hands?

The main difference between Stropuv and other types of long-burning furnaces is the fuel combustion zone. In this design, combustion occurs from above, as in a regular fire. In other types, the combustion zone is located below on the grate.

What are the advantages of the first option? The zone will gradually decrease from the highest point to the grate. In this case, there is no specific effect of high temperatures on any boiler height level. This allows the use of material with a smaller thickness for the manufacture of the furnace, which not only saves money, but also ensures convenience during work.

Boiler classification

Let's start with the stove model range, which is divided depending on the fuel used:

- Boilers running on wood, sawdust and other similar types of fuel. This is the simplest design, energy-independent and cheap when it comes to making it yourself.

- Coal or other more durable types of solid fuel are used. In this case, the solid fuel boiler is equipped with a small fan that will supply oxygen to the combustion zone. Hence the more complex design of the heating unit and its energy dependence. The last criterion complicates the manufacturing process and increases the cost of the product, so we will not consider it.

Drawings of this type of long-burning boilers can now be found freely available on the Internet. So in this regard, there will be no problems if someone takes the drawings as the basis for production. But even without them, it’s not very difficult to assemble homemade boilers based on Stropuva.

Manufacturing of the Stropuva boiler

To make this type of furnace, metal products with a thick wall are not needed. Therefore, we will take an ordinary two-hundred-liter metal barrel as a basis. If you can find a Soviet-style barrel, this would be ideal.

In addition to the barrel you will need:

DEFORT DWM-161. 4 510

- A metal sheet 4 mm thick - we will use it to make a load.

- A pipe with a diameter of 100 mm for making a pipe for the chimney and pipes for supplying fresh air to the combustion zone.

- Wire 6 mm thick or several corners for making a grate.

- Channels for weighting the load.

Tools needed:

- welding machine;

- Bulgarian;

- hammer;

- chisel;

- roulette.

Additional materials you will need are fiberglass and asbestos cord. Please note that a welding machine is used, which you must be able to operate. Without it, you cannot make a Stropuva solid fuel boiler with your own hands.

Manufacturing sequence

Type of homemade installation

- A lid with a small side is cut out of the barrel, for which a grinder is used. A hole is made in the lid right in the middle for a pipe with a diameter of 100 mm.

- Next, a grate is made from wire or corners. In fact, this is a regular grill, where it is important to determine the size of the cells. The smaller they are, the better, especially when it comes to such small fuels as sawdust or husks. By the way, the grate is not used in all models - sometimes you can do without it. If there is one, then it is installed inside the barrel closer to the bottom. Fastening is done by electric welding.

- Now let's move on to making the load - the press. To do this, a round pancake is cut out of a 4 mm thick steel sheet, the diameter of which is 2–3 cm less than the diameter of the metal barrel. A through hole with a diameter of 100 mm is made in it.

- We weld the pipe to the pancake. Please note that the length of the pipe should be 20–50 cm greater than the height of the barrel. Now 4 channels need to be welded on the back side of the pancake. They are needed to weigh down the press and create a small space under it - this will be the combustion zone. The channels are welded in such a way as not to cover the hole in the pancake. The usual fastening pattern is criss-cross.

- In the barrel just above the location where the grate is installed, you need to make a door through which you can clean the boiler from ash and ashes. This device must be sealed using an asbestos cord.

- A through hole is made on the side of the upper part of the barrel, almost near its upper edge, and a small pipe with a diameter of 100 mm is welded to this place from the outside. This will be the location where the chimney will be installed.

- Now you need to take care of the removable cover. The upper part of the barrel, which was cut out, must be brought into proper shape. To do this, its sides are slightly expanded - you can simply tap them with a hammer. It is necessary to weld two handles on the top side, with the help of which the cover will be installed manually. On the outside of the side around the entire perimeter, you need to glue an asbestos cord or a strip of fiberglass, which will contain the smoke coming out of the combustion zone.

At this point, all parts of the boiler are ready, and you can begin adding fuel, as well as assembling the structure.

Procedure for assembling the structure

Attention! The closer you pack the firewood, leaving minimal space between them, the longer it will burn. As for sawdust, everything is simpler - you just need to compact it well.

Combustion chamber

The press is installed on the stacked fuel with the pipe facing up, and the barrel lid is put on it. The chimney is connected to the pipe. Long-burning furnaces have a unique design that ensures the removal of carbon monoxide only through a horizontal pipe. That is, the chimney will not be vertical, but horizontal with a slight upward slope. This is another distinctive feature of long-burning stoves.

Before placing the press, it is necessary to ignite the top layer of fuel. Then the press and lid are installed. In this case, the firewood or sawdust in the combustion zone will simply smolder, releasing a large amount of thermal energy. At the same time, as it burns out, the zone will gradually settle under the influence of the load. Smoke from the combustion of solid fuel comes out of the zone between the gap formed by the walls of the barrel and the edges of the metal pancake. It is then discharged through the chimney. Oxygen enters the combustion zone through a pipe welded vertically to the pancake.

Since the metal from the barrel will become very hot, the structure is considered unsafe in terms of fire. Therefore, experts recommend:

- Install such a stove near walls that are built from non-combustible materials.

- A foundation needs to be poured under a long-burning furnace. It can be concrete or fire brick.

- To increase operational safety, you can install a protective heat shield made of metal or bricks.

Conclusion on the topic

As you can see, there is nothing complicated in this process if you have the skills to work with a welding machine. The design is not that complicated, so there shouldn't be any problems. It is only important to take correct measurements and accurately connect all parts of the structure. And don't forget about sealing the joints.

Related Posts

Comments and reviews on the material

gidotopleniya.ru

Main models

You can buy a Stropuva boiler in specialized stores that are dealers of the manufacturer, as well as in online stores. The minimum price is 60 thousand rubles for the minimum power model. Let's continue the review with a description of the models being produced.

Stropuva Mini S8

Before us is the smallest wood-burning boiler with a power of 8 kW, designed to heat rooms up to 80 square meters. m. It works on wood briquettes and firewood, is equipped with a safety valve and a thermometer. The heating temperature of the coolant is from +60 to +95 degrees. The maximum pressure in the circuit is up to 1.5 Bar. The efficiency of the model is 85% - a pretty good result for solid fuel equipment. The estimated cost of this boiler is 61 thousand rubles.

Stropuva Mini SP8

This boiler differs from the previous model by supporting operation with pellets. In this mode, it needs to be connected to an electrical network with a voltage of 220 Volts - the electricity is used to operate the fan used in the fuel ignition system. When working with wood and briquettes, the boiler operates in autonomous mode. The remaining parameters are almost 100% similar.

Stropuva S20

One of the most popular models. It allows you to heat residential buildings up to 200 square meters. m. The boiler is built according to an energy-independent scheme; briquettes and ordinary firewood are used as fuel. Burning time is up to 31 hours. If you want to forget about adding fuel for several days, we recommend purchasing the Stropuva S20U modification - it can run on coal, providing up to 120 hours of continuous combustion. The Stropuva S20P model can work on pellets for up to three hours.

Stropuva S40

Before us is the most powerful boiler in the entire line. Its thermal power is 40 kW, combustion duration is up to 31 hours, heated area is up to 400 sq. m. The device is equipped with a rather impressive heat exchanger jacket that holds 58 liters of water. The maximum pressure in the system is up to 2 atmospheres at an average temperature of up to +75 degrees. Over 90 kg of firewood is placed in the combustion chamber of the device. Modifications for working on pellets and coal are also available.

Other models and manufactured modifications

Also on sale are solid fuel boilers from the Stropuva company with a capacity of 15 and 30 kW. They are designed for areas up to 150 and 300 square meters. m. All models discussed in the review are available in three modifications:

- The main one is that the equipment runs only on wood and fuel briquettes (euro firewood).

- With index P – the possibility of working on pellets is provided, burning up to 72 hours.

- With index U - units with the ability to operate on coal, burning time up to 120 hours.

Types of boilers

The manufacturer produces Stropuv equipment, like other types of devices operating on solid fuel, of different capacities. In addition, there are simpler models that work on wood and waste of this material, and there are more universal ones. The combustion chamber of the latter allows you to burn different grades of coal (except for those used in blast furnaces), as well as various fuel briquettes and pellets.

Long-burning conventional solid propellant

Types of fuel for the universal solid fuel boiler Stropuva

The devices operate only on firewood and wood waste. Technical characteristics of the medium power device:

- Thermal energy output is 10 kilowatts.

- The recommended heating area is no more than 100 square meters.

- Efficiency is about 87%.

- The volume of the water jacket is 34 liters.

- The capacity of the firewood hopper is about 25 kg.

- The length of the log is no more than 0.35 meters.

- The parameters of the firebox are 0.350X0.210X0.250 meters.

- Weight and dimensions – 1.92 meters height, 0.45 meters diameter, 185 kilograms.

The original models of devices are produced in the Republic of Lithuania.

Long-burning boilers Stropuva universal

For the unit you need to allocate a separate combustion chamber

These units are floor-mounted and can operate on various fuels of natural origin: wood materials, coal, peat and briquettes. The models are equipped with a forced air fan and a spacious combustion chamber, which allows fuel to be stored for a long time. Technical characteristics of high power equipment:

- Heat transfer power – 20 kilowatts.

- Heated space – 200 square meters.

- Efficiency is within 85%.

- The heat exchanger capacity is 45 liters.

- The volume of the coal bunker is 130 kilograms.

- Weight and dimensions – 2.1 meters height, 0.56 meters diameter, 246 kilograms.

Due to its compactness, the device can be placed in a small furnace room.

How to start a Stropuva boiler

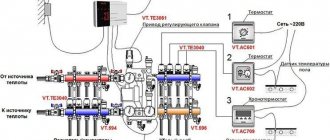

First, you need to purchase a piping kit to connect the equipment to the heating system. We recommend purchasing a kit with the ability to connect an indirect heating boiler. It includes a set of pipes, a safety group, an expansion tank and a circulation pump. Also on sale are kits for connecting underfloor heating.

It is not recommended to use damp firewood - this will interfere with the normal operation of the boiler.

Ignition is carried out in the following way - here are brief instructions for use:

- We load the wood combustion chamber full with the air distributor raised.

- We fill the finished masonry with sawdust.

- Open the flap for switching to wood.

- Open the air damper 3-5 cm.

- We light the top layer, close the loading door, leaving a gap 3-5 cm wide.

- We wait for reliable combustion, close the loading door and immediately lower the air distributor.

Please note that the cleaning door must be closed.

A new portion of firewood can be added to the Stropuv boiler at any time, but doing this with coal is dangerous. In any case, the manufacturer recommends that you always wait until the fuel burns out completely before adding a new portion.

Polypropylene strapping

Tying a solid fuel boiler with polypropylene allows you to create a circuit of varying complexity. To implement it yourself, simpler options are suitable, in other cases - of any level of complexity.

It is recommended to connect a pipeline made of polypropylene pipes using a welding machine. An easier way is to select and fix fittings. However, the main disadvantage is the formation of leaks at the slightest movement of these parts.

A more durable and reliable heating system should consist of a small number of connections and have smooth transitions. Such a pipeline can last more than 35-40 years, withstanding pressures above 25 bar. A coolant whose temperature does not exceed 95 o C can not harm the inside of the pipes.

Reservation of work

The Stropuva boiler will delight you with long-lasting fuel combustion. But even in this case, you can miss the moment of the next bookmark. As a result, the temperature of the coolant in the heating circuit will begin to fall. To prevent this from happening, we recommend installing a backup electric boiler in the circuit. If it detects a temperature drop below the set limit, it will turn on and maintain the set temperature.

Electricity consumption will be small if you don’t forget to add firewood for 2-3 days. The vast majority of the time the boiler will burn, providing heat to consumers. Therefore, you should not expect huge expenses. In addition, the auxiliary boiler does not have to be as powerful as the main one - a model with a power 2-3 times lower is quite enough so as not to make your teeth chatter in the morning. We also recommend working on insulating your home so that it retains the accumulated heat longer.

Peculiarities

The Stropuva boiler has one striking feature - it has top combustion of fuel. This means that the flame moves from top to bottom, which allows the fuel to burn for a longer time. In this way, you can save significantly, because you will need much less coal or firewood to heat the room. The principle of top combustion also determines the vertical cylindrical shape of the device.

The device is a barrel made of cast iron or steel, inside of which there are two cylinders (small and large), differing in diameter. The large one is separated from the boiler itself using a layer of thermal insulation. A heat exchanger, also known as a heating circuit, is located between the cylinders. The coolant is evenly distributed in this zone and a so-called “water jacket” is formed. The combustion chamber is mounted in a small cylinder, that is, the firebox is located there.

The combustion temperature is maintained due to the presence of an air duct. It works in such a way that air flows only to the burning fuel. With its help you can regulate the entire process. The smoke leaves the boiler in its upper part and is directed immediately into the chimney due to the presence of strong draft. The diameter of the latter varies from 160 to 200 millimeters depending on the model. In any case, it must match or even exceed the diameter of the pipe on the boiler. Ash and other waste are removed from below - the door is placed 2 centimeters higher than the bottom itself.

To light the boiler, you have to follow simple instructions. First, the air distributor is raised and fuel, such as firewood and wood chips, is loaded. The dampers open, including the air damper, and the top layer is set on fire. At this moment, the door through which the fuel is loaded should remain ajar a few centimeters. When the fire reaches the desired state, the air distributor is lowered and the loading door is closed. A new portion of wood material can be added at any time, but it is not recommended to do this with coal - you need to wait until the previous portion burns out.

For Stropuva, various types of solid fuel are selected: types of wood (sawdust, wood chips, briquettes and firewood), coal or peat briquettes. The quality of the chosen fuel largely determines how long it will burn and warm the room. In addition, the presence of insulation in the house and the correct selection and installation of the device play an important role. If the room is not insulated enough, then you will have to buy a powerful boiler and be prepared for the fact that the bookmarks will last for less time.

Reviews from real owners

While manufacturers do their best to praise their equipment, real owners work with it. They are the ones who can tell how the equipment behaves under constant operating conditions. Reviews from Stropuvo boiler owners will definitely be useful to you when choosing heating equipment for your home.

Tired of traffic jams and noise, I moved with my wife and child outside the city, to a small village. It is quiet and comfortable here, there is no city noise. And there is no gas here. I had to buy a wood-burning boiler from the Lithuanian company Stropuva, since I didn’t want to bother with constantly throwing in new bundles of firewood. The choice turned out to be successful - for a house of 65 square meters. m of the selected boiler turned out to be more than enough. I load the logs once a day, after removing the coals and ash. Hot water is heated in an 80 liter electric boiler. The Stropuva boiler heats just fine, but in reality it still doesn’t last up to 30 hours.

I went to specialized forums to get reviews about these boilers. Some people praise them, while others complain about their low reliability. I made my choice quickly, but in the end I was wrong. It’s really better to spend more money and buy a boiler with a pellet burner and automatic pellet supply. Stropuva also knows how to work with pellets, but automation is difficult. It would be much easier with a bunker for bulk fuel. And the temperature control on Stropuv is not the best. Cleaning away ash is inconvenient. In general, the expensive purchase did not justify itself. It would be better if I took a universal boiler with a pellet burner, which could later be converted to gas.

As with everything, it has its drawbacks. When you start cleaning, smoke pours out in all directions from the still burning coals, since there is no grate here. I can’t understand how anyone could even think of doing without an ash pan. I fixed the problem, but spending almost 100 thousand rubles to fix the manufacturer’s defects yourself is an incredibly interesting activity. Secondly, reloading firewood is very inconvenient, the heat radiates into your face. Moreover, it is not recommended to do this, they say, it is necessary for the firewood to burn out completely. But in the evening there is no time to think about it - I want to sleep, and not wait for the logs to burn out. What I liked is that it heats up quickly, literally after an hour of operation the rooms become warm. Stropuva burns for a long time, at least a day. In cold weather, the burning time is reduced, but this is not so critical. For hot water, I installed a boiler in the system; in the summer it will work from the built-in heating element.

Description of Bubafoni

The prototype of the structure was the Lithuanian heat generator “Stropuva”. They have the same operating principle and main external features:

- The boiler has an elongated cylindrical shape.

- Large combustion chamber.

- Air distribution device (disc-shaped with metal deflectors).

- Air duct pipe.

- An outlet pipe connecting to the chimney.

Materials for all these elements can easily be found in any household.

Principle of operation

The structure consists of two chambers:

- Primary combustion of fuel occurs at the bottom.

- Pyrolysis gases burn in the top, which are released by smoldering firewood.

A disc-shaped piston divides the firebox into two chambers. It lowers under its own weight and rests against the fuel layer, thereby ensuring long combustion and maximum heat transfer. A pipe is welded to the piston, through which oxygen is gradually supplied to the lower chamber. The amount of air is regulated using a damper on the pipe. The wider it is open, the more oxygen, the higher the combustion intensity and heating temperature.

Peculiarities

In addition to the qualities borrowed from the prototype, bubafonya has its own unique features:

- The loading door is located at the top of the case, and not at the bottom, as usual. Thanks to this, heated air flows from top to bottom, and the loading process is much faster.

- The firebox is made in such a way that the wood burns in layers, and the combustion efficiency increases to a maximum (more than 70%).

- The fire can be extinguished instantly: just close the damper on the air duct. This is very convenient, because at the end of the work the owners do not have to wait until the fuel burns out completely.

Advantages and disadvantages

The main advantages of this heating unit are listed below:

- Ease of manufacture. If you have the necessary materials and a welding machine, you can assemble the heater in a matter of hours.

- Compactness. The Lithuanian analogue of bubafoni is almost twice the size of the Russian invention.

- In theory, one load of fuel can heat a room for 12 hours.

- The possibility of reverse combustion is completely excluded.

- The highest efficiency among similar devices.

But you shouldn’t think that such a stove is a masterpiece of engineering that has no drawbacks. Like any device, it has its disadvantages and limitations:

- Do not add firewood until the previous combustion cycle has completed. Otherwise, fresh fuel will ignite from below and burn out instantly.

- Cleaning such a unit is a rather labor-intensive process. It is especially difficult to get to the bottom of the body, although this is where ash and unburnt residues accumulate.

- An attempt to improve the design using a water jacket leads to a sharp decrease in its efficiency.

- Adjustment of combustion power has to be done manually.

- Bubafonya is not installed in residential premises, since its design leaves much to be desired.

- Such a system takes a long time to ignite, so it is not recommended to install it where the owners spend little time.

Patented combustion scheme ↑

The long-burning solid fuel boiler under the Stropuva brand is well-deservedly popular in the country due to its certain fuel versatility and affordable price.

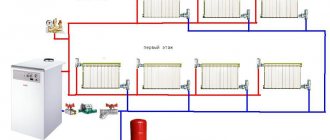

Heating boilers using solid fuels are widely used when there is no possibility of connecting to a gas main or in places where there are problems with the electricity supply. In such cases, wood, coke or coal can be used as fuel. Also, these devices are in demand as a backup (additional) heat source.

The manufacturer of Stropuva products is a Russian-Lithuanian company that produces solid fuel boilers, the operating principle of which is based on a patented top-down combustion scheme. The long period of fuel combustion ensures continuous operation of the boiler for up to several days.

Stropuvo boilers offer such advantages on the heating market as a unique (up to 5 days!) combustion duration on one load of solid fuel, as well as energy independence and simplicity of design

New piping units for solid fuel boilers Stropuva are already on sale

Recommended piping scheme for a long-burning boiler Stropuva S40/S40U (option 2)

Operation of the circuit with a boiler connection, without a backup boiler and heated floor

The circulation pump (P) supplies coolant from the heating system, driving it through the boiler.

The heated coolant from the Stropuva S 40 (1k) boiler enters through the indirect heating boiler (B). If the diameter of the incoming pipes of the boiler is sufficient, the valve (3) closes and the entire coolant flow goes through the boiler, which is connected in series, so the water in it heats up faster.

After heating domestic water (DHW), the coolant enters the radiator system.

(bk3 – 17) – balancing valve designed to regulate the flow. With its help, the flow from the circulation pump is distributed so that it is enough to heat the radiators, and at the same time, so that it is sufficient for the boiler itself. The total flow volume depends on the power of the circulation pump and can be changed by switching the pump speed settings. A circulation pump with a power of 50–100 W is sufficient.

(bk1 – 3) – balance valve of the protective gravity radiator, with the help of which the flow is adjusted so that the radiator return pipe is approximately 40°C colder than the supply pipe.

Recommended wiring diagram for a long-burning solid fuel boiler Stropuva S40/S40U with connection of a boiler and heated floor, without a backup boiler

Fig.8. Elements of a prefabricated boiler room assembly

1. Air vent, 2. Reduction ø 25 – 1, 3. Reduction ø 32 – 25, 4. Nipple ø 25, 5. Tee ø 25, 6. Connection ø 25, 7. Elbow ø 25 internal, 8. Nipple ø 15, 9. Pressure safety valve 1.5 bar, 10. Ball valve with nut ø 25 internal, 11. Ball valve with nut ø 25 internal, 12. Circulation pump nut connection ø 25, 13. Circulation pump, 14. Ball valve ø 15 internal, 15. Three-way distribution valve ø 25, 16. Valve nut connection ø 25, 17. Elbow ø 15 internal/external, 18. Elbow ø 25 internal/external, 19. Filter ø 25 , 20. Balancing valve ø 25, 21. Reduction ø 25 – 20, 22. Expansion tank, 23. Plug ø 25 male, 24. Cross ø 25, 25. Tee ø 25 – 15, 26. Three-way mixing valve ø 25 , 27. Balance valve ø 15, R – to/from radiators, B – to/from boiler/s, F – to/from floor heating, Н – to/from dryer/s with thermostatic valves

The three-way control valve ø 25 (15) can be installed manually.

Fig.9. Recommended piping scheme for long-burning boiler Stropuva S 40 (option 3)

Operation of the circuit with connection of a boiler and heated floor, without a backup boiler

The coolant heated in the Stropuva S40/S40U boiler passes through ø 25 steel pipes. Air is removed from the device through an automatic air vent (0). A safety valve (9) is installed on the external circuit.

The coolant is directed along the external circuit to a three-way mixing unit (12). The mixing unit (12) in the lower part of the circuit is necessary for mixing the return coolant after the circulation pump.

The temperature difference between the supply and return lines should be within 15-20°C. Accordingly, with a supply line temperature of 75°C, the return line temperature should be 55-60°C.

The boiler (4) is connected in a small circuit through a valve (8a, 8b). After heating the boiler, water enters the nearest radiator (2) through the balance valve (8c).

The additional radiator (2) must be connected independently. The radiator is necessary to prevent the boiler from overheating when the circulation pump (7a) is turned off.

The radiator system is connected at the top of the small circuit via valve (8d). The return line from the radiators is fed to the circulation pump (7a) through the valve (8f). On the small circuit, after the coolant is drawn off to the radiators, the heated floors are connected through the circulation pump (7b).

The coolant from the return line of underfloor heating is supplied to the three-way distribution valve (6) through valve (8e).

A three-way mixing valve (6) is necessary to mix the flow and return lines and bring the temperature of the underfloor heating flow line to a temperature of 25-35°C.

The three-way separating valve (12) is connected to the circulation pump (7a) to the common return line. In the lower part of the circuit, after the mixing unit (12), a balancing valve (13) with a flow meter is installed to regulate the water flow into the boiler.

In the return line after the balancing valve (13), drain valves (14a, 14b) are installed to replenish and drain coolant from the system, as well as an expansion tank (10). The pressure in the expansion tank should be 0.5-0.8 atmospheres.

Technical characteristics and features ↑

The Stropuva boiler consists of two cylinders, between which the coolant passes. Access to the combustion zone is through the upper and lower doors. Heated air from a special chamber enters the top layer of fuel; as the wood or coal burns out, the air distributor moves down and is always located in the combustion area. A draft regulator is used to regulate the water temperature and the amount of air required.

Stropuva long-burning boilers are available in two types: universal and wood-burning . On universal varieties there is a forced air flow to increase combustion intensity. The optimal operating mode is achieved within 2-3 hours and is maintained evenly throughout the combustion time of one portion of fuel.

Different Stropuv models make it easy to select a boiler for each room, based on the following technical characteristics:

- Power – from 7 to 40 kW

- Heating area – 50-400 sq.m.

- Burning duration – from 6 to 130 hours

- Volume of fuel placed – 150-320 cubic dm

- Equipment weights – from 180 to 330 kg

All boilers have high efficiency (86.3-86.8%) and an operating coolant temperature of about 85°C.

The duration of operation of the boiler at one load, and therefore its performance, depends on the fulfillment of certain conditions:

- The degree of insulation of the room and the correct choice of device power.

- The quality of fuel, determined by such parameters as its humidity, ash content and composition.

- Proper organization of the heating system as a whole.

- Optimal draft in the chimney.

- Professional installation.

Operating principle and design

The main technological feature of the Stropuva boiler is the use of a “top-down” combustion scheme.

Combustion is ensured by air supply through a diffuser telescopic pipe on which a round seal is mounted. Acting like a piston, the pipe with the seal under the influence of its own weight constantly descends towards the burning layer of fuel, providing an oxygen supply. The compactor compresses the ash that remains at the top. The heated gases transfer their heat to the walls of the firebox and are then removed through the chimney. Oven Stropuva

Diagram 1. structural elements of the Stropuva boiler

- Blower damper.

- Damper regulator.

- Damper regulator support.

- Thermometer coupling.

- Air heating chamber.

- Telescopic diffuser.

- Fuel loading door.

- Nozzle.

- Fuel.

- Ash collector flap.

- Foundation.

- Air flow adjustment lever for different types of fuel (station wagon models only).

- Window for air supply to the heating chamber.

- Heating circuit supply connection.

- Chimney socket.

- Thermal valve connector (burst safety valve).

- Telescopic diffuser control cable.

- Travel limiter.

- Return supply.

This scheme provides the following advantages:

- A large amount of fuel can be stored.

- By burning out in stages, rather than all at once, fuel can be used more economically and efficiently.

- Long burning in this design contributes to maximum heating of the heat exchanger, reducing heat loss through the chimney - the flue gases enter the chimney almost cold.

Table 1. Long-burning boilers Stropuva SU. Specifications

| Thermal power, kW | 10 | 20 | 40 |

| Efficiency, % | 91,6 | ||

| Heated area, m2 | 50–100 | 100–250 | 200–400 |

| Maximum fuel volume, l | 120 | 200 | 330 |

| Power of electrical units, W | 20 | 20 | 20 |

| Time for complete combustion of one maximum load of coal, days | 4 | 5 | 5 |

| Fuel | Wood, coal, | ||

| Weight, kg | 196 | 246 | 333 |

| Water temperature, оС | 85 | 85 | 85 |

| Maximum water pressure in the unit, bar | 2 | 2 | 2 |

Since Stropuv heating devices do not produce excess heat, there is no storage tank in the design. Thanks to this fact, the boiler, compared to analogues, is smaller in size.

Stropuva stove piping

The design includes a bimetallic draft regulator (does not require power), which allows the consumer to regulate the supply of oxygen to the firebox, changing the combustion strength and coolant temperature.

Structure of the Stropuva boiler

Other benefits:

- non-volatile operation or extremely low power consumption for embedded systems;

- high efficiency – up to 90%;

- reliable layout and quality of production ensure safe operation. The boiler belongs to the “non-explosive” class: when overloaded, it contracts inward (where a vacuum is formed) without destroying the room.

Table 2. Dimensions of universal boilers Stropuva SU

| Rated power, kW | 10 | 20 | 40 |

| Height, mm | 1920 | 2120 (1920*) | 2120 (1920*) |

| Diameter, mm | 450 | 560 | 680 |

* - available upon request

Advantages and disadvantages ↑

Sectional diagram of the Stropuva boiler

It is worth briefly listing the main advantages of Stropuva boilers:

- Cost-effectiveness and convenience - their installation does not require an expensive gas supply, and the long duration of work on a one-time fuel supply saves money and time.

- Energy independence - there are no electronics in the design, so wood-burning boilers, when used in a gravity heating system, do not require electricity.

- Safety and reliability - one of the advantages is control using a bimetallic valve - a simple and trouble-free draft regulator.

- Aesthetics along with simplicity - STROPUVA boilers differ from similar types of devices in their elegant appearance and compact placement. The clear design of the unit eliminates any difficulties during operation.

Among the disadvantages, the following can be noted: their performance is greatly affected by the humidity of the loaded fuel. But this is rather a minus of all solid fuel boilers, and not of a specific brand in particular. The solution here is simple - keep firewood or coal in a dry place.

Comparative data

If we compare Stropuva solid fuel equipment with units of similar functionality, we cannot help but notice that fuel consumption with a similar release of thermal energy is significantly lower. That is, there is the possibility of significant savings when heating quite large areas.

This makes it possible to use solid fuel boilers from this manufacturer for industrial and production purposes. When using them, it is possible to heat greenhouses, workshops, warehouses and other similar premises where it is necessary to maintain the required temperature during the cold season.

Stropuva boilers can be used in remote regions where communications have not yet been established. If there is no electricity there and there are no alternative sources of power supply, it is optimal to use wood-burning boilers, which can operate autonomously for more than a day.

Advantages compared to similar models:

- Wide scope of use.

- Possibility of adjusting temperature conditions.

- Easy to use.

- Does not require significant space for installation.

- They can work for a long time on one load.

- There are models of varying power.

Stropuva boilers are recognized as the most convenient and efficient for use as heaters or as a source of hot water supply, which determines their constant demand.

https://youtube.com/watch?v=ODbvNqTXYjY

Consumer reviews ↑

We were able to collect several reviews from conversations with users of Stropuva boilers in Russia.

Vasily Nikolaevich Nazarov: Before last season, I bought an S20U boiler for my woodworking workshop. Once every 5-6 days you fill a full bunker with coal - and that’s it, no problems. With pieces of wood, of course, there is more hassle, but I still need to put them somewhere.

Oleg Vladimirovich Serov: The main thing is to correctly determine the required power. There is no point in taking based on the principle: the more, the better. Each model will be effective where it is designed, and the price will be higher - why overpay?

Andrey P.: I have a dacha, there’s not even light there always. At first I tried to heat it with gas from cylinders, it was a hassle and too expensive. Now I have installed a small wood-burning unit with ten kilowatts, the car has enough firewood for the winter. I heat it 2-3 times a week, the house is 6x12 meters plus massandra, I haven’t seen any shortcomings yet.

For using wood materials as fuel and heating buildings up to 100 square meters. meters, it is enough to purchase a Stropuva S10 boiler (power 10 kW) costing about 80 thousand rubles. A universal solid fuel unit model S40U, capable of heating a room of at least 200 square meters. meters will cost the buyer more - about 120,000 rubles.

Recommendations for installation and operation

To install the device, choose an isolated room equipped with forced ventilation or an opening window. The height of the boiler room ceilings must be at least 2.5 m, the area - from 4 sq. m. Installation work is carried out strictly according to the instructions.

Installation features:

- the boiler is installed on a concrete foundation 10 cm high from the floor or on a non-combustible base;

- the bottom is lined with concrete mortar, the joint is sealed with heat-resistant sealant;

- maintain the following intervals: in front - at least 1 m of free space, in the back - 0.6 m, on the side to the wall - 0.6 m;

- The connection points between the device and the chimney and heating system are carefully sealed.

The heat generator is a source of increased danger. The boiler room must be equipped with fire extinguishing equipment and a container with sand for emergency fire extinguishing.

Other operating features:

- Do not store fuel or other flammable materials near the heating device;

- once a month it is necessary to check the condition of the chimney using a mirror, and if necessary, clean it from soot accumulation;

- operation in systems with forced circulation is not allowed if the pump fails or there is a power outage;

- When heating with wood, ash is removed as needed;

- when using peat or coal, the ash pan must be cleaned every time before refilling;

- It is advisable to lubricate the distributor lifting cable with oil to prevent wear;

- It is necessary to inspect the doors for tight closure.

Reservation of work

The use of two or more boilers in a heating system is justified by the risk of failure of one of the devices. The circuit is also used to quickly increase power if necessary.

Stropuva units are easily assembled in a cascade, thereby increasing the reliability of the heating system.

Advantages of cascade installation:

- uninterrupted operation (if one device fails, the other will continue to operate);

- increased power (in the off-season you can use one unit, in winter - two);

- ease of repair and maintenance;

- saving space in height (for limited spaces - attics, basements).

The disadvantage of parallel connection is that for each device you have to connect a separate piping unit and chimney. Study the Grundfos circulation pump at the link.

Operating instructions for boilers Stropuva ↑

- First of all, you will need to adjust the bimetallic valve. To do this, before the first kindling, use the adjusting screw to set a gap of 3-4 cm between the heating chamber and the damper. Next, the boiler is ignited and when it reaches 70°C (if wood) or 85°C (if coal), the damper is lowered with the same screw, stopping the further increase in water temperature.

- Firewood is laid horizontally until the firebox is fully loaded, and a layer of wood chips and sawdust is poured on top. You can use kindling liquids for stoves. It is possible to replenish fuel during operation, but this reduces combustion efficiency for a short time.

- To use coal, the boiler must be equipped with an air supply manifold. The coal is ignited using firewood weighing about 5 kg, loaded on top. When the boiler is operating, the fuel is never mixed - this can lead to combustion failure.

- It is not recommended to use too fine fractions - both wood and anthracite or coal. After the bookmark burns out, it is necessary to remove the remaining ash.

Comparison of the Stropuva boiler and the Bubafonya stove

We will begin our analysis with the scope of application. If we are talking about a residential building, the Stropuva boiler definitely has the advantage. The characteristics of this unit allow it to work for a long time on one load, it is stable and reliable. At least, cases of complete failure have not yet been encountered. The operating principle of the Stropuva boiler allows you to connect to it both high-temperature heating and a hot water supply system with heated floors. Bubafonya cannot boast of this.

It is more suitable for heating greenhouses, garages, or, at most, summer houses. For more serious projects it is simply not applicable. Advantages of the Stropuva boiler design:

- continuous operation on coal for 5 days;

- temperature stability;

- ease of fuel loading compared to Bubafone.

There are also disadvantages, such as the complexity of the piping, the need for a separate room and the impossibility of repairs until a complete stop. It is also impossible to add fuel while the stove is operating and therefore you have to relight it every time you reload the firebox. But at the same time, of the two units being compared, only the Stropuva factory furnace is still suitable for serious projects. But Afanasy Budyakin’s invention is excellent for utility rooms, since the Bubafonya stove can be made quickly and inexpensively, which in this case is of decisive importance.

Wood-fired boilers Stropuvo

The design and arrangement of all Stropuva solid fuel equipment is based on the principle of top combustion. Thanks to this, the boiler can operate for up to 30 hours from one fill. At the same time, the efficiency reaches 86.3%.

The Stropuva long-burning solid fuel wood boiler is designed for heating small houses and cottages with a maximum area of up to 400 m². The line includes five models with performance from 8 to 40 kW.

It is prohibited to burn long-burning wood-burning boilers at Stropuva with coal, as this may lead to loss of integrity of the heat exchanger. It is better to burn coal using combined universal models.

A small disadvantage of top-burning wood-burning boilers is that you can load wood into the firebox only before kindling; it is impossible to refuel during the combustion process.

Boiler classification

Let's start with the stove model range, which is divided depending on the fuel used:

- Boilers running on wood, sawdust and other similar types of fuel. This is the simplest design, energy-independent and cheap when it comes to making it yourself.

- Coal or other more durable types of solid fuel are used. In this case, the solid fuel boiler is equipped with a small fan that will supply oxygen to the combustion zone. Hence the more complex design of the heating unit and its energy dependence. The last criterion complicates the manufacturing process and increases the cost of the product, so we will not consider it.

Drawings of this type of long-burning boilers can now be found freely available on the Internet. So in this regard, there will be no problems if someone takes the drawings as the basis for production. But even without them, it’s not very difficult to assemble homemade boilers based on Stropuva.

Stropuva pellet boilers

Stropuva solid fuel pellet boilers can operate in two modes.

- Designed for burning wood in long-term burning mode. At the same time, autonomous combustion from one stack of firewood is ensured for 30 hours, with minimal load.

- The operating mode is associated with the ability to burn with pellets. Burning from one bookmark to 72 hours.

Dual-fuel boilers have almost identical technical characteristics as equipment that runs exclusively on wood.

Pellets are burned using a special burner, which gradually goes down as the pellets burn out. This design of the Stropuva solid fuel pellet boiler allows you to increase efficiency and reduce heat loss. Due to the fact that the coolant circulates around the entire heat exchanger, its rapid and uniform heating is ensured.

What can a Bubafon cauldron be made from?

Half of the entire structure is the boiler, which can be made of any material, suitable shape and characteristics. These may be the following items.

- Do-it-yourself bubafonya stove from gas cylinders. Welding cylinders are the best basis for a boiler. Just adjust it to size and you can use it. Since the gas is under pressure, it is held back by thick metal walls, which will prevent burning in the stove.

- Old fire extinguisher. Large volume industrial fire extinguishers are convenient for boiler making. Despite the fact that their diameter is smaller, they are able to withstand thermal stress.

- Metal barrel. Manufacturing instructions are similar to the previous options. To prepare, you need to cut out the top and use it as an air vent.

- Pipe. A wide sewer pipe with wide walls is suitable for the boiler. But to do this, you need to cut two circles from sheet steel yourself and weld them as a bottom and a lid.

- Homemade body made of sheet steel. You can make your own boiler from a steel sheet by rolling it into a cylinder and welding it.

One of the simplest barrel designs

One of the easiest ways to assemble is from a tin barrel. It has thin walls, which reduces efficiency and low heat transfer. The advantage of the method is the large loading volume and on one tab it can work for more than twelve hours. Barrels are standardized sizes. If the walls burn out, it will be easy to replace it with a new one.

Assembly instructions:

You need to remove the weld that secures the cover. It is best to do this with an angle grinder to prevent the formation of burrs. To ensure a perfectly even seam, you can use a diamond-coated disc. The edges of the barrel are beaten with a mallet or hammer. On the lid, on the contrary, they are flared. As a result, the lid should fit tightly onto the barrel. A hole is drilled in the center for installing the chimney. The distributor will require a lid from a similar barrel. If this is not available, the part can be made from sheet steel. Air vents are welded to the lower part. They can be made from sections of U-shaped profile or channel. This is necessary to increase the performance of the stove. If you need low efficiency for a small room, you don’t have to do this. A damper is mounted on an axle on top of the hot air pipe. To increase ease of use, it is better to provide a “wing” fastening method. A hole is made on the body for the chimney pipe

It is important that the seam is sealed

For added convenience, you can install a screen made of a solid metal sheet.

Cylinders and pipes

Do-it-yourself bubafonya stoves made from a gas cylinder are relevant. The principle of manufacturing from a cylinder and a pipe is similar. The main difference is that the pipe will need to be prepared. Two circles in diameter are cut from a sheet of steel and the bottom is welded.

You need to cut several steel disks to fit the diameter of the cylinder. In each of them you need to cut out a small segment to make it larger than a semicircle. They are installed inside by welding

It is important to weld them so that they are mirrored to each other. This results in a multi-stage system for lifting air

At the level of the first floor, you need to make several holes in the wall with a diameter of 5 millimeters. The end of the channel is connected to the outlet of the pipe. In the middle of the wall there is a door for a rectangular firebox. A grate is mounted below the door.

Universal boilers Stropuva

The advantages of the multi-fuel series include the ability to operate the boiler on almost any type of solid fuel:

- Coal.

- Pellets.

- Wood waste.

- Firewood.

The Stropuva universal solid fuel boiler, according to research and consumer reviews, can be classified as one of the most economical types of heating equipment produced by the Stropuva company.

The use of wood waste only is not permitted. With each fire, you will need to add a small amount of high-quality solid fuel. Stropuva universal dual-fuel coal-wood boilers require regular maintenance.

In practice, it has been proven that it is better to use coal for a combination boiler. This type of fuel significantly increases the battery life from one load, as well as the efficiency of heat transfer. In normal mode without extreme loads, the unit can operate for up to 130 hours. Firebox capacity 220 kg. It is not allowed to add coal during combustion.

Installation and operation of Stropuva boilers

When installing and connecting, you must adhere to the basic rules that apply to all solid fuel units. The housing contains two outlets for supply and return of coolant, and connections to the central heating of the house.

It is mandatory to install an overheating protection system. If necessary, install circulation equipment.

A check valve and a coarse filter must be installed in the boiler piping. For the universal and pellet models, you will additionally need to purchase and install an air manifold.

The chimney is located on the rear side of the housing. It is recommended to install the chimney using insulated sandwich pipes.

Cleaning of carbon deposits is necessary after each fuel burnout. This is done through a special hatch located at the bottom of the boiler.

Kindling is carried out as follows:

- The air damper opens and the draft regulator is fixed in the raised position using a cable.

- Firewood is laid in layers. As a rule, large logs are placed in the center of the firebox, small ones at the edges.

- The top layer is filled with sawdust and wood chips. It will not be possible to add firewood until the already stored fuel has burned out, due to the internal structure and operating principle of the unit. Therefore, it is immediately necessary to fill the firebox completely (with the exception of the first kindling).

- The reason for the lack of draft may be the accumulation of soot in the smoke exhaust manifold, as well as insufficient heating of the chimney. Therefore, it is recommended to leave the damper open until the wood burns. This will provide good traction and reduce the formation of condensation.

Pros and cons of operating long-burning boilers Stropuva

Stropuva long-burning boilers have their own advantages and disadvantages, which require consideration before choosing and purchasing this heating unit. The following advantages of this brand of heaters can be highlighted:

- Long burning. The boiler can operate on one charge from several hours to five days. The time it takes to supply heat to a home depends on many factors, for example, the type and quality of fuel, thermal insulation of the premises, and correct piping. The use of high-quality, dry fuel and optimal settings of boiler equipment will ensure independent operation of the system, and the owner will not need to constantly monitor its operation.

- High efficiency. The efficiency of solid fuel boilers in Stropuvo can be compared with gas units. Due to the top combustion and the special design of the boiler, the fuel burns quite economically. The owner’s funds do not disappear inexplicably, and every penny goes towards heating the house.

- Independence from electricity. A boiler of this brand does not require an electrical network to operate. The unit can be installed even in remote areas where there is no access to electricity. But a universal and solid fuel pellet boiler requires a small amount of electrical energy to operate the air supply collector.

- Convenient cleaning. Due to efficient fuel consumption, very little waste remains. Ash can be removed only twice a month; resin deposits can be avoided by using the correct fuel.

- Safe to use. Stropuv's solid fuel boilers are safe, this is their advantage over, for example, electric boilers, where a short circuit may occur, or gas units, where there is a possibility of gas leakage. Even if a solid fuel boiler overheats, it will not explode, but will shrink inward.

- Dimensions and appearance. It's no secret that many long-burning units are very bulky and look angular, but the Stropuva boiler is quite elegant and takes up little space in the boiler room.

You can find out how to clean a solid fuel boiler here

As for the disadvantages, the following points can be highlighted:

- Almost all of the manufacturer’s models are demanding on fuel (humidity should be a maximum of 20%). When very wet fuel is added, the operation of the boiler ceases to be effective, soot and soot appear. The use of coniferous trees is not recommended for the same reasons.

- Inconvenient loading. In order for a solid fuel boiler to operate for as long as possible, the fuel should be packed very tightly. With homogeneous coal or pellet granules, this does not pose a problem, while with firewood you will have to tinker. And the windows to the structure do not make it possible to reach the lower level of firewood.

The Stropuwa long-burning boiler has many distinctive advantages, but at the same time it is not without minor disadvantages.